Professional Documents

Culture Documents

Dokumen - Tips - 1gr Fe Engine Control System Es81 Toyota FJ Cruiser Repaires82 1gr Fe Engine PDF

Uploaded by

Anh Ngô HoàngOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dokumen - Tips - 1gr Fe Engine Control System Es81 Toyota FJ Cruiser Repaires82 1gr Fe Engine PDF

Uploaded by

Anh Ngô HoàngCopyright:

Available Formats

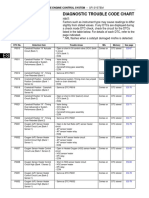

1GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM ES–81

Crankshaft Position - Camshaft Position Corre-

DTC P0016

lation (Bank 1 Sensor A)

Crankshaft Position - Camshaft Position Corre-

DTC P0018

lation (Bank 2 Sensor A)

DESCRIPTION

Refer to DTC P0335 (See page ES-187).

DTC No. DTC Detection Conditions Trouble Areas

Deviations in crankshaft and camshaft position sensor 1

P0016 • Mechanical system (Timing chain has jumped tooth or

signals (2 trip detection logic)

P0018

Deviations in crankshaft and camshaft position sensor 2 •

chain stretched)

ECM

ES

signals (2 trip detection logic)

MONITOR DESCRIPTION

The ECM optimizes the valve timing by using the VVT (Variable Valve Timing) system to control the intake

camshaft. The VVT system includes the ECM, the Oil Control Valve (OCV) and the VVT controller.

The ECM sends a target duty-cycle control signal to the OCV. This control signal regulates the oil

pressure supplied to the VVT controller. The VVT controller can advance or retard the intake camshaft.

The ECM calibrates the intake valve timing by setting the intake camshaft to the most retarded angle while

the engine is idling. The ECM closes the OCV to retard the cam. The ECM stores this value as the VVT

learning value. When the difference between the target and actual intake valve timings is 5°CA

(Crankshaft Angle) or less, the ECM stores it.

If the VVT learning value matches the following conditions, the ECM determines the existence of a

malfunction in the VVT system, and sets the DTC.

• VVT learning value: Less than 22.5°CA, or more than 45.2°CA.

• Above condition continues for 18 seconds or more.

This DTC indicates that the intake camshaft has been installed toward the crankshaft at an incorrect

angle, caused by factors such as the timing chain having jumped a tooth.

This monitor begins to run after the engine has idled for 5 minutes.

MONITOR STRATEGY

Related DTCs P0016: Camshaft Timing Misalignment at idling

Required Sensors/Components (Main) VVT actuator

Required Sensors/Components (Related) Camshaft position sensor, Crankshaft position sensor

Frequency of Operation Once per driving cycle

Duration Less than 1 minute

MIL Operation 2 driving cycles

Sequence of Operation None

TYPICAL ENABLING CONDITIONS

P0011 (VVT system 1 - advance)

P0012 (VVT system 1 - retard)

Monitor runs whenever following DTCs not present P0021 (VVT system 2 - advance)

P0022 (VVT system 2 - retard)

P0115 - P0118 (ECT sensor)

Engine RPM 500 to 1,000 rpm

ES–82 1GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

TYPICAL MALFUNCTION THRESHOLDS

One of following conditions is met -

VVT learning value at maximum retarded valve timing (Bank 1) Less than 22.5 °CA (crankshaft angle)

VVT learning value at maximum retarded valve timing (Bank 2) Less than 22.5 °CA (crankshaft angle)

VVT learning value at maximum retarded valve timing (Bank 1) More than 45.2 °CA (crankshaft angle)

VVT learning value at maximum retarded valve timing (Bank 2) More than 45.2 °CA (crankshaft angle)

WIRING DIAGRAM

Refer to DTC P0335 (See page ES-189).

Refer to DTC P0340 (See page ES-195).

ES INSPECTION PROCEDURE

HINT:

Read freeze frame data using an intelligent tester. Freeze frame data record the engine condition when

malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was

moving or stationary, if the engine was warmed up or not, if the air-fuel ratio was lean or rich, and other

data, from the time the malfunction occurred.

1 CHECK VALVE TIMING (CHECK FOR LOOSE AND A JUMPED TOOTH OF TIMING CHAIN)

(See page ES-79)

NG ADJUST VALVE TIMING (REPAIR OR

REPLACE TIMING CHAIN)

OK

REPLACE ECM (See page ES-446)

You might also like

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- DTC P0016 Crankshaft Position - Camshaft Position Corre-Lation (Bank 1 Sensor A)Document2 pagesDTC P0016 Crankshaft Position - Camshaft Position Corre-Lation (Bank 1 Sensor A)robin blahoutNo ratings yet

- C05Document1 pageC05Clodoaldo BiassioNo ratings yet

- DTC P0011 Camshaft Position "A" - Timing Over - Advanced or System Performance (BANK 1) DTC P0012 Camshaft Position "A" - Timing Over - Retarded (Bank 1)Document1 pageDTC P0011 Camshaft Position "A" - Timing Over - Advanced or System Performance (BANK 1) DTC P0012 Camshaft Position "A" - Timing Over - Retarded (Bank 1)Clodoaldo BiassioNo ratings yet

- OcvDocument4 pagesOcvIsmail SetiawanNo ratings yet

- Checking VVT Sensor PDFDocument6 pagesChecking VVT Sensor PDFDoDuyBacNo ratings yet

- DTC P0021 Motor Lexus Is250 1gr-FeDocument9 pagesDTC P0021 Motor Lexus Is250 1gr-FeDivi AutotecnicNo ratings yet

- DTC P0766 Shift Solenoid "D" Performance (Shift Solenoid Valve S4)Document4 pagesDTC P0766 Shift Solenoid "D" Performance (Shift Solenoid Valve S4)marran almarranyNo ratings yet

- Camshaft Position A TimingDocument7 pagesCamshaft Position A TimingDannyDDannyDNo ratings yet

- Sincronia YarisDocument8 pagesSincronia YarisJimmy AlemanNo ratings yet

- DTC P0776 Pressure Control Solenoid "B" Performance (Shift Solenoid Valve SL2)Document4 pagesDTC P0776 Pressure Control Solenoid "B" Performance (Shift Solenoid Valve SL2)freddys merchanNo ratings yet

- Cip0340 CHECKING VVT SENSOR PDFDocument5 pagesCip0340 CHECKING VVT SENSOR PDFDoDuyBacNo ratings yet

- P2102 - Throttle Actuator Control MotorDocument4 pagesP2102 - Throttle Actuator Control Motorpjoko9672No ratings yet

- Engine Control System QR Service Information DTC p2138 App SensorDocument8 pagesEngine Control System QR Service Information DTC p2138 App SensorEvander Leon RoblesNo ratings yet

- P0011 - P0012Document8 pagesP0011 - P0012jeremih alhegnNo ratings yet

- Cip 2102Document4 pagesCip 2102pjoko9672No ratings yet

- DTC P0420 Catalyst System Efficiency Below Threshold (Bank 1) Catalyst System Efficiency Below Threshold (Bank 2)Document7 pagesDTC P0420 Catalyst System Efficiency Below Threshold (Bank 1) Catalyst System Efficiency Below Threshold (Bank 2)Malik GINo ratings yet

- Vehicle Speed SensorDocument3 pagesVehicle Speed SensorDaniel Mamani ParedezNo ratings yet

- Es 62 Es Diagnostic Trouble Code Chart PDFDocument10 pagesEs 62 Es Diagnostic Trouble Code Chart PDFSR BangashNo ratings yet

- DTC P0045/34 Turbo/Super Charger Boost Control Solenoid Circuit / OpenDocument4 pagesDTC P0045/34 Turbo/Super Charger Boost Control Solenoid Circuit / OpenYani Yani0% (1)

- DTC P1346 VVT Sensor (Camshaft Position Sensor) Cir-Cuit Range/Performance ProblemDocument1 pageDTC P1346 VVT Sensor (Camshaft Position Sensor) Cir-Cuit Range/Performance ProblemTeguh PriyonoNo ratings yet

- DI120Document2 pagesDI120Erln LimaNo ratings yet

- Es 63 PDFDocument18 pagesEs 63 PDFaris madayagNo ratings yet

- DTC P0121 Throttle / Pedal Position Sensor / Switch "A" Circuit Range / Performance ProblemDocument2 pagesDTC P0121 Throttle / Pedal Position Sensor / Switch "A" Circuit Range / Performance ProblemHlayn Wai PhyoNo ratings yet

- DTC P1602 Deterioration of Battery: DescriptionDocument5 pagesDTC P1602 Deterioration of Battery: DescriptionEdy SudarsonoNo ratings yet

- Diagnostic Trouble Code (DTC) Charts and DescriptionsDocument126 pagesDiagnostic Trouble Code (DTC) Charts and DescriptionsVicente GarciaNo ratings yet

- P2714Document10 pagesP2714Jose Francisco GuzmánNo ratings yet

- 2gr-Fe P0200 PDFDocument7 pages2gr-Fe P0200 PDFhappy yuliasantiNo ratings yet

- 2gr-Fe P0200 PDFDocument7 pages2gr-Fe P0200 PDFhappy yuliasantiNo ratings yet

- Description: 2Gr-Fe Engine Control System - Sfi SystemDocument7 pagesDescription: 2Gr-Fe Engine Control System - Sfi Systemhappy yuliasantiNo ratings yet

- 1gr-Fe Engine Control System4Document7 pages1gr-Fe Engine Control System4mike chenNo ratings yet

- Camshaft Position Sensor ADocument4 pagesCamshaft Position Sensor ADannyDDannyDNo ratings yet

- Engine Control System QR Service Information DTC p2127, p2128 App SensorDocument8 pagesEngine Control System QR Service Information DTC p2127, p2128 App SensorEvander Leon RoblesNo ratings yet

- 0060035Document7 pages0060035Ydelkadiasmela Dominguezmorel100% (1)

- DTC P0101 Mass Air Flow Circuit Range / Performance Problem: DescriptionDocument3 pagesDTC P0101 Mass Air Flow Circuit Range / Performance Problem: Descriptioncarlos gil100% (1)

- Control System Control System Schematic BtraDocument52 pagesControl System Control System Schematic BtraRoe De HardtoknowNo ratings yet

- 13OBDG06 Hybrid DiagnosticsDocument462 pages13OBDG06 Hybrid DiagnosticsIonflorin TelegaruNo ratings yet

- DTC P0010 Camshaft Position "A" Actuator Circuit (Bank 1) : DescriptionDocument10 pagesDTC P0010 Camshaft Position "A" Actuator Circuit (Bank 1) : Descriptionsharon truck trailerNo ratings yet

- Cartilla de Reparacion Corolla Negro KINALDocument10 pagesCartilla de Reparacion Corolla Negro KINALNico ArtNo ratings yet

- Nissan Altima: Motor 3.5L Vq35De CODIGOS P0011 y P0021Document9 pagesNissan Altima: Motor 3.5L Vq35De CODIGOS P0011 y P0021waltech2005No ratings yet

- Diagnostic Trouble Code (DTC) Charts and DescriptionsDocument176 pagesDiagnostic Trouble Code (DTC) Charts and DescriptionsfredNo ratings yet

- Brake Switch B HighDocument2 pagesBrake Switch B HighDannyDDannyDNo ratings yet

- 1nzfe Isc PDFDocument10 pages1nzfe Isc PDFMatt SholitNo ratings yet

- Fault Codes - P0627/78 Pump System Description: Click HereDocument4 pagesFault Codes - P0627/78 Pump System Description: Click HereLudwig HernandezNo ratings yet

- Audio-Navigation System DTCS: DTC Index HR-VDocument19 pagesAudio-Navigation System DTCS: DTC Index HR-VAda MaknaNo ratings yet

- DTC Summaries: AJ27 Engine Management - 2000 MYDocument43 pagesDTC Summaries: AJ27 Engine Management - 2000 MYMiguel CarrilloNo ratings yet

- Stantard Powertrain DTC - Codes - 2008 PDFDocument17 pagesStantard Powertrain DTC - Codes - 2008 PDFEltiezo EcheverriaNo ratings yet

- PTFE1223 13MY MIRAGE TH J Spec Part2 Revised1Document89 pagesPTFE1223 13MY MIRAGE TH J Spec Part2 Revised1Genevieve Diaz MorenoNo ratings yet

- DTC P0121 Throttle / Pedal Position Sensor / Switch "A" Circuit Range / Performance ProblemDocument2 pagesDTC P0121 Throttle / Pedal Position Sensor / Switch "A" Circuit Range / Performance Problempeter_nicks5441No ratings yet

- Mass or Volume Air Flow Range ProblemDocument2 pagesMass or Volume Air Flow Range ProblemDaniel Mamani ParedezNo ratings yet

- DTC P2138 App Sensor DTC P2138 App Sensor Component DescriptionDocument9 pagesDTC P2138 App Sensor DTC P2138 App Sensor Component DescriptionAndres AriasNo ratings yet

- A L L Diagnostic Trouble Codes (DTC) : P Code Charts P2135Document4 pagesA L L Diagnostic Trouble Codes (DTC) : P Code Charts P2135PeterNo ratings yet

- DTC P2714 Pressure Control Solenoid "D" Performance (Shift Solenoid Valve SLT)Document7 pagesDTC P2714 Pressure Control Solenoid "D" Performance (Shift Solenoid Valve SLT)Igor MarkovicNo ratings yet

- DTC P2138 App Sensor DTC P2138 App Sensor Component DescriptionDocument8 pagesDTC P2138 App Sensor DTC P2138 App Sensor Component DescriptionPhyo KyawNo ratings yet

- DTC P0101 Mass or Volume Air Flow Circuit Range/Performance ProblemDocument1 pageDTC P0101 Mass or Volume Air Flow Circuit Range/Performance ProblemClodoaldo BiassioNo ratings yet

- 15 Diagnóstico de Componentes IntegralesDocument18 pages15 Diagnóstico de Componentes IntegralesmongongoNo ratings yet

- Control SystemDocument44 pagesControl SystemKolo BenduNo ratings yet

- P0237 y P0238 Motor 2az-FeDocument4 pagesP0237 y P0238 Motor 2az-FeGabriela Mendoza ZúñigaNo ratings yet

- Knock Sensor 1 CircuitDocument4 pagesKnock Sensor 1 CircuitDaniel Mamani ParedezNo ratings yet

- HiluxDCThai PMGDocument175 pagesHiluxDCThai PMGAnh Ngô HoàngNo ratings yet

- Dx420lc Shop ManualDocument900 pagesDx420lc Shop Manualrodrigoborges10100% (2)

- 2d Lap XylanhchinhDocument1 page2d Lap XylanhchinhAnh Ngô HoàngNo ratings yet

- 2d Truc CamDocument1 page2d Truc CamAnh Ngô HoàngNo ratings yet

- Thanh Truyền PDFDocument1 pageThanh Truyền PDFAnh Ngô HoàngNo ratings yet

- Mặt cắt tổng PDFDocument1 pageMặt cắt tổng PDFAnh Ngô HoàngNo ratings yet

- 29092+UPDATED+3CX,+4CX,+5CX+Stage+v+e Brochure+en GB+Issue1Document9 pages29092+UPDATED+3CX,+4CX,+5CX+Stage+v+e Brochure+en GB+Issue1binhui wanNo ratings yet

- BOLETINDocument15 pagesBOLETINCarlos PeraltaNo ratings yet

- 2000-2004 Renault Twingo I Fuse Box DiagramDocument3 pages2000-2004 Renault Twingo I Fuse Box Diagramdface_031No ratings yet

- Kawasaki KLX110 & KLX110L Service Repair Manual - Chapter 4 - Engine Top EndDocument41 pagesKawasaki KLX110 & KLX110L Service Repair Manual - Chapter 4 - Engine Top EndbarackkNo ratings yet

- TurboDocument31 pagesTurboWaqas SadiqNo ratings yet

- Form 20 To, The Registering Authority Tambaram Rto ...........................Document4 pagesForm 20 To, The Registering Authority Tambaram Rto ...........................Prasad BabuNo ratings yet

- Sepeda Thrill Katalog JULI 2020 (28-07-20)Document2 pagesSepeda Thrill Katalog JULI 2020 (28-07-20)Leonardus Kadho SaputraNo ratings yet

- TF Jo'l: ( AlmarDocument20 pagesTF Jo'l: ( AlmarcutoNo ratings yet

- TOYOTADocument7 pagesTOYOTAAlejandro MendezNo ratings yet

- Shimano 2015-2016 Road & MTN Bike Parts Compatibility - v029 - enDocument32 pagesShimano 2015-2016 Road & MTN Bike Parts Compatibility - v029 - enquestor4425No ratings yet

- b5 Vacuum Hose Diagram - PassatDocument3 pagesb5 Vacuum Hose Diagram - Passatjackass_tNo ratings yet

- Xy-Sa-Gpi2304-2 CiDocument6 pagesXy-Sa-Gpi2304-2 CirafaelNo ratings yet

- 4BarLinkV3 1dDocument13 pages4BarLinkV3 1dFirman Maulana Ja'farNo ratings yet

- Mtii 14-4507 Elt-210 Manual PartesDocument324 pagesMtii 14-4507 Elt-210 Manual PartesCristian ArroyaveNo ratings yet

- Manual de Piezas Motor Mack 370 1 PDFDocument95 pagesManual de Piezas Motor Mack 370 1 PDFCarlos Zamorano JaraNo ratings yet

- FRS - Brake System - TrainsetDocument12 pagesFRS - Brake System - TrainsetCad TutorNo ratings yet

- Lynch MotorDocument1 pageLynch MotorJustin SimNo ratings yet

- Lincoln MKX 2008 Owners PDFDocument328 pagesLincoln MKX 2008 Owners PDFClayton RothNo ratings yet

- Fms StandardDocument18 pagesFms StandardParrex ParraNo ratings yet

- 2engine System ENGLISG-G9165Document52 pages2engine System ENGLISG-G9165George Jhonson100% (4)

- Quon With New Features - UPDATE v3 SmallDocument14 pagesQuon With New Features - UPDATE v3 SmallOthman ElhamriNo ratings yet

- Bombas Estacionarias SP 2800Document2 pagesBombas Estacionarias SP 2800SchwingLatinoamerica100% (1)

- Bujias Champion y Cables Power Max 23-03-12Document3 pagesBujias Champion y Cables Power Max 23-03-12Rafael SotoNo ratings yet

- Watchkeeping and TroubleshootingDocument16 pagesWatchkeeping and TroubleshootingAditya JoglekarNo ratings yet

- Assembly Piston PDFDocument1 pageAssembly Piston PDFClaudius Barenta BarusNo ratings yet

- Camber Car Design DynamicsDocument77 pagesCamber Car Design Dynamicspathak2891No ratings yet

- Scooptram ST2D: Underground Diesel Loader With 3.6 Tonne Load CapacityDocument5 pagesScooptram ST2D: Underground Diesel Loader With 3.6 Tonne Load CapacityJohel Bautista HernandezNo ratings yet

- Wheel Loaders in Rehandling: L150H, L180H, L220H, L260H, L350HDocument20 pagesWheel Loaders in Rehandling: L150H, L180H, L220H, L260H, L350HMiguel SilvaNo ratings yet

- Ei PDFDocument32 pagesEi PDFOscar VillaseñorNo ratings yet

- Catalogue IFHS 2015-2016Document16 pagesCatalogue IFHS 2015-2016Nolan DescotNo ratings yet