0% found this document useful (0 votes)

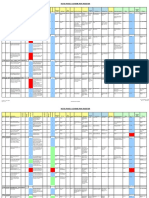

226 views16 pagesProject Risk Management

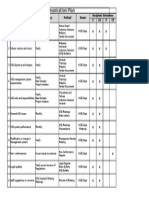

PROJECT RISK MANAGEMENT

Uploaded by

MAXWELL gwatiringaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

226 views16 pagesProject Risk Management

PROJECT RISK MANAGEMENT

Uploaded by

MAXWELL gwatiringaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd