Professional Documents

Culture Documents

XH200 - SpecSheet - SYKES ARICA-email

XH200 - SpecSheet - SYKES ARICA-email

Uploaded by

antonio rodriguesvieiraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

XH200 - SpecSheet - SYKES ARICA-email

XH200 - SpecSheet - SYKES ARICA-email

Uploaded by

antonio rodriguesvieiraCopyright:

Available Formats

WATER

XH

Diesel Drive Auto Prime

XTRA High Head Pump

As Mines and Quarries go deeper the Sykes engineers have ensured that the

Xtra High Head automatic priming solids enormous pressures and heads associated

handling pumpset is designed to dewater with such performance do not compromise

more efficiently and effectively. seal integrity through shaft flexing.

Boasting one of the best shaft stiffness Sykes Xtra High Head Pump range caters

ratio’s of any automatic priming pump on to the demands of the global mining

the market the Sykes Xtra High Head range industry and all models have the ability

provides the reliability to meet the market to operate unattended at high discharge

expectations. heads.

www.allightsykes.com LIGHT WATER AIR

Features • Diesel, electric or hydraulic drive Application

• Low fuel usage • Solids handling • Construction • Solids laden

• Reduced engine sizes • Simple maintenance • Environmental liquids

• Lower maintenance costs • Replaceable wear parts • Industrial • Ground

• Dry self prime and reprime • Chassis - skid, road tow, • Mining Dewatering

• Close coupled SAE Bearing Frames wheeled, caged • Clean Water • Pipeline &

• Suction lifts to 9m • Powered by Cat Engine. • Sludge Drilling

• Operates in ‘snore’ conditions • Other engines available on request • Slimes • Jetting

• Vacuum Priming option available for • Custom build available • Sewage • Quarries

ground dewatering. • Sykes purpose built Control panel

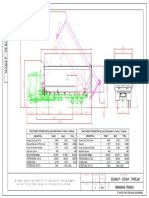

Technical Data

materials of construction

Pump Casing: S.G. IRON 370/17

Suction Cover: S.G. IRON 370/17

220

XH200 - 1750 Air Separation Tank: S.G. IRON 400/12

e f

Bearing Bracket: S.G. IRON 400/12

210 1750RPM RECOMMENDED

g

OPERATING Pump Shaft: 431 Stainless Steel

1700RPM

200 RANGE Impeller: 316 Stainless Steel

d h

1650RPM

190 Wearplates: 316 Stainless Steel

180 1600RPM Mechanical Seal: Silicon Carbide/

c

170 Silicon Carbide

160 1500RPM

b N.R.V. (Ball Type): S.G. IRON 370/17

150 Engine: CAT C-27

a

140 design details

1400RPM

130 Single stage end suction 5 vane closed

HEAD (METRES)

120

1300RPM impeller centrifugal pump

110 Suction Flange (mm/in): 250/10

100 Delivery Flange (mm/in): 200/8

90 Solids Handling Size (mm/in): 31/1.2

80 a = 180kW Maximum Head (m/ft): 208/682

b = 220kW

70 c = 280kW

Maximum Capacity: 230 L/sec

best efficiency point(s) d = 340kW

60

e = 400kW fuel usage (l /hr) @ bep

50 f = 460kW

Power curves include power consumtion of pump priming system g = 500kW Speed POWER FUEL RUN TIME (hrs -

40 (rpm) USAGE RATE 2500L fuel tank)

h = 540kW

30 0 10 (kW) (L/hr)

SUCTION LIFT

(METRES)

(METRES)

20 1750 RPM 1300 212 52.38 48

NPSHR

5 5

10 1400 256 63.25 40

0 10 0 1500 326 80.54 31

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200 210 220 230 240 1600 366 90.42 28

FLOW (LITRES PER SECOND) 3500L fuel tank

1750 516 127.48 27

CALCULATIONS BASED ON 210 g/kw.hr

Dry Weight: 12,800 kg

Fuel Capacity: 3100 litres CL

CL CL

CL

XH200 x CAT C-27 ENGINE ON A 3100L CHASSIS

APPROX. DRY WEIGHT = 12,800KG

APPROX. WET WEIGHT = 15,500KG

www.allightsykes.com LIGHT WATER AIR

You might also like

- Chapter 1 Maintenance Principle and ProceduresDocument10 pagesChapter 1 Maintenance Principle and ProceduresHafizuddin Senawi100% (1)

- Presentasi DND KSBDocument50 pagesPresentasi DND KSBBlank Kusuma100% (2)

- Verilog by ExampleDocument18 pagesVerilog by Examplemaunghtaik100% (1)

- Motobomba SykesDocument144 pagesMotobomba Sykesmuahdib100% (1)

- HD 465 605-7 KomatsuDocument8 pagesHD 465 605-7 KomatsuHarry Wart WartNo ratings yet

- Pump Solutions Brochure (Digital) - AllightsykesDocument24 pagesPump Solutions Brochure (Digital) - Allightsykesbagus_adityaNo ratings yet

- Dnd200-5Hx: Medium Head Dewatering PumpDocument3 pagesDnd200-5Hx: Medium Head Dewatering Pumphendryn100% (1)

- Hard Facing Overlay PDF FreeDocument2 pagesHard Facing Overlay PDF Freemayav1No ratings yet

- HH220 IDocument2 pagesHH220 Iprimelly0% (1)

- WO23465 HH160i X Cat C-7 - Phu Bia MiningDocument117 pagesWO23465 HH160i X Cat C-7 - Phu Bia MiningTego_903779395100% (1)

- Excavator XCMG Xe215cDocument2 pagesExcavator XCMG Xe215casme aceh100% (1)

- MF420EXDocument2 pagesMF420EXYolanda100% (2)

- Pengenalan DNDDocument53 pagesPengenalan DNDAfiffudin Mukhlis Adtya100% (2)

- KTIP2016-16 - Excavator Bucket Fill Factors - 102217Document1 pageKTIP2016-16 - Excavator Bucket Fill Factors - 102217WIDYANo ratings yet

- Tipe Dozer Berat Unit (Ton) Kapasitas Blade (m3) Tinggi Blade (M) Lebar Blade (M) Tinggi Total (M) Panjang Total (M)Document7 pagesTipe Dozer Berat Unit (Ton) Kapasitas Blade (m3) Tinggi Blade (M) Lebar Blade (M) Tinggi Total (M) Panjang Total (M)mufqi fauziNo ratings yet

- CP150 SMDocument50 pagesCP150 SMjacklyn ade putra100% (1)

- Xh150 - Spec Sheet - Sykes - Australia - Nz-EmailDocument2 pagesXh150 - Spec Sheet - Sykes - Australia - Nz-Emailaas asriady100% (1)

- 05 Excitation Basics of Rectifiers (Notes Pages)Document19 pages05 Excitation Basics of Rectifiers (Notes Pages)JŐn PardédéNo ratings yet

- PR776-Bull DozerDocument24 pagesPR776-Bull Dozerhendryn100% (1)

- TV45 - Less Longitudinal - Scania P - 8x4 (R8040AR4-1704010) Berat Dimensi Dan Lain LainDocument2 pagesTV45 - Less Longitudinal - Scania P - 8x4 (R8040AR4-1704010) Berat Dimensi Dan Lain LainrioajisaputrariyantoNo ratings yet

- WMM MF-385G SS Spare PartDocument41 pagesWMM MF-385G SS Spare PartJeniverRanyC.Awombo100% (1)

- G H Specification of MultiFlo Pump Australia PDFDocument38 pagesG H Specification of MultiFlo Pump Australia PDFMuhammad Didik100% (1)

- PR736 - Bull DozerDocument10 pagesPR736 - Bull DozerhendrynNo ratings yet

- D85ESS-2: Rawler OzerDocument12 pagesD85ESS-2: Rawler OzerLuqman Cuopreakt'zNo ratings yet

- P410CB 8x4Document2 pagesP410CB 8x4Rendy FahleviNo ratings yet

- Model Mfc-420: Multiflo PumpsDocument2 pagesModel Mfc-420: Multiflo PumpsKevin Hill100% (2)

- Handbook Multiflo Australia (Spec Pumps)Document32 pagesHandbook Multiflo Australia (Spec Pumps)Vivi Nurhayati87% (15)

- CGE Quester Spec Sheet E29Document2 pagesCGE Quester Spec Sheet E29Ruveen Jeetun100% (2)

- Multiflo Rf420exhv Spec SheetDocument2 pagesMultiflo Rf420exhv Spec SheetIvo Mario100% (1)

- MF-420E Technical DataDocument3 pagesMF-420E Technical DataSylvester S. Turnip100% (3)

- 395 - ExcavatorDocument12 pages395 - ExcavatorhendrynNo ratings yet

- Attachment 2 - Multiflo® 420EXHV Pump Performance CurveDocument1 pageAttachment 2 - Multiflo® 420EXHV Pump Performance Curveachmadj1405No ratings yet

- Model MF-390 Diesel Powered, Self Priming Pump Unit: Weir Minerals MultifloDocument12 pagesModel MF-390 Diesel Powered, Self Priming Pump Unit: Weir Minerals Multiflobayu enasora100% (1)

- X-Pro Vessel: Quality That Is Easy To SeeDocument4 pagesX-Pro Vessel: Quality That Is Easy To Seealfan cita nyalaNo ratings yet

- Renr7885renr7885 03 Sis CMCDocument2 pagesRenr7885renr7885 03 Sis CMCsayeed younis sadaatNo ratings yet

- Dragflow Hy 85-160 A/bDocument2 pagesDragflow Hy 85-160 A/bMarselino SudartoNo ratings yet

- Diesel Drive Auto Prime XTRA High Head PumpDocument2 pagesDiesel Drive Auto Prime XTRA High Head Pumpekho_febryNo ratings yet

- Hh220i - Spec Sheet - Sykes - Australia - NZDocument2 pagesHh220i - Spec Sheet - Sykes - Australia - NZMuhammad NoorNo ratings yet

- XH200 Spec Sheet USLETTER PrintDocument2 pagesXH200 Spec Sheet USLETTER PrintTiago HenriquesNo ratings yet

- Multiflo rf85mv Dewatering Pump Spec SheetDocument2 pagesMultiflo rf85mv Dewatering Pump Spec SheetAjyNo ratings yet

- Dnd200-Mhx: Medium Head Dewatering PumpDocument3 pagesDnd200-Mhx: Medium Head Dewatering PumpMuhammad Jaka Surya100% (1)

- HH160i Spec Sheet USLETTER PrintDocument2 pagesHH160i Spec Sheet USLETTER PrintFaisal RijaniNo ratings yet

- DND 150 Volvo Tad1343veDocument8 pagesDND 150 Volvo Tad1343veSupriyo AdiNo ratings yet

- 826 Weir Multiflo CF48H Curve RELDocument1 page826 Weir Multiflo CF48H Curve RELMichael ChandraNo ratings yet

- Model Mfc-160: General Information ConstructionDocument3 pagesModel Mfc-160: General Information Constructionyosuatogi panjaitan100% (1)

- Brosur Sany SY750-HDocument2 pagesBrosur Sany SY750-Hmbah petruk100% (1)

- 4140D Motor Grader: Tough World. Tough EquipmentDocument2 pages4140D Motor Grader: Tough World. Tough EquipmentAmirul Wiyatno100% (1)

- b2. Spesifikasi Komatsu HD 785Document2 pagesb2. Spesifikasi Komatsu HD 785Marpaung Jhontala RonalNo ratings yet

- Daftar Peralatan RigDocument14 pagesDaftar Peralatan RigYogie Prananta SurbaktiNo ratings yet

- DND 100 SpecuficationDocument8 pagesDND 100 SpecuficationIrfan FauzieNo ratings yet

- Weir CF Diesel Brochure Sept 09Document8 pagesWeir CF Diesel Brochure Sept 09dennis blanco100% (1)

- PC1250-8 Eess018304 1011Document20 pagesPC1250-8 Eess018304 1011Ioannis Zorzos100% (2)

- Partsbook LS4-1400 - PA0430Document60 pagesPartsbook LS4-1400 - PA0430Yanse PurnamaNo ratings yet

- Dnd150-4H: Medium Head Dewatering PumpDocument3 pagesDnd150-4H: Medium Head Dewatering PumpAdrie AmaiaNo ratings yet

- Kajian Efisiensi Bahan Bakar HD465 (Devi Diansyah R. Pratama - 10070112045)Document8 pagesKajian Efisiensi Bahan Bakar HD465 (Devi Diansyah R. Pratama - 10070112045)Devi RahmaditaNo ratings yet

- COATES INDONESIA - Godwin Presentation BaturajaDocument22 pagesCOATES INDONESIA - Godwin Presentation BaturajaAyu FijriNo ratings yet

- Weir Minerals Multiflo Electro-Magnetic (Robatic) Clutch Disassembly AND Assembly ProcedureDocument10 pagesWeir Minerals Multiflo Electro-Magnetic (Robatic) Clutch Disassembly AND Assembly ProcedurePutra JawaNo ratings yet

- HD785 7 LubricantsDocument3 pagesHD785 7 LubricantsWan ImranNo ratings yet

- Mudflo200 & MF-125 MEB-86 Techical AspekDocument46 pagesMudflo200 & MF-125 MEB-86 Techical Aspekachmadj1405No ratings yet

- TORO 301 High Lift PDFDocument2 pagesTORO 301 High Lift PDFpressisoNo ratings yet

- Brochure - SDLG 956F Wheel LoaderDocument2 pagesBrochure - SDLG 956F Wheel LoaderErvin Mesa100% (1)

- M Mining P Pump 415 S: Model Number Sukses Inti SolusindoDocument15 pagesM Mining P Pump 415 S: Model Number Sukses Inti Solusindohendryn100% (2)

- Patria Light Vessel HD 1500-5Document8 pagesPatria Light Vessel HD 1500-5bayu enasoraNo ratings yet

- Ft20kl-Scania P360CB (Sis) (Ra020ar3-1905010)Document3 pagesFt20kl-Scania P360CB (Sis) (Ra020ar3-1905010)tiko fajarNo ratings yet

- BR Primax XH100Document1 pageBR Primax XH100Bassie100% (1)

- Hh80 - Spec Sheet - Sykes - AustraliaDocument7 pagesHh80 - Spec Sheet - Sykes - AustraliaDavid ReskyNo ratings yet

- SpecSheet Pumps HH220 432 SRDocument3 pagesSpecSheet Pumps HH220 432 SRagung2 sepdieNo ratings yet

- Built Tough: Contractor Pump SRDocument5 pagesBuilt Tough: Contractor Pump SRammeenaqualiamaceNo ratings yet

- Built Tough: High HeadDocument3 pagesBuilt Tough: High HeadDodyNo ratings yet

- EH1700 EuclidDocument8 pagesEH1700 EuclidhendrynNo ratings yet

- Cat CS66B: Smooth Drum Vibratory Soil CompactorDocument4 pagesCat CS66B: Smooth Drum Vibratory Soil CompactorhendrynNo ratings yet

- AD AT 410T44 H - Dump TruckDocument2 pagesAD AT 410T44 H - Dump TruckhendrynNo ratings yet

- Read On.: Drills and Bulldozers Up To 120 TonnesDocument4 pagesRead On.: Drills and Bulldozers Up To 120 TonneshendrynNo ratings yet

- Notes: January February MarchDocument13 pagesNotes: January February MarchhendrynNo ratings yet

- (HL200M) (HL200M) : Skid Trailer Sound AttenuatedDocument2 pages(HL200M) (HL200M) : Skid Trailer Sound AttenuatedhendrynNo ratings yet

- HH200S22Document1 pageHH200S22hendrynNo ratings yet

- M Mining P Pump 415 S: Model Number Sukses Inti SolusindoDocument15 pagesM Mining P Pump 415 S: Model Number Sukses Inti Solusindohendryn100% (2)

- Godwin UHH250Document1 pageGodwin UHH250hendrynNo ratings yet

- Multiflo Mudflo™ 150 Hydraulic Submersible Slurry PumpDocument2 pagesMultiflo Mudflo™ 150 Hydraulic Submersible Slurry PumphendrynNo ratings yet

- DB120PLUS: Read OnDocument4 pagesDB120PLUS: Read OnhendrynNo ratings yet

- Read On.: Drills and Bulldozers Up To 120 TonnesDocument4 pagesRead On.: Drills and Bulldozers Up To 120 TonneshendrynNo ratings yet

- Technical Airworthiness Management Manual: WWW - Dgta.gov - MyDocument2 pagesTechnical Airworthiness Management Manual: WWW - Dgta.gov - MyDG TANo ratings yet

- UMBA ENSC 35 List of TechnologiesDocument1 pageUMBA ENSC 35 List of TechnologiesPEARL ANGELIE UMBANo ratings yet

- Calibration of A Bourdon Pressure GaugeDocument4 pagesCalibration of A Bourdon Pressure GaugesubyNo ratings yet

- 1Document2 pages1MINo ratings yet

- Jardine Et Al 1984Document18 pagesJardine Et Al 1984Anonymous D5s00DdUNo ratings yet

- ZedDocument32 pagesZedYared100% (2)

- ERM1602 2.1 DatasheetDocument20 pagesERM1602 2.1 Datasheetstranger72_28No ratings yet

- Oracle HRMSDocument30 pagesOracle HRMSSingari Sridhar100% (1)

- 45CB Thermal Magnetic Electronic TripDocument23 pages45CB Thermal Magnetic Electronic Tripryan varonaNo ratings yet

- Ch13 MCQDocument14 pagesCh13 MCQMadhukar ScribdNo ratings yet

- 3.macro Processor2016Document51 pages3.macro Processor2016prachitiNo ratings yet

- ALESIS - RA150, RA300, RA500 Amplifier ManualDocument38 pagesALESIS - RA150, RA300, RA500 Amplifier ManualJFIonienNo ratings yet

- Kuliah 1Document18 pagesKuliah 1Adam Hidana Yudo SaputroNo ratings yet

- HVACManl PDFDocument166 pagesHVACManl PDFErvinaNo ratings yet

- Analog Mixed Modules, 12-Bit: Product Description Module SpecificationsDocument4 pagesAnalog Mixed Modules, 12-Bit: Product Description Module SpecificationsUsman AliNo ratings yet

- 5Document10 pages5Ariel Carlos De LeonNo ratings yet

- SOP (Standard Operation Procedure) PDFDocument126 pagesSOP (Standard Operation Procedure) PDFIb JensenNo ratings yet

- Oracle Financials E-Business Suite Release 12 Period End ProceduresDocument60 pagesOracle Financials E-Business Suite Release 12 Period End ProceduresandiglynnNo ratings yet

- 3249U Engineering Notebook 2022-2023Document510 pages3249U Engineering Notebook 2022-2023Ivan Miguel Londoño SilvaNo ratings yet

- GRD Pu Sole Making MachineDocument4 pagesGRD Pu Sole Making Machinemohommed shahedNo ratings yet

- Diff Probe BOM V2Document4 pagesDiff Probe BOM V2Niki HristovNo ratings yet

- Javascript Basics (Assignment 1)Document4 pagesJavascript Basics (Assignment 1)Tariq TaeemNo ratings yet

- Servotek Tachometer 2011 CatalogDocument8 pagesServotek Tachometer 2011 CatalogServo2GoNo ratings yet

- Idirect Evolution - X1 Data SheetDocument1 pageIdirect Evolution - X1 Data SheetАнатолий МаловNo ratings yet

- PolyPhen Insulation DataDocument2 pagesPolyPhen Insulation DataDanLorenaNo ratings yet