Professional Documents

Culture Documents

W502-PR-0133 engineering document title

Uploaded by

Rainbow EngineeringOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

W502-PR-0133 engineering document title

Uploaded by

Rainbow EngineeringCopyright:

Available Formats

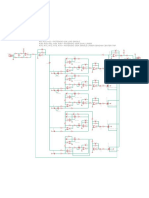

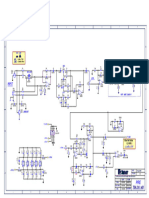

ZZ YY XX WW VV UU TT SS RR PP NN MM LL KK JJ HH GG FF EE DD CC BB AA Z Y X W V U T S R P N M L K J H G F E D C B A

ECN NO. C/L DATE ZONE REV.

DGNR

ENGR

APPD

0401DBB0005TD

CAD

STD

W502-PR-0046 01 KHP SPP SPP PUJ 26/03/2022 NEW RELEASE FOR MP BUILD

R 25

W502-PR-0133 02 SPP SPP SPP PUJ 24/09/2022 RELEASE FOR VP BUILD

R2

R2

.5 R2

R9

30

2

R

2

Section cut H-H

Scale: 1:1

Section cut D-D

Scale: 1:1

Section cut G-G

Scale: 1:1

0401DBB00860N 0401DBB00870N +0.2

SHIELD DUST FRT KNUCKLE LH SHIELD DUST FRT KNUCKLE RH D 3-HOLES, 7.5 0

0.1 A

11.5

1.0 A B C

( 30 ) 117.98 ±0.5 ENTIRE SURFACE

B

R1

R8

0

NOTES:-

45

R

1

8

1. LH SHOWN RH OPPOSITE.

17.32

D

2. FOR ALL DIMENSIONED DETAILS REFER ASSOCIATED 3D SURFACE / SOLID MODEL.

3. DIMENSIONS SHOWN IN BRACKET FOR REFERENCE ONLY.

4. SUPPLIER MUST COMPLY WITH THE REQUIREMENTS OF ELV & HAZARDOUS MATERIAL CONTENT

AS SPECIFIED IN M&M STD. F-00-1474/REV005, AS PER THE MARKET REQUIREMENTS.

131.9

5. IN CASE OF MULTIPLE MARKETS, PART MUST COMPLY WITH ALL LEGISLATIVE REQUIREMENTS OF

THE RESPECTIVE MARKET.

172

F F

6. REDUCTION IN METAL THICKNESS NOT TO EXCEED 20% OF SPECIFIED METAL THICKNESS

MATERIAL COMPRESSION TO BE A MAXIMUM OF 10% ON EDGE OF PART

( 257.18 )

3.08

7. PART MUST BE FREE OF BURRS, FLASH AND SHARP EDGES THAT MAY AFFECT THE FUNCTION

±0.5

SAFE HANDLING, INSTALLTION OF REMOVAL OF THE PART

8 3.2

R1

242.5

H 16.12

H CONSTANT

G 12

R4

0 48.13 64.5 R8

R9 20 ±0.5

96.8

R

R2 8

0

0

R2 0.3 A B

R 50 C

0.3 A B C

25

R 20 Section cut E-E

Scale: 1:1

R 25

SHIELD DUST FRT KNUCKLE LH 0401DBB00860N 2

G

Right view SHIELD DUST FRT KNUCKLE RH 0401DBB00870N 2

E

Scale: 1:1 DESCRIPTION PART NO. C/L

MAHINDRA & MAHINDRA LTD.

R9 APPD PUJ 18/11/2021

22

49

AUTOMOTIVE SECTOR, CHENNAI

CAD CHK SPP 18/11/2021

MATERIAL --- 18/11/2021

MATERIAL:- SYMBOLS TOTAL

ALL UNSPECIFIED TOLERANCE No.

0.8 THK CR STEEL MM21 D AS PER M&M STD G-00-0167 REV07 ENGR SPP 18/11/2021

42 67 NOMINAL CRITICAL CHARACTERISTICS<CC>

DGNR KHP 18/11/2021

TOLERANCE

DIMENSION SIGNIFICANT CHARACTERISTICS<SC>

0 TO 150 ±0.6 HEAT TREATMENT :- SURFACE FINISH BY SIGN. DATE

N/A CRITICAL SPOT WELD

Section cut F-F 150 TO 300 ±0.8 WT : 0.195(kg) (CAD wt) S.AREA : 629.38cm2 (CAD)

ASSOC 3-D MODEL: Y VER NO.:

REF/LAYOUT No.

300 TO 1000 ±1.2

Scale: 1:1 ( 194.48 ) SURFACE TREATMENT :- ALL DIMSENSIONS ARE IN mm.

PF CODE 0401D00

OVER 1000 ±1.5

BLACK POWDER COATING AS PER G 00 1291 REV 4 TYPE 2 – 480 H SST SURFACE FINISH SYMBOL : ISO 1302

FOR ANGULAR TOLERANCE (CHIPPING RESISTANCE MUST PASS) WELDING SYMBOL : IS:813-1986 MODEL W502

0°TO 10° ±10'

C/L

SHIELD DUST FRT KNUCKLE

Front view SCALE DESCRIPTION DRG No.

1:1

0401DBB0005TD 2

10°TO 50° ±20'

Scale: 1:1 50°TO 100° ±30'

OVER 100° ±1° SHEET 1 OF 1

This drawing is property of Mahindra & Mahindra Ltd.And must be returned upon request. This part must not be sold to any other concern.

You might also like

- Statement-Jan 2019 PDFDocument4 pagesStatement-Jan 2019 PDFPatricio Rodriguez Jr100% (1)

- 6505 MHDocument10 pages6505 MHJulio Güissa57% (7)

- Meanwell RSP 1000 SchematicsDocument4 pagesMeanwell RSP 1000 SchematicsAndrea Casini100% (3)

- Peterbilt 362 Schematics Wiring DiagramDocument10 pagesPeterbilt 362 Schematics Wiring Diagramhamilton miranda100% (1)

- Schematic Redmi Note 8 PDFDocument29 pagesSchematic Redmi Note 8 PDFwillian mv100% (4)

- Tech Elevator School Catalog, 2020 PDFDocument29 pagesTech Elevator School Catalog, 2020 PDFjohanmulyadi007No ratings yet

- Mda1370 PDFDocument1 pageMda1370 PDFRam KumarNo ratings yet

- Parametrix EqualizerDocument1 pageParametrix EqualizerSegaNo ratings yet

- 06-MP-02B2.00-MP02B2.00Document1 page06-MP-02B2.00-MP02B2.00ISH-QUENo ratings yet

- High Speed Rotor Control Circuit DiagramDocument19 pagesHigh Speed Rotor Control Circuit DiagramBernard MendisNo ratings yet

- Skema FullDocument1 pageSkema FullZubaidin ChannelNo ratings yet

- China-Chassis 3y03-With strg6653Document1 pageChina-Chassis 3y03-With strg6653Sàenz JoséNo ratings yet

- 8997 0846 00 DrawingsDocument41 pages8997 0846 00 Drawingsedduami montoya neyraNo ratings yet

- Esq Manager Senoidal 1400 USB (T0339500)Document1 pageEsq Manager Senoidal 1400 USB (T0339500)Guilherme GelainNo ratings yet

- Voxman 1000w x2Document1 pageVoxman 1000w x2Lorenzo Balam ChayNo ratings yet

- Riviera RT2903S Chasis A5Y021 StereoDocument1 pageRiviera RT2903S Chasis A5Y021 StereoSàenz JoséNo ratings yet

- BTT SKR V1.4-SCHDocument1 pageBTT SKR V1.4-SCHguru100% (1)

- 24-MP-0202.03-MP0202.03Document1 page24-MP-0202.03-MP0202.03ISH-QUENo ratings yet

- The New Cairo Mall: Cairo Company For Housing &developmentDocument1 pageThe New Cairo Mall: Cairo Company For Housing &developmentMahmud MaherNo ratings yet

- Country Garden BSD: RevisionDocument1 pageCountry Garden BSD: RevisionhendriNo ratings yet

- Bridge Sub8 Circuit Bridge Sub8 Circuit: Schematic Diagram Schematic DiagramDocument1 pageBridge Sub8 Circuit Bridge Sub8 Circuit: Schematic Diagram Schematic Diagramwilmer leonNo ratings yet

- 21-MP-0202.00-MP0202.00Document1 page21-MP-0202.00-MP0202.00ISH-QUENo ratings yet

- 12 - Schematic DiagramDocument6 pages12 - Schematic Diagrampaulo actecNo ratings yet

- HV65T 100T Preamp - REVEDocument1 pageHV65T 100T Preamp - REVESzabo Mihai-PaulNo ratings yet

- Lse QR 21-5-23 (Final)Document1 pageLse QR 21-5-23 (Final)MarcelaNo ratings yet

- Konka K2171taDocument1 pageKonka K2171taserkalemtayeNo ratings yet

- Bose Companion 5 Io SCHDocument2 pagesBose Companion 5 Io SCHFrancisco SanchezNo ratings yet

- SKEMA Dobel TrafoDocument1 pageSKEMA Dobel TrafoKabul PriyonggoNo ratings yet

- Esq Manager Net 3+ USB (T0300101)Document1 pageEsq Manager Net 3+ USB (T0300101)RobertoBarbosaNo ratings yet

- Detail A: Shuqaiq 3 Independent Water ProjectDocument1 pageDetail A: Shuqaiq 3 Independent Water ProjectABAID ULLAHNo ratings yet

- Diesel Engine Fire Pump Controller Negative Ground DC 24V:Gpd ModelDocument6 pagesDiesel Engine Fire Pump Controller Negative Ground DC 24V:Gpd ModelpochoNo ratings yet

- Esq Nobreak T0726601 Net 4 + 886 SilverblackDocument1 pageEsq Nobreak T0726601 Net 4 + 886 SilverblackGuilherme GelainNo ratings yet

- Esquema Nobreak SMS Manager Net 4+1400bi 886 Silverblack T0726601Document1 pageEsquema Nobreak SMS Manager Net 4+1400bi 886 Silverblack T0726601Anildo Eldivar De Oliveira SarmentoNo ratings yet

- SMS Nobreak T0726601 Net 4Document1 pageSMS Nobreak T0726601 Net 4Paulo SantanaNo ratings yet

- Esquema Nobreak SMS - T0726601 Net 4 - 886 SilverblackDocument1 pageEsquema Nobreak SMS - T0726601 Net 4 - 886 SilverblackDayamLauthOliveiraNo ratings yet

- Delta LCD Power G2d-Dps-250ap PDFDocument4 pagesDelta LCD Power G2d-Dps-250ap PDFJoseni FigueiredoNo ratings yet

- Job No. 26418: CollahuasiDocument1 pageJob No. 26418: Collahuasicutcnc.concepcionNo ratings yet

- Optimized title for 22K smt 1/4w documentDocument1 pageOptimized title for 22K smt 1/4w documentRobby AhyanaNo ratings yet

- CSCR Lot SDPDocument1 pageCSCR Lot SDPMartin OrtillaNo ratings yet

- District 26Document1 pageDistrict 26Genna ContinoNo ratings yet

- Esq Net Winner (t0534602)Document1 pageEsq Net Winner (t0534602)Paulo CostaNo ratings yet

- R2 Circuit DiagramDocument6 pagesR2 Circuit DiagramSubhasish ChakrabartyNo ratings yet

- 109018AE0026-27_Rev_0 Layout Panel de ControlDocument2 pages109018AE0026-27_Rev_0 Layout Panel de ControlAlonzo Rueda PeraltaNo ratings yet

- Model Rx340 SchematicsDocument8 pagesModel Rx340 Schematicsa1elgNo ratings yet

- 300M Schematic DiagramDocument2 pages300M Schematic DiagramAdriano Andrade100% (3)

- L - Ar-100.1part PlansDocument1 pageL - Ar-100.1part PlansAslam YaseenNo ratings yet

- SA04C2-03-WP-D-42008-01-5: 3. FJ - Field Joint 4. SJ - Shop JointDocument4 pagesSA04C2-03-WP-D-42008-01-5: 3. FJ - Field Joint 4. SJ - Shop JointABAID ULLAHNo ratings yet

- 15-6-41 Plano Energia Regulada e Iluminacion Piso 7Document1 page15-6-41 Plano Energia Regulada e Iluminacion Piso 7Rodrigo GuevaraNo ratings yet

- Important Information: Naphtha Fractionation UnitDocument1 pageImportant Information: Naphtha Fractionation UnitTouseef HaiderNo ratings yet

- Power Supply Skyworth 8M51BDocument1 pagePower Supply Skyworth 8M51BautreraNo ratings yet

- HBD-TZ140 - (DAV-TZ140) Diagrama FuenteDocument1 pageHBD-TZ140 - (DAV-TZ140) Diagrama FuenteIngeniero Uvm100% (1)

- AngkurDocument1 pageAngkurJundiNo ratings yet

- F.J. S.J.: Shuqaiq 3 Independent Water ProjectDocument1 pageF.J. S.J.: Shuqaiq 3 Independent Water ProjectABAID ULLAHNo ratings yet

- SBGR - Rnav Vovbi 1a Rwy 09l - Sid - 20190912 PDFDocument1 pageSBGR - Rnav Vovbi 1a Rwy 09l - Sid - 20190912 PDFRodrigo HalzenthNo ratings yet

- alternative floor space ratio map kensingtonDocument1 pagealternative floor space ratio map kensingtonVaishnavi HallikarNo ratings yet

- (Cont. Next Page) 10 Toyota Fortuner: Power Source ECT and A/T Indicator (1GR-FE)Document3 pages(Cont. Next Page) 10 Toyota Fortuner: Power Source ECT and A/T Indicator (1GR-FE)alexander pintoNo ratings yet

- CP 332 Me DDD 0001 - 0Document1 pageCP 332 Me DDD 0001 - 0Percy HurtadoNo ratings yet

- PRE TSA 420Document1 pagePRE TSA 420Antonio Fernandes de JesusNo ratings yet

- Button 747682Document1 pageButton 747682Luciano LuceroNo ratings yet

- Job No. 25800: Quebrada Blanca Fase 2Document1 pageJob No. 25800: Quebrada Blanca Fase 2Ricardo Alberto Zapata Balcazar100% (1)

- Darlington Transistor 2SB1626 SpecsDocument1 pageDarlington Transistor 2SB1626 Specswds657No ratings yet

- Citect ModnetDocument5 pagesCitect ModnetKuncoroNuryantoNo ratings yet

- LinhNg BSBXCM301 ProjectPortfolio Task2Document11 pagesLinhNg BSBXCM301 ProjectPortfolio Task2Trần Thái Bảo HânNo ratings yet

- Harmonization and Standardization of The ASEAN Medical IndustryDocument75 pagesHarmonization and Standardization of The ASEAN Medical IndustryGanch AguasNo ratings yet

- People v. Tomawis y AliDocument2 pagesPeople v. Tomawis y AliJeanne Pauline ResurreccionNo ratings yet

- Computer MCQ NotesDocument88 pagesComputer MCQ NotesWaqas AliNo ratings yet

- 1.1 Online Shopping Is The Process Whereby Consumers Directly Buy Goods Services Ete From ADocument5 pages1.1 Online Shopping Is The Process Whereby Consumers Directly Buy Goods Services Ete From Aഅർജുൻ പിണറായിNo ratings yet

- Math 11 ABM Org - MGT Q2-Week 2Document16 pagesMath 11 ABM Org - MGT Q2-Week 2Gina Calling Danao100% (1)

- Performance Evaluation of Object Tracking AlgorithDocument9 pagesPerformance Evaluation of Object Tracking AlgorithEren Cem GöksülükNo ratings yet

- Unit 13Document28 pagesUnit 13Tinh NguyenNo ratings yet

- Topic No-11 AIRCRAFT OXYGEN REQUIREMENTDocument9 pagesTopic No-11 AIRCRAFT OXYGEN REQUIREMENTSamarth SNo ratings yet

- Mil DTL 32157Document44 pagesMil DTL 32157Gavin GuldnerNo ratings yet

- CH 01 Intercorporate Acquisitions and Investments in Other EntitiesDocument38 pagesCH 01 Intercorporate Acquisitions and Investments in Other Entitiesosggggg67% (3)

- Tata-Aig General Insurance Company LTD: Policy No. 0238443404 / 0238443469 Claim No.Document3 pagesTata-Aig General Insurance Company LTD: Policy No. 0238443404 / 0238443469 Claim No.Mahendra SinghNo ratings yet

- Free Fall LabDocument1 pageFree Fall Labapi-276596299No ratings yet

- Absent Father, Absent Mother: Its Effect in The Behavior and Academic Performance of The Senior High School in SPCCDocument3 pagesAbsent Father, Absent Mother: Its Effect in The Behavior and Academic Performance of The Senior High School in SPCCRendel PorlaresNo ratings yet

- MSDS - SYCAMORE Spray PaintDocument6 pagesMSDS - SYCAMORE Spray PaintBatanNo ratings yet

- Technical Data Sheet - RELY PAINTS PRIVATE LIMITED - 2Document5 pagesTechnical Data Sheet - RELY PAINTS PRIVATE LIMITED - 2iR DesignNo ratings yet

- Orthopaedic BiomechanicsDocument17 pagesOrthopaedic BiomechanicsIacobescu EmiliaNo ratings yet

- Pizano v. Indiana Department of Correction Et Al - Document No. 3Document2 pagesPizano v. Indiana Department of Correction Et Al - Document No. 3Justia.comNo ratings yet

- MKT202 - Group 6 - Marketing Research ProposalDocument9 pagesMKT202 - Group 6 - Marketing Research ProposalHaro PosaNo ratings yet

- Supply Chain Analysis of PRAN GroupDocument34 pagesSupply Chain Analysis of PRAN GroupAtiqEyashirKanakNo ratings yet

- Filipino Department's Culminating Activities Foster LearningDocument6 pagesFilipino Department's Culminating Activities Foster LearningJhonlee GananNo ratings yet

- Alfornon Joshua Madjos. Strategic Management Bsba 3FDocument7 pagesAlfornon Joshua Madjos. Strategic Management Bsba 3FJoshua AlfornonNo ratings yet

- RESOLUTION (Authorize To Withdraw)Document2 pagesRESOLUTION (Authorize To Withdraw)Neil Gloria100% (4)

- SWOT Analysis of Standard Chartered BankDocument4 pagesSWOT Analysis of Standard Chartered BankparthNo ratings yet

- Tutorial: Creating A Middleware Application Using CMSIS ComponentsDocument25 pagesTutorial: Creating A Middleware Application Using CMSIS ComponentsJose Romero MurilloNo ratings yet

- Enjoy Magazine - May 2019Document16 pagesEnjoy Magazine - May 2019Stanley KellyNo ratings yet

- Waymo LetterDocument14 pagesWaymo LetterSimon AlvarezNo ratings yet