Professional Documents

Culture Documents

25605-240-GPP-GHX-00015 Hazard Communication Program Procedure Rev 000

Uploaded by

Amril Al RizaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

25605-240-GPP-GHX-00015 Hazard Communication Program Procedure Rev 000

Uploaded by

Amril Al RizaCopyright:

Available Formats

APLNG MODULE YARD PROJECT

HAZARD COMMUNICATION PROGRAM PROCEDURE

Electronic documents, once printed, are uncontrolled and may become outdated.

Refer to the electronic document management system (EDMS) for the current revision.

Bechtel Confidential

© Bechtel Oil, Gas and Chemicals, Inc. 2012. All rights reserved.

This document contains information that is confidential and proprietary to Bechtel or its affiliates, clients or suppliers,

and may not be used, reproduced or disclosed without Bechtel’s prior written permission.

000 5/23/12 Issued for Use BKT BS TW

00A 5/17/12 Issue for Review BKT BS TW

REV DATE REASON FOR REVISION BY CK’D APPR

BECHTEL

JOB NO. 25605

OG&C INC.

BECHTEL DOCUMENT NO. REVISION

AUSTRALIA PACIFIC 240-GPP-GHX-00015 000

LNG MODULE YARD

PROJECT Client Document No.:

APLNG Module Yard Project

Hazard Communication Program

TABLE OF CONTENTS

1.0 PURPOSE...........................................................................................................3

2.0 SCOPE................................................................................................................3

3.0 DEFINITIONS......................................................................................................3

4.0 REFERENCES....................................................................................................3

5.0 RESPONSIBILITIES...........................................................................................3

5.1 Site Manager......................................................................................................................... 3

5.2 Area Superintendent............................................................................................................. 3

5.3 HSE Manager........................................................................................................................ 3

5.4 Environmental Coordinator.................................................................................................... 4

5.5 Discipline Superintendent...................................................................................................... 4

5.6 Project Personnel.................................................................................................................. 4

6.0 REQUIREMENTS................................................................................................4

6.1 Ordering................................................................................................................................ 4

6.2 Asbestos................................................................................................................................ 4

6.3 Hazardous Substance Request.............................................................................................5

6.4 Hazardous Substance Register.............................................................................................5

6.5 Material Safety Data Sheets (MSDS's)..................................................................................6

6.6 Storage of Hazardous Substances........................................................................................6

6.7 Labelling................................................................................................................................ 7

6.8 Signage................................................................................................................................. 8

6.9 Emergency Response........................................................................................................... 8

6.10 Spills and Clean Up............................................................................................................... 8

6.11 Disposal................................................................................................................................ 8

7.0 EXPOSURE MONITORING AND HEALTH SURVEILLANCE..........................9

8.0 AUDITS...............................................................................................................9

9.0 RECORDS........................................................................................................10

10.0 INFORMATION AND TRAINING REQUIREMENTS.......................................10

11.0 RECORDS.........................................................................................................11

12.0 ATTACHMENTS................................................................................................11

25509-100-GPP-GHX-00015 Rev 000

Bechtel Confidential © Copyright Bechtel Oil Gas & Chemicals 2012. Page 2 of 12

All rights reserved

APLNG Module Yard Project

Hazard Communication

1.0 PURPOSE

To define applicable standards and set minimum requirements for the man- agement of

hazardous substances and dangerous goods.

2.0 SCOPE

This procedure applies to the APLNG Module Yard project.

3.0 DEFINITIONS

MYEMP – Module Yard Environmental Management Plan

Container - Object in which hazardous substances have been stored, en- closed or

packaged whether such container is partially or completely full or empty.

Hazardous Material –. Any material that poses a hazard to humans or the en-

vironment.

Hazardous Material Register – Log of hazardous materials stored and in use on-

site, including type, quantity, location and material safety data sheet (MSDS).

Material Safety Date Sheet (MSDS) – Document that states the substance’s

hazardous constituents, chemical and physical properties, health hazards, per- missible

exposure levels, first-aid procedures, emergency procedures, and the recommended

handling, use and disposal requirements. The manufacturer must provide an MSDS for

all potentially hazardous substances.

4.0 REFERENCES

Bechtel CP 202 Hazard Communication Program

Bechtel CP 200 General safe Working Practices

Compilation of the Environmental Legislative Regulations & Decrees by the Environmental

Impact Control Agency & DEPNAKERTRANS of Batam City.

5.0 RESPONSIBILITIES

5.1 Site Manager

Responsible for the overall hazard communication program.

Ensuring the procedure is implemented on the project.

5.2 Area Superintendent

Hazardous substances brought on-site for defined scope of work.

Ensuring the number and the amount of hazardous substances stored are

based on need.

Ensuring only approved hazardous substances are brought on-site.

5.3 HSE Manager

Providing information concerning the hazardous substance standard.

25509-100-GPP-GHX-00015 Rev 00A

Bechtel Confidential © Copyright Bechtel Oil Gas & Chemicals 2012. Page 3 of 12

All rights reserved

APLNG Module Yard Project

Hazard Communication

Assisting the Site Manager with performing hazardous substance regis- ter

surveys.

5.4 Environmental Coordinator

Reviewing and approving chemicals and MSDS

Approving hazardous substances for purchase.

Maintaining the Hazardous Substance register.

Maintaining Material Safety Data Sheets (MSDS’s) for the project.

5.5 Discipline Superintendent

Ensuring that all hazardous substances are properly labelled, stored, and

disposed of in accordance with the MSDS and project procedures.

Conducting training of team members in the safe use of hazardous

substances for routine and non-routine tasks.

5.6 Project Personnel

Handling, storing and using hazardous substances in the proper man- ner at

all times.

Reporting any problems/issues/concerns/incidents/spills regarding haz- ardous

substances.

6.0 REQUIREMENTS

6.1 Ordering

Hazardous substances should not be ordered in excess, nor should bulk containers

be specified where an excess will be left over. Choose the cor- rect size container

that will meet the estimated quantity required.

6.2 Asbestos

No materials containing asbestos are to be brought to the project site.

In the event a team member finds material that contains or is suspected to

contain asbestos the following actions are to be taken:

Cease work in the area

Barricade the immediate area

Notify the Area Superintendent and HSE Manager

An appropriate course of action in line with Legislative and Indonesian Standards

will be developed.

Removal of asbestos materials is to be undertaken by personnel with the required

certification level as stated in the legislation. A detailed work plan approved by

the Site Manager is to be in place prior to the commence- ment of any asbestos

removal task.

No asbestos material is envisaged to be encountered on the project

25509-100-GPP-GHX-00015 Rev 00A

Bechtel Confidential © Copyright Bechtel Oil Gas & Chemicals 2012. Page 4 of 12

All rights reserved

APLNG Module Yard Project

Hazard Communication

6.3 Hazardous Substance Request

All hazardous substances to be brought on-site must be evaluated for hazard

potential, possible substitutes, use, handling, storage and disposal requirements.

Hazardous substances can be brought onto site after a Hazardous Substances

Request for the substance has been approved by the Environmental Coordinator.

The request is to be completed by the team member requiring the haz- ardous

substance on-site and forwarded with a copy of the MSDS to the Environmental

Coordinator. The Environmental Coordinator will evaluate each hazardous

substance prior to being brought on-site. In performing the evaluation, the

Environmental Coordinator will utilize available infor- mation such as project

drawings and documentation, current online and/or hard copy MSDS and other

available references.

In addition, hazardous substance evaluations will be based on applicable

legislative requirements for the management of the substance, training of team

members, recognized HSE standards and information in the MSDS.

Once the evaluation is complete, the request may be approved, approved with

restrictions or rejected.

When a hazardous substance is rejected for use on-site, the reason(s) for the

rejection and an alternative substance will be suggested.

If an unapproved hazardous substance is received on-site, the hazardous

substance will be appropriately stored in a quarantine area and not re- leased until

an approval has been obtained or shall be removed and dis- posed of in

accordance with the project CEMP.

6.4 Hazardous Substance Register

The Hazardous Substance Register is the master list of all approved haz- ardous

substances on-site. The register will contain the following informa- tion:

Register number

Generic name/product type

Trade name

HAZCHEM code

Dangerous good code

Packaging group

Applicant

Comments/restrictions

Location stored

Quantity on hand

Annual usage

25509-100-GPP-GHX-00015 Rev 00A

Bechtel Confidential © Copyright Bechtel Oil Gas & Chemicals 2012. Page 5 of 12

All rights reserved

APLNG Module Yard Project

Hazard Communication

MSDS received

MSDS manufacturer issue date

Contractor name

The Hazardous Substance Register will be developed and maintained by the

Environmental Coordinator for all hazardous substances. The register will be

updated each time a hazardous substance is approved.

The Environmental Coordinator will perform an annual physical inventory of all

hazardous substances on-site and will compare this to the Hazard- ous Substance

Register to ensure accuracy. Substances no longer stored or used on-site will be

moved from the register to a redundant file.

Contractors are required to maintain a register of approved hazardous substances

relevant to their scope of work. Once a contractor has fin- ished with a substance

they are to remove any residual stock from the project and notify the

Environmental Coordinator for the project manifest to be updated.

6.5 Material Safety Data Sheets (MSDS's)

MSDS’s are to be retained for each approved hazardous substance on- site.

MSDS’s for hazardous substances no longer being stored or used onsite shall be

filed and retained.

MSDS’s shall be available and accessible to team members, including first

aid attendants and medical personnel, during all work shifts in rea- sonable

proximity to the work location.

Hazardous substances observed during inspections without the proper MSDS

shall be tagged Out of Service by the person conducting the in- spection and

stored separately from products in use until such time an MSDS for the substance

is provided or the substance is removed from the site.

6.6 Storage of Hazardous Substances

Hazardous substances must be stored in a manner that adequately pro- tects both

human health and the environment from unintended exposure to the substance.

The exposures may include explosion, fire, reactivity, toxicity or any combination

of the hazards.

Storage areas for hazardous substances will be reviewed and approved by the

Environmental Coordinator prior to receipt of the substances on the site. Criteria

for the location of suitable storage areas include:

Located away from high traffic areas on-site and protected from poten- tial

impact by vehicles/plant, guardrails, fences, or other structural con- trols.

25509-100-GPP-GHX-00015 Rev 00A

Bechtel Confidential © Copyright Bechtel Oil Gas & Chemicals 2012. Page 6 of 12

All rights reserved

APLNG Module Yard Project

Hazard Communication

Provided with a means to control access to the substances in order for

authorized (e.g., trained) team members to remove and use the sub- stances.

Located away from fence line locations immediately adjacent to envi-

ronmentally sensitive resources (e.g. wetlands, streams, archaeological sites).

Provided with secondary containment in the form of a bund with the capacity

of 110% of the maximum storage level.

Provided with a means of segregating combustible and flammable sub- stances

from oxidizing agents and other sources of ignition.

Provided with a means of preventing water reactive and pyrophoric substances

from coming in contact with accumulated water.

Appropriate signage to highlight the storage location, the hazardous, codes and

controls for the risk associated with the storage space (i.e., No Smoking).

The Environmental Coordinator may review additional guidance informa- tion on

the location, design, and maintenance or hazardous substances storage areas as

contained in governmental regulations, requests, and/or the Module Yard

Environmental Management Plan (MYEMP).

Contractors shall manage, store, and transport to site location of all haz- ardous

materials generated, handled or disturbed by contractors during its work in

accordance with applicable legislation and all other requirements outlined in the

Module Yard Environmental Management Plan (MYEMP). This includes, but is

not limited to, waste minimization; hazardous materi- als registration; hazardous

materials inventory with Material Safety Data Sheets (MSDS) for each hazardous

material on-site; employee training; hazardous materials spill management and

reporting; proper storage of hazardous materials; LDGL registration, equipment

decontamination and on-site transport of hazardous materials.

All hazardous substances and dangerous goods locations are strictly no smoking

areas. All potential ignition sources are banned from the areas.

6.7 Labelling

All hazardous substances are to be legibly labelled with the product name,

relevant risk and safety phrases and the name and address of the manufacturer or

supplier. All hazardous substances which are decanted into another container and

not used immediately are to be labelled in the same manner. Labels are not to be

removed or modified for any reason.

Any container of a substance found not having a label is to be tagged with an Out

of Service with the words “UNKNOWN SUBSTANCE – DO NOT USE” and

reported to the Environmental Manger/Coordinator or HSE de- partment.

25509-100-GPP-GHX-00015 Rev 00A

Bechtel Confidential © Copyright Bechtel Oil Gas & Chemicals 2012. Page 7 of 12

All rights reserved

APLNG Module Yard Project

Hazard Communication

A hazardous substance contained in an enclosed system, such as a pipe, piping

system, process or reactor vessel, shall be identified by having signs, placards, or

other appropriate signage attached containing the same information as a

manufacturer’s original label.

6.8 Signage

Signs are to be placed in appropriate locations to provide information to those

entering the area or use the substances and for emergency re- sponse.

A site HAZCHEM sign will be displayed and the manifest kept in a weather

proof container at the site entrance for the information of external emergency

services.

6.9 Emergency Response

Emergency procedures for a spill, fire, leak or explosion involving hazard- ous

substances are to be developed as part of the work method state- ment process and

refer to the actions contained in the Emergency Pre- paredness and Response

Plan.

Where a risk assessment has identified a need for eye protection to pre- vent eye

injuries from hazardous substances, provision for eye wash sta- tions must be

made.

Handling of corrosive or reducing agents will require eye wash stations and

safety showers be located within close proximity to the work area. The safety

stations will be denoted by the appropriate signage and the eye wash and shower

tested before handling of any substances.

6.10 Spills and Clean Up

Information on spills and clean-up can be found in the relevant Material Safety

Data Sheet, Project Waste Management Procedure and Emer- gency Preparedness

and Response Plan (EP&RP).

All spills are to be reported and promptly cleaned up. Spills with the po- tential to

cause significant environmental harm or injury shall be immedi- ately reported to

the emergency response team. All efforts should be made to contain the spill or

prevent further leakage.

6.11 Disposal

Land fill disposal of hazardous substances will not be accepted unless

specifically authorized by the Environmental Coordinator. All excess haz-

ardous materials and the containers must be removed from site as each phase of

the project is completed.

All contaminated soil from chemical spills must be reported to the Project

Environmental Department before being removed from site. Documented

25509-100-GPP-GHX-00015 Rev 00A

Bechtel Confidential © Copyright Bechtel Oil Gas & Chemicals 2012. Page 8 of 12

All rights reserved

APLNG Module Yard Project

Hazard Communication

evidence of disposal methods are to be maintained. Refer to the Project Waste

Management Procedure for more detail.

7.0 EXPOSURE MONITORING AND HEALTH SURVEILLANCE

If a risk assessment, MSDS or legislation indicates there is a significant risk to the

health of team members from dusts, mists or fumes, atmospheric monitor- ing shall be

undertaken. For substances absorbed through the skin or in- gested, biological

monitoring may be required.

Where and how monitoring of the substances shall be performed shall depend on the

location and the nature of the substances. Monitoring may be by per- sonal dosimeter

or area analysis or a combination of both. The qualified per- son performing the

monitoring shall decide, in consultation with the project En- vironmental Coordinator,

upon the monitoring technique to be used.

Atmospheric monitoring shall, as a minimum, comply with legislative require- ments

and personnel performing monitoring shall be suitably trained in moni- toring

techniques. (refer to CP 313 - Air Surveillance Program)

Records of monitoring shall comply with the following:

Record of the dates, exact locations and results taken of the monitoring.

Any worker who has been or could be exposed to a hazardous substance which is

subject to monitoring, shall be provided with the results of the monitoring.

A record of monitoring will be available to project personnel.

Records of monitoring requiring follow up shall be kept for thirty (30) years.

Results not requiring follow up shall be kept for five (5) years.

Health surveillance requirements for specific hazardous substances will be de- pendent

on the health effect and the existence of a valid technique to detect signs of the effect.

All health surveillance is to be conducted by or in consultation with the Nomi- nated

Medical Attendant.

Monitoring and surveillance requirements are to be implemented by the con- tractor in

control of the use and storage of the hazardous substance.

8.0 AUDITS

To ensure hazardous substances are stored, labelled, signed, transported and disposed

of in accordance with the procedures and legislative requirements, all workplaces and

vehicles transporting hazardous substances shall be sub- ject to audit. Audits shall be

performed by suitably qualified and trained team members, or suitably qualified

external consultants appointed by the HSE Manager or Environmental Coordinator.

All managers shall be notified of the results of the audit and any remedial action

required.

25509-100-GPP-GHX-00015 Rev 00A

Bechtel Confidential © Copyright Bechtel Oil Gas & Chemicals 2012. Page 9 of 12

All rights reserved

APLNG Module Yard Project

Hazard Communication

9.0 RECORDS

The following records are to be retained as long as the project is active:

Copy of procedure

Team members training records

Hazardous substances requests

MSDS’s

Current Hazardous Substance Register

Risk assessments

10.0 INFORMATION AND TRAINING REQUIREMENTS

Information and training will be provided to team members:

During the project orientation for new team members

When new team members are first assigned to a work area they may be exposed

to hazardous substances under normal working conditions or in a foreseeable

emergency.

Additionally, when a new hazard is introduced into the work area. Example of new

hazards are:

A new substance is to be used, and,

A previously used substance is to be used in a different manner poses a new

hazard

The following general information is to be provided to all team members:

Rights to access and obtain information.

Location and availability of the Hazardous Substances Register and MSDS’s.

Operating in work areas where hazardous substances are used.

The person(s) to contact for further information.

Hazardous substances and states of matter ( e.g., liquid, solid, gas).

Chemical physical, and health hazards.

Routes of entry (e.g., inhalation, ingestion, absorption).

Exposure limits and ways to control exposure.

Personal protective equipment and engineering controls.

Labelling requirements.

MSDS’s, contents and use.

Visitors will be provided with the same general topics of information as team

members. Visitors entering areas where hazardous substances are used, will be fully

advised of the potential hazards and given the opportunity to review the MSDS’s.

25509-100-GPP-GHX-00015 Rev 00A

Bechtel Confidential © Copyright Bechtel Oil Gas & Chemicals 2012. Page 10 of 12

All rights reserved

APLNG Module Yard Project

Hazard Communication

11.0 RECORDS

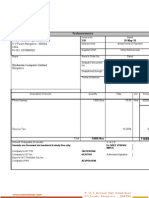

Hazardous Substance Request

12.0 ATTACHMENTS

Attachment A - Hazardous Substance Request Form

25509-100-GPP-GHX-00015 Rev 00A

Bechtel Confidential © Copyright Bechtel Oil Gas & Chemicals 2012. Page 11 of 12

All rights reserved

APLNG Module Yard Project

Hazard Communication

REQUEST

Contractor:

Name: Position:

Signature: Date:

SUBSTANCE DETAIL

Trade Name:

Hazchem Code: DG Code:

Known Hazards:

Intended Use:

Location - Use:

Location - Storage:

Order Quantity:

Estimated Usage:

MANUFACTURER/SUPPLIER

Name:

Address:

Phone: Fax:

EVALUATION

Are less harmful substances/materials available? Yes/No

Storage compatibilities assessed? Yes/No

Can the substance/material be used in a less harmful form? Yes/No

Control measures currently in use?

New control measures required?

Changes to work practices required?

Additional PPE required?

Risk Score: Refer to project risk matrix

Submit form and current MSDS to HSE Department

………………………………………………………………………………………………………………………………………….....

HSE Manager Evaluation Only

Approval/Rejection by Environmental Co-ordinator

YES – THE PRODUCT IS APPROVED FOR USE ON SITE.

It must be used in accordance with the MSDS and the additional controls listed above. A current MSDS

must be available for the user and all exposed team members must be trained in its contents.

YES – THE PRODUCT IS APPROVED FOR USE WITH THE FOLLOWING RESTRICTIONS:

Exposure is maintained to 10% of the allowable limit identified on the MSDS

The defined engineering controls and personal protective equipment are used.

NO – THE PRODUCT IS NOT APPROVED FOR USE.

Reason –

Suggested Alternative –

Name: Position:

Signature: Date:

25509-100-GPP-GHX-00015 Rev 00A

Bechtel Confidential © Copyright Bechtel Oil Gas & Chemicals 2012. Page 12 of 12

All rights reserved

You might also like

- UntitledDocument4 pagesUntitledAmril Al RizaNo ratings yet

- Pt. Lancang Kuning Sukses: Hse Training ProcedureDocument6 pagesPt. Lancang Kuning Sukses: Hse Training ProcedureAmril Al RizaNo ratings yet

- Daftar Peralatan Pertamina EPDocument8 pagesDaftar Peralatan Pertamina EPAmril Al RizaNo ratings yet

- WMS Erection Roofing - 2Document8 pagesWMS Erection Roofing - 2Amril Al RizaNo ratings yet

- Secondary ContainmenDocument1 pageSecondary ContainmenAmril Al RizaNo ratings yet

- S/C Letter HeadDocument1 pageS/C Letter HeadAmril Al RizaNo ratings yet

- Work Method StatamentDocument4 pagesWork Method StatamentAmril Al RizaNo ratings yet

- White Minimalist No Smoking Signage FlyerDocument1 pageWhite Minimalist No Smoking Signage FlyerAmril Al RizaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Intellectual Property Law-REPORTING SCHEDULE: Reportin G Date Topic Case NO. Case Title Reporter RemarksDocument2 pagesIntellectual Property Law-REPORTING SCHEDULE: Reportin G Date Topic Case NO. Case Title Reporter RemarksArrianne ObiasNo ratings yet

- A Study On Online Payment Methods Among College Students With Special Reference To Christ CollegeDocument60 pagesA Study On Online Payment Methods Among College Students With Special Reference To Christ CollegeAnjaliNo ratings yet

- Summary Of: The Value of Saving A Life: Evidence From The Labor MarketDocument2 pagesSummary Of: The Value of Saving A Life: Evidence From The Labor MarketFreed DragsNo ratings yet

- Options - SIPP - Fee ScheduleDocument5 pagesOptions - SIPP - Fee Schedulelopaz777No ratings yet

- Warehouse Management PlanDocument20 pagesWarehouse Management PlanMachel100% (1)

- Dont Stop BelievinDocument5 pagesDont Stop BelievingelliottbassNo ratings yet

- An Empirical Analysis of Growth of Msme in India and Role of SidbiDocument14 pagesAn Empirical Analysis of Growth of Msme in India and Role of SidbiShubhi SinghNo ratings yet

- Usha Letter Head CurvedDocument1 pageUsha Letter Head Curvedsales7705No ratings yet

- E41.50.530.N Avril2011 ENDocument14 pagesE41.50.530.N Avril2011 ENEhsan Arbabtafti100% (1)

- Third Party Ownership and Multi-Club OwnershipDocument36 pagesThird Party Ownership and Multi-Club OwnershipBruno ToniniNo ratings yet

- MGT-513 Corporate Law Course ContentDocument4 pagesMGT-513 Corporate Law Course Contentsheraz akramNo ratings yet

- Published Document Recommendations For The Design of Structures To BS EN 1991-1-1Document10 pagesPublished Document Recommendations For The Design of Structures To BS EN 1991-1-1cuong100% (1)

- Strategic Management Concepts Competitiveness and Globalization Hitt 11th Edition Solutions Manual Full DownloadDocument11 pagesStrategic Management Concepts Competitiveness and Globalization Hitt 11th Edition Solutions Manual Full Downloaddonnaparkermepfikcndx100% (36)

- ME76 Comprehensive Guidelines For The Graduating StudentsDocument8 pagesME76 Comprehensive Guidelines For The Graduating StudentsDanielle Angela TaccadNo ratings yet

- SF 5.2A Training Center Inspection ReportDocument9 pagesSF 5.2A Training Center Inspection ReportPriyaranjan NayakNo ratings yet

- Ogdcl Internship Program 2021Document1 pageOgdcl Internship Program 2021masroor umairNo ratings yet

- Fdocuments - in PNB Training ReportdocxDocument87 pagesFdocuments - in PNB Training ReportdocxAviral Pratap Singh KhareNo ratings yet

- 21 00202 Proposed Construction of Basketball Court Roofing at Bugallon PlazaDocument84 pages21 00202 Proposed Construction of Basketball Court Roofing at Bugallon PlazaJN CNo ratings yet

- Reflection Paper: Laborers in The PhilippinesDocument6 pagesReflection Paper: Laborers in The PhilippinesJv ManuelNo ratings yet

- Rockwell Deep Freezer InvoiceDocument2 pagesRockwell Deep Freezer InvoiceKuldeep KushwahaNo ratings yet

- SOP AhsanDocument5 pagesSOP AhsanAli RazaNo ratings yet

- Recruitment Case StudyDocument12 pagesRecruitment Case Studyarchangelkhel100% (1)

- New Prospect Intake Checklist Template: Schedule A CallDocument3 pagesNew Prospect Intake Checklist Template: Schedule A Callyou forNo ratings yet

- Consumer Reactions To Sustainable PackagingDocument10 pagesConsumer Reactions To Sustainable Packagingxi si xingNo ratings yet

- CH 15Document56 pagesCH 15Quỳnh Anh Bùi ThịNo ratings yet

- Sfom Impl B2ceDocument28 pagesSfom Impl B2cesergio paredesNo ratings yet

- Essay Plans 1: Across The Economy and Thus Stimulate Lending, Borrowing, AD and Economic GrowthDocument24 pagesEssay Plans 1: Across The Economy and Thus Stimulate Lending, Borrowing, AD and Economic GrowthAbhishek JainNo ratings yet

- Operational Data StoreDocument0 pagesOperational Data StorerajsalgyanNo ratings yet

- Chapter 7 Logistics ManagementDocument16 pagesChapter 7 Logistics Managementmariam jamilNo ratings yet

- School of Business, Hospitality & Tourism ManagementDocument28 pagesSchool of Business, Hospitality & Tourism Managementjulie ann mayoNo ratings yet