Professional Documents

Culture Documents

Design of Bunkers New PDF

Design of Bunkers New PDF

Uploaded by

Utkarsh Kumar0 ratings0% found this document useful (0 votes)

44 views9 pagesOriginal Title

Design of Bunkers new.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

44 views9 pagesDesign of Bunkers New PDF

Design of Bunkers New PDF

Uploaded by

Utkarsh KumarCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 9

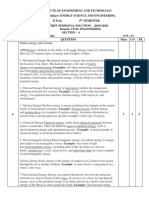

4 BUNKERS

In the bunkers, because of shallo i betwee

: S s WW depth, it is assumed tha i

: : : H : it th

ge wall and oi fill an negligible, Fig. 26.5 shows a bunker with other ai Ganson

och as fOP TH, Junction beam, hopper bottom with central opening, and supporting columns

(a) Pressure and moments on walls

Let a be the angle of surcharge of the fill. Fu Top nib

The pressure against the vertical wall is given by = C7 2

Rankine’s formula:

cos a = Ver

pa Gi

cos & + Veos* & - cos? > Cylindrical portion a

[26.16 (a)

The pressure acts in a direction parallel to

the top surface of the retained material, The horizontal

component is c

5 ET Junction

pe=p cos a = wh cos’ eon

S¢ : ‘epoer

= x bottom

Opening

if

: ea coun

Boece go | V516, O

HF a=0, (ce. top_surface is horizontal),

ie ant -.126.16(0)]

pe=vh Trane | vol mie ol bem

iti fee be —

The edge conditions are such that P ns es

fice and the botiom as well as the vertical odae®

are restrained ntinuity. For_this case,

=o ee late may be computed with the help of

moment due to tiangularly distributed lateral pressure

Table 3 of IS : 3370- Part IV. A simpler approach is to assume that the lateral, pressure

is taken entirely in the horizontal direction. ‘This is reasonably true if the height of the

wall is large as compared 10 its length, In that case, for a gore bunker, the bending

2 ee

g :

moment at ‘any depth will boca no at_the corners and py. 57 at mid. span, where

L is the span between the centre Tues of the supporting walls, Generally, haunches are

Provided at the corners, due (0 which negative ments are a7 oo penne

Much Jesser than py. L'/12, and the desi

* uniform 6.

For a reciangular bunker” ( Fig. 26.6), the negative

‘Moments at the corners are

Ma= Ma = Mo = Mc =~

REINFORCED CONCRETE STRUCTUpy

Mey = O28! pe ns By 50 we

o> yar 41 = fe (8 + 2BL - wy 4126.18 (ay

at the centre of spantis Ge kine ee

Mena Ph -

aq G+ 2BL = 25%) 126.18 (by)

In addition to the bending mor

due to pressure on the

that on wall B

ant the positive moment

ment, the walls are also subjected to direct tension

Adjoining walls. Thus, direct tension on wall L will be 0.5 p,.B and

Wil be_0.5 by. Apari From the bending moment and direct tension,

the walls are also Subjected to vertical weight of material transferred to it by hopper bottom.

Te vertical wall is therefore designed as a deep beam supported between columns.

Creular bunkers. The vertical wall of the circular bunker of diameter 6

for a hoop tension of Pr. b/2.

26.8. HOOPER BOTTOM : io

(a) Conical hopper. Conical hoppers are subjected essentially aoe a

hoop ‘tensions. The total meridional tension at any horizontal on Baka a

hopper is such that its vertical component is equal to total vertical pressure ae

plus the weight of the hopper and contents below the plane. Consider any ae —<

4D x depth ‘h below the top surface of the material. Let W, be the weight of the gr:

and W. be the weight of the cone

below this plane. The meridional tension

N is given by — 0

Nsina.2xb=py xb? + We+ We

Pe KO + Wy + We

~ 2nbsng

-.-(26.19)

Let py be the normal pressure. If %,

2 ceded Pe FIG. 26.7. CONICAL HOPPERS.

unit area, we have, from Fig. 26.7(6)

Po . EG = py.EF cos &+ pr. FG sina +ws EG cos a

or Pa= pv COS? & + pr sin? cw + Ws cos & «--(26.20)

‘The ring eee 7 H. any plane is given by peace

=Pa. te

where r= radius of curvature [Fig. 26.7 (a)] =6 cosec « ‘

For bins, p, and p, are obtained from the expressions developed c

ewer: oe ofp will be taken equal to p in the equation for Seek

“For shallow bins, #, on any horizontal cross-section will be equal © * os

the material above the section and py will be given by Eq. 26.23, given by

( § 26.6 ) substituting 9 for 9. ;

. (%) Pyramidal hoppers : Pyramidal hoppers are subjected to bending moments and

direct tensions besides meridional tension along the slope. :

Meridional tension | ‘yy ‘ B

he weight ct

vy sping bottom Find the Ant Of retained material, weight

Weight of

fie rise t@ vertical pull inthe Ree nate Opening etc. will |

f the side wall. If W is the we if rection, at the

Re ee cciatrec, Ue Weight mentioned above, er uni on Ale newesece

the maximum meridional tension at A, per unit lengne ee enet

a A, per unit length will be given os

| z anal Occ

= Weosec a _| .

ay Gs 4 (26.22)

This direct tension will gradually decrease to zero at the opening, B. eee

The

an hopper bottom is also Subjected to bending moment due to bending of the slab

spanning

horizontally between the intersection of adjacent’ sfoping faces. For example, if

we consider unit length of the slab between levels XX and YY (Fig. 26.%b)], the

span of the slab AB will be 1 andyit will be subjected to a normal load intensity

p. where p, is given by Eq. 26.20. Since the strip is continuous on all the four sides

of the hopper, it forms a closed frame, developing negative moments at joints and positive

moment at the centre of each span, The

magnitude of negative moment may be taken

as (p,./°)/12 and the positive moment

equal to(p, . 1* )/12. The reinforcement will

be placed at the outer fac men

and inside for negative mo

zonial span 1 of the slab will increase from

minimum at the opening to maximum at

the junction with vertical wall. The pressure

p, will, however, decrease from maximum

at the opening to minimum at junction with

vertical wall. The section of the slab should

be designed at the centre. In addition to 2

this, the strip will also be subjected to a direct pull equal to p,!/2.

26.6. INDIAN STANDARD ON DESIGN OF BINS(IS : 4995-1968)

1. Permissible stresses

(a) In concrete :

(i) Resistance to cracking. The permissible stresses in tension (direct and due to

bending) and shear shall conform to the values specified in Table 26.2. The values given

in 18 - 4995-1968 are in kg/cm? units, These have been converted inN/mm* unit by

the approximate relation ; 10 kg/em?= 1 N/mm’, The permissible tensile stress due to bending

apply w the outside face of the bin. In members less than 225 mm thick and in contact

with the grain on one side, the permissible stresses in bending apply also on the side

‘0 contact with the grain.

(ii) Resistance to buckling. ‘The maximum compressive stress on the net wall section

ing all openings, recesses, ew. shall not exceed 0.15 f where f, is the compressive

Strength of concrete at the age of 28 days. Where wind or earth quake forces are taken

into account, the stress on net wall section shall not exceed 0.2 f..

FIG. 26.9.

REINFORCED CONCRETE STRUCTURES

TABLE 26.2 PERMISSIBLE §

ES IN CONCRETE

ate Crake ohitanersi: Permissible stresses (N/mm?) Pettis

a Piven Tension due to bending (W/mm?)

MOS 3 ne uy

Mw ne _ 2

’ Mas Ne za

nee 12 | 21

_ (Pi In steel In strength calculations, the stresses in plain mild steel reinforcement,

ans in high yield strength bars (HYSD bars), the values given in Table 21.2 are adopted

2. Design parameters

() Cnit weight and angle of internal friction, Table 26.3 gives the values of unit

weight and angle of internal friction for same of the common types of grains.

UNIT WEIGHT AND ANGLES OF INTERNAL FRICTION

|___ Unis weight w/nc’)__|__ Angle ofinteral friction 9 _ |

| 8340 | we i

| 5640 | 36

8830 3°

| 7850 30°

6770 wr

seenGarr a us Bi Eanigy*

Wall friction. In the absence of test results, the angle of wall friction may

be assumed 10 be 0.75 © during filling and 0.6 4 during emptying, where © is the angle

of imernal friction of the material,

ui) Pressure ratio, The ratio of horizontal pressure to vertical pressure shall be

assumed 10 be 0.5 during filling and 1.0 during emptying, i.e. K,=0.5 and K,=1.0.

3. Design of walls

() Pressure on walls of a shallow bin : The horizontal pressure p, on a vertical

wall of a shallow bin shall be calculated by the following formula

Pree —— =

[rsfieee ane ]

(i) Pressure in a deep bin ; \n deep bins, the maximum values of the horizontal

Pressure on the wall (p,), the vertical pressure on the horizontal cross-section of the stored

material (p,) and the vertival load wansferred to the wall per unit area due to friction

Y.) tha a la ing i) :

fe dy be calculated jain formulae given below :

+ Nae of pressure | ring filing [During emptying

{ Maximum — p,

-.(26.23) where o’=angle of wall friction. :

wr

1 { Ke th a

| Maxisiusn |

| gn - |

I i \ jhe —{

Lb \ wr J

ee

whet We Unit weight of stored p :

Ky= pressure ae ne

RUS cat atlag ea = area/perimeter ratio

cine condition = 0.5

Wall friction during filling conditions

all friction during emptying condition.

+ Py and py — with

Obtained from the following

He’ = coefficient of ya

The vatiation ofp

depth (Fig, 26.10) may be obta

expression

(Pda = (Pi)max. (1 = e° /*0 (26.24)

ore P stands for pressure and suffix i stands 4

for yh or w, and z assumes following values:

During filling,

.

During emptying,

Ra L --(26.25) FIG. 26.10. PRESSURE VARIATION WITH

sits DEPTH.

The value of (1—e"%) may be taken from Table 26.1 ;

To take advantage of the decrease in lateral pressure caused by the bottom of a

bin, the horizontal pressure due to emptying, over a height of 1.2 b or 0.75_H_whichever

is smaller, may be taken to be varying linearly from the emptying pressure at this height

to the filling pressure at bottom as shown in Fig. 26.10.

The wall of a storage bin shall be examined for strength as well as stability under

the following two cases of loading separately:

(@) When the bin isMempty. All possible vertical loads (including the weight of the

material transferred to the wall due to friction) and lateral loads due to wind or quake

(whichever is critical ) shall be considered in this case.

(b) When the bin is empty. In this case, the self weight of, the bin and other permanent

loads on the bin shall be considered to act vertically in combination with the maximum

Jateral load caused by wind or earthquake.

(iii) Thickness of walls + The thickness of walls shall be computed on no crack

basis, The minimum thickness of the wall of a concrete bin having an internal diameter

‘of 6 m or less shall be 15 cm, When the internal diameter exceeds 6 m, the minimum

thickness shall be determined from the equation :

o1s+2=0 cx where Dw Oe ineral ameer of te bin in cm.

Walls of circular bins shall be desig!

rectangular bins, the lateral pressure at any

approximate values of r given below :

For square bin, r= 0.283 a, where @ is the side of the squre.

For rectangular bin, with short side a and long side, b,

y= 0.283 a, for obtaining pressure on short side

ned essentially for hoop stresses. For walls. of

depth may be obtained from Eq. 26.24, taking

pins AND SILOS

Ww

™

(ii) Vertical Reinforecment, V

¥ tical reinforc

Half the : jcement shi i

6 me het vate and shrinkage stress. Where the base felt aio face

ee eel a Teinforcement duly calculated shall be provided on the tension face.

Reis Cover of 5 cm shall be provided for the reinforcement.

4 Be F +1, Design a bunker to store 300 kN of coal, for the following data:

init weig c 1

oe weight of coal = 8340 N/m! ; Angle of repose = 30°. The stored codl is to be

surcharg ,

Bea angle of repose. Take permissible stress in steel as 140 N/mnt.

Solution

1, Capacity and dimensions : Let us provide

a square bunker of size 3m x 3 m. Let the hopper

portion have a height of 1.25 m with a central hole

of sie 0.5 m x 0.5 m.

Height of surcharge = 1.5 tan 30°=0.87 m.

300 x 1000 3

Volume required = 2

require ma 37

\Volume provided by top surcharge, A,* J

=4(x3) 0.87 =2.61 m’ (Ai

Nolume provided by conical bottom

[axa+0sx05+yex05F ]x125

48 m Alternatively, volume

=$Bx3xl 50.50 x 0.5 x 0.25] = 4.48 m

“=: Remaining volume to be provided by the chamber

FIG. 26.11

= 35.97 - (2.61 + 4.48) = 28.88 m

28.88

3x3

=3.25 x9 =29.25 m’, making a total capacity of 2.61

36.34 x 8.34 = 303 KN of coal.

2, Design of side walls ; The side walls will be designed pees

4s continuous slab, Since the angle of surcharge is equal to the

angle of repose @, the horizontal pressure at any level is

n= wh cos’ > At 3,25 m_— depth, \

pi = 8340 x 3.25 (cos 30°)! = 20329 N/m*

Using M 15 concrete mix, m= 19, k= 0.404 , j= 0,865 and

R= 0,875. Let the thickness of the wall be 180 mm, Effective span

of slab =/=3+0,18=3.18 m, - B.M, at the corners of the square

pl? 20329 (3,18)

eine ere 17131 Nem

21 m. Let the height h be 3.25 m, so that its volume will be

Height h =

+ 4.48 + 29.25 = 36.34 m’ and storing

i

fe 88 mm abe 85 mm 4

FIG. 26,12,

frame =

‘ REINFORCED CONCRETE srmucTUREg

Direct tension in the wath = 20329 x 3.18

3 932323,_N.

Of steel be 30

of steel from the

Let the cover to the centre

ators mm, so that effective d

2

lepth will be 170 — 39 =

centre of the slab ane

as marked in will be = 85-30-55 mm

Net B.M

= 15353 N-m at the corners 2

Span = ( py . 1? )/24 = 8566 N-m

Centre of span = 8566

4 Effective depth = \/ 15353 x 1000

five depth = 1000 x0.874 = 133 mm.

Provide a total depth of 170 mm:

tol thickness may be varied fro

BM. at the

Net B.M

centre of

at the 32323 x 0.055 = 6788 N-m

me » $0 that effective depth d= 170-30= 140 mm

% m 120 mm at top to 170 mm at the bottom.

Area of steel at comers = —!5353 x 1000 323 2

0.865 x 140 x 140 * 4p = 1136 mm

Using 12 mm © bars, spacing = IS § 99.5 mm 7

Beet eee termi © Pers 95 mi clo ct the comers, at the inner face, Half

Of these ‘bars may be curtailed at the centre of the span.

Steel required at centre = —©788 x 1000 32323

TRESeaG = 631 mm*

0.865 x 140x140 * 49 63! mm

3

Spacing of the 12 mm © bars = HO A1B @ 179 mm c/c.

Hence provide 12 mm © bars 175 mm c/c at the outer face, at the centre of the

span. Half of the bars can be curtailed at the comers. ; paeeias) no

e se

: 12417 \' az)

Vertical reinforcement = 0.3 | "> is S

ee

_ _ 1000 x 78.5

Area on each face=218 mm’. Using 10 mm @ bars, spacing 74 Ae ome

Reinforcement at 2 m below top

Pr = 20329 x 5 =12510 Nem ; BLM, at supports = 17131 x

BM at cone =8566x=2—= 5271 Nem ; Direct tension = 32323 x Zags HN

Thickness of wall = 120-4 52x 50= 150.8 mm *

1508,

———— |= 9639 N-m

Net BM. at syne 20541980 |

150.8 _ 4g

2

Net BM. at centre = $271 ae |

dy al support 9639 x 1000 19191

0.865 140.5 130.8 * jqqn® HOE min?

fy at contre 4368 « 1000 19891

0,865 x 140 10.8 * page 44 an?

qving of 12 ars at cre = 2000 «113

ar 286

gpwcing of 12 mm a bars at ends = 100013 4)

mn

i 801

3, Design of hop

eae cs er bottom ; The ‘ i ‘

sg vell a 10 bending e : m ; The hopper bottom is subjected to meridional tension,

Se ds joment due to normal pressure acting on it, ‘The meridional tension

es REG aaeiOh due (© weight of coal above the section, weight of coal in the hopper

e section, weight of the hopper below the section and the weight of the gate

at the opening,

of weight of coal in bunker = 1 303000 = 75750 N

et the thickness of hopper slab be 160 mm, with 20 mmm lining.

1 . 3+0. - \ ‘

+ of weight of hopper slab ies Je 1.25 V2 x at 25000 = 13919 N

\ aoe 4

Rm 4

1 weight gate ete = 200 N (Say) Ayayi cm Metin :

Total W= 75750 + 13919 +200 = 89869 N

% _spirect tension = Weosec ot = 89869 cosee 45°= 127094 N fe, fea Oo

As = 127094/140 =908 mm?

No. of 10 mm ® pars = 908/78.5 ~ 12. Provide half bars on each face.

Since the meridional tension decreases towards the opening, these bars may be curtailed

to half at the opening. / The slab is also subjected to BM. due to bending of the slab

spanning horizontally between the intersection of adjacent sloping faces. The horizontal span

of the slab will increase from minimum at the opening to maximum at the junction, while

the pressure will decrease from maximum atthe opening to minimum at junction.

The section of the slab is normally designed at the centre of the hoppers where

+ 125, O87 y 0.625 = 4.24 m. (

2 : Zip Somfert

Lateral pressure

1

a

L

depth upto coal surface = 3,25

+05 =

Span of the sige = 1,75 m.

)

p=wh psind =wh+whsin > cos >

tte pi= pcos o= Ww hcos'

4" set eight of hopper. slab lining = 0.18 x 25000 = 4500 N/m’,

Inclination a = 45° (Fig. 26.7). Hence from Eq. 26.20.

bu = pr cos’ a+ py sin’ a + Ww, cos a= wh {cos a + cos’a.sin @ cos @ + cos’ sin? a) + ws cos a

= B340 x 4.24 [oos? 45° + cos" 45° sin 30° cos 30° + gos? 30° sin? 45°} + 4500 cos 45°

=41779 N/m? ee past

59 wh

Dia ff

BAM « 11779(1.78)

10662 Nem

depth = 160

REINFORCED CONCRE

PP CONCRETE stayc

TURES

Pull = Pat 41779 x (1.75)

Overall

— = 36557

effective depth 130 mm :

Net WM 10992 36557 (2

1000 | 5 30 | 8834 Nem

Effective d= 8834 x 1000

mm,

9.874. 1000,.° 100.5. min

36557 :

140 822 mm:

S834 1000

Actual d_ provided = 130 mm

« 1

180 0.805. 130

‘Spacing of 12 mm bars =

mm © bars @ 130 m

Span, the BLM. will be hal

Hence provide 12

At the middle of the

dat pall will be

mM c/c at the inner face, at the corners,

f of the above value

» Le. M=5351 Nem,

the same, ie. 36557 N. Hence

Nec BM. = $331 - 36557 x 0.05 = 3503 N-m. Hence,

‘ 3803.5 1000 36557. 1%,

40 0.865 x

30 "140 Fil 6 mm ¢stps @ 200 mm fe

)

+t2mms IEA)

= 484 mm Fe

10 mm ¢ @ 960 mm ele on 4)

Spacing 7 ‘each face nya,

ee ean. L 12 mms @ $25 mmo CEE i

‘These bars are to be provided | |

a the outer face a 4

4. Top and bottom ribs : Provide i 4

= top rib of size 300 x 300 mm \

“ith nominal reinforcement of eee

© bars, and 6 mm

surrups @ 200 mm c/c. Simi-

erly. provide a bottom rib (junc- aes

ton beam) of size 400 x 400 ae

} 12mm @ 95 mm cle

r2mme —

@175mnee

’ '

mm at the junction of the wall 5 lg

wath be with the same re- 10mm :

pee as the top rib. The a) Siemon +

1p nib allows for the attachement 3

of stanctuon bases, conveyor sup-

ports and other super-structure. 12mm6

The juncuon beam is provided @ sp ina.as

1 acommodate the reinforce-

sent in the wall behaving as

tach tae

” i (a) Secton at ond of (©) Secton at miata

2 deep bean The details of main pee

feulorvement etc. are shown in

FIG. 26.13,

Fig. 2613

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Unesco - Eolss Sample Chapters: Land Use ManagementDocument9 pagesUnesco - Eolss Sample Chapters: Land Use ManagementUtkarsh KumarNo ratings yet

- Btech 3 Sem Energy Science and Engineering Koe033 2020Document1 pageBtech 3 Sem Energy Science and Engineering Koe033 2020Utkarsh KumarNo ratings yet

- Reinforced Concrete DesignDocument73 pagesReinforced Concrete DesignUtkarsh KumarNo ratings yet

- NPV Slides PDFDocument3 pagesNPV Slides PDFUtkarsh KumarNo ratings yet

- Btech Ce 6 Sem Water Resources and Systems Engineering 36036 2020Document4 pagesBtech Ce 6 Sem Water Resources and Systems Engineering 36036 2020Utkarsh KumarNo ratings yet

- Metro Systems and Engineering Cv0425 Oe 5 Unit 1Document6 pagesMetro Systems and Engineering Cv0425 Oe 5 Unit 1Utkarsh KumarNo ratings yet

- Lecture 2 WREDocument25 pagesLecture 2 WREUtkarsh KumarNo ratings yet

- Steel One Linear NotesDocument102 pagesSteel One Linear NotesUtkarsh KumarNo ratings yet

- KOE043Document15 pagesKOE043Utkarsh KumarNo ratings yet

- Construction Management II ET 525Document3 pagesConstruction Management II ET 525Utkarsh KumarNo ratings yet