Professional Documents

Culture Documents

KNG1015 Pa6-Gf15

Uploaded by

pava16230.meOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

KNG1015 Pa6-Gf15

Uploaded by

pava16230.meCopyright:

Available Formats

®

BGFecomaterials KNG1015

* Description PA6 Glass fiber 15% reinforced

* Characteristics Rigidity, Mechanical strength, Heat & Light resistance

* Application Automotive : Underhood parts, Interior/Exterior parts etc.

Inside Door bracket

Injection Molding Guide

Drying

Dryer Temperature(℃) Time(hr) Moisture

Dehumidifier 100 3~4 < 0.12%

Hot air 110 3~4 < 0.12%

cc) Definitely dehumidifier is superior to color stability

Processing temperature (℃)

Mold Nozzle Mixing Metering Feeding

60~80 255~260 250~255 245~250 240~245

Processing condition

Injection speed Medium ~ High

Injection pressure 60 ~ 70% (vs. Injection capacity)

back pressure 10 ~ 20% (vs. Injection pressure)

Holding pressure 40 ~ 60% (based on injection pressure value)

Screw speed 20 ~ 50 RPM (depends on current screw status like wear, abrasion)

Injection / cooling time 3-5 / 10-20 seconds

cc) Recommended condition above are subject to change, according to injection type and capacity.

General tips

Polyamide, in general, is very sensitive material to moisture. Though BGFecomaterials provides the material in

sealed package after drying, it is highly recommended to preheat it under recommended moisture limit before

injection molding, which is an important process for unsealed package, regardless of unsealed duration.

The material exposed to moisture over recommended limit might cause quality concerns such as gas flow mark,

silver streak and drooling, making material properties significantly dropped in molded part.

Thus, preheating is always recommended to improve quality of a molded part in surface, mold deposit and molding

process ability.

BGFecomaterials CO., LTD. | Engineering plastics, compositing

525, Jangan-ri, Jangan-myeon, Hwaseong-si, Geyonggi-do, 445-943, Korea

www.bgfecomaterials.com 1 of 2

BGFecomaterials® KNG1015

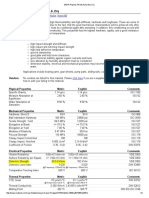

Properties Test Method Condition Unit Value

Physical properties

Density ISO 1183 1.23

Water Absorption ISO 62 23°C, Water 24h % 1.10

Poisson's Ratio ISO 527 0.36

Mold Shrinkage ISO 294 % 0.5~0.8

Thermal properties

Melting Point ISO 3146 °C 220

Heat Deflection Temperature ISO 75 0.45MPa °C 220

1.82MPa °C 195

Thermal Expansion ISO 11359 x10-5 1/K 3.7

Flammability UL94 HB

Mechanical properties

Tensile Strength ISO 527 MPa 125

Tensile Modulus ISO 527 MPa 5,800

Tensile Elongation ISO 527 % 3

Flexural Strength ISO 178 MPa 205

Flexural Modulus ISO 178 MPa 5,150

IZOD Impact Strength ISO 180/1A Notched 23°C KJ/m2 5.0

Notched -30°C KJ/m2 3.0

Rockwell Hardness ISO 2039-2 23℃ R-scale 120

Electrical properties

Dielectric Constant ASTM D150 1 MHz -

Dielectric Dissipation Factor ASTM D150 1 MHz -

Volume Resistivity ASTM D257 Ω.cm 1x1014

Dielectric Strength ASTM D149 KV/mm -

Disclaimer : the data in table are typical property values measured by standard test, not guarantied as specification limits.

BGFecomaterials CO., LTD. | Engineering plastics, compositing

525, Jangan-ri, Jangan-myeon, Hwaseong-si, Geyonggi-do, 445-943, Korea

www.bgfecomaterials.com 2 of 2

You might also like

- PA66-G30 Glass Fiber Reinforced Polyamide 66 Properties Applications ProcessingDocument2 pagesPA66-G30 Glass Fiber Reinforced Polyamide 66 Properties Applications ProcessingVinoth SekarNo ratings yet

- POM_KEPITAL_F30-03_EnDocument2 pagesPOM_KEPITAL_F30-03_EnAthonioMourinhoNo ratings yet

- Kepital F20 - 03Document2 pagesKepital F20 - 03Kumaar RanjanNo ratings yet

- Technical Data Sheet for ALTECH ABS C 2017/500 GF17 PlasticDocument1 pageTechnical Data Sheet for ALTECH ABS C 2017/500 GF17 PlasticarmandoNo ratings yet

- PA 6.6 Nylon 6.6Document2 pagesPA 6.6 Nylon 6.6Naeem KhanNo ratings yet

- Ecopond PBATDocument3 pagesEcopond PBATsoniud14No ratings yet

- Styrolution TDS400900481370Document3 pagesStyrolution TDS400900481370joshNo ratings yet

- Caring Formula High Flow Glass Filled PA6Document3 pagesCaring Formula High Flow Glass Filled PA6ratz23695No ratings yet

- PP Gf30 - Suplen v30 LCDocument2 pagesPP Gf30 - Suplen v30 LCarmandoNo ratings yet

- CAMPUS® Datasheet: Ultradur® B 4406 G6 Q798 SW 15138 - PBT-GF30 FR BasfDocument5 pagesCAMPUS® Datasheet: Ultradur® B 4406 G6 Q798 SW 15138 - PBT-GF30 FR BasfdivyarasinNo ratings yet

- K300 TDSDocument2 pagesK300 TDSM. Kürşad ArslanNo ratings yet

- Styrolution PS 454N: High Impact Polystyrene (HIPS)Document3 pagesStyrolution PS 454N: High Impact Polystyrene (HIPS)Inês MorgadoNo ratings yet

- Pom 90Document2 pagesPom 90busyNo ratings yet

- Grand Pacific Petrochemical Corp: Grade: Gramid N200GP Typical Properties of GPPC Pa66-N200Gp ResinsDocument1 pageGrand Pacific Petrochemical Corp: Grade: Gramid N200GP Typical Properties of GPPC Pa66-N200Gp ResinsPhuoc Thinh TruongNo ratings yet

- PLEXIGLAS Satinice df20 8N - ENDocument2 pagesPLEXIGLAS Satinice df20 8N - ENmstevkaNo ratings yet

- Tarolox 10 g6 Standard 003 enDocument3 pagesTarolox 10 g6 Standard 003 enMohamed Ali MaâlaouiNo ratings yet

- Styrolution PS 147F: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 147F: General Purpose Polystyrene (GPPS)Ayaan Anowar100% (1)

- Plexiglas Satinice Df21 8n - enDocument3 pagesPlexiglas Satinice Df21 8n - enjonathan6657No ratings yet

- Styrolution PS 476L: Technical DatasheetDocument3 pagesStyrolution PS 476L: Technical DatasheetTRUONGNo ratings yet

- PC 8B35 Ge Lexan PCDocument3 pagesPC 8B35 Ge Lexan PCbalu gunaNo ratings yet

- Novodur P2MC: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur P2MC: Acrylonitrile Butadiene Styrene (ABS)heliocoelhojrNo ratings yet

- (Jay Shoemaker) Moldflow Design Guide 'A ResourcDocument3 pages(Jay Shoemaker) Moldflow Design Guide 'A ResourcFahri ibişoğluNo ratings yet

- Chang Chun Plastics CO., LTDDocument2 pagesChang Chun Plastics CO., LTDChunYenHuangNo ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- Styrolution Basf Terluran GP-22Document3 pagesStyrolution Basf Terluran GP-22medo.k016No ratings yet

- POM - KEPITAL F20-03 - Standard GradeDocument2 pagesPOM - KEPITAL F20-03 - Standard GradeMadhav RajpurohitNo ratings yet

- TDS PBT 5829F-105Document2 pagesTDS PBT 5829F-105TRUONGNo ratings yet

- Technyl Safe C 116FC NCDocument3 pagesTechnyl Safe C 116FC NCkls.thorodinsonNo ratings yet

- Styrolution PS 495N: High Impact Polystyrene (HIPS)Document3 pagesStyrolution PS 495N: High Impact Polystyrene (HIPS)Inês MorgadoNo ratings yet

- Elix ABS M220: Technical InformationDocument3 pagesElix ABS M220: Technical InformationDiegoTierradentroNo ratings yet

- Vesbo PPR EnglishDocument50 pagesVesbo PPR Englishcool.boys4200No ratings yet

- Novodur H802: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur H802: Acrylonitrile Butadiene Styrene (ABS)Maribel GutierrezNo ratings yet

- CAMPUS® Datasheet: Ultradur® B 4330 G6 HR - PBT-I-GF30 BasfDocument4 pagesCAMPUS® Datasheet: Ultradur® B 4330 G6 HR - PBT-I-GF30 BasfAngererNo ratings yet

- TITLE Fast Molding Polyamide for Thin Wall PartsDocument3 pagesTITLE Fast Molding Polyamide for Thin Wall PartsSATHISH KUMAR SNo ratings yet

- InnoPlus HD8100MDocument1 pageInnoPlus HD8100MLe Minh TuanNo ratings yet

- RGF33NATURALDocument1 pageRGF33NATURALCassianNo ratings yet

- Terluran HI-10: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran HI-10: Acrylonitrile Butadiene Styrene (ABS)bobNo ratings yet

- Terluran GP-35: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran GP-35: Acrylonitrile Butadiene Styrene (ABS)DiegoTierradentroNo ratings yet

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- Luran HH-120: Please SelectDocument3 pagesLuran HH-120: Please SelectDavid Costi da RosaNo ratings yet

- Terluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Mahdi VolgarNo ratings yet

- BL6 - HM 7255Document1 pageBL6 - HM 7255ShahryarNo ratings yet

- Hdpe Bl3-MarunDocument1 pageHdpe Bl3-MarunChetan PandyaNo ratings yet

- ABS N Fisa TehnicaDocument1 pageABS N Fisa TehnicaFloare de PrimavaraNo ratings yet

- Mineral Reinforced PP: Features ApplicationsDocument2 pagesMineral Reinforced PP: Features ApplicationskatolokchokNo ratings yet

- Elix ABS P2M-AT: Technical InformationDocument3 pagesElix ABS P2M-AT: Technical InformationDiegoTierradentroNo ratings yet

- Pa66-R10g25 Tds-Iso-EngDocument2 pagesPa66-R10g25 Tds-Iso-EngTRUONGNo ratings yet

- Styrolution PS 485N: High Impact Polystyrene (HIPS)Document2 pagesStyrolution PS 485N: High Impact Polystyrene (HIPS)Inês MorgadoNo ratings yet

- Polyamide Carbon Fiber: DissipativeDocument2 pagesPolyamide Carbon Fiber: DissipativeLeonardo MurilloNo ratings yet

- ABS Technical Data SheetDocument1 pageABS Technical Data SheetarmandoNo ratings yet

- PocanB3235000000 GF30 1Document5 pagesPocanB3235000000 GF30 1rihabNo ratings yet

- Luran S 777K: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 777K: Acrylonitrile Styrene Acrylate (ASA)Leonardo DguezNo ratings yet

- Styro Lution Tds 200400070620Document3 pagesStyro Lution Tds 200400070620gv_ScribdNo ratings yet

- Elix ABS E401: Technical InformationDocument3 pagesElix ABS E401: Technical InformationDiegoTierradentroNo ratings yet

- ULTRAMID_sup_®️__sup_+B3WG6+BGVW+BLACK+00564 (1)Document2 pagesULTRAMID_sup_®️__sup_+B3WG6+BGVW+BLACK+00564 (1)Luis Enrique Ramos PérezNo ratings yet

- Product Summary: FZ-3600 Is A Glass Fiber and Mineral Filled Branched PPSDocument1 pageProduct Summary: FZ-3600 Is A Glass Fiber and Mineral Filled Branched PPSMark DingalNo ratings yet

- Elix Pc-Abs 5130Document4 pagesElix Pc-Abs 5130DiegoTierradentroNo ratings yet

- ABS Data Sheet with Heat Resistance and Impact StrengthDocument1 pageABS Data Sheet with Heat Resistance and Impact StrengthDanielNo ratings yet

- OKW ABS,+Guide+ValuesDocument1 pageOKW ABS,+Guide+ValuesDanielNo ratings yet

- Arranging Dissimilar Centrifugal Pumps in Series and ParallelDocument8 pagesArranging Dissimilar Centrifugal Pumps in Series and ParallelPujo BagusNo ratings yet

- Shoring CalculationDocument7 pagesShoring CalculationNicky198No ratings yet

- ConocoPhillips Welding Procedure SpecificationDocument18 pagesConocoPhillips Welding Procedure SpecificationAgus Budiono100% (5)

- Mohr Stress Circle Exercise-KrDocument8 pagesMohr Stress Circle Exercise-KrFelipe Camacho HurtadoNo ratings yet

- Analysis of Drive Shaft: Bhirud Pankaj Prakash, Bimlesh Kumar SinhaDocument6 pagesAnalysis of Drive Shaft: Bhirud Pankaj Prakash, Bimlesh Kumar SinhakumarNo ratings yet

- Barley Straw: A Potential Method of Algae Control in PondsDocument4 pagesBarley Straw: A Potential Method of Algae Control in PondsArmando Chiclla SalazarNo ratings yet

- A Connection of Ideal Gas Laws by ExperimentDocument14 pagesA Connection of Ideal Gas Laws by ExperimentCedric YueNo ratings yet

- Chapter Four 4Document14 pagesChapter Four 4Bizuye Shetie100% (1)

- Acid CorrosionDocument26 pagesAcid CorrosionTamer Abd ElrasoulNo ratings yet

- School Iron Supplement TrackingDocument7 pagesSchool Iron Supplement TrackingYoj Evol J. RomafNo ratings yet

- COSHH Assessment FormDocument5 pagesCOSHH Assessment FormEnus BenjaminNo ratings yet

- Influence Line DiagramDocument23 pagesInfluence Line Diagramarif_rubinNo ratings yet

- 22 Aptitude Pipes Cisterns PDFDocument13 pages22 Aptitude Pipes Cisterns PDFDivya patidarNo ratings yet

- Momentum Linkage ProblemsDocument18 pagesMomentum Linkage ProblemsAna Lorraine DalilisNo ratings yet

- Multilateral Wells Outline 1-05Document3 pagesMultilateral Wells Outline 1-05abdounouNo ratings yet

- Aquastore Brochure WaterstorageDocument4 pagesAquastore Brochure WaterstoragePraveenNo ratings yet

- Tds-Tasnee PP h4120Document2 pagesTds-Tasnee PP h4120أبو أميرNo ratings yet

- Science Activity Sheets for Grade 5 (1st QuarterDocument49 pagesScience Activity Sheets for Grade 5 (1st QuarterPrecious RubaNo ratings yet

- HP Lubricants CataloguesDocument170 pagesHP Lubricants CataloguesdhanusagNo ratings yet

- Turbidity StandardsDocument18 pagesTurbidity StandardsRizky Cahya PutraNo ratings yet

- Strength of Materials (Part I & II) - TimoshenkoDocument450 pagesStrength of Materials (Part I & II) - TimoshenkoJuan David Zapata Oliveros100% (1)

- NanobotsDocument22 pagesNanobotsSasi KumarNo ratings yet

- Antibacterial Activity of Crude Extracts of Cyanobacteria Phormidium and Microcoleus SpeciesDocument6 pagesAntibacterial Activity of Crude Extracts of Cyanobacteria Phormidium and Microcoleus SpeciesCaro RosasNo ratings yet

- Final SotAR TU1207Document415 pagesFinal SotAR TU1207mikorizNo ratings yet

- Chemistry Form 6 Sem 3 Chapter 1Document47 pagesChemistry Form 6 Sem 3 Chapter 1Yuzamrah Awang Noh50% (2)

- Choke Specification - CCI PDFDocument4 pagesChoke Specification - CCI PDFAakashRanjan100% (1)

- ParijatDocument10 pagesParijatRd PatelNo ratings yet

- Reporting Properties For Plastics and Thermoplastic ElastomersDocument4 pagesReporting Properties For Plastics and Thermoplastic ElastomersAndres Camilo BenitezNo ratings yet

- Oilfield Water ChemistryDocument51 pagesOilfield Water ChemistryOV Gut100% (2)