Professional Documents

Culture Documents

eSUN PETG-Filament TDS V4.0

Uploaded by

AlbertOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

eSUN PETG-Filament TDS V4.0

Uploaded by

AlbertCopyright:

Available Formats

Nov.2021 Version 4.

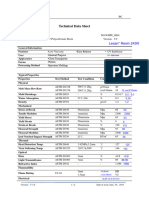

PETG Technical Data Sheet

PETG is a high cost performance material with water resistance, chemical resistance and high toughness. It's tougher than ABS. The

printed product has translucent and smooth surface. It's easy to print as PLA with no need of temperature chamber.

Material Status Mass Production

Characteristics • Transparent • Chemical resistance

• Great toughness • Water resistance

Applications • Advertisement • Snap-in parts

• Waterproof application • Flower pot

Form • Filament

Processing method • 3D Print, FDM Print

testing method Typical value

Physical Properties

Density GB/T 1033 1.27 g/cm 3

Melt Flow Index GB/T 3682 20 (190℃/2.16kg)

Mechanical Properties

Tensile Strength GB/T 1040 52.2 MPa

Elongation at Break GB/T 1040 83 %

Flexural Strength GB/T 9341 58.1 MPa

Flexural Modulus GB/T 9341 1073 MPa

IZOD Impact Strength GB/T 1843 4.7 kJ/m2

Thermal Properties

Heat distortion Temperature GB/T 1634 64 ℃

Continuous Service Temperature IEC 60216 N/A

Maximum (short term) Use Temperature N/A

Electrical Properties

Insulation Resistance DIN IEC 60167 N/A

Surface Resistance DIN IEC 60093 N/A

Wuhan University Building A403-I,A901,No.6 Yuexing 2 Road,Nanshan District,Shenzhen,Guangdong

China

Tel +86 755 86581960

fax +86 755 26031982

Email: bright@brightcn.net

www.esun3d.net 1/2

Nov.2021 Version 4.0

Recommended printing parameters

Extruder Temperature 230- 250℃

Build Platform Temperature 75-90°C

Fan Speed 100%

Printing Speed 40 - 100mm/s

Based on 0.4 mm nozzle and Simplify 3D v.4.1.2. Printing conditions may vary with different nozzle diameters

Drying Recommendations

N/A

Precautions:

Turn on the Z seam alignment . Turn off the Z-axis lifting with drawing.

Slower the printing speed.

Mechanical Properties

Tensile testing specimen GB/T 1040 Flexural testing specimen GB/T 9341 Impact testing specimen GB/T 1043

The physical properties, mechanical properties, thermal properties, and electrical properties of the line are obtained based on the

injection molding spline test.

Print test condition:

Extruder Temperature 230-250℃

Build Platform Temperature 75℃

Outline/Perimeter Shells 4

Top/Bottom Layers 4

Infill Percentage 20%

Fan speed 100%

Printing speed 40mm/s

Based on 0.4 mm nozzle and Simplify 3D v.4.1.2.

Notice

All information supplied by or on behalf of eSUN in relation to this product, whether in the nature of data, recommendations or

otherwise, is supported by research and, in good faith, believed reliable, but the product is sold “as is”. eSUN assumes no liability and

makes no representations or warranties, express or implied, of merchantability, fitness for a particular purpose, or of any other nature

with respect to information or the product to which information refers and nothing herein waives any of the seller's conditions of sale.

Wuhan University Building A403-I,A901,No.6 Yuexing 2 Road,Nanshan District,Shenzhen,Guangdong

China

Tel +86 755 86581960

fax +86 755 26031982

Email: bright@brightcn.net

www.esun3d.net 2/2

You might also like

- eSUN PLA+-Filament TDS V4.0Document2 pageseSUN PLA+-Filament TDS V4.0Socheata channNo ratings yet

- Especificaciones Tecnicas eSUN - eASA-FilamentDocument2 pagesEspecificaciones Tecnicas eSUN - eASA-FilamentDiego TellezNo ratings yet

- ESPECIFICACIONES TECNICAS ePA-CF NYLON FIBRA DE CARBONO ESUNDocument2 pagesESPECIFICACIONES TECNICAS ePA-CF NYLON FIBRA DE CARBONO ESUNArq.mauricioaguilarNo ratings yet

- Tds A1105 en 2017pdfpdfDocument2 pagesTds A1105 en 2017pdfpdfagungNo ratings yet

- Plexiglas Satinice Df21 8n - enDocument3 pagesPlexiglas Satinice Df21 8n - enjonathan6657No ratings yet

- Wanhua PC Injection Moulding 20 Mfi Clarnate A1227Document2 pagesWanhua PC Injection Moulding 20 Mfi Clarnate A1227lucasNo ratings yet

- Moplen: Technical Data SheetDocument2 pagesMoplen: Technical Data SheetLaxman AhirNo ratings yet

- 5SL43327 Datasheet enDocument4 pages5SL43327 Datasheet enprabuNo ratings yet

- POM KEPITAL F30-03 enDocument2 pagesPOM KEPITAL F30-03 enAthonioMourinhoNo ratings yet

- 5SL62326 Datasheet enDocument4 pages5SL62326 Datasheet enJosé Miguel LarezNo ratings yet

- RTP 299 X 90078 SSC 63023Document2 pagesRTP 299 X 90078 SSC 63023kls.thorodinsonNo ratings yet

- Datasheet LWSB560055 enDocument1 pageDatasheet LWSB560055 enAura ZakiNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetIVANCHUNo ratings yet

- 5SL42167 Datasheet enDocument4 pages5SL42167 Datasheet enprabuNo ratings yet

- 5SL41167RC Datasheet enDocument4 pages5SL41167RC Datasheet enomarqasimNo ratings yet

- DG2/40 HS: Flat Transmission Belts Technical Data SheetDocument2 pagesDG2/40 HS: Flat Transmission Belts Technical Data Sheetdirkz26No ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetIVANCHUNo ratings yet

- Data Sheet 5SJ4101-8HG40: ModelDocument4 pagesData Sheet 5SJ4101-8HG40: ModelFaiz 3BNo ratings yet

- 5SL31106 Datasheet enDocument4 pages5SL31106 Datasheet enBão Sa MạcNo ratings yet

- 5SL41166 Datasheet enDocument4 pages5SL41166 Datasheet enPankaj RamoleNo ratings yet

- TP Wanhua Clarnate A1227 Vs Lexan 243RDocument2 pagesTP Wanhua Clarnate A1227 Vs Lexan 243RMitja GorseNo ratings yet

- Technical Data Sheet PC: Filament SpecificationsDocument3 pagesTechnical Data Sheet PC: Filament SpecificationsVladimir SarmientoNo ratings yet

- 5SL33327MB Datasheet enDocument5 pages5SL33327MB Datasheet enLferchoi IdrovoNo ratings yet

- 5SL62047 Datasheet enDocument3 pages5SL62047 Datasheet endachinicuNo ratings yet

- POM - KEPITAL F20-03 - Standard GradeDocument2 pagesPOM - KEPITAL F20-03 - Standard GradeMadhav RajpurohitNo ratings yet

- Trirex 3020HF: Polycarbonate ResinDocument5 pagesTrirex 3020HF: Polycarbonate ResinAlbert FortunatoNo ratings yet

- Data Sheet 5SY8310-7: ModelDocument4 pagesData Sheet 5SY8310-7: ModelRadyan PradiptaNo ratings yet

- Technyl Star S 218 V30 BK 31NDocument3 pagesTechnyl Star S 218 V30 BK 31Nratz23695No ratings yet

- Tds PBT 1130Document2 pagesTds PBT 1130Huyền VũNo ratings yet

- 5SL63107 Datasheet enDocument3 pages5SL63107 Datasheet enMS COPNo ratings yet

- 5SJ43208HG42 Datasheet enDocument4 pages5SJ43208HG42 Datasheet enJake WongNo ratings yet

- 5SL43137RC Datasheet enDocument5 pages5SL43137RC Datasheet enMohammed HanifNo ratings yet

- Technical Data Sheet - ASTM PDFDocument2 pagesTechnical Data Sheet - ASTM PDFnielNo ratings yet

- Polyamide Carbon Fiber: DissipativeDocument2 pagesPolyamide Carbon Fiber: DissipativeLeonardo MurilloNo ratings yet

- Vampamid 6 0024 V0Document1 pageVampamid 6 0024 V0Plasticos CusenNo ratings yet

- HOSTAPHAN® Polyester films..PETDocument10 pagesHOSTAPHAN® Polyester films..PETsreeeragNo ratings yet

- 5SY52067 Datasheet enDocument5 pages5SY52067 Datasheet enhassNo ratings yet

- Polimaxx 1102K Product Data Sheet 1 1Document1 pagePolimaxx 1102K Product Data Sheet 1 1Kaleb Rido ManurungNo ratings yet

- Polimaxx 1102K Product Data Sheet 1 1Document1 pagePolimaxx 1102K Product Data Sheet 1 1Kaleb Rido ManurungNo ratings yet

- 5SL61107 Datasheet enDocument3 pages5SL61107 Datasheet enMS COPNo ratings yet

- 5SY42047 Datasheet enDocument6 pages5SY42047 Datasheet enRiver Trash andNo ratings yet

- 5SY42638FA Datasheet enDocument5 pages5SY42638FA Datasheet enWelton CorreiaNo ratings yet

- Data Sheet 5SJ4101-7HG42: ModelDocument4 pagesData Sheet 5SJ4101-7HG42: ModelFaiz 3BNo ratings yet

- Kepital F20 - 03Document2 pagesKepital F20 - 03Kumaar RanjanNo ratings yet

- Siemens 5sy62017Document4 pagesSiemens 5sy62017Kleiber OrtegaNo ratings yet

- 5SL41047 Datasheet enDocument5 pages5SL41047 Datasheet enkavireeshgh_007No ratings yet

- TDS LF-360Document2 pagesTDS LF-360Ofer ShochetNo ratings yet

- Pei 0270 RTP 2183Document2 pagesPei 0270 RTP 2183Vincent NguyenNo ratings yet

- Data Sheet 5SY4213-6KK11: ModelDocument5 pagesData Sheet 5SY4213-6KK11: ModelDavid Ramírez RojasNo ratings yet

- CEM 1203 42 BuzzerDocument5 pagesCEM 1203 42 BuzzerEAKIT SPAINNo ratings yet

- High Temperature Epoxy Tooling Board: Trelleborg Applied TechnologiesDocument3 pagesHigh Temperature Epoxy Tooling Board: Trelleborg Applied TechnologiesMert KıraçNo ratings yet

- 5SY Siemens Miniature CircuitDocument5 pages5SY Siemens Miniature Circuitm.hatemNo ratings yet

- 5SL42067RC Datasheet enDocument5 pages5SL42067RC Datasheet enpkarthik30No ratings yet

- Data Sheet 5SL4232-7CC: ModelDocument3 pagesData Sheet 5SL4232-7CC: ModelAtiqah Putri SariNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetLeductoan LeNo ratings yet

- 5SP43927 Datasheet enDocument3 pages5SP43927 Datasheet enLucas GiacomelliNo ratings yet

- RHODIA Technyl A218 V30Document3 pagesRHODIA Technyl A218 V30paquienNo ratings yet

- KNG1015 Pa6-Gf15Document2 pagesKNG1015 Pa6-Gf15pava16230.meNo ratings yet

- Akulon K224-G3: PA6-GF15Document2 pagesAkulon K224-G3: PA6-GF15vaibhav dhandeNo ratings yet