Professional Documents

Culture Documents

RMU TestSheet

Uploaded by

Tihomir BotevOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RMU TestSheet

Uploaded by

Tihomir BotevCopyright:

Available Formats

FORM

SAFETY HEALTH AND ENVIRONMENT MANAGEMENT SYSTEM

DISTRIBUTION COMMISSIONING FORM 4.9 – High Voltage Ring Main

Switchgear

Purpose: This instruction covers the testing and commissioning of all replacements or new

installations of high voltage (HV) ring main switchgear.

For more information refer to the Distribution Commissioning Forms Guideline (EDM

34137510)

Notes: The following tests and checks must be carried out after installation and before the switchgear is put into

service. Ensure the HV cables on either side of the ring main units are de energised and disconnected before

carrying out this commissioning exercise.

Address/Pole No.

Work Package No. Test Site/Location:

1. HV Ring Main Switchgear: Visual Inspection and Safety Check

HV switchgear serial number:

Check that the HV switchgear matches the drawings provided.

Check that the gas pressure is sufficient and record the value (if applicable). MPA

Check that the HV ring main switchgear is de-energised before testing. (Cables disconnected.)

Verify the minimum heights and protective barrier clearances.

Conduct functional tests of electrical equipment and parts of the installation; verify the settings, circuitry

and programming; verify the operation and configuration by measurement or testing of protective,

monitoring, measuring and control devices.

Verify that the fire ratings for the building and enclosures are correct and that the emergency exits are

operational.

Verify the minimum clearances between the live parts and earth.

Inspect the markings, safety signs and safety devices.

2. Insulation Resistance Test

Test Connection Expected Values Resistance

This test must be carried out before any cables are Red - white > 5,000 MΩ/5 GΩ Ω

connected.

White - blue > 5,000 MΩ/5 GΩ Ω

Open all earthing switches and close all load carrying

switches. Blue - red > 5,000 MΩ/5 GΩ Ω

Conduct an insulation resistance test of the busbar

with a 5 kV insulation resistance tester for 1 minute Red - earth > 5,000 MΩ/5 GΩ Ω

and record the value.

The value must be greater than 5,000 MΩ/5 GΩ. White - earth > 5,000 MΩ/5 GΩ Ω

Blue - earth > 5,000 MΩ/5 GΩ Ω

Date published: 26/10/2018 Published Version: EDM 21611007

HV Ring Main Switchgear – DCFI Version 24.1 I Working Version: EDM 44088728

Page 1 of 4

FORM

SAFETY HEALTH AND ENVIRONMENT MANAGEMENT SYSTEM

3. Continuity Test

The purpose of this test is to verify the connection between the same phases.

Expected

Test Connection Resistance

Values

Connect an insulation resistance tester set at 1

Red - red 0 MΩ Ω

kV and test between all bushings of the same

phase to prove continuity. White - white 0 MΩ Ω Pass/Fail

Blue - blue 0 MΩ Ω

Close all earthing switches and open all load Red - earth 0 MΩ Ω

carrying switches. Connect an insulation Pass/Fail

White - earth 0 MΩ Ω

resistance tester between all bushings of the

same phase and earth bar to prove continuity. Blue - earth 0 MΩ Ω

4. Handover of Responsibility for the Completion of Items 1 - 3

I hereby certify that items 1 to 3 have been completed with the above results.

Tested by NAC

Signature Date & Time

Note: A final insulation test between all phases and neutral/earth on all low voltage circuits must be performed

before energising for the first time. This also applies if any connections have been disturbed or replaced.

5. Cable and Site Checks

Check that the earthing has been installed, tested (DCF 4.1) and connected as per the design drawings.

Check that all the HV cable terminations are secure and that the correct bailing assemblies are used.

Check that all the HV cable terminations are tightened to the required manufacturer standard.

Check that the drain wires are fitted to all HV elbow connectors and are connected to the cable screen.

Check that the HV cable screens are all solidly and separately connected and bolted to the HV earth bar.

Check that the HV cables are numbered and labelled correctly,

Ensure that the 25 mm clearance between the cable screens and the cable support brackets is maintained.

(Refer to drawing number DSM– 8– 07.)

Check that no HV cables are exposed. Backfill if necessary.

If the ring main unit is in a kiosk, check that the kiosk body is earthed correctly, including the kiosk doors.

Ensure that all load-carrying switches are OFF, that their earth switches are ON, and that padlocks and

danger labels are fitted.

Ensure the site is safe and barricaded where necessary, with no hazards to personnel or the public.

For Schneider RM6 ring main Check that the two black bolts located on the top edge of all switch

switchgear, check the disconnector panels are installed and tightened.

following: Check the interlocking pin and metal tab located on the top edge of

• black bolts on the top switch disconnector door panels and on the inner edge of the fuse cover

edge of all switch top panel. Ensure they are not bent and are firmly attached to the

disconnector panels panels.

• interlocking pin and metal Ensure that the chassis of the RM6 ring main unit is mounted on a flat,

tab even surface and is not distorted.

• chassis correctly installed Check that the short lintel bars located at the front bottom of the RM6

• short lintel bars cable compartments are installed and bolted down. Align the front lintel

For more information, refer to bars and tighten the mounting bolts so that the door panels fit the cable

EDM 27510115. compartment door frames properly.

Date published: 26/10/2018 Published Version: EDM 21611007

HV Ring Main Switchgear – DCFI Version 24.1 I Working Version: EDM 44088728

Page 2 of 4

FORM

SAFETY HEALTH AND ENVIRONMENT MANAGEMENT SYSTEM

6. HV Metering Unit (if applicable): Visual Inspection and Safety Check

Indicate whether the HV metering unit is an indoor unit or an outdoor unit. Indoor Outdoor

Check that the voltage of the extensible metering unit is correct for the application.

Check that the HV metering unit has a HV test lab test certificate or tags for the current transformers and

voltage transformers.

Ensure that the HV test lab accuracy test certificate serial number matches the extensible metering unit

serial number.

Ensure that the metering officer has completed the Distribution Commissioning Form for HV metering

units.

Record the name of the metering officer:

7. Handover of Responsibility for the Completion of Item 5 - 6

I hereby certify that item 5 and 6 have been completed with the above results.

Tested by NAC

Signature Date & Time

8. Commissioning and Energisation

Ensure that the high voltage cable testing schedule is available and that the results are acceptable.

Ensure that the earthing system test result (DCF 4.1) is available and that the results are acceptable.

Ensure that the inside of the fuse compartment is clean and install the correct rating HV high

rupturing capacity fuses according to the fuse chart. Ensure that the striker pin faces the striker bar.

The switching operator must contact NOCC and ensure that the switchgear labels correctly match

the ENMAC or PowerOn Fusion diagrams.

Record the switching program number:

The following phasing out

checks need to be completed

in conjunction with the Connection Connection Connection

appropriate steps in the

switching program (where

applicable).

o Check that the neon light is R1 – R2 W1 – R2 B1 – R2

connected to the correct Max V Max V Max V

Should be Should be Should be

phase by measuring the Min V Min V Min V

Min V Max V Max V

voltage at the test points.

o Take one cubicle as a

reference and test the red

phase of that cubicle R1 – W2 W1 – W2 B1 – W2

Max V Max V Max V

against the red phase and Should be Should be Should be

Min V Min V Min V

other phases of the other Max V Min V Max V

cubicle.

o Red to red should return

minimum volts, and other R1 – B2 W1 – B2 B1 – B2

phases should have a Max V Max V Max V

Should be Should be Should be

maximum voltage. Min V Min V Min V

Max V Max V Min V

o Repeat this procedure with

the other phases.

Ensure that all equipment is in its final circuit conditions as per the switching program.

Ensure that all equipment is locked, and secure from unauthorised entry.

Note: Any changes to the original design must be marked, documented and stamped “As Constructed”.

Date published: 26/10/2018 Published Version: EDM 21611007

HV Ring Main Switchgear – DCFI Version 24.1 I Working Version: EDM 44088728

Page 3 of 4

FORM

SAFETY HEALTH AND ENVIRONMENT MANAGEMENT SYSTEM

9. Handover of Responsibility

I hereby certify that item 8 has been completed with satisfactory results and transfer control to the network

operating authority.

Commissioned by NAC

Signature Date & Time

1. Ensure the work area is left tidy with no hazards to the public.

2. Hand over responsibility to the operating authority.

3. Return this form to the project file as a record of the commissioning/handover certificate.

4. After the on-site project officer signs off on the DCF, a scanned copy of the DCF must be attached to the

relevant project documentation.

Date published: 26/10/2018 Published Version: EDM 21611007

HV Ring Main Switchgear – DCFI Version 24.1 I Working Version: EDM 44088728

Page 4 of 4

You might also like

- HV XLPE Cable Commissioning FormDocument3 pagesHV XLPE Cable Commissioning FormMustafa MohamedNo ratings yet

- Metal Clad Switchgear TestingDocument7 pagesMetal Clad Switchgear Testingengr.ayaz7772No ratings yet

- Dcwi 4.9 - High Voltage Ring Main Switchgear: Observe Safety LifesaversDocument3 pagesDcwi 4.9 - High Voltage Ring Main Switchgear: Observe Safety LifesaversDesmond Prince OmorogiuwaNo ratings yet

- FORM SAFETY HEALTH AND ENVIRONMENT MANAGEMENT SYSTEMDocument2 pagesFORM SAFETY HEALTH AND ENVIRONMENT MANAGEMENT SYSTEMMustafa MohamedNo ratings yet

- Distribution Commissioning Work InstructionDocument7 pagesDistribution Commissioning Work InstructionfuatbolatNo ratings yet

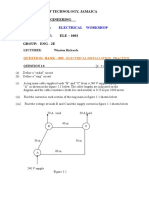

- Exp. 5 - Continuity Test For A Given Electrical Circuit Need For Continuity TestingDocument12 pagesExp. 5 - Continuity Test For A Given Electrical Circuit Need For Continuity Testingrishika chhibberNo ratings yet

- Exp 6 Electrical CircuitsDocument15 pagesExp 6 Electrical Circuitsdegapudi prabhadityaNo ratings yet

- HPC 4dl 07 0005 2014 DCT HV Xlpe Cables 170321Document5 pagesHPC 4dl 07 0005 2014 DCT HV Xlpe Cables 170321pralya930No ratings yet

- CB021Document8 pagesCB021Mauricio SaulNo ratings yet

- CB TESTING GUIDEDocument6 pagesCB TESTING GUIDEJarrett MathewsNo ratings yet

- CB012Document16 pagesCB012Mauricio SaulNo ratings yet

- TransformerDocument9 pagesTransformerVikas GuptaNo ratings yet

- Electrical Continuity TestDocument2 pagesElectrical Continuity TestMechanical EngineerNo ratings yet

- Electrical Power Transmission 4Document7 pagesElectrical Power Transmission 4FaisalSoNo ratings yet

- QCP e 11 Hipot TestDocument4 pagesQCP e 11 Hipot Testari_prasNo ratings yet

- LESSON NOTES HeszronDocument7 pagesLESSON NOTES HeszronHezron gibronNo ratings yet

- Transformer Testing Method of StatmentDocument11 pagesTransformer Testing Method of Statmentsite.eng1100% (1)

- Dry Type Transformer Testing ManualDocument23 pagesDry Type Transformer Testing Manualyalewlet tarekeggnNo ratings yet

- Testing Procedures For HV Voltage TransformersDocument4 pagesTesting Procedures For HV Voltage TransformersbinodeNo ratings yet

- Shamco Turns Ratio TestingDocument19 pagesShamco Turns Ratio TestingZahir MohammedNo ratings yet

- APFC O&M ManualDocument54 pagesAPFC O&M ManualTarun Godiyal100% (1)

- Testing Procedures For HV Voltage TransformersDocument4 pagesTesting Procedures For HV Voltage TransformersZeeshanNo ratings yet

- Transformer Test ProceduresDocument28 pagesTransformer Test ProceduresGonzalesCha100% (25)

- Tcee 161003100321Document30 pagesTcee 161003100321Anil KumAr MoteNo ratings yet

- Distribution Transformer TestingDocument2 pagesDistribution Transformer TestingjamilsoriaNo ratings yet

- Electrical Installation Testing ProceduresDocument10 pagesElectrical Installation Testing ProcedurestemamNo ratings yet

- Elite Precommissioning Procedures and Formats For SS Bay EquipmentDocument92 pagesElite Precommissioning Procedures and Formats For SS Bay EquipmentSurya Mvs100% (1)

- Voltage Withstand TestDocument4 pagesVoltage Withstand Testmshahidshaukat100% (1)

- Testing Procedures For HV Voltage TransformersDocument4 pagesTesting Procedures For HV Voltage Transformersbinode100% (3)

- Importance of HIPOT Testing: Dielectric Withstand TestDocument6 pagesImportance of HIPOT Testing: Dielectric Withstand TestelsayedNo ratings yet

- Megger MTB7671 - 2 - 2002-525 - V04Document14 pagesMegger MTB7671 - 2 - 2002-525 - V04melanitisNo ratings yet

- Hipot TestDocument5 pagesHipot TestSanjeet Saud100% (2)

- Loop Cheking ProcedureDocument5 pagesLoop Cheking ProcedureMd Omar FaruqueNo ratings yet

- EDOC-Transformer Diagnostics and Condition AssessmentDocument16 pagesEDOC-Transformer Diagnostics and Condition AssessmentEl Comedor BenedictNo ratings yet

- Switchgear Pre-Commissioning TestsDocument14 pagesSwitchgear Pre-Commissioning TestsKarthikeyan SNo ratings yet

- HIPOT Test Checks Electrical InsulationDocument4 pagesHIPOT Test Checks Electrical InsulationAriel DimacaliNo ratings yet

- What Is Cable Testing. How Is Cable Testing DoneDocument8 pagesWhat Is Cable Testing. How Is Cable Testing DoneNaveed IrshadNo ratings yet

- New Microsoft Word DocumentDocument13 pagesNew Microsoft Word Documentsoumyajit1986No ratings yet

- Healthiness Confirmation TestDocument3 pagesHealthiness Confirmation TestMoatter SiddiquiNo ratings yet

- Transformer ConceptsDocument97 pagesTransformer Conceptssubbaiah54No ratings yet

- HIPOT Testing (Dielectric Strength Test)Document5 pagesHIPOT Testing (Dielectric Strength Test)Wathik AbmNo ratings yet

- KT62 ManualDocument30 pagesKT62 ManualandyjwatsonNo ratings yet

- EDOC-Transformer Winding Resistance Testing ExplainedDocument13 pagesEDOC-Transformer Winding Resistance Testing ExplainedEl Comedor BenedictNo ratings yet

- Measurement of FLUKE Insulation Resistance MeggerDocument22 pagesMeasurement of FLUKE Insulation Resistance MeggerEmmanuel S SombilonNo ratings yet

- EDOC-Transformer Diagnostics and Condition AssessmentDocument16 pagesEDOC-Transformer Diagnostics and Condition AssessmentEl Comedor Benedict100% (1)

- MU PHENIX PAD10 25 Rev1Document25 pagesMU PHENIX PAD10 25 Rev1soporte.widaggNo ratings yet

- MU PHENIX PAD56 Rev1Document21 pagesMU PHENIX PAD56 Rev1soporte.widaggNo ratings yet

- MV Cables DC High Pot Test DraftDocument6 pagesMV Cables DC High Pot Test Draftp.srinivasaluNo ratings yet

- Medium Voltage Circuit Breaker Test ProcedureDocument8 pagesMedium Voltage Circuit Breaker Test ProcedureUsman HaroonNo ratings yet

- Transformer MaintenanceDocument68 pagesTransformer MaintenanceBayeNo ratings yet

- Megger TestDocument1 pageMegger TestHamada ElsharawyNo ratings yet

- Transformers 22Document32 pagesTransformers 22aiswaryaNo ratings yet

- Testing, Maintenance & Protection of Distribution TransformersDocument47 pagesTesting, Maintenance & Protection of Distribution TransformersHarikrishnan Natarajan92% (25)

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- Claydons Org Public HTML Elec Testing HTMDocument7 pagesClaydons Org Public HTML Elec Testing HTMYan AungNo ratings yet

- Industrial Directory of IndiaDocument47 pagesIndustrial Directory of IndiaRamesh Ananthanarayanan50% (2)

- Ampletek DeadbreakDocument36 pagesAmpletek DeadbreakEko SusantoNo ratings yet

- QUS 202 - Principles of Engineering MeasurementDocument86 pagesQUS 202 - Principles of Engineering MeasurementGoddey OnofuaNo ratings yet

- Final Internship ReportDocument39 pagesFinal Internship ReportKawooya CharlesNo ratings yet

- Instructions - Eng Sterling InverterDocument12 pagesInstructions - Eng Sterling InverterMVPNo ratings yet

- House WiringDocument9 pagesHouse WiringhassjayawardanaNo ratings yet

- Ringmaster installation, operation and maintenance guideDocument92 pagesRingmaster installation, operation and maintenance guideosmpot100% (1)

- Js 21 ElectricalDocument4 pagesJs 21 ElectricalCourtney 'Jackworld' JackNo ratings yet

- Installation and Operating Instructions 1VDD005976 GB - 8Document24 pagesInstallation and Operating Instructions 1VDD005976 GB - 8Muhammed MekkiNo ratings yet

- Lucy Electric Ring Main UnitsDocument42 pagesLucy Electric Ring Main UnitsShu Yan CheungNo ratings yet

- Schedule of Rates 2018-19 PDFDocument327 pagesSchedule of Rates 2018-19 PDFNagarjuna Kuncham40% (5)

- LV Cable TestsDocument18 pagesLV Cable TestsEbrahim ArzaniNo ratings yet

- RM6 Amted398032en 1018 PDFDocument100 pagesRM6 Amted398032en 1018 PDFcesarchiletNo ratings yet

- Household AppliancesDocument32 pagesHousehold Appliancesbhaskar51178No ratings yet

- Electrical Design Project (Three Bedroom House)Document13 pagesElectrical Design Project (Three Bedroom House)Sufi Shah Hamid Jalali100% (1)

- Lucy Middle East FZE: ET ProjectDocument5 pagesLucy Middle East FZE: ET Projectaseel aseelNo ratings yet

- Medium Voltage Products and Equipment - Australian Catalogue 2015Document112 pagesMedium Voltage Products and Equipment - Australian Catalogue 2015Dariush JavanNo ratings yet

- Electrical Wiring in The United Kingdom - WikipediaDocument17 pagesElectrical Wiring in The United Kingdom - WikipediasorinproiecteNo ratings yet

- Catalogue Ringmaster Part1Document70 pagesCatalogue Ringmaster Part1Mallampati RamakrishnaNo ratings yet

- Sabre Range Brochure WebDocument64 pagesSabre Range Brochure WebKadirou BigstarNo ratings yet

- Fire Safety Requirements Part 5 - Water Supplies For Fire-Fighting PDFDocument28 pagesFire Safety Requirements Part 5 - Water Supplies For Fire-Fighting PDFkhurshidoman123No ratings yet

- Common Mistakes in Electrical Wiring PracticeDocument37 pagesCommon Mistakes in Electrical Wiring PracticeSanda Kinithi100% (1)

- Medium Voltage SF GAS Insulated Ring Main Unit Up To 15Kv: Al-Ahleia Switchgear CoDocument20 pagesMedium Voltage SF GAS Insulated Ring Main Unit Up To 15Kv: Al-Ahleia Switchgear Cor_mukuyuNo ratings yet

- Zesa Installation GuideDocument10 pagesZesa Installation GuideKudakwashe Charera100% (2)

- House Wiring For Beginners - DIYWikiDocument9 pagesHouse Wiring For Beginners - DIYWikiRazmiNo ratings yet

- Radial Distribution NetworkDocument8 pagesRadial Distribution Networkdallisrinivas14100% (1)

- EE101 6 Electrical InstallationsDocument8 pagesEE101 6 Electrical InstallationsKasun WerangaNo ratings yet

- Ring Main Unit RMU As An Important Part of Secondary Distribution SubstationsDocument5 pagesRing Main Unit RMU As An Important Part of Secondary Distribution SubstationsBabar SaleemNo ratings yet

- A Belco Industrial Plugs & Sockets Reyrolle EasigoDocument32 pagesA Belco Industrial Plugs & Sockets Reyrolle Easigorocketvt100% (1)