0% found this document useful (0 votes)

320 views12 pagesISO 15243 - 2004 - Matrix of Defects

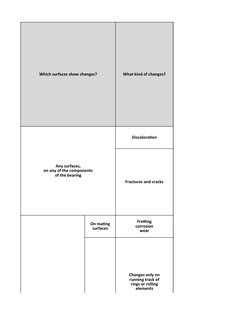

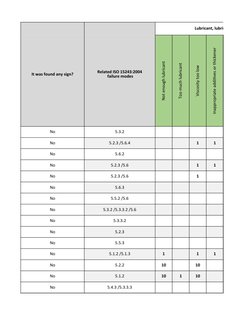

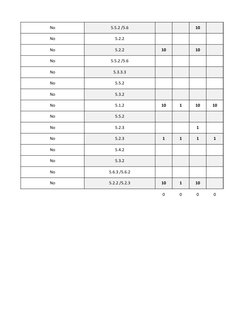

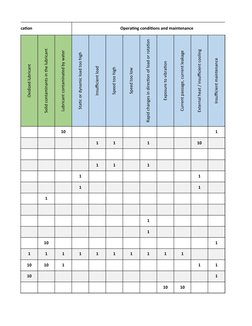

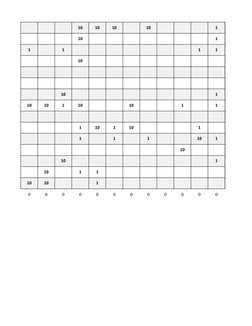

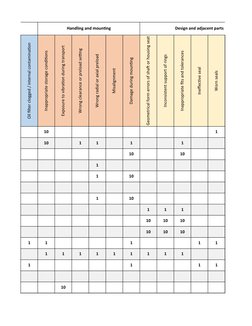

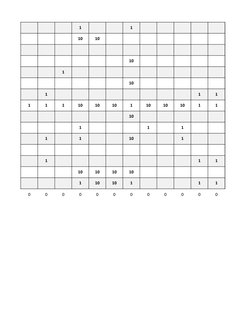

The document lists various surfaces and components of a bearing that may show changes, including the running track of rings or rolling elements, raceways, and cages. It then lists specific types of changes such as discoloration, fractures, cracks, fretting corrosion, and wear. Finally, it discusses potential causes of these changes related to issues with lubrication, operating conditions, maintenance, handling, and mounting of the bearing.

Uploaded by

Waldir CorrêaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

320 views12 pagesISO 15243 - 2004 - Matrix of Defects

The document lists various surfaces and components of a bearing that may show changes, including the running track of rings or rolling elements, raceways, and cages. It then lists specific types of changes such as discoloration, fractures, cracks, fretting corrosion, and wear. Finally, it discusses potential causes of these changes related to issues with lubrication, operating conditions, maintenance, handling, and mounting of the bearing.

Uploaded by

Waldir CorrêaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

- Surface Changes Analysis: Analyzes the types of surface changes in bearings, questioning surfaces, and nature of changes.

- Specific Surface Damage Details: Lists and details various types of surface damage, providing specific visual and structural symptoms.

- Standards and Lubrication Correlations: Correlates different surface issues with specific standards and lubrication problems.

- Operating Conditions and Maintenance: Explores how different environmental and operational conditions affect surface changes.

- Handling, Mounting, and Design: Examines the impact of mechanical settings such as mounting and design on surface condition.

- Bearing Manufacturing Influences: Discusses how manufacturing processes impact surface changes, correlating design decisions with observed effects.