Professional Documents

Culture Documents

Poster

Poster

Uploaded by

Alexandre SprichOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Poster

Poster

Uploaded by

Alexandre SprichCopyright:

Available Formats

Application of a Quality-by-Design (QbD) approach to a digital twin bioreactor

A. SPRICH, J. BUDZINSKI, T. BASTOGNE1,2,3

1CYBERNANO, 2CRAN UL-CNRS UMR 7039, 2INRIA BIGS

Background. Optimizing the performance of a bioreactor is a multifactorial problem that can take a long time to achieve

the desired objectives. In a competitive context, reducing the time of development becomes a major industrial challenge for

bioproduction. This study presents and compares two different strategies to couple digital twin simulation and

pharmaceutical Quality-by-Design (ICH Q8) to speed up the determination of a Design Space in bioproduction.

Methods

A stirred tank bioreactor simulator proposed was implemented

into the MATLAB/Simulink computational environment (Fig.1). The

EasyQBD platform was used to apply the good practice of

Pharmaceutical Quality by Design, involving the statistical design

of experiments and the identification of the design space. Three

critical process parameters (input factors) were considered :

temperature, pH and concentration of dissolved oxygen. The

critical quality attribute (output variable) is the number of cells in

the bioreactor, with an expected specification on the

production yield of at least 8E+6 cells. This first approach relies on

Fig.1: Simulink model of a bioreactor

a meta-modeling strategy composed of a Doehlert design (13

points, 3 reproductions) and a second-order response surface

model. The alternative approach uses a quasi-Monte-Carlo

design (Sobol sequence based on 1024 points, 100

reproductions) directly applied to the simulator. A 3D probability

map and a design space are computed from the simulated

responses obtained by each design.

Results

The 3D probability maps obtained with the common approach,

is presented in Fig.2. This diagram is a cube whose each axis is

associated with an input factor. It is composed of probability

values to meet the production yield requirement. The green Fig.2 : Probability map and Design Space (green region) built

from the strategy 1 (Doehlert Design + Response Surface Model)

region of this diagram, called Design Space (DS), represents the

set of input values for which this probability is greater than 95%.

Fig.3 presents the design space computed with the second

strategy, i.e. the one based on a space filling design directly

applied to the simulator. The comparison of the two probability

maps shows the size of the design space is clearly overestimated

by the classical approach. This result is probably a consequence

of the meta-modeling approximation.

Conclusion

When a calibrated and validated simulator of a bioreactor is

available, we show how it can be used within an QbD framework

to obtain a first estimate of the Design Space before field trials. Fig.3 : Probability map and Design Space (green dots) built from

Bioreactor simulators are generally computationally time- the strategy 2 (Quasi Monte-Carlo Design applied to the digital

twin without metamodeling)

efficient. For this reason, this study shows that it is preferable to

apply directly space filling designs to digital twins when we wish

to get an initial estimate of a Design Space. The latter can

drastically speed up the Quality by Design study by focusing the

investigation domain on the most promising region.

Congrès France Bioproduction 2023, Tours,

April 5th & 6th 2023

You might also like

- Saxophone Grade 2Document18 pagesSaxophone Grade 2Kailash Rai Bala100% (1)

- Reece's Motion To SuppressDocument19 pagesReece's Motion To SuppressLisa VaasNo ratings yet

- Stock AnalysisDocument5 pagesStock AnalysisArun Kumar GoyalNo ratings yet

- WG 15a Structural Systems - OffshoreDocument273 pagesWG 15a Structural Systems - OffshoreIlkin hasanovNo ratings yet

- Comprehensive Quality by Design for Pharmaceutical Product Development and ManufactureFrom EverandComprehensive Quality by Design for Pharmaceutical Product Development and ManufactureGintaras V. ReklaitisNo ratings yet

- LF1 LF2 LF3Document11 pagesLF1 LF2 LF3Bilal AhmadNo ratings yet

- Restrictive Lung DiseaseDocument32 pagesRestrictive Lung DiseaseSalman Khan100% (1)

- Rtari: RemainDocument10 pagesRtari: RemainLucas KnightNo ratings yet

- Diabatix - P3-Battery Cold Plate DesignDocument10 pagesDiabatix - P3-Battery Cold Plate DesignNagarjuna MummidiNo ratings yet

- Surogate ModelingDocument11 pagesSurogate ModelingGamini SureshNo ratings yet

- 94 Handling Distribution Shift inDocument8 pages94 Handling Distribution Shift inscribdtomsmith2No ratings yet

- Panos Faim2022Document9 pagesPanos Faim2022George VosniakosNo ratings yet

- Materials Today: Proceedings: Robin H. Helle, Hirpa G. LemuDocument8 pagesMaterials Today: Proceedings: Robin H. Helle, Hirpa G. LemuRaj PatelNo ratings yet

- Probabilistic Engineering DesignDocument7 pagesProbabilistic Engineering DesignAnonymous NyeLgJPMbNo ratings yet

- Hybridization of An Evolutionary Algorithm and Simulations o - 2021 - AutomationDocument18 pagesHybridization of An Evolutionary Algorithm and Simulations o - 2021 - AutomationelysianvelaNo ratings yet

- Reinforcement Learning For Architectural DesignDocument10 pagesReinforcement Learning For Architectural Designjoaopedro.bragaiaNo ratings yet

- Quantum Computing For Chemical and Biomolecular Product DesignDocument10 pagesQuantum Computing For Chemical and Biomolecular Product DesignkorichiNo ratings yet

- Assessment of Multi-Objective Genetic Algorithms With Different Niching Strategies and Regression Methods For Engine Optimization and DesignDocument25 pagesAssessment of Multi-Objective Genetic Algorithms With Different Niching Strategies and Regression Methods For Engine Optimization and DesignrrathoreNo ratings yet

- DOE-Exercise SciLife - 1Document9 pagesDOE-Exercise SciLife - 1Neelesh GangwarNo ratings yet

- Design and Optimization of 3D Radial Slot Grain ConfigurationDocument7 pagesDesign and Optimization of 3D Radial Slot Grain ConfigurationpingliNo ratings yet

- 05.TOSN IrvanAriefAng Final V8Document29 pages05.TOSN IrvanAriefAng Final V8haydee_hitcul13No ratings yet

- Content ServerDocument22 pagesContent ServerIgnacius Garridum ContulianoNo ratings yet

- Two Dimensional Airfoil Optimisation Using CFD in A Grid Computing EnvironmentDocument8 pagesTwo Dimensional Airfoil Optimisation Using CFD in A Grid Computing Environmentananth9660No ratings yet

- Digital Optimisation Workflow in Early Project Phases and What It Can Bring When Looking at The MacLeamy CurveDocument6 pagesDigital Optimisation Workflow in Early Project Phases and What It Can Bring When Looking at The MacLeamy CurveLuân NguyễnNo ratings yet

- Franschescini e Macchieto 2007Document13 pagesFranschescini e Macchieto 2007André Luís AlbertonNo ratings yet

- 1-s2.0-S2212827121002584-main-đã chuyển đổiDocument6 pages1-s2.0-S2212827121002584-main-đã chuyển đổiKiều Anh Trần NguyễnNo ratings yet

- Ensemble U-Net Model For Efficient Polyp SegmentationDocument3 pagesEnsemble U-Net Model For Efficient Polyp SegmentationshrutiNo ratings yet

- Design and Optimization of 3D Radial Slot Grain ConfigurationDocument6 pagesDesign and Optimization of 3D Radial Slot Grain ConfigurationrakeshsakoteNo ratings yet

- Petsoc 2004 097Document10 pagesPetsoc 2004 0979412ttjNo ratings yet

- Matlab ConcreteDocument8 pagesMatlab ConcreteMichael Asmith UniqueNo ratings yet

- Alvarado - Rodriguez Et AlDocument8 pagesAlvarado - Rodriguez Et AlCarlos AlvaradoNo ratings yet

- IET Image Processing - 2013 - Naskar - Histogram Bin Shifting Based Reversible Watermarking For Colour ImagesDocument12 pagesIET Image Processing - 2013 - Naskar - Histogram Bin Shifting Based Reversible Watermarking For Colour ImagesRuchira NaskarNo ratings yet

- Path Planning For An Industrial Robotic ArmDocument7 pagesPath Planning For An Industrial Robotic ArmZahid IqbalNo ratings yet

- Cascade Structural Sizing Optimization With Large Numbers of Design VariablesDocument17 pagesCascade Structural Sizing Optimization With Large Numbers of Design Variablespraveen kumarNo ratings yet

- Panel Caving Scheduling Under Precedence Constraints Considering Mining SystemDocument17 pagesPanel Caving Scheduling Under Precedence Constraints Considering Mining SystemJose ChambillaNo ratings yet

- The Development of Computational Model Through Reverse Engineering - Side Mirror Case StudyDocument18 pagesThe Development of Computational Model Through Reverse Engineering - Side Mirror Case StudywanameiNo ratings yet

- Ai-Accelerated CFD Simulation Based On Openfoam and Cpu/Gpu ComputingDocument14 pagesAi-Accelerated CFD Simulation Based On Openfoam and Cpu/Gpu ComputingCihat EnsarioğluNo ratings yet

- Reverse Engineering Using A Knowledge-Based Approach: Alexandre DuruptDocument17 pagesReverse Engineering Using A Knowledge-Based Approach: Alexandre DuruptAparna DuggiralaNo ratings yet

- Prototyping Strategies For The Agile Development of Additive Manufactured Products: A Case Study From The COVID-19 PandemicDocument8 pagesPrototyping Strategies For The Agile Development of Additive Manufactured Products: A Case Study From The COVID-19 Pandemicmahmoud sameerNo ratings yet

- Aerodynamic Optimization Design of Centrifugal Compressor's Impeller With Kriging ModelDocument9 pagesAerodynamic Optimization Design of Centrifugal Compressor's Impeller With Kriging ModelGeorge Guimarães Dias SiqueiraNo ratings yet

- Automatic Generation of A Pattern of Geometric Features For Industrial DesignDocument16 pagesAutomatic Generation of A Pattern of Geometric Features For Industrial DesignDiego AndradeNo ratings yet

- 3d Image Processing RobotDocument8 pages3d Image Processing RobotIJRASETPublicationsNo ratings yet

- Energies 14 02197 v2Document27 pagesEnergies 14 02197 v2quang tranNo ratings yet

- Genetic Algorithm Based Optimization Model For Time-Cost Trade-Off For Construction ProjectDocument12 pagesGenetic Algorithm Based Optimization Model For Time-Cost Trade-Off For Construction ProjectIJRASETPublicationsNo ratings yet

- Journal of Building Engineering: SciencedirectDocument10 pagesJournal of Building Engineering: SciencedirectKiflom BirhaneNo ratings yet

- Dditive Manufacturing Process Design With Differentiable SimulationsDocument12 pagesDditive Manufacturing Process Design With Differentiable SimulationsRasha KaNo ratings yet

- Mining Course Program - PT. Stania Bara ConsultingDocument7 pagesMining Course Program - PT. Stania Bara ConsultingWira Aulia Fadhil PNo ratings yet

- Innovations in T-Way Test Creation Based On A Hybrid Hill Climbing-Greedy AlgorithmDocument12 pagesInnovations in T-Way Test Creation Based On A Hybrid Hill Climbing-Greedy AlgorithmIAES IJAINo ratings yet

- Optimal Solution For Multi-Objective Facility Layout Problem Using Genetic AlgorithmDocument7 pagesOptimal Solution For Multi-Objective Facility Layout Problem Using Genetic AlgorithmshubNo ratings yet

- Electronic SurveyingDocument4 pagesElectronic SurveyingKirti SharmaNo ratings yet

- Explainable Artificial Intelligence For Manufacturing Cost Estimation and Machining Feature VisualizationDocument20 pagesExplainable Artificial Intelligence For Manufacturing Cost Estimation and Machining Feature VisualizationadsxzNo ratings yet

- Prod - Plann. ProblemDocument6 pagesProd - Plann. ProblembalakaleesNo ratings yet

- Waste Classification Using Convolutional Neural NetworkDocument7 pagesWaste Classification Using Convolutional Neural NetworkIJRASETPublicationsNo ratings yet

- Perhitungan Luas Penulangan Metode Bisection Pada Kolom: Biaxial Menggunakan Delphi Dengan Rumus BreslerDocument8 pagesPerhitungan Luas Penulangan Metode Bisection Pada Kolom: Biaxial Menggunakan Delphi Dengan Rumus BreslerNurul AdawiyahNo ratings yet

- Automatic FE Modeling and Parameterization in GeotDocument17 pagesAutomatic FE Modeling and Parameterization in GeotJuan BrugadaNo ratings yet

- Minimization of Casting Defects Using Casting Simulation Technique and Casting Defects Analysis Using Design of ExperimentDocument6 pagesMinimization of Casting Defects Using Casting Simulation Technique and Casting Defects Analysis Using Design of ExperimentruturajNo ratings yet

- A27-Article 1686731246Document12 pagesA27-Article 1686731246Safiye SencerNo ratings yet

- Tutorial CGASEDocument18 pagesTutorial CGASEoipiniNo ratings yet

- A30-Article 1687707235Document11 pagesA30-Article 1687707235Safiye SencerNo ratings yet

- Simulation Algorithm For The Integration of Solar and Farming Systems On Tropical FaçadesDocument10 pagesSimulation Algorithm For The Integration of Solar and Farming Systems On Tropical FaçadesThong Diep TruongNo ratings yet

- ISCSM 2018 KapageridisI - Etal.Document17 pagesISCSM 2018 KapageridisI - Etal.Sondang BerlianNo ratings yet

- Optimizing Exhibition Spaces: A Multi-Objective ApproachDocument10 pagesOptimizing Exhibition Spaces: A Multi-Objective ApproachKhawla EbrhimNo ratings yet

- Computers and Operations Research: Franco Quezada, Céline Gicquel, Safia Kedad-Sidhoum, Dong Quan VuDocument15 pagesComputers and Operations Research: Franco Quezada, Céline Gicquel, Safia Kedad-Sidhoum, Dong Quan VuQuỳnh NguyễnNo ratings yet

- DOE-Exercise CHOptimizer Design Space EstimationDocument15 pagesDOE-Exercise CHOptimizer Design Space EstimationNeelesh GangwarNo ratings yet

- Acs Iecr 7b05173Document10 pagesAcs Iecr 7b05173minh leNo ratings yet

- Determination of Optimum Drawpoint Layout in Block Caving Using Sequential Gaussian SimulationDocument12 pagesDetermination of Optimum Drawpoint Layout in Block Caving Using Sequential Gaussian SimulationDiego Ignacio VelizNo ratings yet

- Bell Crank White PaperDocument9 pagesBell Crank White PaperagniflameNo ratings yet

- Key Scientific Knowledge and CurriculumDocument4 pagesKey Scientific Knowledge and Curriculumapi-269943051No ratings yet

- The Picture of Dorian Gray Essay ThesisDocument8 pagesThe Picture of Dorian Gray Essay Thesismichellejohnsoncharleston100% (2)

- Employment News 2024, 1,00,000+ Vacancies - 2430Document50 pagesEmployment News 2024, 1,00,000+ Vacancies - 2430Devang BorahNo ratings yet

- NTCC Sem 6 2023 by Ulmasbek SattorovDocument9 pagesNTCC Sem 6 2023 by Ulmasbek SattorovShokhrukhNo ratings yet

- Alok Industries Stock Soars 9 Times in 4 MonthsDocument2 pagesAlok Industries Stock Soars 9 Times in 4 MonthsAryan KapoorNo ratings yet

- Psychobiography of Cristiano Ronaldo: BY RAVINDER SINGH (A00251515)Document11 pagesPsychobiography of Cristiano Ronaldo: BY RAVINDER SINGH (A00251515)Ravi DhillonNo ratings yet

- LVACWS Bermuda - Economic Impact Assessment - Feb 25 16Document19 pagesLVACWS Bermuda - Economic Impact Assessment - Feb 25 16BernewsAdminNo ratings yet

- Subject: Introductory Concepts and Petroleum Systems Genetic Classification (Demaison & Huizinga, 1994) - Answers in English or Portuguese LanguageDocument4 pagesSubject: Introductory Concepts and Petroleum Systems Genetic Classification (Demaison & Huizinga, 1994) - Answers in English or Portuguese LanguageAdeAdhyaksaNo ratings yet

- FE Yeet Trolling GUIDocument3 pagesFE Yeet Trolling GUIBy BobNo ratings yet

- Belden 7807A DatasheetDocument3 pagesBelden 7807A DatasheetAMNo ratings yet

- Group 2Document135 pagesGroup 2arpitshahNo ratings yet

- Unimog Factsheet-Uge-Uhe-EnDocument42 pagesUnimog Factsheet-Uge-Uhe-EnKsar BenitoNo ratings yet

- 5 - Financial Analysis of Combine Harvester DC 70Document10 pages5 - Financial Analysis of Combine Harvester DC 70metaladhayNo ratings yet

- (Template) Project Management Draft OutputDocument63 pages(Template) Project Management Draft OutputAnonymous DTdeag3SP7No ratings yet

- EN - GEF - C.62 - 03 - Summary of Negotiations of The 8th Replenishment of The GEF Trust FundDocument293 pagesEN - GEF - C.62 - 03 - Summary of Negotiations of The 8th Replenishment of The GEF Trust FundJuan Diego VargasNo ratings yet

- Ajay Kumar (Iocl)Document15 pagesAjay Kumar (Iocl)Ajay GuptaNo ratings yet

- James Becker 2014Document1 pageJames Becker 2014Jim BeckerNo ratings yet

- Vhe Economizer For Deodorization and Physical Refining of Fats and OilsDocument2 pagesVhe Economizer For Deodorization and Physical Refining of Fats and Oilsmostafizur rahmanNo ratings yet

- Myeloproliferative DisorderDocument36 pagesMyeloproliferative DisorderKalpana ShahNo ratings yet

- AES 31 10 2022 385 J.SrilathaDocument9 pagesAES 31 10 2022 385 J.SrilathaMuruga NandhanNo ratings yet

- CCL PDFDocument7 pagesCCL PDFSangeetha RajgopalNo ratings yet

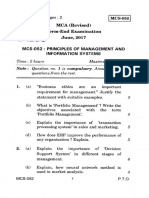

- MCS-052 MCA (Revised) Term-End Examination June, 2017: Principles of Management and Information SystemsDocument2 pagesMCS-052 MCA (Revised) Term-End Examination June, 2017: Principles of Management and Information SystemsOm Prakash MishraNo ratings yet

- IM EAMC ENDORSEMENT (Updated Feb 2020)Document7 pagesIM EAMC ENDORSEMENT (Updated Feb 2020)Joshua Elijah ArsenioNo ratings yet