Professional Documents

Culture Documents

CRCW... C E3: Vishay

CRCW... C E3: Vishay

Uploaded by

Lab TyrcoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CRCW... C E3: Vishay

CRCW... C E3: Vishay

Uploaded by

Lab TyrcoCopyright:

Available Formats

CRCW...

C e3

www.vishay.com

Vishay

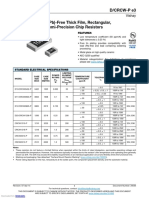

Lead (Pb)-free Thick Film, Rectangular

Commodity Chip Resistors

FEATURES

• High volume product suitable for commercial

applications

• Stability (R/R 1 % for 1000 h at 70 °C)

• Lead (Pb)-free solder contacts on Ni barrier

layer

• Metal glaze on ceramic

• Material categorization: for definitions of compliance

please see www.vishay.com/doc?99912

STANDARD ELECTRICAL SPECIFICATIONS

LIMITING

CASE CASE POWER RATING TEMPERATURE RESISTANCE

ELEMENT TOLERANCE

MODEL SIZE SIZE P70 °C COEFFICIENT RANGE E-SERIES

VOLTAGE %

INCH METRIC W ppm/K

MAX. V

± 100 ±1 1R0 to 10M E24; E96

0.063 50

CRCW0402...C 0402 RR 1005M ± 200 ±5 1R0 to 10M E24

Zero-Ohm-Resistor: Rmax. = 20 m, Imax. at 70 °C = 1.5 A

± 100 ±1 1R0 to 10M E24; E96

0.10 75

CRCW0603...C 0603 RR 1608M ± 200 ±5 1R0 to 10M E24

Zero-Ohm-Resistor: Rmax. = 20 m, Imax. at 70 °C = 2.0 A

± 100 ±1 1R0 to 10M E24; E96

0.125 150

CRCW0805...C 0805 RR 2012M ± 200 ±5 1R0 to 10M E24

Zero-Ohm-Resistor: Rmax. = 20 m, Imax. at 70 °C = 2.5 A

± 100 ±1 1R0 to 10M E24; E96

0.25 200

CRCW1206...C 1206 RR 3216M ± 200 ±5 1R0 to 10M E24

Zero-Ohm-Resistor: Rmax. = 20 m, Imax. at 70 °C = 3.5 A

Notes

• These resistors do not feature a limited lifetime when operated within the permissible limits. However, resistance value drift increasing over

operating time may result in exceeding a limit acceptable to the specific application, thereby establishing a functional lifetime

• Power rating depends on the max. temperature at the solder point, the component placement density and the substrate material

TECHNICAL SPECIFICATIONS

PARAMETER UNIT CRCW0402...C CRCW0603...C CRCW0805...C CRCW1206...C

Rated dissipation at 70°C (1) W 0.063 0.10 0.125 0.25

Limiting element voltage

V 50 75 150 200

Umax. AC/DC

Insulation voltage Uins. (1 min) V > 75 > 100 > 200 > 300

Insulation resistance > 109

Category temperature range °C - 55 to + 155

Failure rate h-1 0.1 x 10-9

Weight/1000 pieces g 0.65 2 5.5 10

Note

(1) The power dissipation on the resistor generates a temperature rise against the local ambient, depending on the heat flow support of the

printed-circuit board (thermal resistance). The rated dissipation applies only if the permitted film temperature of 155 °C is not exceeded

Revision: 02-Nov-17 1 Document Number: 28773

For technical questions, contact: ff3aresistors@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Downloaded from Arrow.com.

CRCW...C e3

www.vishay.com

Vishay

PART NUMBER AND PRODUCT DESCRIPTION

PART NUMBER: CRCW0603562RFKECC

C R C W 0 6 0 3 5 6 2 R F K E C C

MODEL/SIZE VALUE TOLERANCE TCR PACKAGING SPECIAL

CRCW0402 R = decimal F = ± 1.0 % K = ± 100 ppm/K EA, EB, Up to 2 digits

CRCW0603 K = thousand J = ± 5.0 % N = ± 200 ppm/K EC, ED, C = commodity

CRCW0805 M = million Z = jumper 0 = jumper EE

CRCW1206 0000 = jumper

PRODUCT DESCRIPTION: CRCW0603-C 100 562R 1 % ET6 E3

CRCW0603-C 100 562R 1% ET6 e3

RESISTANCE

MODEL TCR TOLERANCE PACKAGING LEAD (Pb)-FREE

VALUE

CRCW0402-C ± 200 ppm/K 10R = 10 ±5% ET1, ET5, e3 = pure tin

CRCW0603-C ± 100 ppm/K 562R = 562 ±1% ET6, ET7, termination

CRCW0805-C 10K = 10.0 k EF4 finish

CRCW1206-C 1M = 1 M

0R0 = jumper

PACKAGING

PACKAGING

TYPE / SIZE CODE QUANTITY PACKAGING STYLE WIDTH PITCH

DIMENSIONS

ED = ET7 10 000 Ø 180 mm/7"

CRCW0402…C 2 mm

EE = EF4 50 000 Ø 330 mm/13"

EA = ET1 5000 Ø 180 mm/7"

CRCW0603…C EB = ET5 10 000 4 mm Ø 254 mm/10"

EC = ET6 20 000 Ø 330 mm/13"

Paper tape acc. to

EA = ET1 5000 8 mm Ø 180 mm/7"

IEC 60286-3, Type 1a

CRCW0805…C EB = ET5 10 000 4 mm Ø 254 mm/10"

EC = ET6 20 000 Ø 330 mm/13"

EA = ET1 5000 Ø 180 mm/7"

CRCW1206…C EB = ET5 10 000 4 mm Ø 254 mm/10"

EC = ET6 20 000 Ø 330 mm/13"

DIMENSIONS

SOLDER PAD DIMENSIONS (1) (in millimeters)

SIZE DIMENSIONS (in millimeters)

REFLOW SOLDERING WAVE SOLDERING

INCH METRIC L W H T1 T2 a b l a b l

0402 1005 1.0 ± 0.10 0.5 ± 0.05 0.30 ± 0.05 0.25 ± 0.10 0.2 ± 0.1 0.4 0.6 0.5

0603 1608 1.60 ± 0.10 0.80 ± 0.10 0.45 ± 0.10 0.3 ± 0.2 0.3 ± 0.2 0.5 0.9 1.0 0.9 0.9 1.0

0805 2012 2.0 ± 0.10 1.25 ± 0.15 0.50 ± 0.10 0.35 ± 0.15 0.35 ± 0.2 0.7 1.3 1.2 0.9 1.3 1.3

+ 0.10

1206 3216 3.05 ± 0.10 1.55 ± 0.10 0.55 - 0.05

0.35 ± 0.15 0.45 ± 0.2 0.9 1.7 2.0 1.1 1.7 2.3

Note

(1) The rated dissipation applies only if the permitted film temperature is not exceeded. Furthermore, a high level of ambient temperature or of

power dissipation may raise the temperature of the solder joint, hence special solder alloys or board materials maybe required to maintain

the reliability of the assembly. Specified power rating above 125 °C requires dedicated heat-sink pads, which depend on board materials.

The given solder pad dimensions reflect the considerations for board design and assembly as outlined e.g. in standards IEC 61188-5-x, or

in publication IPC-7351. They do not guarantee any supposed thermal properties, particularly as these are also strongly influenced by many

other parameters. Still the given solder pad dimensions will be found adequate for most general applications

Revision: 02-Nov-17 2 Document Number: 28773

For technical questions, contact: ff3aresistors@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Downloaded from Arrow.com.

CRCW...C e3

www.vishay.com

Vishay

FUNCTIONAL PERFORMANCE

Rated Power in %

120

100

80

60

40

20

0

- 55 - 25 0 25 50 75 100 125 155 175

Derating 70 Ambient Temperature in °C

TEST PROCEDURES AND REQUIREMENTS

REQUIREMENTS PERMISSIBLE

IEC 60068-2 CHANGE (R)

EN 60115-1

TEST TEST PROCEDURE STABILITY STABILITY

CLAUSE

METHOD CLASS 1 CLASS 2

OR BETTER OR BETTER

Stability for product types:

CRCW...C e3 1 to 10 M 1 to 10 M

4.5 - Resistance - ±1% ±5%

Temperature (20/- 55/20) °C and

4.8.4.2 - ± 100 ppm/K ± 200 ppm/K

coefficient (20/125/20) °C

Short time

4.13 - U = 2.5 x P 70 x R 2 x Umax.; 5 s ± (2 % R + 0.1 )

overload

Solder bath method;

Sn60Pb40

Good tinning ( 95 % covered)

non activated flux;

(235 ± 5) °C no visible damage

Pre-aging (2 ± 0.2) s

4.17.5 58 (Td) Solderability 4 h at 155 °C,

dryheat Solder bath method;

Sn96.5Ag3Cu0.5

Good tinning ( 95 % covered)

non activated flux;

(245 ± 5) °C no visible damage

(3 ± 0.3) s

Resistance to Solder bath method

4.18.2 58 (Td) ± (1% R + 0.05 )

soldering heat (260 ± 5) °C; (10 ± 1) s

30 min. at - 55 °C;

Rapid change

4.19 14 (Na) 30 min. at 125 °C; ± (0.25 % R + 0.05 ) ± (0.5 % R + 0.05 )

of temperature

5 cycles

(40 ± 2) °C;

Damp heat,

4.24 78 (Cab) 56 days; ± (1 % R + 0.05 ) ± (2 % R + 0.1 )

steady state

(93 ± 3) % RH

Operation at low

4.36 - -55 °C, 1 h ± (1 % R + 0.05 )

temperature

U = P 70 x R Umax.;

1.5 h on; 0.5 h off;

Endurance

4.25.1 -

at 70 °C 70 °C; 1000 h ± (1 % R + 0.05 ) ± (2 % R + 0.1 )

70 °C; 8000 h ± (2 % R + 0.1 ) ± (4 % R + 0.1 )

Endurance at

4.25.3 - upper category 155 °C, 1000 h ± (1 % R + 0.05 ) ± (2 % R + 0.1 )

temperature

Revision: 02-Nov-17 3 Document Number: 28773

For technical questions, contact: ff3aresistors@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Downloaded from Arrow.com.

CRCW...C e3

www.vishay.com

Vishay

APPLICABLE SPECIFICATIONS

• EN 60115-1 Generic specification

• EN 140400 Sectional specification

• EN 140401-802 Detail specification

• IEC 60068-2-X Variety of environmental test procedures

• IEC 60286-3 Packaging of SMD components

Revision: 02-Nov-17 4 Document Number: 28773

For technical questions, contact: ff3aresistors@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Downloaded from Arrow.com.

Legal Disclaimer Notice

www.vishay.com

Vishay

Disclaimer

ALL PRODUCT, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE TO IMPROVE

RELIABILITY, FUNCTION OR DESIGN OR OTHERWISE.

Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf (collectively,

“Vishay”), disclaim any and all liability for any errors, inaccuracies or incompleteness contained in any datasheet or in any other

disclosure relating to any product.

Vishay makes no warranty, representation or guarantee regarding the suitability of the products for any particular purpose or

the continuing production of any product. To the maximum extent permitted by applicable law, Vishay disclaims (i) any and all

liability arising out of the application or use of any product, (ii) any and all liability, including without limitation special,

consequential or incidental damages, and (iii) any and all implied warranties, including warranties of fitness for particular

purpose, non-infringement and merchantability.

Statements regarding the suitability of products for certain types of applications are based on Vishay's knowledge of typical

requirements that are often placed on Vishay products in generic applications. Such statements are not binding statements

about the suitability of products for a particular application. It is the customer's responsibility to validate that a particular product

with the properties described in the product specification is suitable for use in a particular application. Parameters provided in

datasheets and / or specifications may vary in different applications and performance may vary over time. All operating

parameters, including typical parameters, must be validated for each customer application by the customer's technical experts.

Product specifications do not expand or otherwise modify Vishay's terms and conditions of purchase, including but not limited

to the warranty expressed therein.

Hyperlinks included in this datasheet may direct users to third-party websites. These links are provided as a convenience and

for informational purposes only. Inclusion of these hyperlinks does not constitute an endorsement or an approval by Vishay of

any of the products, services or opinions of the corporation, organization or individual associated with the third-party website.

Vishay disclaims any and all liability and bears no responsibility for the accuracy, legality or content of the third-party website

or for that of subsequent links.

Except as expressly indicated in writing, Vishay products are not designed for use in medical, life-saving, or life-sustaining

applications or for any other application in which the failure of the Vishay product could result in personal injury or death.

Customers using or selling Vishay products not expressly indicated for use in such applications do so at their own risk. Please

contact authorized Vishay personnel to obtain written terms and conditions regarding products designed for such applications.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this document or by

any conduct of Vishay. Product names and markings noted herein may be trademarks of their respective owners.

© 2023 VISHAY INTERTECHNOLOGY, INC. ALL RIGHTS RESERVED

Revision: 01-Jan-2023 1 Document Number: 91000

Downloaded from Arrow.com.

You might also like

- Course Content GCPV DesignDocument1 pageCourse Content GCPV Designfarani87100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- CRCW25123K30JNTG DatasheetzDocument8 pagesCRCW25123K30JNTG DatasheetzVadim ZorinNo ratings yet

- CRCW0201 E3: VishayDocument5 pagesCRCW0201 E3: VishaycuperiniNo ratings yet

- Crcw0805390rfkta PDFDocument8 pagesCrcw0805390rfkta PDFManu MathewNo ratings yet

- SBSM Data SheetDocument4 pagesSBSM Data SheetAlex JonesNo ratings yet

- 694-3 - R10KDocument5 pages694-3 - R10KJosé AdelinoNo ratings yet

- D/CRCW E3: VishayDocument10 pagesD/CRCW E3: VishayBenyamin Farzaneh AghajarieNo ratings yet

- RCS E3: VishayDocument10 pagesRCS E3: VishayMae MegumiNo ratings yet

- DatasheetDocument2 pagesDatasheetOmar LababidiNo ratings yet

- 180 Ohm ResistorDocument11 pages180 Ohm ResistorNidhi PanditNo ratings yet

- 多圈的 /圓形/綫繞/面板式 (Multiturn/ Round/ Wirewound) 2 種轉軸的樣式 (2 Shaft Style) sDocument1 page多圈的 /圓形/綫繞/面板式 (Multiturn/ Round/ Wirewound) 2 種轉軸的樣式 (2 Shaft Style) sjonatan arangoNo ratings yet

- RBV1000 - RBV1010: Silicon Bridge Rectifiers PRV: 50 - 1000 Volts Io: 10 AmperesDocument2 pagesRBV1000 - RBV1010: Silicon Bridge Rectifiers PRV: 50 - 1000 Volts Io: 10 AmperesmaheseeeNo ratings yet

- Resistor 1k - Vishay - 0.6wDocument3 pagesResistor 1k - Vishay - 0.6wLEDNo ratings yet

- Ponte de Diodo RBV3510Document3 pagesPonte de Diodo RBV3510Allyfranhy Nunes AlvesNo ratings yet

- CRCW06032431FRT1Document7 pagesCRCW06032431FRT1鄭建銘(小銘)No ratings yet

- Carbon Film ResistorsDocument2 pagesCarbon Film ResistorsGopichandNo ratings yet

- D/CRCW-P E3: VishayDocument6 pagesD/CRCW-P E3: VishayMohendra PatiNo ratings yet

- ABNTC-0201: MSL Level: 2A (This Product Is Packed With Dry Packaging)Document3 pagesABNTC-0201: MSL Level: 2A (This Product Is Packed With Dry Packaging)ricky syandiNo ratings yet

- Bour S A0011536976 1Document4 pagesBour S A0011536976 1Alex Prim NavajasNo ratings yet

- NIC Components NLQ SeriesDocument4 pagesNIC Components NLQ SeriesNICCompNo ratings yet

- Aluminum Single-Point Load Cell Aluminum Single-Point Load CellDocument3 pagesAluminum Single-Point Load Cell Aluminum Single-Point Load CellMakhis RifaiNo ratings yet

- Sfr16S/25/25H: Vishay BccomponentsDocument11 pagesSfr16S/25/25H: Vishay BccomponentsMuhammad BilalNo ratings yet

- 250 VAC, +85 °C: - RC Unit, Class X1, Metallized Paper With Integrated Resistor - 0.022 - 0.1 F, 100Document2 pages250 VAC, +85 °C: - RC Unit, Class X1, Metallized Paper With Integrated Resistor - 0.022 - 0.1 F, 100alonso leonNo ratings yet

- 2864 VT DS 2864-EN 614 LoresDocument3 pages2864 VT DS 2864-EN 614 Lorestulio enrique leon ayalaNo ratings yet

- T491 Series Industrial Grade Mno: Tantalum Surface Mount Capacitors - Standard TantalumDocument24 pagesT491 Series Industrial Grade Mno: Tantalum Surface Mount Capacitors - Standard TantalumSebastian ChaileNo ratings yet

- AWCCA-48R32 Series: Moisture Sensitivity Level (MSL) - MSL 1Document2 pagesAWCCA-48R32 Series: Moisture Sensitivity Level (MSL) - MSL 1cbdk71No ratings yet

- Bourns CRM2512 DatasheetDocument5 pagesBourns CRM2512 DatasheetbarisNo ratings yet

- Vishay Dale: FeaturesDocument4 pagesVishay Dale: FeaturesFouquetNo ratings yet

- Capacitor 104j63Document4 pagesCapacitor 104j63Peter PeterNo ratings yet

- ATBI2012Document2 pagesATBI2012marina anastasovaNo ratings yet

- NIC Components NRCEDocument2 pagesNIC Components NRCENICCompNo ratings yet

- Inbound 1310313221Document2 pagesInbound 1310313221freedownNo ratings yet

- Resistor SMD SizesDocument11 pagesResistor SMD Sizescarlos.antouryNo ratings yet

- Tension Compression Load Cell Tension Compression Load Cell: Model 614Document3 pagesTension Compression Load Cell Tension Compression Load Cell: Model 614Juan Carlos BallinariNo ratings yet

- MKP 1840Document4 pagesMKP 1840api-3701386No ratings yet

- NIC Components NRSJ SeriesDocument5 pagesNIC Components NRSJ SeriesNICCompNo ratings yet

- Cement Coated Wirewound Resistors: Electrical DataDocument2 pagesCement Coated Wirewound Resistors: Electrical DataTanay ShahNo ratings yet

- Abd 0000 Ce 6 Pto 47 Uf 100 VbseriesDocument6 pagesAbd 0000 Ce 6 Pto 47 Uf 100 VbseriesIrvin FrederickNo ratings yet

- CRT0603 PX 2321elfDocument4 pagesCRT0603 PX 2321elfFernando MarquezNo ratings yet

- Wing 24 OPzV 3000 EN201711 1Document1 pageWing 24 OPzV 3000 EN201711 1Daniel SepulvedaNo ratings yet

- Vishay Resistors Precision mpr24Document7 pagesVishay Resistors Precision mpr24SamaelNo ratings yet

- Isa-Plan // Precision Resistors: SMV-PW // Size 4723Document3 pagesIsa-Plan // Precision Resistors: SMV-PW // Size 4723AliNo ratings yet

- (Safety Regulations) : Ceramic Disc CapacitorsDocument6 pages(Safety Regulations) : Ceramic Disc CapacitorsPedro GomezNo ratings yet

- NF C 33 226 12 20 24 KV CableDocument3 pagesNF C 33 226 12 20 24 KV CableIrvan FauziNo ratings yet

- RCA-HP E3: Vishay DraloricDocument10 pagesRCA-HP E3: Vishay DraloricMohendra PatiNo ratings yet

- RBV5006Document3 pagesRBV5006Adah BumboneNo ratings yet

- Fixed Carbon Composition Resistors: CharacteristicsDocument3 pagesFixed Carbon Composition Resistors: CharacteristicsHiru SegwayNo ratings yet

- Eng DS 1773193 1 B-2888555Document4 pagesEng DS 1773193 1 B-2888555diego234.axelNo ratings yet

- Ω), Surface Mount: Vishay DaleDocument3 pagesΩ), Surface Mount: Vishay DaleRodrigo BronzeriNo ratings yet

- Excel Shortcuts CFIDocument19 pagesExcel Shortcuts CFIRAVICHANDRAN LNo ratings yet

- MT Series: SpecificationsDocument2 pagesMT Series: SpecificationsEnrique Sanchez (KicKeWoW)No ratings yet

- Resistencia 220 Ohm 5 W PDFDocument2 pagesResistencia 220 Ohm 5 W PDFAndrés JassoNo ratings yet

- Surface Mount Aluminum Electrolytic Capacitors: NACE SeriesDocument5 pagesSurface Mount Aluminum Electrolytic Capacitors: NACE SeriesNICCompNo ratings yet

- SRF0905A Series - Line Filter: FeaturesDocument4 pagesSRF0905A Series - Line Filter: FeaturesIbai BiNo ratings yet

- DatasheetDocument3 pagesDatasheetDAVID FELIPE RUIZ BENITEZNo ratings yet

- 14D Series Metal-Oxide Varistor: FeaturesDocument3 pages14D Series Metal-Oxide Varistor: Featuresch_menesesNo ratings yet

- 10 Series: Axial Wire Element Current Sense Two Terminal AxialDocument2 pages10 Series: Axial Wire Element Current Sense Two Terminal AxialWagner de LeonNo ratings yet

- Excelitas VTB6061UVJH DatasheetDocument1 pageExcelitas VTB6061UVJH DatasheetJosé FariaNo ratings yet

- Capacitor For Power Electronics: R Tanδδδδ CxrDocument6 pagesCapacitor For Power Electronics: R Tanδδδδ Cxrraza239No ratings yet

- MP 42 High Capacity Single Point Load Cell: 50kg 500kg Type N/C3Document2 pagesMP 42 High Capacity Single Point Load Cell: 50kg 500kg Type N/C3aziz ttlNo ratings yet

- MBI5026Document16 pagesMBI5026Racer RacerNo ratings yet

- EMI Testing Using Spectrum Analyzers vs. Test Receivers: Vic Hudson Rohde&SchwarzDocument38 pagesEMI Testing Using Spectrum Analyzers vs. Test Receivers: Vic Hudson Rohde&SchwarzLOUKILkarimNo ratings yet

- Distance ProtectionDocument5 pagesDistance ProtectionVelu SamyNo ratings yet

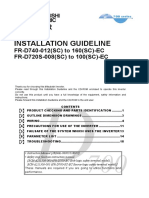

- FR-D700 Installation Guideline Inverter: FR-D740-012 (SC) To 160 (SC) - EC FR-D720S-008 (SC) To 100 (SC) - ECDocument30 pagesFR-D700 Installation Guideline Inverter: FR-D740-012 (SC) To 160 (SC) - EC FR-D720S-008 (SC) To 100 (SC) - ECLászló LósNo ratings yet

- Cortinas de Luz - SF4B Linha CDocument32 pagesCortinas de Luz - SF4B Linha Cdpto teNo ratings yet

- RF Power Amplifiers and ProjectsDocument76 pagesRF Power Amplifiers and ProjectsDiego García MedinaNo ratings yet

- Vacuum Circuit-Breaker 12 - 17,5 KV ( 2500 A, 31,5 Ka) : Installation Operation Maintenance No. DRC NTV 142Document24 pagesVacuum Circuit-Breaker 12 - 17,5 KV ( 2500 A, 31,5 Ka) : Installation Operation Maintenance No. DRC NTV 142Prasad ShahNo ratings yet

- Bose Designmax DM8SDocument4 pagesBose Designmax DM8SAmit KidechaNo ratings yet

- LG Beginners Guide To Solar 2018Document16 pagesLG Beginners Guide To Solar 2018Arslan AsgharNo ratings yet

- Voltage Drop CalculationDocument30 pagesVoltage Drop Calculationjohannie ukaNo ratings yet

- 96X96 Mems 3D Matrix Optical Switch: FeaturesDocument2 pages96X96 Mems 3D Matrix Optical Switch: FeaturesKlaudio MarkoNo ratings yet

- Service New V24N02Document16 pagesService New V24N02angelo marraNo ratings yet

- EE 302 Exam 1 and Histogram F10Document3 pagesEE 302 Exam 1 and Histogram F10Richard WangNo ratings yet

- Hareem Ahmad CV - Electrical EngineerDocument2 pagesHareem Ahmad CV - Electrical Engineerrana sulemanNo ratings yet

- Tech Ref For Garmin NMEA2k enDocument42 pagesTech Ref For Garmin NMEA2k enAlara UrgunNo ratings yet

- Digital Ic Applications SyllabusDocument2 pagesDigital Ic Applications SyllabusSuyog ChavanNo ratings yet

- Horse Herd Optimization MPPT For Grid Connected PV System Under Partial Shading ConditionsDocument6 pagesHorse Herd Optimization MPPT For Grid Connected PV System Under Partial Shading Conditionsindra setyawanNo ratings yet

- Power Pack DC40 ManualDocument22 pagesPower Pack DC40 ManualBoris KalachnikovNo ratings yet

- Electrical & Electronic Measurements: 2.3 Wattmeter and Energy MeterDocument2 pagesElectrical & Electronic Measurements: 2.3 Wattmeter and Energy MeterSanjay RaajNo ratings yet

- 10 Simple Steps To Learn ToDocument4 pages10 Simple Steps To Learn ToYoussef EnnouriNo ratings yet

- Description: Data Cable, U/UTP, Category 6, AWG23, Euroclass CDocument2 pagesDescription: Data Cable, U/UTP, Category 6, AWG23, Euroclass Cosmanovic2020No ratings yet

- Earthing and ProtectionDocument45 pagesEarthing and Protectionlvsaru100% (1)

- 74HC93Document7 pages74HC93oscarberriossilvaNo ratings yet

- Gae CT-110Document2 pagesGae CT-110aditarmandoNo ratings yet

- Paper IEEE Template 10.11.21Document15 pagesPaper IEEE Template 10.11.21Bajarla IsmailNo ratings yet

- UG - Mining - BEV - GMG-WG-v02-r01 (1) (51-66) PDFDocument16 pagesUG - Mining - BEV - GMG-WG-v02-r01 (1) (51-66) PDFJuan RodriguezNo ratings yet

- Sunpal Commercial Off GridDocument6 pagesSunpal Commercial Off GridDukuai Buseryo YokariNo ratings yet

- 2007 - A Near State PWM Method With Reduced Switching Frequency and Reduced Common Mode Voltage For Three-Phase Voltage Source InvertersDocument6 pages2007 - A Near State PWM Method With Reduced Switching Frequency and Reduced Common Mode Voltage For Three-Phase Voltage Source InvertersNguyễn Nhật TưởngNo ratings yet

- PE Buck Boost 5.sqprojDocument4 pagesPE Buck Boost 5.sqprojIra CervoNo ratings yet