Professional Documents

Culture Documents

FAA - Form - 337 Stiffener 2 4 6 8

Uploaded by

Nguyễn Đức ÝOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FAA - Form - 337 Stiffener 2 4 6 8

Uploaded by

Nguyễn Đức ÝCopyright:

Available Formats

Paperwork Reduction Act Statement: A federal agency may not conduct or sponsor, and a person is not required to respond

to, nor shall

a person be subject to a penalty for failure to comply with a collection of information subject to the requirements of the Paperwork Reduction Act unless

that collection of information displays a currently valid OMB Control Number. The OMB Control Number for this information collection is 2120-0020.

Public reporting for this collection of information is estimated to be approximately 15 minutes per response, including the time for reviewing instructions,

searching existing data sources, gathering and maintaining the data needed, completing and reviewing the collection of information.

All responses to this collection of information are mandatory CFR 14 Part 43. Send comments regarding this burden estimate or any other aspect of this

collection of information, including suggestions for reducing this burden to: Information Collection Clearance Officer, Federal Aviation Administration,

10101 Hillwood Parkway, Fort Worth, TX 76177-1524

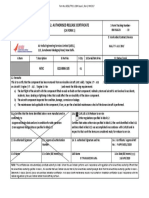

OMB No. 2120-0020 Electronic Tracking Number

Exp: 01/31/2023

US Department

MAJOR REPAIR AND ALTERATION For FAA Use Only

of Transportation (Airframe, Powerplant, Propeller, or Appliance)

Federal Aviation

Administration

INSTRUCTIONS: Print or type all entries. See Title 14 CFR §43.9, Part 43 Appendix B, and AC 43.9-1 (or subsequent revision thereof) for

instructions and disposition of this form. This report is required by law (49 U.S.C. §44701). Failure to report can result in a civil penalty for each

such violation. (49 U.S.C. §46301(a))

Nationality and Registration Mark Serial No.

N186C1 7AC

1. Aircraft Make Model Series

Aeronca 7AC-123 Champion

Name (As shown on registration certificate) Address (As shown on registration certificate)

Address 10440 Black Mountain Rd

2. Owner Felipe Williams

City San Diego State CA

Zip 92126 Country U.S

3. For FAA Use Only

4. Type 5. Unit Identification

Repair Alteration Unit Make Model Serial No.

Aeronca 7AC

X AIRFRAME (As described in Item 1 above)

POWERPLANT

PROPELLER

Type

APPLIANCE

Manufacturer

6. Conformity Statement

A. Agency's Name and Address B. Kind of Agency

Name Duc Nguyen X U. S. Certificated Mechanic Manufacturer

Address 8888 Libra Drive

Foreign Certificated Mechanic C. Certificate No.

City San Diego State CA Certificated Repair Station

Zip 92126 Country U.S

Certificated Maintenance Organization A&P Pending

D. I certify that the repair and/or alteration made to the unit(s) identified in item 5 above and described on the reverse or attachments hereto

have been made in accordance with the requirements of Part 43 of the U.S. Federal Aviation Regulations and that the information

furnished herein is true and correct to the best of my knowledge.

Extended range fuel Signature/Date of Authorized Individual

per 14 CFR Part 43

App. B

7. Approval for Return to Service

Pursuant to the authority given persons specified below, the unit identified in item 5 was inspected in the manner prescribed by the

Administrator of the Federal Aviation Administration and is Approved Rejected

FAA Flt. Standards Maintenance Organization

Persons Approved by Canadian

Manufacturer Department of Transport

Inspector

BY Other (Specify)

FAA Designee Repair Station Inspection Authorization

Certificate or Signature/Date of Authorized Individual

Designation No.

FAA Form 337 (10/06)

Page 1

NOTICE

Weight and balance or operating limitation changes shall be entered in the appropriate aircraft record. An alteration must be

compatible with all previous alterations to assure continued conformity with the applicable airworthiness requirements.

8. Description of Work Accomplished

(If more space is required, attach additional sheets. Identify with aircraft nationality and registration mark and date work completed.)

N186C1 12/06/2022

Nationality and Registration M ark Date

Consult AC43.9-1, for inspection authorization, approval by Physical Inspection, Demonstration,

Testing, etc.—One Aircraft: The alteration or repair identified herein complies with the applicable

airworthiness requirements and is approved for the above described aircraft, subject to conformity

inspection by a person authorized in section 43.7.

Wing inspected, a hole is found on upper camber of the port, wing station 40-46, 3 inches from the

leading eage. hole diameter is 5.5 inch.

1. As follow AC43.13-1B, Page 1-20, Par 1-46, determined single curvature on upper camber.

Performed repairing on plywood skin by scraft patch method in accordance to AC43.13-1, Page

1-26, Para 1-51, Figure 1-16, back of hole not accessible.

2. Marked 2 inches on each side of the hole, cut away the fabric in rectangular shape and leave the

hole in the center.

3. Cutaway the hole in the plywood in rectangular shape, leave 0.375 inch on each side of wing ribs.

4. Remove old varnish by softening open plywood by lacquer thinner, then scrape the varnish from

the ouside wood area, rib caps, underside of the skin along the upper edge.

5. Use 0.375 inch thick spruce to make stiffeners, then lay out gussets

6. Take measurement chordwise stiffeners of the correct length to fit rip cabs.

7. Put glue on 4 sides of underside of the skin, stiffeners, and gussets. Fit them stiffeners tight by

with gussets installed and applied C-clamps on nailing strip

8. Measure 3 inch scarft on four sides of opening, block plane to start the scraft, and finish it off by

sanding and moist rag

9. Use 0.25 inches thickness Birch plywood, take the same measurement of size and shape of the

patch as the opening.

10. Layout 3 inch on each side of the new plywood and use block plane to start the scraft, finish it

off by sanding and moist rag

11. Varnish the underside of the patch inside the scraft, stiffeners, gussets

12. Use plenty of glue on scraft patch, patch the new plywood on the openning hole to fiush tight,

covered with wax paper

13. Nailing strips are used to apply pressure on the patch, 2 strips on each joint, wait till glue is

cured.

14. Remove the nailing strips, trace of wax paper. Apply first coat of spar varnish, wait till dry then

scuff sanding lightly.

15. Prepare fabric by taking measurement to extend 1 inch on each side of plywood, coat plywood

with clear dope.

16. I certify the repair hidden beneath the Poly-Fiber Fabric Covering has been inspected and

certified by John Allen, certificated number: A&P 191323 IA, dated 12/06/2022.

17.Apply fabric patch and coat clear dope on top, wait 30 minutes then apply second coat of clear

dope.

18.Apple first coat of pigment dope, wait 30 minutes, sand lightly, apply second coat of pigment

dope with right angle.

Repair area covered in accordance with Poly-Fiber Procedure Manual No. 1, Revision 21,

September 2006, Appendix I, Page 108 - 109."

✔ Additional Sheets Are Attached

FAA Form 337 (10/06)

Page 2

You might also like

- FAR/AIM 2019: Federal Aviation Regulations / Aeronautical Information ManualFrom EverandFAR/AIM 2019: Federal Aviation Regulations / Aeronautical Information ManualNo ratings yet

- Airman Certification Standards: Remote Pilot - Small Unmanned Aircraft Systems (2024): FAA-S-ACS-10BFrom EverandAirman Certification Standards: Remote Pilot - Small Unmanned Aircraft Systems (2024): FAA-S-ACS-10BNo ratings yet

- How To Make FireworksDocument14 pagesHow To Make FireworksLeonardo BiancoNo ratings yet

- Interplay The Process of Interpersonal Communication Fifth Canadian Edition 5nbsped 9780199033478 9780199038701 9780199033522 - Compress PDFDocument481 pagesInterplay The Process of Interpersonal Communication Fifth Canadian Edition 5nbsped 9780199033478 9780199038701 9780199033522 - Compress PDFNguyễn Đức Ý100% (2)

- Receiving Inspections Power PointDocument44 pagesReceiving Inspections Power PointDarby Morgan100% (6)

- Faa Form 8070-1Document2 pagesFaa Form 8070-1api-520948779No ratings yet

- Aerody Design of BladeDocument90 pagesAerody Design of BladeB Bala Venkata GaneshNo ratings yet

- Service Difficulty Report: N-A16WEDocument2 pagesService Difficulty Report: N-A16WEapi-520948779No ratings yet

- Material Specifications: Low Carbon Steel, Hot Rolled Sheet and StripDocument5 pagesMaterial Specifications: Low Carbon Steel, Hot Rolled Sheet and Striptim0% (1)

- Form 8130-FAADocument1 pageForm 8130-FAAJoel Cordova100% (2)

- Faa Form 337Document3 pagesFaa Form 337api-540697945No ratings yet

- Form 377Document3 pagesForm 377Obi WanNo ratings yet

- Faa Form 337Document3 pagesFaa Form 337api-540697339No ratings yet

- 337 FaaDocument3 pages337 FaaWilliam LoNo ratings yet

- Faa Form 337Document3 pagesFaa Form 337api-521155773No ratings yet

- Installation of SpidersDocument54 pagesInstallation of SpidersUriel CasiqueNo ratings yet

- DGCA Form 43-337 RTS Embodiment of Alteration or Major Repair - Oct 2017Document2 pagesDGCA Form 43-337 RTS Embodiment of Alteration or Major Repair - Oct 2017ahmad ramdaniNo ratings yet

- Form 43-337 REV05Document2 pagesForm 43-337 REV05Avian50% (4)

- Major Repair and Alteration (Airframe, Powerplant, Propeller, or Appliance)Document3 pagesMajor Repair and Alteration (Airframe, Powerplant, Propeller, or Appliance)Juan Daniel Granada AriasNo ratings yet

- Faa Form 337Document3 pagesFaa Form 337bnolasco100% (1)

- Lamp CoverDocument1 pageLamp Coveralejandro.perezNo ratings yet

- Instructions For Completing FAA Form 8120-11, Suspected Unapproved Parts ReportDocument3 pagesInstructions For Completing FAA Form 8120-11, Suspected Unapproved Parts Reportapi-520836597No ratings yet

- Advisory Circular: Subject: Instructions For Completion of Date: 1/25/07 AC No: 43.9-1F Initiated By: AFS-350 ChangeDocument10 pagesAdvisory Circular: Subject: Instructions For Completion of Date: 1/25/07 AC No: 43.9-1F Initiated By: AFS-350 ChangeMIKE SPENCERNo ratings yet

- TMC Annual ChecklistDocument26 pagesTMC Annual ChecklistEstevamNo ratings yet

- Advisory Circular 43 Ac-43!9!1fDocument9 pagesAdvisory Circular 43 Ac-43!9!1fDave PennyNo ratings yet

- Supplemental Type Certificate: NumberDocument2 pagesSupplemental Type Certificate: NumberOmri AmayaNo ratings yet

- Ac43 9-1eDocument8 pagesAc43 9-1eRaul ChaveroNo ratings yet

- AC 43-9-1F Filling 337Document9 pagesAC 43-9-1F Filling 337JesseNo ratings yet

- SA09856ACDocument2 pagesSA09856ACJosue Jet avionicsNo ratings yet

- Paperwork Reduction Act StatementDocument3 pagesPaperwork Reduction Act Statementpucarapucara2No ratings yet

- SA00756DEDocument2 pagesSA00756DEMaria Luisa CucunubaNo ratings yet

- Form 337Document3 pagesForm 337api-287640313No ratings yet

- Ac 43.9-1e, Instructions For Completion of Faa Form 337 (Omb No (1) - 2120-0020), Major Repair and AlteraDocument5 pagesAc 43.9-1e, Instructions For Completion of Faa Form 337 (Omb No (1) - 2120-0020), Major Repair and Alterabobbyo56No ratings yet

- Supplemental Type Certificate: Department of Transportation Federal Aviation AdministrationDocument3 pagesSupplemental Type Certificate: Department of Transportation Federal Aviation AdministrationJuan C BalderasNo ratings yet

- Ca Form 19-10 PDFDocument4 pagesCa Form 19-10 PDFPanneer SelvamNo ratings yet

- 18-1738-10 PMA LetterDocument2 pages18-1738-10 PMA LetterBaCresNo ratings yet

- AC 20-62E (Eligibility Quality and Identification of Aeronautical Replacement Parts (Page 5 & 6)Document2 pagesAC 20-62E (Eligibility Quality and Identification of Aeronautical Replacement Parts (Page 5 & 6)kinqpinzNo ratings yet

- Ca FormDocument1 pageCa FormDeepak Singh50% (2)

- SA02426AKDocument3 pagesSA02426AKMaria Luisa CucunubaNo ratings yet

- MRADocument1 pageMRAChristine RucklinNo ratings yet

- SA04567CHDocument3 pagesSA04567CHjohnNo ratings yet

- Faa Registry: N-Number Inquiry ResultsDocument3 pagesFaa Registry: N-Number Inquiry Resultsolga duqueNo ratings yet

- Css+fa8139 24 Q 0005Document45 pagesCss+fa8139 24 Q 0005issacjacob907No ratings yet

- Faa Form 8120-11 Hechaa UltimaDocument3 pagesFaa Form 8120-11 Hechaa Ultimaapi-520948779No ratings yet

- Easa Ad Us-2005-01-09 1Document6 pagesEasa Ad Us-2005-01-09 1RS BANo ratings yet

- Faa Form 8120-11 2Document3 pagesFaa Form 8120-11 2api-520948779No ratings yet

- ARC - Top Kit 65C38689-67 - 091215Document1 pageARC - Top Kit 65C38689-67 - 091215YusakNo ratings yet

- FAA201625730001 Attachment 1Document4 pagesFAA201625730001 Attachment 1Diego fernando PortelaNo ratings yet

- SA02930NYDocument3 pagesSA02930NYDavid Samaniego PánchezNo ratings yet

- Easa Ad Us-2016-07-28 1Document7 pagesEasa Ad Us-2016-07-28 1Kattuko_111No ratings yet

- SSL 525Document4 pagesSSL 525Svtorrent SvtorrentNo ratings yet

- ST04231ATDocument4 pagesST04231ATSergio LópezNo ratings yet

- AC - 21-29D - Detecting and Reporting Suspected Unapproved PartsDocument16 pagesAC - 21-29D - Detecting and Reporting Suspected Unapproved PartsOmar Andres Simijaca CantorNo ratings yet

- Faa Form 8120-11 Jhon Homez 1Document3 pagesFaa Form 8120-11 Jhon Homez 1api-520948779No ratings yet

- Supplemental Type Certificate: NumberDocument3 pagesSupplemental Type Certificate: NumberJuan C BalderasNo ratings yet

- Type Inspection Authorization, Faa Form 8110-1Document9 pagesType Inspection Authorization, Faa Form 8110-1Fadill GunawanNo ratings yet

- Advisory Circular: Subject: Detecting and ReportingDocument16 pagesAdvisory Circular: Subject: Detecting and ReportingLinson Omar Gonzalez GomezNo ratings yet

- FAA Legal Interpretation 13 Jun 2018 Inoperative EquipmentDocument5 pagesFAA Legal Interpretation 13 Jun 2018 Inoperative EquipmentMinivationNo ratings yet

- Axp340 Sa00352boDocument4 pagesAxp340 Sa00352boMIGUEL FRANCONo ratings yet

- 12 06 26 12 51 52 16256 104673+8130tdDocument2 pages12 06 26 12 51 52 16256 104673+8130tdPrabin T PrasadNo ratings yet

- SA02203AKDocument4 pagesSA02203AKMaria Luisa CucunubaNo ratings yet

- Easa Ad Us-2014-03-06 1Document7 pagesEasa Ad Us-2014-03-06 1aliNo ratings yet

- Car 66 Issue Ii R 1 Appendix V - Applications and FormatsDocument4 pagesCar 66 Issue Ii R 1 Appendix V - Applications and FormatsAnil KumarNo ratings yet

- AS-DO-P7.03 - Inspection Stamp and Tag Rev1 - 06-15-2016 - UnlockedDocument7 pagesAS-DO-P7.03 - Inspection Stamp and Tag Rev1 - 06-15-2016 - UnlockedDavid SiahaanNo ratings yet

- Ad2000 01 16 1Document29 pagesAd2000 01 16 1Nguyễn Đức ÝNo ratings yet

- A17WE Rev 23Document17 pagesA17WE Rev 23Nguyễn Đức ÝNo ratings yet

- Interpersonal COMM Syllabus - COMS 135-23917 Spring 2023 PDFDocument14 pagesInterpersonal COMM Syllabus - COMS 135-23917 Spring 2023 PDFNguyễn Đức ÝNo ratings yet

- Chapter 11 (Shorten Version) Fall 2022Document3 pagesChapter 11 (Shorten Version) Fall 2022Nguyễn Đức ÝNo ratings yet

- "Renaissance" Is French For "Rebirth": WhereDocument27 pages"Renaissance" Is French For "Rebirth": WhereNguyễn Đức ÝNo ratings yet

- Art Orientation CH 15 9th Ed OnlineDocument48 pagesArt Orientation CH 15 9th Ed OnlineNguyễn Đức ÝNo ratings yet

- Art Orientation CH 13 9th Ed OnlineDocument50 pagesArt Orientation CH 13 9th Ed OnlineNguyễn Đức ÝNo ratings yet

- Art Orientation CH 17 9th Ed OnlineDocument23 pagesArt Orientation CH 17 9th Ed OnlineNguyễn Đức ÝNo ratings yet

- Art Orientation CH 19 9th Ed OnlineDocument45 pagesArt Orientation CH 19 9th Ed OnlineNguyễn Đức ÝNo ratings yet

- FileDocument30 pagesFileNguyễn Đức ÝNo ratings yet

- Drawing Is The Result of An Implement Running Over The Surface and Leaving Some Trace of The GestureDocument26 pagesDrawing Is The Result of An Implement Running Over The Surface and Leaving Some Trace of The GestureNguyễn Đức ÝNo ratings yet

- Iso 3932 1976Document8 pagesIso 3932 1976NaveedNo ratings yet

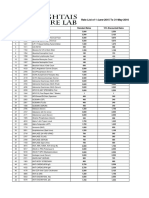

- Rate List of 1-June-2015 To 31-May-2016: S.No Code Test Name Standard Rates 15% Discounted RatesDocument25 pagesRate List of 1-June-2015 To 31-May-2016: S.No Code Test Name Standard Rates 15% Discounted RatesMirza BabarNo ratings yet

- Multical® 402: Data SheetDocument20 pagesMultical® 402: Data SheetSundar RamasamyNo ratings yet

- GenesDocument33 pagesGenesJerick RoxasNo ratings yet

- Portable Load Banks: CressallDocument1 pagePortable Load Banks: CressallYashveer26No ratings yet

- Radiant ThinkingDocument4 pagesRadiant Thinkingeehwa88No ratings yet

- hw10 PDFDocument10 pageshw10 PDFTahok24No ratings yet

- Effect of Toe Treatments On The Fatigue Resistance of Structural Steel WeldsDocument12 pagesEffect of Toe Treatments On The Fatigue Resistance of Structural Steel WeldsVicente Palazzo De MarinoNo ratings yet

- PerthDocument21 pagesPerthjohn_wlmns3929No ratings yet

- Modeling and Simulation For Olefin Production in Amir Kabir PetrochemicalDocument7 pagesModeling and Simulation For Olefin Production in Amir Kabir PetrochemicalGhasem BashiriNo ratings yet

- X-Ray Radiation and Gamma RadiationDocument13 pagesX-Ray Radiation and Gamma RadiationVence MeraNo ratings yet

- Ycaj CHILLERDocument108 pagesYcaj CHILLERAbhilash Joseph100% (2)

- Power System Analysis and Design EE-461: Tassawar Kazmi Lecturer, EE Department, Seecs, NustDocument10 pagesPower System Analysis and Design EE-461: Tassawar Kazmi Lecturer, EE Department, Seecs, NustShahab SaqibNo ratings yet

- DHI-ITALE-060AA-P: White Strobe LampDocument2 pagesDHI-ITALE-060AA-P: White Strobe LampXlabs MedanNo ratings yet

- Trucks Fin Eu PCDocument117 pagesTrucks Fin Eu PCjeanpienaarNo ratings yet

- Lesson 5 African LiteratureDocument3 pagesLesson 5 African LiteratureMiguel CarloNo ratings yet

- Medical BiotechnologyDocument4 pagesMedical Biotechnologyعمر بن عليNo ratings yet

- ASTM E 1066 - 95 Standard Practice For Ammonia Colorimetric Leak Testing PDFDocument5 pagesASTM E 1066 - 95 Standard Practice For Ammonia Colorimetric Leak Testing PDFАртем ТитовNo ratings yet

- C.4. Quiz Conservation of BiodiversityDocument2 pagesC.4. Quiz Conservation of Biodiversitylaura pongutaNo ratings yet

- 1 s2.0 S0092867422011734 MainDocument29 pages1 s2.0 S0092867422011734 MainIoanna NikdimaNo ratings yet

- Material of OFFERING HELPDocument7 pagesMaterial of OFFERING HELPShorn x NyteNo ratings yet

- Dell Inspiron 16 5000 (5625) Laptop - Dell IndiaDocument5 pagesDell Inspiron 16 5000 (5625) Laptop - Dell IndiamubbunNo ratings yet

- Portland PortDocument18 pagesPortland PortAnonymous Lx3jPjHAVLNo ratings yet

- Run Omega Run Lunar Omegaverse Book 5 Shyla Colt All ChapterDocument52 pagesRun Omega Run Lunar Omegaverse Book 5 Shyla Colt All Chapterkate.brown975100% (6)

- Tycho BraheDocument3 pagesTycho BraheAienna Lacaya MatabalanNo ratings yet

- Gen Math DianaDocument5 pagesGen Math DianaDon Marlon BuquisNo ratings yet

- E2870-13 Standard Test Method For Evaluating RelativDocument6 pagesE2870-13 Standard Test Method For Evaluating RelativA MusaverNo ratings yet