Professional Documents

Culture Documents

Fire Protection

Uploaded by

jia wangOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fire Protection

Uploaded by

jia wangCopyright:

Available Formats

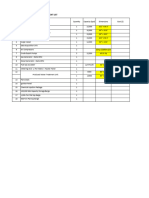

PIF KAEC, Velocity Paint Shop, 0143020

Fire Protection Process Equipment 09.09.2022

Equipment Length (m) Standard Deluge

No. Protected Area amount CO² by

Level or Sprinkler System by Dürr Comment

Name of Process of lines System customer

(m) amount System

12,2 l/min 24 l/min

ASRS from BIW 1 x x Storage: 168

+9m Mounting jigs 1 6,5 x open workdeck/protected by building sprinkler

+9m Jig Check 1 6,5 x open workdeck/protected by building sprinkler

+9m Jig Check 1 6,5 x open workdeck/protected by building sprinkler

PT/EC

+9m Pretreatment plant 1 107,5 x inside enclosure: no protection

+9m Transfertunnel to EC 1 6,5 x x

below obstructions PT 1 137,0 x x

+9m EC Plant 1 85,6 x inside enclosure: no protection

+9m Transfer to EC Oven (tunnel) 1 40,0 x x

below obstructions EC 1 151,0 x x

+9m Observation deck 1 7,5 x x

+9m EC Oven 1 117,7 x inside oven and cooling Zone: no protection

below obstructions EC-Oven and Cooling Zone 1 154,0 x x

ASRS EC 1 x Storage: 84

Sealer-Line

+9m Robotic Laser Braze Inspection 1 11,0 x open workdeck/protected by building sprinkler

±0m Jig Change 1 9,5 x open workdeck/protected by building sprinkler

±0m Jig Change 1 9,5 x open workdeck/protected by building sprinkler

±0m EC Sand Booth 1 19 x x

±0m Heavy Metal Repairs 1 7,5 x x

±0m Robotic Plugs cell #1 1 11,5 x x

±0m Robotic Plugs cell #2 1 10,0 x x

±0m Manual Plugs 1 9,5 x x

±0m UBS from beneath, automatic 1 13,5 x x

±0m UBC from beneath, automatic 1 8,5 x x

±0m UBS Repair / Demask / Inspect 1 8,0 x x

±0m Interior Seam sealing, automatic 1 20,5 x open workdeck/protected by building sprinkler

±0m LASD, automatic 1 18,5 x open workdeck/protected by building sprinkler

±0m Roof/Ditch 1 9,5 x open workdeck/protected by building sprinkler

±0m HEM Seal 1 19,0 x open workdeck/protected by building sprinkler

±0m Manual Sealer Deck (Single Pass) 1 36,0 x open workdeck/protected by building sprinkler

±0m Wipe Deck (2 Stations) 1 12,0 x open workdeck/protected by building sprinkler

±0m Option Training cell sealing & paint 1 5,0 x open workdeck/protected by building sprinkler

±0m Primer Quality Check 1 7,5 x open workdeck/protected by building sprinkler

Primer Booth

+9m Lower Plenum Pimer Spray Booth 1 39,0 x x

+9m Cleaning/Control 1 12,5 x x

+9m Manual Tack off 1 5,5 x x

+9m Primer: exterior, automatic 1 15,5 x x incl. Detection

+9m Inspection 1 5,5 x x

±0m Scrubber/ Scrubber Area 1 15,5 x Eco-Dry Scrubber, Deluge from Booth

+9m Flash off 1 33,0 x x

+9m Transfer 1 7,0 x x

+9m Robot (Bell) Protection x scope of supply: Paint robot contractor

inside spray booth recirculation air ducts 1 70,0 x x where necessary

inside spray booth exhaustair ducts 1 70,0 x x where necessary

+9m Cleanroom 1 30,0 x x

+20,2 ASU Primer 1 25,0 x x till first filter

±0m RAU Primer 1 25,0 x x till first filter

platform around spray booth Primer 1 600m² x x

below obstructions Primer/BC Line 1 210 x x

+9m Primer Oven 1 91,6 x inside oven and cooling Zone: no protection

below obstructions Primer-Oven and Cooling Zone 1 120,0 x x

±0m Roof sanding 1 7,5 x x

±0m Sanding 1 7,5 x x

±0m Vacuum cleaning 1 7,5 x x

±0m Flash primer 1 7,5 x x

±0m Inspection 1 7,5 x x

±0m Heavy Reprocess Booth 1 1 7,5 x x

±0m Heavy Reprocess Booth 2 1 7,5 x x

±0m Off-Line Data PAQ 1 7,0 x open workdeck/protected by building sprinkler

BC/CC Booth

+9m Cleaning/Control 1 8,0 x x

+9m Vest 1 5,5 x x

+9m HVLP blow-off 1 6,0 x x

+9m EcoClean (EMU) 1 6,0 x x

+9m Vest 1 5,5 x x

+9m Turntable 1 7,0 x x

+9m Transfer 1 45,0 x x

+9m Transfer to BC/CC Lines 4 5,5 x x

+9m Lower Plenum BC Spray Booth 1 25,0 x x

+9m Service Cubicle 2 1,5 x x

+9m BC automatic 4 11,0 x x incl. Detection

+9m Service Cubicle 2 1,5 x x

±0m Scrubber/ Scrubber Area 4 11,0 x Eco-Dry Scrubber, Deluge from Booth

+9m Flash-off/Observer 4 7,5 x x

+9m Tunnel/Lift 4 6,8 x x

+9m Intermediate Oven 4 24,0 x no protection

+9m Tunnel/Lift 4 6,8 x x

+9m Transfer 4 1,5 x x

+9m Lower Plenum CC Spray Booth 1 21,5 x x

+9m Service Cubicle 2 1,5 x x

+9m CC automatic 4 11,0 x x incl. Detection

+9m Service Cubicle 2 1,5 x x

+9m Flash-off/Observer 4 7,5 x x

+9m Scrubber/ Scrubber Area 4 11,0 x Eco-Dry Scrubber, Deluge from Booth

+9m Transfer after CC 1 16,0 x x

+9m Turntable 1 7,0 x x

+9m Transfer 1 5,0 x x

+9m Transfer after CC 1 16,0 x x

+9m Turntable 1 7,0 x x

+9m Transfer 1 5,0 x x

±0m Tunnel/Lift 4 6,5 x x

±0m Buffer 4 5,5 x x

±0m OFLA 4 8,0 x x incl. Detection

±0m Flash off 4 5,5 x x

±0m Buffer 4 5,5 x x

±0m Tunnel/Lift 4 6,5 x x

+9m Robot (Bell) Protection x scope of supply: Paint robot contractor

+9m Railhouse/Robot-Tower Primer 1 176,0 x x

inside spray booth recirculation air ducts 1 70,0 x x where necessary

inside spray booth exhaustair ducts 1 70,0 x x where necessary

+20,2 ASU Cleaning 1 25,0 x x till first filter

±0m RAU BC 1 1 12,0 x x till first filter

±0m RAU BC 2 1 12,0 x x till first filter

±0m RAU OFLA 1 12,0 x x till first filter

platform around spray booth BC/CC 1 3200m² x x

+9m below obstructions Primer/BC Line 1 210 x x

+9m TC Oven 2 49,8 x inside oven and cooling Zone: no protection

below obstructions Primer-Oven and Cooling Zone 1 65,0 x x

ASRS Primer &. TC 3 x x Storage. 3x84

Finish Line

+9m Quality check 1 7,5 x open workdeck/protected by building sprinkler

+9m Robotic inspection cell 1 9,0 x open workdeck/protected by building sprinkler

+9m Robotic pelt offline 1 8,0 x open workdeck/protected by building sprinkler

±0m Inspect 1 7,5 x open workdeck/protected by building sprinkler

±0m Inspect 1 7,5 x open workdeck/protected by building sprinkler

±0m Finesse/Polish 4 7,5 x open workdeck/protected by building sprinkler

±0m Panel exchange deck 2 7,5 x open workdeck/protected by building sprinkler

±0m Pelt Deck 1 7,5 x open workdeck/protected by building sprinkler

±0m Audit Deck 1 7,5 x open workdeck/protected by building sprinkler

±0m Quality Deck 1 7,5 x open workdeck/protected by building sprinkler

±0m Quality, Pick-Up & Buy-off Deck 1 7,5 x open workdeck/protected by building sprinkler

±0m Heavy Rework 1 7,5 x x

±0m Heavy Rework/Pelt 1 7,5 x x

±0m Spot Box 4 7,5 x x

ASRS (Storage to GA) 1 x x Storage: 168

±0m Autom. Door application 1 6,0 x x

±0m Autom. Wax 1 (protected) 1 8,0 x x

±0m Autom. Wax 2 (protected) 1 8,0 x x

±0m Skid repair 1 7,5 x open workdeck/protected by building sprinkler

±0m Skid Cleaning 1 14,0 x x

inside Spot Box. exhaust ducts 1 120,0 x x where necessary

inside WAX. exhaust ducts 1 30,0 x x where necessary

below obstructions Working Booth 1 250,0 x x

General Process Area

below conveyor platforms 5000m² x x

Abatement System no protection

below obstructions Shop ventil x by PIF KAEC/Construction

technical Rooms (WWT, DI, Lab, Material, etc) x by PIF KAEC/Construction

Social Rooms x by PIF KAEC/Construction

PMR x by PIF KAEC/Construction

below obstructions Ventilation PMR x by PIF KAEC/Construction

Smoke detectors x by PIF KAEC/Construction

Gas Warning System for solvents C7H8 x by PIF KAEC/Construction

Gas Warning System for natural Gas x by PIF KAEC/Construction

below platforms (process, conveyor) 8.800 m² according layout

running meter

below obstruction 1.297 below/beside process equipment (e.g., tanks, walkways, etc.)

process

below obstruction ductwork running meter

1.000 estimate; routing not yet finalized; to be done in detail engineering

(included in 1297 running meter process) ductwork

ASRS 672 units

You might also like

- Operations Manual For BROMMA Telescopic Spreader Type EH170UDocument474 pagesOperations Manual For BROMMA Telescopic Spreader Type EH170UReinaldo Zorrilla100% (5)

- AppointedPerson CalculationTemplateDocument5 pagesAppointedPerson CalculationTemplateviniciusgdelimaNo ratings yet

- Understanding and Servicing Alarm SystemsFrom EverandUnderstanding and Servicing Alarm SystemsRating: 1 out of 5 stars1/5 (1)

- Matematik K1Document1 pageMatematik K1HASHMI MAHMOODNo ratings yet

- Pe Ducted SplitDocument12 pagesPe Ducted SplitRamadan RashadNo ratings yet

- Ship Particular Onasis 10 PLB 150 PaxDocument3 pagesShip Particular Onasis 10 PLB 150 PaxMuhammad RIZALNo ratings yet

- COMPLETE LIST OF ATRsDocument63 pagesCOMPLETE LIST OF ATRslevi metzgarNo ratings yet

- Reading 1 - Science - BIOL105 - Disease - ResponseDocument9 pagesReading 1 - Science - BIOL105 - Disease - ResponsemykrohNo ratings yet

- Antenna Seatel Series 94 Troubleshooting GuideDocument248 pagesAntenna Seatel Series 94 Troubleshooting GuideDo0k13100% (3)

- System BreakdownDocument16 pagesSystem BreakdownYousuf Nasser ALAbriNo ratings yet

- Crane Tech Eval AR 05-13 Rev 2 02-05-15Document60 pagesCrane Tech Eval AR 05-13 Rev 2 02-05-15eko123No ratings yet

- Cleaning and Repair Boiler and Shoot Blower Scope of Works and SupplyDocument1 pageCleaning and Repair Boiler and Shoot Blower Scope of Works and SupplydharwinNo ratings yet

- PVE CREANES Technical Proposal For Paint BoothDocument9 pagesPVE CREANES Technical Proposal For Paint BoothVeenaNo ratings yet

- Scope of Work DivisionDocument2 pagesScope of Work DivisiondahuallNo ratings yet

- SC 600 Electro Pneumatic DevicesDocument60 pagesSC 600 Electro Pneumatic DevicesSetyohdWNo ratings yet

- FCM Function Overview - Signals - 14RTflex96CBDocument2 pagesFCM Function Overview - Signals - 14RTflex96CBKesavan Vimal KumarNo ratings yet

- SC 600 Electro Pneumatic DevicesDocument60 pagesSC 600 Electro Pneumatic DevicesCarlos MolinaNo ratings yet

- Deck Plate Check at Upper Deck: Proj No Calc No X Deck Plating CheckDocument2 pagesDeck Plate Check at Upper Deck: Proj No Calc No X Deck Plating Checkhk089No ratings yet

- Bromma - EH170U PDFDocument458 pagesBromma - EH170U PDFTopo MendigoNo ratings yet

- Operations Manual: Bromma Telescopic SpreaderDocument438 pagesOperations Manual: Bromma Telescopic Spreaderkron32No ratings yet

- Artemis Brochure 2022Document7 pagesArtemis Brochure 2022StylianosNo ratings yet

- Scotian Sentinel Data Sheet LODocument2 pagesScotian Sentinel Data Sheet LOtukidutraNo ratings yet

- 47 EH170Ueng 00Document443 pages47 EH170Ueng 00Mohamed El Gamal100% (1)

- P&G SowDocument4 pagesP&G SowsigmaintipurnamaNo ratings yet

- Appendix No.2 TUM-5Document2 pagesAppendix No.2 TUM-5Nguyễn Xuân ThắngNo ratings yet

- 75M PSV Specifications PDFDocument2 pages75M PSV Specifications PDFAlex1906No ratings yet

- Alternative To "Cork" Isolation at Pump PlinthDocument4 pagesAlternative To "Cork" Isolation at Pump PlinthMahmoud El-KatebNo ratings yet

- Shaw Bill of MaterialsDocument16 pagesShaw Bill of MaterialsChristan Reed MoquiaNo ratings yet

- Exit GateDocument38 pagesExit GateMATRIX ENGINEERSNo ratings yet

- Hettich EBA - 20 - EnglDocument2 pagesHettich EBA - 20 - EnglCV Tri R FamiliNo ratings yet

- Mesa Con Bucky Axiom Iconos MD - Requerimientos Técnicos de PreinstalaciónDocument11 pagesMesa Con Bucky Axiom Iconos MD - Requerimientos Técnicos de PreinstalaciónCamila LopezNo ratings yet

- GV Actuator Upgrade From TM25 To Varistroke TCL Rev 1Document2 pagesGV Actuator Upgrade From TM25 To Varistroke TCL Rev 1Magdalena PanggabeanNo ratings yet

- Lightweighting Your World.: Rapid Efficient LayupDocument4 pagesLightweighting Your World.: Rapid Efficient Layupavinash3285No ratings yet

- X Line Overview Presentation en Us 180792Document58 pagesX Line Overview Presentation en Us 180792jeemaajeeNo ratings yet

- Service Manual: Twin-Tub Washing Machine ModelDocument19 pagesService Manual: Twin-Tub Washing Machine ModelTop ElectronicNo ratings yet

- PC60 Single Point Load Cell: Product Description ApprovalsDocument3 pagesPC60 Single Point Load Cell: Product Description ApprovalsSeidelNo ratings yet

- SU Technical Specifications August 2022Document4 pagesSU Technical Specifications August 2022Brett SmithNo ratings yet

- Presentation Duxvalves B.VDocument25 pagesPresentation Duxvalves B.Vanwarhas05No ratings yet

- Exit Gate Civil PartDocument30 pagesExit Gate Civil PartMATRIX ENGINEERSNo ratings yet

- DOW - SupplyDocument3 pagesDOW - SupplySuleman InamNo ratings yet

- 7VK87Document5 pages7VK87Ganesh DuraisamyNo ratings yet

- Renold Rev2015Document12 pagesRenold Rev2015anandparasu5459No ratings yet

- 04Document29 pages04mancangkulNo ratings yet

- Tank Farm InstrumentationDocument2 pagesTank Farm InstrumentationBABILIN VNo ratings yet

- Tedea Huntleigh 1010Document4 pagesTedea Huntleigh 1010Osvaldino JuniorNo ratings yet

- DOW - InstallationDocument3 pagesDOW - InstallationSuleman InamNo ratings yet

- 7UM6 Gen Prot-Schemes EDocument10 pages7UM6 Gen Prot-Schemes EruslaninstNo ratings yet

- Attachment-#1 Scope of Work & Supply - EPDocument3 pagesAttachment-#1 Scope of Work & Supply - EPAAN ANHARINo ratings yet

- Fastnet Sentinel Data Sheet LODocument2 pagesFastnet Sentinel Data Sheet LOtukidutraNo ratings yet

- Clean Rooms, Wafer Cleaning and Gettering. Reading Assignments - Plummer, Chap 4.1 - 4.4, 4.6Document61 pagesClean Rooms, Wafer Cleaning and Gettering. Reading Assignments - Plummer, Chap 4.1 - 4.4, 4.6ArianaNo ratings yet

- Kistler - Biomecanica - Olataforma Fuerza ColombiaDocument3 pagesKistler - Biomecanica - Olataforma Fuerza ColombiaV.v. TaguisNo ratings yet

- Posh Enterprise SpecsDocument1 pagePosh Enterprise SpecsmiguelNo ratings yet

- Project Costing - Navin TexDocument6 pagesProject Costing - Navin Texsugunec2013No ratings yet

- Ultrasonic Watertight Integrity TesterDocument10 pagesUltrasonic Watertight Integrity TesterTharusha UpulangaNo ratings yet

- Túnel VEITDocument27 pagesTúnel VEITgamusino2No ratings yet

- Early Production Facility (EPF) Equipment DetailsDocument3 pagesEarly Production Facility (EPF) Equipment DetailsEPT OperationsNo ratings yet

- Painting Inspection Report Angle Bars PDFDocument1 pagePainting Inspection Report Angle Bars PDFpstechnical_43312697No ratings yet

- Documentation 69357N4Document129 pagesDocumentation 69357N4Ronald RoblesNo ratings yet

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Ticket 655Document1 pageTicket 655jia wangNo ratings yet

- GF 6320 Thermostatic Balancing Valves - CSI Format SpecificationDocument4 pagesGF 6320 Thermostatic Balancing Valves - CSI Format Specificationjia wangNo ratings yet

- VaccineCertificate VCC01012349431Document1 pageVaccineCertificate VCC01012349431jia wangNo ratings yet

- Access and Water Supply BrochureDocument2 pagesAccess and Water Supply Brochurejia wangNo ratings yet

- WorkLOG CEPDocument5 pagesWorkLOG CEPjia wangNo ratings yet

- 334100Document5 pages334100jia wangNo ratings yet

- UtilitiesDocument31 pagesUtilitiesjia wangNo ratings yet

- Nu - 23 6500 - Cooling TowersDocument16 pagesNu - 23 6500 - Cooling Towersjia wangNo ratings yet

- Div 21 1116 Facility Fire HydrantsDocument3 pagesDiv 21 1116 Facility Fire Hydrantsjia wangNo ratings yet

- Tests For Surface Wellheads and BOP Equipment Used in Operations On Land and Above Water LevelDocument6 pagesTests For Surface Wellheads and BOP Equipment Used in Operations On Land and Above Water Levelahmed121No ratings yet

- Social Construction of DisasterDocument385 pagesSocial Construction of DisasterPratik Kumar BandyopadhyayNo ratings yet

- Discovery LearningDocument14 pagesDiscovery LearningYuki JudaiNo ratings yet

- Concurrent Manager ConceptDocument9 pagesConcurrent Manager Conceptnikhil_cs_08No ratings yet

- 8th and 9th Houses PDFDocument3 pages8th and 9th Houses PDFtechkasambaNo ratings yet

- Rec1967 124Document70 pagesRec1967 124anaghaNo ratings yet

- Easyworship Documentation ManualDocument34 pagesEasyworship Documentation ManualAragorn100% (2)

- Sec D CH 12 Regression Part 2Document66 pagesSec D CH 12 Regression Part 2Ranga SriNo ratings yet

- Goulds Pumps: WE SeriesDocument4 pagesGoulds Pumps: WE SeriesJorge ManobandaNo ratings yet

- None C9efb7c9Document6 pagesNone C9efb7c9liana iwiwNo ratings yet

- PPT10-super and UltracapacitorDocument22 pagesPPT10-super and UltracapacitorChaudhari Jainish100% (1)

- My Intro To ChatGPT SlideshowDocument38 pagesMy Intro To ChatGPT SlideshowKamelia SavovaNo ratings yet

- Manual Testing 1Document4 pagesManual Testing 1shanthan117No ratings yet

- Analysis of Transfer Lines: UNIT-3 Automation Manufracturing PvpsitDocument14 pagesAnalysis of Transfer Lines: UNIT-3 Automation Manufracturing PvpsitSravanth KondetiNo ratings yet

- 0-5352 AaDocument70 pages0-5352 AaSergiu CandramanNo ratings yet

- Tracing The Location of A Typhon Lesson PlanDocument4 pagesTracing The Location of A Typhon Lesson PlanJoh A Nna100% (2)

- Heater & Air ConditionerDocument104 pagesHeater & Air ConditionerMusat Catalin-Marian100% (1)

- 1977 The Reactive Agility TestDocument6 pages1977 The Reactive Agility TestJessica Sepúlveda SalasNo ratings yet

- Engineering Practices Lab-ECEDocument43 pagesEngineering Practices Lab-ECEPraveen KarthickNo ratings yet

- B.tech Project Stage-II Presentation - MidsemDocument25 pagesB.tech Project Stage-II Presentation - Midsemkaalin bhaiyaNo ratings yet

- Report 1 Water Quality Test TTS 301115 FinishedDocument9 pagesReport 1 Water Quality Test TTS 301115 FinishedJeana Lew SCNo ratings yet

- 1 s2.0 S223878542300652X MainDocument14 pages1 s2.0 S223878542300652X MainFahra Aqilla AzzurahNo ratings yet

- Liberty Ships Brittle Fracture (Final)Document5 pagesLiberty Ships Brittle Fracture (Final)hsemargNo ratings yet

- A Report: Smt. Shantaben Haribhai Gajera Engineering CollegeDocument5 pagesA Report: Smt. Shantaben Haribhai Gajera Engineering CollegePranav. ThubeNo ratings yet

- DYNAMIC MODELLING AND CONTROL OF A 3-DOF PLANAR PARALLEL ROBOTIC (XYthetaZ MOTION) PLATFORMDocument10 pagesDYNAMIC MODELLING AND CONTROL OF A 3-DOF PLANAR PARALLEL ROBOTIC (XYthetaZ MOTION) PLATFORMVinoth VenkatesanNo ratings yet

- DISS TOS Q3 TESTDocument3 pagesDISS TOS Q3 TESTMichelle GariandoNo ratings yet

- Rubric For Use When Evaluating Lesson Plan PresentationsDocument1 pageRubric For Use When Evaluating Lesson Plan PresentationsSajid AwanNo ratings yet