Professional Documents

Culture Documents

Fiche-En374 en

Uploaded by

Phạm Thu HuyềnOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fiche-En374 en

Uploaded by

Phạm Thu HuyềnCopyright:

Available Formats

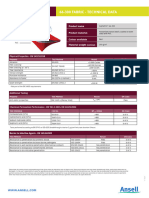

The novelties of

the European Standard EN 374

Protective gloves against dangerous

chemicals and micro-organisms

Personal Protective Equipment

PROTECTIVE GLOVES COMMISSION

- Ensure that the glove is not subjected to a contact of a duration longer than the breakthrough time

- When using water based chemicals that may strongly degrade the glove’s material (e.g. 96% sulfuric acid,

65% nitric acid), the glove may be recommended to protect against accidental splashes only, even if the

The various parts of the EN374 Standard have been largely amended in the last years. Let us breakthrough time is measured high. In such case, the test shows a highly visible degradation of the glove

explain the main changes, which are summarized below: (turning brownish, cracks, stiffening…), that can be detected by the end-user, and a low performance level.

2. Second change : new chemicals have been added to the initial table

New version Title Main changes

EN ISO 374-1 : 2016 Terminology and performance - Protection types and associated pictograms

replacing requirements for chemical risks. - Determination of the performance List of test chemicals (Table 2 - EN ISO 374-1 :2016)

EN 374-1 : 2003 - List of test chemicals

- Case of gloves with long cuff

Code Chemical CAS Number Class

EN 374-2 : 2014 Determination of resistance to - The AQL is removed (an AQL is the responsibility

remplace penetration. of the manufacturer and cannot be checked by a A Methanol 67-56-1 Primary alcohol

EN374-2 : 2003 Notified Body)

EN 16523-1 : 2015 Determination of material - No major change of the permeation test B Acetone 67-64-1 Ketone

remplace resistance to permeation by method, which becomes the unique test method

C Acetonitrile 75-05-8 Nitrile compound

EN 374-3 : 2003 chemicals -Part 1 : Permeation by to determine resistance to permeation (by liquid

liquid chemical under conditions chemicals under conditions of continuous contact) D Dichloromethane 75-09-2 Chlorinated hydrocarbon

of continuous contact. of the materials used in manufacturing protective

garments, gloves and shoes. Sulphur containing organic

E Carbon disulphide 75-15-0

compound

EN 374-4 : 2013 Determination of resistance to - New standard F Toluene 108-88-3 Aromatic hydrocarbon

degradation by chemicals. - Compulsory test for all chemicals tested in

permeation G Diethylamine 109-89-7 Amine

- No level of performance

- The test result must be included in the information H Tetrahydrofuran 109-99-9 Heterocyclic and ether compound

supplied with the gloves

I Ethyl acetate 141-78-6 Ester

EN ISO 374-5 : 2016 Terminology and performance - New standard

requirements for micro- - Specific test to claim protection against viruses

J n-Heptane 142-82-5 Saturated hydrocarbon

organisms risks.

K Sodium hydroxide 40% 1310-73-2 Inorganic base

L Sulphuric acid 96% 7664-93-9 Inorganic mineral acid, oxidizing

Latest developments :

- EN ISO 374-1 : 2016 : an amendment for editorial corrections has been published in July 2018; M Nitric acid 65% 7697-37-2 Inorganic mineral acid, oxidizing

- EN 374-2 et EN 374-4 : these standards will become EN ISO standards in 2020.

Hereafter are some essential details of these changes : N Acetic acid 99% 64-19-7 Organic acid

O Ammonium hydroxide 25% 1336-21-6 Inorganic base

P Hydrogen peroxide 30% 7722-84-1 Peroxide

EN ISO 374-1 : 2016

S Hydrofluoric acid 40% 7664-39-3 Inorganic mineral acid

1. First change : Only one pictogram remains for a chemical protective glove, with three T Formaldehyde 37% 50-00-0 Aldehyde

types defined according to the level of performance

Type Exigence Exemple de marquage

Type A - Liquidproof (EN 374-2) EN ISO 374-1/Type A

- Breakthrough time ≥ 30 min – Level 2 (EN 16523-1) for at least

3. Third change : For gloves designed with a long cuff, with a total length of 400mm or more,

6 products in the list the tests must be performed on specimens taken out of the glove’s palm area and at 80mm

- Degradation test result (EN 374-4) provided with the from the end of the cuff.

information supplied with the gloves The permeation performance level is based on the lowest result between the palm and the cuff.

AJKLPR

Type B - Liquidproof (EN 374-2) EN ISO 374-1/Type B

- Breakthrough time ≥ 30 min – Level 2 (EN 16523-1) for at least

3 products in the list

- Degradation test result (EN 374-4) provided with the Quick reminder on the principles of chemical resistance :

information supplied with the gloves

JKL

Type C - Liquidproof (EN 374-2) EN ISO 374-1/Type C Resistance to penetration (liquidproofness) :

- Breakthrough time ≥ 10 min – Level 1 (EN 16523-1) for at least the glove shall not leak when subjected to the air and water leak tests.

1 product in the list

- Degradation test result (EN 374-4) provided with the Resistance to permeation, breakthrough time :

information supplied with the gloves measure of the time taken by a chemical in contact with the external

surface of the glove to be detected inside the glove.

Note 1 : Thus the following pictogram disappears. Resistance to degradation :

measure of the change in puncture resistance according to EN 388,

Note 2 : The degradation test result, as well as the breakthrough time of the permeation test may help the after a one hour contact of the external surface of the glove with the

end-user in selecting and using the glove in a proper manner. Of course it is not directly giving a recommended chemical. It is also possible to measure the weight change of the glove

usage time, the latter depends on the condition of use (continuous or repeated contacts or risk of splashes, sample.

temperatures, movements and stresses on the glove etc.). Nevertheless, some principles may be given :

EN ISO 374-5 : 2016

Changement : Un essai spécifique selon la méthode B de la norme ISO 16604 :2004 doit être

pratiqué pour prétendre protéger contre les virus. Il existe en conséquence deux marquages

possibles :

Protection Requirement Example of marking

Against - Liquidproof (EN 374-2). EN ISO 374-5

bacteria

and fungi

Against - Liquidproof (EN 374-2) EN ISO 374-5

bacteria, - No detection according to EN 16604 :2004 method B

fungi and (bacteriophage Phi-X 174)

virus

VIRU

How to apply the revised EN374 standards ?

As soon as published on the OJEU (Official Journal of the European Union), the revised standards become the

new reference document for any certification of a new product.

For existing products, it is not necessary to rush to have the certification revised. Nevertheless, it is reminded

that the new PPE regulation requires a new certification, with the following considerations :

- PPE manufactured and placed on the European market before April 21, 2019 according to the Directive, may

continue be sold on the market after this date. Their CE certificate will remain valid until April 21, 2023, or until

their CE certificate expire, if an expiry date is given on the CE certificate.

- PPE manufactured after April 21, 2019 shall comply with the Regulation. Compliance may be based on the CE

certificate according to the Directive but it will need renewal, also as per the newest EN 374 standards, at the

latest by April 21, 2023 if they do not have an expiry date, or otherwise at the latest once the former certificate

has expired.

Moreover, it is recommended to update the certification if the CE-certificate is older than 5 years, in order to

prevent difficulties with state organizations such as the customs services.

For more information...

The different parts of the EN (ISO) 374 standard as well as the EN 16523-1 standard may be purchased on the

site of your standard organization, such as (for France) : www.boutique.afnor.org/

Syndicat national des acteurs du marché de la prévention et de la protection

21 rue Leblanc - 75015 PARIS

Tél. : 01 79 97 75 10 - Fax : 01 79 97 75 15

info@synamap.fr - www.synamap.fr

You might also like

- Maquette 14 06 Leaflet - Norme 374 Retenu en EcranDocument2 pagesMaquette 14 06 Leaflet - Norme 374 Retenu en Ecranrenny krisnawatiNo ratings yet

- Astm D2140 97Document3 pagesAstm D2140 97Narges alikhaniNo ratings yet

- Phosphate Ester Based Fluids For Turbine Lubrication and Steam Turbine Electro-Hydraulic Control (EHC) ApplicationsDocument5 pagesPhosphate Ester Based Fluids For Turbine Lubrication and Steam Turbine Electro-Hydraulic Control (EHC) ApplicationsJicheng PiaoNo ratings yet

- EN374 Change SummaryDocument11 pagesEN374 Change SummarycanacNo ratings yet

- Efc - Seguridad Industrial - Lakeland - Emn428o PDFDocument2 pagesEfc - Seguridad Industrial - Lakeland - Emn428o PDFMarisol Martinez HuamanNo ratings yet

- EPAPROOF FPCS 08.EN - Rev.11.060917Document8 pagesEPAPROOF FPCS 08.EN - Rev.11.060917Ali HashemiNo ratings yet

- Norma D4378-03 Monitoreo AceitesDocument11 pagesNorma D4378-03 Monitoreo AceitesSebastian DimianNo ratings yet

- Synthite Er 41 Polyurethane Enamel Varnish - DatasheetDocument4 pagesSynthite Er 41 Polyurethane Enamel Varnish - DatasheetJerry Mar LucenaNo ratings yet

- ASTM D 86 - 07b PDFDocument27 pagesASTM D 86 - 07b PDFJulian Felipe Noguera Cruz100% (1)

- Distillation of Petroleum Products at Atmospheric Pressure: Standard Test Method ForDocument27 pagesDistillation of Petroleum Products at Atmospheric Pressure: Standard Test Method ForAcácio AlvesNo ratings yet

- Industry Guide: Food ProcessingDocument4 pagesIndustry Guide: Food ProcessingGheorghita VladNo ratings yet

- EMEAIndustry Guide Machinery Equipment ENDocument4 pagesEMEAIndustry Guide Machinery Equipment ENPhạm Thu HuyềnNo ratings yet

- Micromax NS Coolsuit: Technical Data SheetDocument2 pagesMicromax NS Coolsuit: Technical Data Sheetwilson sepulveda carvajalinoNo ratings yet

- D6074 PDFDocument8 pagesD6074 PDFCorina StanculescuNo ratings yet

- r2000 Fr3 Data Sheet - 10-21Document8 pagesr2000 Fr3 Data Sheet - 10-21Dirt FilterNo ratings yet

- Evaluation of Hydrocarbon-Based Quench Oil: Standard Guide ForDocument9 pagesEvaluation of Hydrocarbon-Based Quench Oil: Standard Guide ForNguyễn Bằng NộiNo ratings yet

- Informed Protected Ahead: Well Well WellDocument4 pagesInformed Protected Ahead: Well Well WellThaís SouzaNo ratings yet

- Astm D4378-22Document19 pagesAstm D4378-22Hani YilmazNo ratings yet

- New GLOVE Standards & RequirementsDocument6 pagesNew GLOVE Standards & RequirementsΚαίτη ΔιαμαντήNo ratings yet

- Epoxy Resins: Standard Specification ForDocument3 pagesEpoxy Resins: Standard Specification Fornicolas fernando cardona valenciaNo ratings yet

- ASTM D-130 (Corrosión)Document6 pagesASTM D-130 (Corrosión)Kratos EspejoNo ratings yet

- Corrosiveness To Copper From Petroleum Products by Copper Strip TestDocument9 pagesCorrosiveness To Copper From Petroleum Products by Copper Strip TestmuhannadNo ratings yet

- Brayco Micronic™ SV/B: DescriptionDocument5 pagesBrayco Micronic™ SV/B: DescriptionAlfonsus W.M.No ratings yet

- Astm D3238Document3 pagesAstm D3238Eder Fajardo ValenciaNo ratings yet

- Astm D 543-06Document7 pagesAstm D 543-06varniktpNo ratings yet

- Microbial Contamination in Fuels and Fuel Systems: Standard Guide ForDocument12 pagesMicrobial Contamination in Fuels and Fuel Systems: Standard Guide ForAlabbas FadhelNo ratings yet

- AffcvDocument2 pagesAffcvValentinNo ratings yet

- Distillation of Petroleum Products at Atmospheric Pressure: Standard Test Method ForDocument22 pagesDistillation of Petroleum Products at Atmospheric Pressure: Standard Test Method Forjohn tanNo ratings yet

- Kerosine: Standard Specification ForDocument3 pagesKerosine: Standard Specification ForDavid CazorlaNo ratings yet

- Acid Number of Crude Oils and Petroleum Products by Catalytic Thermometric TitrationDocument7 pagesAcid Number of Crude Oils and Petroleum Products by Catalytic Thermometric TitrationFanambinantsoa Eddy RAKOTONDRAZAFYNo ratings yet

- Astm D3487-2009 PDFDocument6 pagesAstm D3487-2009 PDFRafael Cruz VazquezNo ratings yet

- Astm D130Document10 pagesAstm D130Rodrigo De la BarreraNo ratings yet

- ASTM D6224 Eksploataciono Praćenje UljaDocument14 pagesASTM D6224 Eksploataciono Praćenje UljaDejan DejanovicNo ratings yet

- D 235 - 99 - Rdizns1sruqDocument4 pagesD 235 - 99 - Rdizns1sruqjuan perezNo ratings yet

- Measurement of Remaining Primary Antioxidant Content in In-Service Industrial Lubricating Oils by Linear Sweep VoltammetryDocument14 pagesMeasurement of Remaining Primary Antioxidant Content in In-Service Industrial Lubricating Oils by Linear Sweep VoltammetryJuan F AlvarezNo ratings yet

- Enersyn RC-S RangeDocument2 pagesEnersyn RC-S RangecarmaNo ratings yet

- TDS AlphaTec 66300 Fabric 2204Document1 pageTDS AlphaTec 66300 Fabric 2204rahmawanianNo ratings yet

- Distillation of Petroleum Products at Atmospheric Pressure: Standard Test Method ForDocument23 pagesDistillation of Petroleum Products at Atmospheric Pressure: Standard Test Method ForM AhmadNo ratings yet

- In-Service Monitoring of Lubricating Oil For Auxiliary Power Plant EquipmentDocument20 pagesIn-Service Monitoring of Lubricating Oil For Auxiliary Power Plant Equipmentمحمد نصیریNo ratings yet

- Tds of Eterset 2844Document2 pagesTds of Eterset 2844Nandkumar PawarNo ratings yet

- Biogrease Ep2Document2 pagesBiogrease Ep2Ciprian AndreescuNo ratings yet

- Astm D2425-19Document14 pagesAstm D2425-19RegianeNo ratings yet

- D095 PDFDocument5 pagesD095 PDFwalterNo ratings yet

- Astm D 2880Document6 pagesAstm D 2880Jherson Ariza GarciaNo ratings yet

- In-Service Monitoring of Mineral Turbine Oils For Steam, Gas, and Combined Cycle TurbinesDocument19 pagesIn-Service Monitoring of Mineral Turbine Oils For Steam, Gas, and Combined Cycle TurbinesEhsan ZiaeiNo ratings yet

- Distillation of Petroleum Products at Atmospheric Pressure: Standard Test Method ForDocument27 pagesDistillation of Petroleum Products at Atmospheric Pressure: Standard Test Method Forpeter gamboaNo ratings yet

- Heat of Combustion of Liquid Hydrocarbon Fuels by Bomb CalorimeterDocument10 pagesHeat of Combustion of Liquid Hydrocarbon Fuels by Bomb CalorimetersaderfendeNo ratings yet

- Astm Contaminacion de Hidrocarburo Con MicroorganismosDocument11 pagesAstm Contaminacion de Hidrocarburo Con Microorganismosfbetzabeth07No ratings yet

- ASTM D 189-06 - Conradson Carbon Residue of Petroleum ProductsDocument7 pagesASTM D 189-06 - Conradson Carbon Residue of Petroleum ProductsAnak AyamNo ratings yet

- ASTM D 524 Residuo Carbonoso PDFDocument8 pagesASTM D 524 Residuo Carbonoso PDFMaria BradaNo ratings yet

- Astm D240Document9 pagesAstm D240waqas ahmadNo ratings yet

- Corrosiveness To Copper From Petroleum Products by Copper Strip TestDocument10 pagesCorrosiveness To Copper From Petroleum Products by Copper Strip TestLuigi MazzuccoNo ratings yet

- Astm D130 PDFDocument10 pagesAstm D130 PDFPedro Alua100% (2)

- Conradson Carbon Residue of Petroleum Products: Standard Test Method ForDocument7 pagesConradson Carbon Residue of Petroleum Products: Standard Test Method ForDan MatNo ratings yet

- Distillation of Petroleum Products at Atmospheric Pressure: Standard Test Method ForDocument27 pagesDistillation of Petroleum Products at Atmospheric Pressure: Standard Test Method ForSebastian DiazNo ratings yet

- Stray Gassing of Mineral OilDocument6 pagesStray Gassing of Mineral OilangelNo ratings yet

- Astm D86Document27 pagesAstm D86dennise8100% (1)

- Ramsbottom Carbon Residue of Petroleum Products: Standard Test Method ForDocument9 pagesRamsbottom Carbon Residue of Petroleum Products: Standard Test Method ForMuhannad NasifNo ratings yet

- Hazardous Gas Monitoring, Fifth Edition: A Guide for Semiconductor and Other Hazardous OccupanciesFrom EverandHazardous Gas Monitoring, Fifth Edition: A Guide for Semiconductor and Other Hazardous OccupanciesNo ratings yet

- Billions BLR-895 Titanium Dioxide TDSDocument1 pageBillions BLR-895 Titanium Dioxide TDSPhạm Thu HuyềnNo ratings yet

- Astm D-7558-09Document5 pagesAstm D-7558-09Phạm Thu HuyềnNo ratings yet

- Preparation of Vinyl Acetate Grafted Natural Rubber by Irradiation MethodDocument6 pagesPreparation of Vinyl Acetate Grafted Natural Rubber by Irradiation MethodPhạm Thu HuyềnNo ratings yet

- Astm D 1076-02 Standard Specification For Rubber-Concentrated, Ammonia Preserved, Creamed, and Centrifuged Natural LatexDocument12 pagesAstm D 1076-02 Standard Specification For Rubber-Concentrated, Ammonia Preserved, Creamed, and Centrifuged Natural LatexGianinaRoncalChávez100% (1)

- Astm F-739 Prueba Resistencia A QuimicosDocument11 pagesAstm F-739 Prueba Resistencia A Quimicosjaire esparza0% (1)

- Thermometer - WISEDocument4 pagesThermometer - WISEPhạm Thu HuyềnNo ratings yet

- Technological and Physical Properties of A New Low Antigenic Protein Natural Rubber LatexDocument8 pagesTechnological and Physical Properties of A New Low Antigenic Protein Natural Rubber LatexPhạm Thu HuyềnNo ratings yet

- Haidzir 2010 Stress RelaxationDocument14 pagesHaidzir 2010 Stress RelaxationPhạm Thu HuyềnNo ratings yet

- ISO-23464-2020 - Nitrile Cleanroom GlovesDocument9 pagesISO-23464-2020 - Nitrile Cleanroom GlovesPhạm Thu HuyềnNo ratings yet

- Acsomega 0c04964Document7 pagesAcsomega 0c04964Phạm Thu HuyềnNo ratings yet

- 5-Clean Room Handbook 2 - 1 - 3Document80 pages5-Clean Room Handbook 2 - 1 - 3Phạm Thu HuyềnNo ratings yet

- E691-99 - Determine The PrecisionDocument22 pagesE691-99 - Determine The PrecisionPhạm Thu HuyềnNo ratings yet

- Contamination of Critical Surfaces From NVR Glove Residues Via Dry Handling and Solvent CleaningDocument17 pagesContamination of Critical Surfaces From NVR Glove Residues Via Dry Handling and Solvent CleaningPhạm Thu HuyềnNo ratings yet

- MEDICAL DEVICES: Guidance DocumentDocument15 pagesMEDICAL DEVICES: Guidance DocumentPhạm Thu HuyềnNo ratings yet

- ASTM D5511 11 Standard Test Method For Determining Anaerobic Biodegradation of Plastic Materials Under High Solids Anaerobic Digestion ConditionsDocument7 pagesASTM D5511 11 Standard Test Method For Determining Anaerobic Biodegradation of Plastic Materials Under High Solids Anaerobic Digestion ConditionsPhạm Thu HuyềnNo ratings yet

- Room Temperature Prevulcanized NR Latex Compounds FOR BETTER LATEX-Based ProductsDocument8 pagesRoom Temperature Prevulcanized NR Latex Compounds FOR BETTER LATEX-Based Productsรอคนบนฟ้า ส่งใครมาให้ สักคนNo ratings yet

- DD Cen - TS 14234-2002 - enDocument30 pagesDD Cen - TS 14234-2002 - enPhạm Thu HuyềnNo ratings yet

- D 5250 - 00 RduyntaDocument3 pagesD 5250 - 00 RduyntaMaick Steven Arriaga SandiNo ratings yet

- Iso 18113-1Document11 pagesIso 18113-1Josephine YauviraNo ratings yet

- 2020 ArticleDocument10 pages2020 ArticlePhạm Thu HuyềnNo ratings yet

- Astm D1331-1989Document5 pagesAstm D1331-1989Phạm Thu HuyềnNo ratings yet

- Nitrile Examination Gloves For Medical ApplicationDocument4 pagesNitrile Examination Gloves For Medical ApplicationPhạm Thu HuyềnNo ratings yet

- Rubber Surgical Gloves: Standard Specification ForDocument4 pagesRubber Surgical Gloves: Standard Specification ForRaya TahomaNo ratings yet

- Swell Test GlovesDocument41 pagesSwell Test GlovesPhạm Thu HuyềnNo ratings yet

- BS en 455-2-2015Document16 pagesBS en 455-2-2015QC apollohxNo ratings yet

- BS en 455-4-2009Document22 pagesBS en 455-4-2009QC apollohx100% (1)

- Iso 18113-1Document11 pagesIso 18113-1Josephine YauviraNo ratings yet

- Iso 18113-1Document11 pagesIso 18113-1Josephine YauviraNo ratings yet

- Iso 1409 2006Document9 pagesIso 1409 2006Phạm Thu HuyềnNo ratings yet

- 1 Property DataDocument3 pages1 Property Dataapi-361935872No ratings yet

- 1-Compleximetric Determination of Water HardnessDocument51 pages1-Compleximetric Determination of Water HardnessBeatrice Del RosarioNo ratings yet

- 3rd SUMMATIVE TEST IN PHYSICAL SCIENCEDocument1 page3rd SUMMATIVE TEST IN PHYSICAL SCIENCEMark Gil SusonNo ratings yet

- TCP - IDocument35 pagesTCP - IPrashant GauravNo ratings yet

- (Term II) : QuestionsDocument11 pages(Term II) : QuestionsHaslimi Bin HassanNo ratings yet

- Chemical and Physical Properties of Sulphur Dioxide and Sulphur TrioxideDocument12 pagesChemical and Physical Properties of Sulphur Dioxide and Sulphur TrioxideAnonymous Qo0kU6No ratings yet

- Liebermann-Burchard Test For Cholesterol: by Sherwin Carl R. DimacutacDocument13 pagesLiebermann-Burchard Test For Cholesterol: by Sherwin Carl R. DimacutacFrancis ValdezNo ratings yet

- Comparision of CTE Values of Different MaterialsDocument107 pagesComparision of CTE Values of Different MaterialsPurvesh NanavatiNo ratings yet

- English-Cht Catalase BFDocument2 pagesEnglish-Cht Catalase BFasebaei95No ratings yet

- Tie DyeDocument2 pagesTie DyeAZIbloodwolf100% (1)

- 56-1-3 (Chemistry)Document16 pages56-1-3 (Chemistry)avineshkushwaha47No ratings yet

- Determination of Total Hardness of Water by EDTA Titration.Document3 pagesDetermination of Total Hardness of Water by EDTA Titration.Saharbano awanNo ratings yet

- COMPLEXATIONDocument22 pagesCOMPLEXATIONAgilandeswari Devarajan100% (1)

- D513 Total and Dissolved Co2 in Water PDFDocument8 pagesD513 Total and Dissolved Co2 in Water PDFArunkumar ChandaranNo ratings yet

- Geopolymer Camp 2019-Ferro-Sialate GeopolymerDocument16 pagesGeopolymer Camp 2019-Ferro-Sialate GeopolymerAlviona KabanNo ratings yet

- Fats Igcse Biology: Fats Are Also Known As LIPIDSDocument10 pagesFats Igcse Biology: Fats Are Also Known As LIPIDSRufaro MhariwaNo ratings yet

- Alkyl Halides & Aryl Halides: Victor GrignardDocument50 pagesAlkyl Halides & Aryl Halides: Victor GrignardsarahNo ratings yet

- HP DecalcificationDocument7 pagesHP DecalcificationMalliga SundareshanNo ratings yet

- Comprehensive Coordination Chemistry Volumen 2 PDFDocument833 pagesComprehensive Coordination Chemistry Volumen 2 PDFJennifer Carolina Rosales NoriegaNo ratings yet

- 1956 - Rapid Colorimetric Methods For Simultaneous Determination of Total Reducing Sugars and Fructose in Citrus Juices PDFDocument4 pages1956 - Rapid Colorimetric Methods For Simultaneous Determination of Total Reducing Sugars and Fructose in Citrus Juices PDFbryanNo ratings yet

- Ninhydrin MethodDocument10 pagesNinhydrin MethodttnduyNo ratings yet

- Experiment 9Document5 pagesExperiment 9Rohit BiswasNo ratings yet

- Urea SynthesisDocument25 pagesUrea SynthesisMuhammad YasirNo ratings yet

- US20030075077A1Document12 pagesUS20030075077A1Kyaw Kyaw LinnNo ratings yet

- Isa 71.04 1985Document22 pagesIsa 71.04 1985Sergio LungrinNo ratings yet

- ChemicalDocument44 pagesChemicalLal BaloushiNo ratings yet

- Leaving Certificate Chemistry Student Laboratory Notebook Teacher's ManualDocument42 pagesLeaving Certificate Chemistry Student Laboratory Notebook Teacher's ManualMusdq Chowdhury0% (1)

- To Determine The Boiling Point of Organic Compounds Like Benzene and BenzaldehydeDocument8 pagesTo Determine The Boiling Point of Organic Compounds Like Benzene and BenzaldehydeSadhvik ReddyNo ratings yet

- CHE-501Carboranes and Boranes Metal ClusterDocument40 pagesCHE-501Carboranes and Boranes Metal Clusteranuthakur100% (1)