Professional Documents

Culture Documents

Core Form Mitsubishi Power Transformer

Uploaded by

Lasitha Ranjeewa Peiris0 ratings0% found this document useful (0 votes)

65 views11 pagesBrocher of Core Form Mitsubishi Power Transformer

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentBrocher of Core Form Mitsubishi Power Transformer

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

65 views11 pagesCore Form Mitsubishi Power Transformer

Uploaded by

Lasitha Ranjeewa PeirisBrocher of Core Form Mitsubishi Power Transformer

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 11

Changes for the Betcer

¢ MITSUBISHI

ELECTRIC

CORE-FORM POWER TRANSFORMERS

Mitsubishi's standard transformers, intended

primarily for transmission and industrial purposes,

employ core-form construction.

Like Mitsubishi's shell-form transformers, the

coresform models are manufactured on the besis

of over half of a century of experience in trans:

TYPES

Mitsubishi's core-form power ttanstormers are designated

according to their cooling method, a5 listed below:

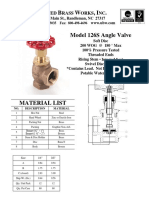

CR Oilimmersed, self-cooled, with detachable radi

ators mounted around the tansformer body

CRB. Cilmmersed, forced-ircooled, with cooling

fans attached to the radiators

CUB Forcedcil, forced-sir-cooled, with oll pumps

and coolers

CUW Forced-oil, water-cooled, with oll pumps anc

oil-to-water heat exchangers

CUR Forcsd-oll, selfcooled, with ofl pumps and radi

ator banks, sometimes separately installed

Fig. 2. Type CRB oihimmersed, forcod:sir- cooled, 3-phose,

SOMVA GOH: 230/24.5kV transformer

CONTENTS.

Types

Features

Construction $$

Special Transformer

‘Standard Accessories-

former production. Continuous research efforts

toward “improvement of technical skills and

materials have earned @ high reputation for, and 2

wide acceptance of, Mitsubishi core-form power

transformers,

ig, 1 Type CR oll immersed, self-sooled 3-phase

23MWVA 6OH2 230/34.5kV transformer

a.

Fig.4 Type CUB forced-oll forced-aircooled, 2-phase

TOOMVA 6OH2 230/115KV transformer

Fig, § Type CUB forcedcil forced:ir-eaoled, single-phase

‘Te8/aMvA 6oH2 222/18 /13 sky autotransformers

val Jal

Fig.6 Type CUW foreed-oll water-cooled, S-phase

TOMVA 60Hz 77/22kV transfoimer

FEATURES

1. High Reliability and Easy Maintenance

Core-form transformers for medium voltages and capacities

can be manufactured at comparatively low cast because of

‘their compoct size and simple insulation structure, and yet

they are mechanically strong end easy to inspect. The set:

cooled system requires no auxiliary devices and permits

easy maintenance

2. Well insulated Against Lightning Surge

‘The coil is wound with untreated kraft paper, and the lack

of varnish treatment allows the coll to be amply impreg

nated with degassed oll, which gives it ahigh Impulse ratio

and high diolectric strength against impulse voltage,

‘The insulation of the col end is also improved, and coils

for high voltages are equipped with a static plate to insure

good voltage distribution and thus give sufficient strength

against lightning surge. Coils for high voltages have a high

serles capacity winding which minimizes internal potential

‘oscillation and abnormal voltages.

3. Cold-Rolled Grain-Oriented Silicon Steel

Cold-olled grein-oriented silicon sheet steel is used, result-

ing in highly efficient transformers of reduced size and

weight

4. Reinforced Oi-Tight Tanks

Mitsubishi core-form transformers employ rectangular

tanks reinforced 5 required to assure high mechanical

Strength. Modols requiring vacuum oil filling and vacu

{OmmHg absolute) at up 10 760mmHg

‘All oll-tight pipas are connected by flange couplings

with gaskets, eliminating screw connections and assuring

that there will be no leskage of oll or nitrogen

‘Also, the rod or dil thermometer has been strengthened

by a double-wall structure, which permits easy removal or

replacement.

‘The oil gauge is a round magnetic type which will not

leak cit

5. Consetvators for Oil Preservation

All Mitsubishi ansformers (except for small units)

ane provided with conservators, which prevent the

deterioration af cil or insulation papers.

6, Seam-Welded Radiators

Self-cooted radiators for Type CR transformers are seam

twolded, making them convenient for onsite inspection

purposes. They ate also free from corrosion and oil leok-

age caused by the rusting of tower welded parts by rain-

‘water. They can withstand full vaguum without being

reinforced,

7. Bushings

Transformers for ovor GOKY use allenclosed center lamp

type condensor bushings with high mechanical and dielee

trie strenath,

Since the bushings are cut off from the oil in the tank,

1 oil leaks will occur in the case of bushing failure

CONSTRUCTION

Fig. 7 An example of se-cooled core-form transformer construction

1. Core

In standard practice, the core of single-phase transformers

has two legs and thet of three phate unite, three lege. In

Special cates, however, a three leg core mey be used for

single phase trensformers and a fivedeg core for three-phase

modes.

All these cores are made of high-grade silicon sheet

stecl with high permeability and low los, and are built up

in layers to fit closely within the circular coi!

When coldrolled grain-oriented silicon sheet steel is

used, the core construetion shown in Fig @ is employed

to take the best advantage of the excellent characteristics

of the sz,

To prevent possible detericration of the steal character:

istics due to core flexing, lock plates are fastened to the

core legs by means of Insulated bolts, end hooks ate welded

{0 the top and bottom of the lock plate.

‘These hooks engage with the hooks welded to the end

frame. The lock plates protect the core legs from the force

‘exerted when fastening the core or lifting the interior

parts

The core layers meat in lap joints and are fattened

securely with bolts or glass bands to prevent vibration and

noise, The core lamp bolts are insulated with mechenk

cally strong and heat-resistant tubes of glass epoxy. Thus

thay ate able to withstand both mechanical impact during

Key

1 [Oi iter vale

weve basting

9] BCT verminal

[tee

eseneraied tap changer

13] Fe

Ta |_Liing hook for core ana

Ts] End tome

‘Greuncing trina

Sead beee

car

Coarpreare ive

Gove

[2e[-Teann

[22] istayoe itevel gue

‘ansportation and the heat inside the core, There is no

danger of increased eddy current fiom dielectric break

down,

fn Iarger-cepacity transformers, with coret of large

cross section, several cil ducts are provided in the core to

prevent internal overheating

Fig. 8 Construction of eore

2. Coil

In coresform transforrars the standard col is a concentric

arrangement with a high-voltage outer winding, a low-volt-

‘age inner winding and a tap ieading from the ourter coll

‘Since transformers vary in voltage and current, coils

‘must be selacted on the basis of electrical and mechanical

suitability 0 each class of transformer.

‘witsubish’s coils come In four standard types (see Figs.

9~ 14),

1, Disk:Type Continuous

‘Shown in Fig 9, the disk type continuous winding col is

Inerspaced with oil duets and is strong both electrically

and mechanically

When there are wo or more parallel conductors for

large cutrents, transposition is made at a large number of

points, s0 that there will be no cross current between the

parallel contuctors.

2. High Series Capacitance

Transformers for high voltages employ the high series

capacitance winding shown in Figs. 1Oand 11b, The series

static capacitance of the coll in Fig, 11b Is increased to

such an extent by this special winding that the initial po:

‘ential distribution of the incoming surge voltage (deter-

mined by the ratio of the series static capacitance 10

‘ground static capacitanes) becomes almost linear, This

reduces intornal potential oscillation to minimum and

‘ieatly improves the impulse voltage characteristics and

dielectric strength of the coll. It also permite reduction of

for an economical design with a good space

Fig, 9 Disk-type continuous winding

aioe

8) Ordinary disk-type b) High sorive-ca

_continuous winding pacitance winding

Fig. 11 Comparison of winding construction

factor. This type of coil is wound continuously except for

several joints which are unavoidable, and is as mechanically

strong as the disk-type continuous winding mentioned

above.

2. Helical

‘Transformers for heavy current are generally Low in voltage

but sequire an increased number of parallel conductors

‘This makes it necessary to use @ helical winding as shown

in Fig 12. Because this holical winding has the same nur:

ber of transpositions as there are patallel conductors, it

ccan withstand the iemendous mechanical force produced

by short-circuit currants and its eylincrcal shape prevents

deformation. The coil is also able to withstand vertical

forces because itis secured at top and bottom by pressure

plates and spacers

4. Cylindrical

Cylindrical windings, shown in Fig. 13 and 14 are used for

medium and smailsize transformers There a1@ 10 con:

rations, one thot has a perfectircle cross-section, the

other with’a squared circle. Both feature simple construc

ton, compact size, and economy, Vertical oil ducts assure

maximum cooling effect The parlle! conductors are com:

pletely transposed usin the other three types,

Choice among the foregoing four types of windings is

made on consideration of economy as wll 2s dielectric

and mechenical strength. All types are provided with suf

ont oil ducts to facilitate the circulation of insulation ol

10 High series capaci-

tance winding

Fig. 13 Cylindrical winding

(perfect cicele)

3. Insulation

Coil conductors are insulated with specially made thin

kraft pape: wound in layers,

Insulation between the high-voltage and low-voltage

ceils and botween these coils and ground, shown in Fig

16, has sufficient dielectsie strength, and is able to with-

stand mechanical impact,

The low-voltage coll, nearest to the core, is wound

‘around a Insulation cylinder. Cylinders of untreated press-

board and oll duct spacers are placed alternately ina con

ceentric arrangement between the high: and lowvoltage

calls Pressboard washers and duct spaces are arranged at

booth ends of the coll to provide for sufficient ereep dit-

tance, In high-voltage models, several cylindrical angle

rings with flanges are arranged paralle! to equipotentiat

surfaces and static plates having large radius to decrease

the dieleotrie stress at call ends are placed between coils

and these cylindrical angle rings, This provides effective

insulation and increased creep distance by celleving local

concentration of dielectric flux at winding ends and

preventing corona formation in the oll, The latter feature

‘assures a very high dialectic strangth in comparetively

small space, The ingenious arrangement of oll duets makes

complete dehumidification, depassing and impregnation

possible when drying and Filing oil, and allows complete

‘il ciculation to cool the windings during operation,

4. Support and Fastening of interior Parts

‘The interior parts of the transformer must be fastened

securely enough to withstand the mechanical force pro-

‘duced by short-circuit current, mechanical impact during

‘transportation, and other factors.

‘The coil is fastened securely and tightly to the core by

‘means of upper and lower end frames and coil clamp rings,

50 that no deformation or loosening of the col ean ozcur

‘The core, which could become a source of noite, is

fastened securely with end frames and clamp bolts. Move

‘ment within the tenk is prevented by fixing the lower enct

frame to the tank bottom, with tank projections fitting

snugly into the frame holes, and fastening the upper end

frame to the walls of the tank {or bolting it to the tank.

cover in the ease of smallereapacity transformers)

Terminal and top wires leading from the coil sre wll,

insulated, and are supported where necessary by well

tied, oilimmersed wood or pressboard pleces, or by

Micorta insulating tubes. These supports are placad at

proper insulation distances from the core, end frame and

ther conductors, and they will not loosen, bend, or shift

positon when subjected to machanical impact.

Fig. 16 shows how the interior parts of the tansformer

ave supported.

5, Vacuum Drying, Degassing and Oil Filling

Fibrous insulating materials tend to absoria moisture from

the ali, which sharply decreases their dielectric strength

against impulse voltage. It is necessary, therefore, to re:

‘move moisture and air bubbles in these materials and

seturate them with insulating ol. For this pupose, the

windings are thoroughly vacuum-dtied and degasted in @

vvecuurm pan or in the transformer tank and ate then soaked

thoroughly, under vacuum, with high quality insulating of

‘which has been degassed and filtered

This degassed oil aot only improves the dielectric

strength of the insulating materials but also absorbs any

‘minute air bubbles that might remain after vacuum drying,

‘This assures complete immersion of the interior parts

cof the transformer in insulating oil. To avoid re-exposure

‘of the oibimmersed parts to sir, they are not taken out of

the tank when tested or transported

‘When removal of the interior parts is necessary, ex

posure time must be os short 2s possible. The vacuum cry.

ing process may have to be repested to assure complete

‘uansformer insulation.

6. Tanks

Mitsubishi core-form transformers use rectangular tanks,

made of rolled ste

‘Tanks to be subjected to vacuum ol filling in the fac-

tory or field ate reinforced to assure sufficient strength

against full vacuum, and undergo strict pressure and leak

age tests to check their strength and oltightness,

Covers are normally welded to tanks, but they may be

bolted if so requested,

Cove naan

“ewan 2

ight om

727 aston

Fig. 16 Support of interior parte of 2 2-pha

30,000KVA transformer

SPECIAL TRANSFORMERS

‘The transformers described in the foregoing pages are

standard models; specially designed models meeting par

teular requirements will be manufactured an request.

Here are a few examples of these special transformers,

1. Dry Types

Orders from indoor substations or power stations are

sometimes filled by dry-type transformers, Dry-type con:

struction is suitable for wansformers under 3OkV and

TOMVA. Fig 17 shows the core and coils of a dry-type

‘wansformer

2. Cable-Connected (Elephant) Types

Power cables are connected directly to the transformer In

the oil or inthe air. This socalled “eable-cannected system’

is now employed at various installations around the world

Because no conductor parts are exposed, greater protec:

tion is assured for personnel and for the equipment itself

against damage from sat-laden alt or dust

Cable-connected transformers come in two types: 2

direct type in which the cable head is inserted directly

Into the transformer, and an indirect type in which the

transformer bushings and cable heads are joined together

in a separated connecting box. The latter is standard,

Fig. 19 shows eable-connected transformers

Fig. 17 Core and coils of 3-phase 7.5MIVA 50H?

22/3.3KV dry-type transformer

1B Sphase SMVA 60H? 77/3.3kV

HV-side cubiele-connected,

LV.side cable-connected transformer

Transformers under 204V are normally of the Indirect

type using no insulating oil in the connecting box,

‘Any brand of cable may be uted for this purpose a:

specified

3. GIS Types

‘Transformers are also designed for direct connection with

SFp gasinsulated switchgear (GIS). The charged parts of

the connection between GIS and transformers are err

closed in earth-potential cates, rendering the connecting

parts safe, relicble and compact. Fig, 20 shows this type

‘uansformer

4, Mobile Types

Mobile transformers provide an effective means of coping

with seasonal changes in load, and with emergency de-

mands resulting from the breakdown of main substation

equipment. In order to make these units as compact and

and lightweight ac possible, forcad oll, foread-sir coating Is

adopted. Trallermounted mobile tansformers can be

manufactured up to 11SkV 10,000kVA for fully equipped

types, while for higher ratings, a type is made with easily

detachable bushings which are removed when the Uni

moved. Fig. 21 shows a trailer-mounted mobile trans

former fully equipped with a power fuse and switchgear,

substation

5. On-Load Tap-Changer-Equipped Types

‘Transformer voltage regulation is normally effected by a

deenergized tap changer on the primary or secondery

Winding However, this method has = number of drave

backs in that the transformer must be separated from the

line before operating the tap-changer, necessitating 3

power outage

Also, depending on tho load charecteratiss, trans:

former voltage may fave to be constantly regulated and

it is often very inconvenient to cut off the power supply

teach time, On-oad tap changers solve such problems, and

face being used increasingly es a means of offering better

power supply service as wall as for general power receiving

purposes

‘Mitsubishi onload tap changers may be classified into

two groups: resistor types (NR, MRM and VSM), and a

feactor type (VRE). Types NR and MRM have oil

switches, while Typas VSM and VRE have vacuum

switches

Since resistor types account for the majority of ep

plications, only they are introduced here

1, Type NR,

‘Type NR (Fig. 22) is s builtin rovistor-type selector

switch intended for use with power distribution trans-

formers having either star- or delta;connected tap wind:

ngs. It can be used up to 77kV SOMVA for star-connec

tion, and up to 77kV GOMVA in the cave of del

It hes @ rotary energy-accumulator mechanism that

ives the ollerype moving contact system of the

selector switch with a quick and reliable motion. It also

has a rotary intermittent mechanism on a common axis,

for driving the rolle-type-moving contact mechanism of

the changeover switch with a smooth and reliable ection.

‘The selector switch insert is housed in 2 compartment

Which is completely separate from the main tank and can

be ifted out for inspection, maintenance and repalt with-

‘out lowering the oil level of the main tank.

2. Type MAM

Type MRM (Fig. 23) isa builtin resistor-type on-load tap

changer intended for use with large power transmission

and industrial transformers, including autotransformers,

having ster-connected tap windings It can be used up to

500kV SOOMVA in star-point applications, ad in the cate

of auto-transformere, at lowevoltage terminals of up to

275K, with 2 maximum current of 1500A,

Type MAM is manufactured according to a design in

troduced through a technical agrooment with Maschinen.

Fabrik Reinhausen of West Germany, It consists of a wo

‘resistor eyclic diverter switch and a tap telentor having an

unequally dfivided contact arrangement. Te fixed son

tacts of the diverter switch can be disassembled on three

shellshaped insulation segments, 50 that the inspection,

maintenance and replacement of arcing contacts ean be

carried out easily. The diverter insert is of course re:

‘movable from the Independent diverter switch chamber

‘The tap selector has wall coordinated insulation due to

the unequally divided contact strangemont, so that its

diameter is the same, respective of the number of con-

vacts

3. Type VSM

‘Type VSM (Fig 24) is @ built-in resistor type on-losd tap)

changer utilizing vacuum switches for its diverter-witeh

areing contacts It is intended for use with powar-trans-

‘mission and distribution transformers as well a: industrial

transformers. It ean be used up to 230kV 1SOMVA in

starpoint applications

Featuring long life and the bare minimum of mainte

nance by utilizing vacuum switches, this ondoad tap

changer offers a considerable reduction in meintenance

‘work and maintenance costs compared with conventional

‘yes, without compromising Its reliability

Fig 22

Fig. 24

6. Low-Noise-Level Types

Increasing noise in urban areas has aroused concern, and

has led to the Formulation of antinoise regulations in many

big cities. On the other hand, the growing demand for

power in these areas has resulted in a steady increase in

‘urban substation facllties, and there are limits to the land

available for the power-eceiving facilities of urban fact:

ries, This situation hes boosted the demand for low-noise

level transformers

To lower the noise level of transformers, the core flux

ensity may be lowered and! more care taken in core con-

struction, but these steps cannot lower the noise level

more than 10 phors fa further reduction is required,

‘transformers must be soundproofed 2s shown In Fig. 25,

Tables of the noise levels in urban areas and of oll

wmersed self.cooled transformers (NEMA standard noise

levels} are given in Tables 1 and 2.

Table 1 Background Noise in Urban Areas (48)

Daytime | _ Midnight

‘40-60 20~20

50~70 30-50

90 “4060

Table 2 NEMA Standard Noise Levels for

Oil-Immersed Self-Cooled Transformers

Equivalent capacity (VAD

| rsoiaton ca Noiptevel

FOR or under —|_T0OKY

[ ma

4,000 66

70,060 %000 [68

75,000 70,000 7

25,000 15,000

“40,000 25,000

Auber gash

Rediaor ange 72

Transformer proper |

Sangpeot bore

rubber socket

Fig. 25 An example of soundproof barrier construction

7. Others

In some cases, transformer

subst

for unit substations or indoor

fons of buildings are designed to meet their dimen:

sional requirements, 2: shown in Fig, 26 And transformers

may have lightning artesters directly mounted on them, 2s

shown In Fig 27. Also, special transformers designed to

be transported in divided form are available

ig. 26 S-phase 2.5MVA 6OH2 66/3.3kV transformer for

Sndoor substation

Fig. 27 3.phaco 25MVA 60H2 115/34.5KV transformer with

lightning arestars

10

STANDARD ACCESSORIES

= T Reference

eon ae | inFig.7

| “Ratna pine (27

id low-voltage bushings 67

(for self-cooted transformers)

ior [with silica gol breather) (For 1OMVA end abovel

De-snergizad tap changer

‘Ski

~Feundation bol

it ar vas

i rain ae saa

Dial thermometer (with slarm contact)

[cave

“Terminal box (for protective devices)

Inaddition to the abovementioned standard accsszories, we cen

also provide others according to customer’s requirements

fa MITSUBISHI ELECTRIC CORPORATION

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Equipment List - Sodium Hypochlorite Generation PlantDocument1 pageEquipment List - Sodium Hypochlorite Generation PlantLasitha Ranjeewa PeirisNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Equipment List - Pre-Teatment PlantDocument2 pagesEquipment List - Pre-Teatment PlantLasitha Ranjeewa PeirisNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Equipment List - Pre-Teatment PlantDocument2 pagesEquipment List - Pre-Teatment PlantLasitha Ranjeewa PeirisNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Equipment List - Makeup Water PlantDocument4 pagesEquipment List - Makeup Water PlantLasitha Ranjeewa PeirisNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Equipment List - Desalination PlantDocument2 pagesEquipment List - Desalination PlantLasitha Ranjeewa PeirisNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Equipment List - Makeup Water PlantDocument4 pagesEquipment List - Makeup Water PlantLasitha Ranjeewa PeirisNo ratings yet

- Equipment List - Makeup Water PlantDocument4 pagesEquipment List - Makeup Water PlantLasitha Ranjeewa PeirisNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Angle Valve Model 126S - United Brass WorksDocument1 pageAngle Valve Model 126S - United Brass WorksLasitha Ranjeewa PeirisNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Equipment List - Desalination PlantDocument2 pagesEquipment List - Desalination PlantLasitha Ranjeewa PeirisNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Equipment List - Pre-Teatment PlantDocument2 pagesEquipment List - Pre-Teatment PlantLasitha Ranjeewa PeirisNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Automatic Shut-Off Valve - TycoDocument2 pagesAutomatic Shut-Off Valve - TycoLasitha Ranjeewa PeirisNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Material List: United Brass Works, IncDocument1 pageMaterial List: United Brass Works, IncLasitha Ranjeewa PeirisNo ratings yet

- Operation Manual MembranesDocument75 pagesOperation Manual MembranesMfundo DlaminiNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Condition Report of Deluge Valve Inspected During Month of August 2020 PDFDocument2 pagesCondition Report of Deluge Valve Inspected During Month of August 2020 PDFLasitha Ranjeewa PeirisNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Condition Report of Deluge Valve Inspected During Month of August 2020 PDFDocument2 pagesCondition Report of Deluge Valve Inspected During Month of August 2020 PDFLasitha Ranjeewa PeirisNo ratings yet

- Grade One Admissions For 2018-EnglishDocument22 pagesGrade One Admissions For 2018-Englishdmonlinelk100% (5)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Degremont - Desalination (Eng)Document6 pagesDegremont - Desalination (Eng)Juanmiguel1968No ratings yet

- Admission - Promotion and Withdrawal ofDocument2 pagesAdmission - Promotion and Withdrawal ofLasitha Ranjeewa PeirisNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- OptimizationDocument28 pagesOptimizationadnan mukhtar100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Energy Consumption Optimization of RO Membrane Desalination Subject To Feed Salinity FluctuationDocument6 pagesEnergy Consumption Optimization of RO Membrane Desalination Subject To Feed Salinity FluctuationLasitha Ranjeewa PeirisNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- E 36Document192 pagesE 36Arvind Kumar SinghNo ratings yet

- Visa-Form - NepalDocument1 pageVisa-Form - NepalLasitha Ranjeewa PeirisNo ratings yet

- POW 2017 Leak Detection1Document27 pagesPOW 2017 Leak Detection1Lasitha Ranjeewa PeirisNo ratings yet

- Guide Full (S) Amd12JuneDocument97 pagesGuide Full (S) Amd12JuneChanuka123456No ratings yet

- 1 Procurement Manual Supplement 8 PDFDocument4 pages1 Procurement Manual Supplement 8 PDFLasitha Ranjeewa PeirisNo ratings yet

- Supplement - 7 Procurement Manual: Democratic Socialist Republic of Sri LankaDocument8 pagesSupplement - 7 Procurement Manual: Democratic Socialist Republic of Sri LankaDinuka MalinthaNo ratings yet

- PM MotorDocument2 pagesPM MotorLasitha Ranjeewa PeirisNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- 4 05Document14 pages4 05Lasitha Ranjeewa PeirisNo ratings yet

- Safety Manual: National Thermal Power Corporation LTDDocument287 pagesSafety Manual: National Thermal Power Corporation LTDHari Krishna.M100% (2)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)