Professional Documents

Culture Documents

Estimation of Molar Excess Gibbs Energy and Component Acti Vities of K-Na, CS-K, Al-Sn and Mg-Si Liquid Alloys From Pair Distribution Functions

Uploaded by

şadan korkmazOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Estimation of Molar Excess Gibbs Energy and Component Acti Vities of K-Na, CS-K, Al-Sn and Mg-Si Liquid Alloys From Pair Distribution Functions

Uploaded by

şadan korkmazCopyright:

Available Formats

Estimation of molar excess Gibbs energy and component acti

vities of K-Na, Cs-K, Al-Sn and Mg-

Si liquid alloys from pair distribution functions

Chun-Long Wang, Xiu-Min Chen, Dong-Ping Tao*

Faculty of Metallurgical and Energy Engineering, Kunming University of Science

and Technology, Kunming 650093, Yunnan Province, People’s Republic of China

Keywords:

Ab-initio molecular dynamics (AIMD); Thermodynamic models; pair distribution function;

Activities prediction;

Abstract: Based on the latest research methods, that estimating the activity and excess Gibbs

energy of liquid mixtures without use thermodynamic data, extracting g1ij(r), the local distribution

function, from the partial pair distribution function gij(r) of liquid mixtures as the unique input

parameter to solve thermodynamic model parameters. AIMD(g1ij(r))/(MIVM, RSM) methods

were proposed and extend to the Wilson and NRTL. The excess Gibbs energy and activity of four

liquid alloys, K-Na, Cs-K, Mg-Si, Al-Sn, were estimated by the AIMD(g1ij(r))/(MIVM, RSM,

Wilson, NRTL) and AIMD(gij(r))/QCM(Quasi Chemical model) proposed by Dorini. The mean

ARD(Average Relative Deviation) of excess Gibbs energy of four liquid alloys for five models are

±29.46%, ±24.82, ±66.68%, ±61.50%, ±32.86% respectively and the ARD of activity are

±10.50%, ±8.76%, ±47.07%, ±26.61%, ±11.47%, respectively, that show estimability are credible.

The estimation for Mg-Si are poor, through verify the excess Gibbs energy and activity

experimental data in literature, the Mg-Si experimental data in STGE not satisfy thermodynamic

consistency might be the mainly reason for poor estimation. The estimation results of MIVM,

Wilson and NRTL were compared, and conclude that MIVM have a good theoretical basis for

structure to compensate for the theoretical deficiencies of the other two models. The comparison

between the RSM and the QCM indicate that the both of the exchange energy parameter not

consistent and cannot interchange, and the difference in estimation mean that to explain the

relation between the two models from theoretical may not accord with the actual situation. The

correlation coefficient analysis and variation coefficient analysis between the models parameters

and liquid alloy components show that the parameters containing volume information are low

correlation, which can be regarded as constants at whole component range, while the model

parameters containing energy information have functional relation with components and the

constant treatment not suitable. Apply mathematical statistical analysis in thermodynamic model

parameters can deepen the understanding of the parameters characteristic. Comparing with the

regression method, the AIMD(g1ij(r))/thermodynamic-models can deepen the understanding of the

characteristics of the liquid system thermodynamic model based on lattice theory, and reveal the

rationality of the theoretical basis of the model construction and the defects of the model caused

by simplified. AIMD(g1ij(r))/thermodynamic-models is meaningful for excess Gibbs energy and

activity estimation.

1 Introduction

The excess Gibbs energy and activity thermodynamics models are widely used in the

calculation of gas-liquid phase equilibrium reactions. Since engineers usually obtain the model

*Corresponding author

E-mail addresses: 1176038593@qq.com (C.L. Wang), dongpingt@aliyun.com (D.P. Tao)

Electronic copy available at: https://ssrn.com/abstract=4121941

parameter by using experimental of activity and excess Gibbs energy to fit regression, it is

challenge to use the thermodynamic models to estimate gas-liquid equilibrium without any

relevant thermodynamic experimental values. In 1999, Sam used AIMD to obtain molecular pair

potential from clusters of eight atoms composed of water and alcohol(acid) as the UNIQUAC

model parameters the prediction well, while Wilson model’s not good[1]. In 2002, Raabe used

AIMD/NRTL to predict the gas-liquid equilibrium of nitrogen and ethane mixtures, and the

prediction results are in good agreement with experimental data[2]. In 2004, Neiman used

COSMO-RS and AIMD/UNIQUAC to predict the phase equilibria of 16 binary organic mixtures,

the prediction result of AIMD/UNIQUAC deviated greatly from the experiments, the same

method applied to Wilson and NRTL could not get good result. Neiman pointed out that there are

two basic issues to consider when using the AIMD/thermodynamic-models. The first one concern

is whether the potential parameters of the model are true molecular pair potentials, Sam support

UNIQUAC, Raabe prefer NRTL, and Neiman's study show that all three models perform poorly.

The second concerns is whether liquid structure interaction energy can be expressed as molecular

cluster energy[3]. The excess Gibbs energy and activity models parameters calculated by first

principles are controversial, and researchers actively explore new method. In 2015, Haghtalab

used gij(r) (The subscript ij also refers to ii, jj, and ji without special explanation, in the following)

of five binary organic mixtures obtained by MD to represent the models parameters of Wilson,

NRTL and UNIQUAC, which have anadjustable parameter, local structure radius to determine the

upper limits of integral for gij(r)[4]. Haghtalab’s method can't achieve prediction, and the local

structure radius in paper, obviously, large than range of lattice theory for liquid[5]. in 2018,

Ravichandran expressed the NRTL model parameter as the function of the molecular pair

potential, molecular diameter and local structure radius, and predicted the gas-liquid equilibrium

of 14 binary organic mixtures. Ravichandran’s study show that the completely miscible mixtures

have a good prediction result, while the partially miscible mixtures are worse[6, 7]. The

AIMD/NRTL need to calculate molecular pair potential and gij(r) at same time, and the method of

acquiring local structure radius not standardized, that may lead to different conclusions in different

studies. In 2019, Dorini proposed AIMD(gij(r))/QCM, the short-range ordering σ defined as a

bridge between the gij(r) and QCM parameters β, ω. The Bi-Pb and Bi-Li liquid alloys use

Dorini’s method has a good prediction result[8]. Dorini’s method require gij(r) fitting regression

under the multi component mixture to obtain ω. In this paper, a set of gij(r) under one component

be used to solve ω, and complex solutions for parameters are appearing, which indicate that the

AIMD(gij(r))/QCM method need to improve in theory. At present, the specific methods for to

predict excess Gibbs energy and activity has different shortcoming. The Gibbs energy and activity

thermodynamics models research mainly aim to propose prediction method with rigorous physical

significance, parameter simple, good reproducibility and good estimability.

In this context, proposing a AIMD(g1ij(r))/(MIVM, RSM) method for to estimate the excess

Gibbs energy and activity of liquid mixtures. The gaussian extrapolation method were used to

extracting g1ij(r) from gij(r) obtained by AIMD simulation, using the g1ij(r) calculate the local

coordination number Zij and local pair potential function ε1ij(r). The local structural parameters,

g1ij(r), Zij and ε1ij(r), were used to derive the models parameter expression, and were extended to

Wilson and NRTL. The excess Gibbs energy and activity of four liquid alloys, K-Na, Cs-K, Mg-Si

and Al-Sn are estimated by the AIMD(g1ij(r))/(MIVM, RSM, Wilson, NRTL) and AIMD(gij(r))

/QCM proposed by Dorini, which enriched the research about estimating excess Gibbs energy and

Electronic copy available at: https://ssrn.com/abstract=4121941

activity. The correlation analysis and discrete analysis to judge the model parameters calculated by

g1ij(r) and liquid alloy components whether both of them have function relations and the feasibility

of constant treatment. Mathematical statistical analysis in thermodynamic model parameters was

applied to deepen the understanding of the parameters characteristic.

2 Methods

2.1 AIMD obtain part pair distribution function

The successful application of simulation methods based on first principles have increased the

recognition that computer experiments as a research method. The gij(r) of liquid obtained by

AIMD are credible as long as the simulation operation standardize and correctly built the the

liquid model. The AIMD has the problems of time consuming and high computational cost, due to

require the large amount of gij(r) data in this research, limited experimental condition make it

difficult to obtain all the data through own’s experiments. AIMD be used to reproduce the

examine the existing gij(r) data in the literature, so as to prove the feasibility of AIMD to obtain

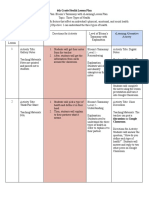

gij(r) and the reliability of published data. Fig.1 are gij(r) of four liquid alloys in different

components. Korkmaz applied the effective ion-ion pair potential function that proposed by

Fiolhais to describe the pair potential of K-Na and Cs-K alloys, and obtaining the gij(r) of nine

components corresponding to Na-K and Na-K by solving the Ornstein-Zernike Integral

equation[9, 10]. LiuDan obtained the gij(r) corresponding to Mg-Si at different temperatures and

different components by AIMD[11]. Roik used Reverse Monte Carlo Simulation to obtain the

gij(r) of Al-Sn at liquid alloy seven components[12].

11

K-K Na-Na K-Na x :0.9

K

10 0.8

0.7

9 0.6

0.5

8

0.4

7 0.3

0.2

6 0.1

g(r)

5

4

3

2

1

0

3 4 5 6 7

2 4 6 3 4 5 6 7

r/Å r/Å r/Å

Electronic copy available at: https://ssrn.com/abstract=4121941

11

x :0.9

Cs-Cs K-K Cs-K Cs

10 0.8

0.7

9 0.6

0.5

8 0.4

7 0.3

0.2

6 0.1

g(r)

5

4

3

2

1

0

4 6 8 4 6 8 4 6 8

r/Å r/Å r/Å

12

Mg-Mg Si-Si Mg-Si x :0.9

Mg

0.8

10 0.67

0.6

0.47

0.4

8 0.3

0.2

0.1

g(r)

0

2 3 4 5 2.5 3 3.5 2.5 3 3.5

r/Å r/Å r/Å

Electronic copy available at: https://ssrn.com/abstract=4121941

9

Al-Al Sn-Sn Al-Sn x :0.97

Al

8 0.92

0.87

0.8

7

0.65

0.5

6 0.25

5

g(r)

0

2 3 4 2 2.5 3 3.5 4 4.5 2 3 4 5

r/Å r/Å r/Å

Fig. 1 Partial pair distribution function gii(r) , gjj(r) , gij(r) ,for the liquid alloys K- Na[9], Cs-

K[10],Mg-Si[11],Al- Sn[12] form literature

The AIMD method, proposed by Car and Parrinello, can calculate particle forces and

trajectory motion[13]. By using VASP(Vienna AB-Initio Simulation Packages) software to carry

AIMD simulation[14]. The generalized gradient parameterized by Perdew and Wang was used to

approximate the exchange correlation potential[15, 16]. The cutoff energy, step size has a great

influence on the accuracy of the results, and they need to be determined by the energy

convergence test, the value listed in Table 1. The K point of all liquid alloys chose 3*3*3. The

temperature is controlled by the regular ensemble (NVT) and Nose thermostat[17]. The simulation

conditional density are consistent with the literature, they are listed in Table 2. AIMD selects two

stages, the first stage is to achieve equilibrium of the system at the corresponding temperature, and

the second stage is used to obtain gij(r).

Table 1 Parameters of AIMD simulation for K0.5Na0.5, Cs0.5K0.5, Mg0.6Si0.4,

Al0.5Sn0.5

Structure VASP

Alloy T/K Atom Length Cutoff Energy t1 t2 ∆t

Number 10-8/cm (Ev) /ps /ps /fs

K0.5Na0.5 373 128 19.664 140 5 10 1

Cs0.5K0.5 373 72 15.96 320 4 6 2

Mg0.6Si0.4 1435 72 11.41 200 4 6 2

Al0.5Sn0.5 973 108 13.76 249 6 9 3

Electronic copy available at: https://ssrn.com/abstract=4121941

Table 2 Numerical density of liquid alloy K0.5Na0.5, Cs0.5K0.5, Mg0.6Si0.4, Al0.5Sn0.5

K-Na[9] Cs-K[10] Mg-Si[11] Al-Sn[12]

ρ0/Å-3 ρ0/Å-3 ρ0/Å-3

xi xi xi T/K ρ0/Å-3 xi

T =373 K T =373 K T =973 K

0.1 0.0223 0.1 0.0123 0.1 1722 0.0452 0.25 0.0367

0.2 0.0207 0.2 0.0118 0.2 1643 0.0446 0.5 0.0404

0.3 0.0192 0.3 0.0114 0.3 1548 0.044 0.65 0.0434

0.4 0.0179 0.4 0.0109 0.4 1431 0.0434 0.8 0.0454

0.5 0.0168 0.5 0.0105 0.47 1319 0.0429 0.87 0.0472

0.6 0.0158 0.6 0.0101 0.6 1435 0.043 0.92 0.0477

0.7 0.0147 0.7 0.0096 0.67 1458 0.0426 0.97 0.0511

0.8 0.0140 0.8 0.0092 0.8 1383 0.0419

0.9 0.0132 0.9 0.0087 0.9 1254 0.0413

2.2 Thermodynamic model

The five models, MIVM, RSM, Wilson, NRTL, QCM are used to estimate the excess energy

and activity of liquid mixture. The corresponding model equation given and point out the

parameters unsolved.

2.2.1 MIVM(Molecular Interaction Volume Model)

Dong-Ping Tao rewrote the partition function of liquid based on lattice and cell theory, and

obtain the excess Gibbs energy expression of liquid mixture——MIVM(Molecular Interaction

Volume Model)[18].

GmE Vmi Vmj xi x j Bij B ji (1)

xi ln x ln ln Bij Z j

x V x V B j x V x V B 2 i x x B

Z ln B ji

RT i mi j mi ij j mj i mi ji i j ij x j xi B ji

GmE is excess Gibbs energy; R is the molar gas constant value 8.314 J/(K.mol); xi, xj are the

component value fractions of substances i and j in the mixture respectively. Vmi,Vmj are the molar

volumes of pure substance i and j respectively; Zi, Zj are the first coordination number of pure

substances i and j; Bij and Bji are unsolved parameters. Dai Heng point out Bij and Bji represent

volume information,while lnBij and lnBij represent energy information, the meanings of Bij and Bji

parameters were not clear enough[19]. In this paper, Dai Heng’s parameter separation method

were adopted, Bij and Bji represent volume information, lnBij and lnBji are replaced by new symbols

∆εij, ∆εij and give new expression in subsequent work.

Z ij Z ji

Bij B ji (2)

Z ii Z jj

ij ii ji jj (3)

ij ln Bij ji ln B ji

kT kT

Bij is the ratio of local coordination number of Zii, Zij, Bji represents the ratio of local

coordination number of Zjj and Zji. The first and second term in MIVM is volume term contain

entropy information. ∆εij, ∆εji is the pair potentials difference of molecular pairs i-i and i-j, j-j and

j-i respectively. The MIVM third term is energy term contain enthalpy information. k is

Boltzmann constant value 1.38*10-23.

Electronic copy available at: https://ssrn.com/abstract=4121941

2.2.2 RSM(Regular Solution Model)

In 1929, Hildebrand proposed the theory of regular solution that the mixing entropy

vanishing at constant temperature and constant volume[20].

GmE w (4)

xi x j

RT kT

w, interchange energy, is the function of coordination number and pair potential.

2.2.3 Wilson

Wilson presented the following expression for the excess Gibbs energy of a binary solution,

on the basis of molecular local structure consideration[21].

gE

xi ln xi Aij x j x j ln x j Aji xi (5)

RT

Aij, Aij are related to the pure components molar volumes and local structure volume. Wilson

expression can convert to the MIVM volume term.

2.2.4 NRTL(Non Random, Two Liquid)

Renon used the concept of local component in derivation of the NRTL(Nonrandom two-

liquid) equation, NRTL unlike Wilson’s, which is applicable to partially miscible as well as

completely miscible systems[22].

gE ji exp ij ij ij exp ij ij

xi x j

RT xi x j exp ij ij x j xi exp ij ij (6)

αij is related to the non-randomness in the mixture, the values range from 0.20 to 0.47, in

paper αij =0.3; τij is the molecular energy difference between i-i and i-j, τij is the difference

between the molecular energy of j-j and j-i.

2.2.5 QCM(Quasi Chemical Model)

The lattice theory assume the different kind of atoms mixing complete random in mixtures,

that can derive the RSM, but the different type atoms will non-random in actual situation.

Guggenheim used the Quasi Chemical approximation to deal with random mixing and non-

random mixing, and gave the parameter β to connect random mixing and non-random mixing,

which is the QCM[23].

GmE 2 (7)

xi x j

RT kT 1

2

1 4 xi x j exp 1 (8)

ZkT

β represent the random mixing factor; Z is the mean coordination number of binary mixtures,

when knowing the Zij can calculated using geometric rule; ω is the exchange energy of the

Electronic copy available at: https://ssrn.com/abstract=4121941

mixture, in theoretically ω=w. Dorini proposed a method AIMD(gij(r))/QCM to calculate β and

ω, which was used in this paper.

2.3 Obtaining model parameter from gij(r)

The five model’s parameters can be divided into volume parameter and energy parameter,

volume parameter: Bij, Bji, Λij, Λji, β ; energy parameter: ∆εij, ∆εji, w, τij, τji. This section introduce

the methods obtaining volume parameters and energy parameters according to g1ij(r).

2.3.1 Volume parameter

The gij(r) of liquid can well represent the liquid structure of short-range ordering and long -

range disordering. The gij(r) have an obvious peak near the origin of coordinates, and the second

peak and the third peak will appear with the distance increase. The first peak contain important

liquid structure information, which can combine with lattice theory[5]. the g1ij(r), the pair

distribution function of the first coordination shell or called local distribution function, extract

from the first peak of gij(r). The g1ij(r) was used to characterize the local structure characteristics

of liquid alloy. I use 27 pure liquid metals to perfect the method of constructing g1ij(r). Fig.2 is the

schematic diagram of constructing g1ij(r), and Eqs.(9) is the expression of g1ij(r). After systematic

evaluation, Eqs.(9) have high accuracy and good performance in coordination number calculation,

and will continue be used in liquid alloy.

Fig.2 Schematic graph of g1ij(r) constructed by the Gaussian function

rm r 2

g ij rm exp - 2

r0 r rm

2 v

g ij1 (r ) (9)

g r exp - r rm r r r

2

ij m 2u 2

m 1

r0 is the start point at gij(r) not 0; r1 is the position of the first valley value of the gij(r); v and

u are solved by fitting the data on the left side of the peak and the coordinates of point 2

[(rm+r1)/2, gij((rm+r1)/2)] in Fig.2. According to the meaning of g1ij(r), the total number of atoms

in the g1ij(r) first coordination shell defined as the local coordination number Zij, the number of

atoms j distributed around the central atom i in the adjacent sphere. Binary mixture have four type

coordination numbers.

Z ii xi 0 4 r 2 g ii1 (r )dr; Z ij x j 0 4 r 2 g ij1 (r )dr;

(10)

Z jj x j 0 4 r 2 g 1jj (r )dr; Z ji xi 0 4 r 2 g 1ji (r )dr;

ρ0, the average number density, is a function of alloy component and temperature; The Zij is an

important indicator of volume information of liquid local structure, and all volume parameters of

Electronic copy available at: https://ssrn.com/abstract=4121941

five models can be calculated based on Zij . An important concepts in two fluid theory —— local

fractions xii, xjj, xij and xji can obtained from Eqs.(10) [18, 21].

Z ii Z ij

xii xij

Z ij

j 1

Z

j 1

ij

(11)

Z jj Z ji

x jj x ji

Z

j 1

ij Z j 1

ij

Wilson parameters Aij, Aji and MIVM’s Bij, Bji both the expressions of xij, bring Eqs.(11) into the

parameters derivation process can obtain new expression expressed by g1ij(r), or bring Eqs.(10)

into Eqs.(2) also can obtaining.

r r

2

gij1 (r )dr 2

g 1ji (r )dr

B ,A = B ji ,A =

r r

ij ij ij

2

gii1 (r )dr 2

g 1jj (r )dr (12)

The parameter form of MIVM and Wilson expressed by g1ij(r) as same as Haghtalab’s. The

Eqs.(12) differ from Haghtalab’s in that the g1ij(r) is complete closed function, which represent the

local structure information, while Haghtalab’s not have this meaning. Haghtalab’s upper limit of

integral not reasonable enough[4]. The Aij, Aji in Wilson’s work have the volume ratio of two pure

substances i and j, but this paper and Haghtalab’s work take the volume ratio out of parameter

expression, because adding volume ration make the estimation worse. The QCM parameter β was

calculated by Zij of liquid alloy in Dorini’s work, and the process was briefly described. The short-

range ordering parameter σ and the average coordination number Z can written as the expression

of the coordination number Zij.

Z ij Z ji

xi xj

Z ii Z ij Z jj Z ji (13)

Z xi ( Z ii Z ij ) x j ( Z ji Z jj ) (14)

The short-range ordering σ also can be expressed by random factor β.

4 xi x j

1 (15)

In the case of knowing Zii, Zjj, Zij, Zji, the β can be obtained by simultaneous Eqs.(13) and (15).

By substituting Eqs.(14) and β into Eqs.(8), ω can be solved. In practical application, Dorini did

not choice solving the equation, but fitting regression to get the parameter ω, the mainly purpose

is to make ω have strong adaptability in the whole range of alloy components, and also to avoid

complex value in the process of solving the equation.

2.3.2 Potential parameter

The molecular pair interaction potential function εij(r) play a decisive role in the liquid structure

study. The gij(r) is the result of dynamic equilibrium under εij(r) interaction. Johnson study the

relation between the two-body distribution function, the three-body distribution function and the

pair interaction potential function εij(r)[24]. At present, there is little understanding and

insufficient research on the three-body distribution function, in order to simplify the representation

Electronic copy available at: https://ssrn.com/abstract=4121941

of the pair potential in terms of distribution functions. using the local distribution function g1ij(r)

to calculate the local pair potential function ε1ij(r) .

ii1 r (16)

ln g (r )

1

ii

kT

According to Eqs.(16), the equation ε1jj(r) and ε1ij(r)=ε1ji(r) can be obtained. In theory, the

model energy parameters can be calculated based on the ε1jj(r). The energy parameters of RSM,

MIVM and NRTL models have equations (17) and (18).

(17)

w ij 1 ii jj

Z

kT kT 2 kT kT

ij - ii ji - jj (18)

ij , ij = ji , ji =

kT kT

εii is the potential of atom i interacting with atom i, the εjj, εij = εji meaning similar with εii.

The energy parameters of a model is function of pair potential of atoms, but the the specific εij

values still unsolved. The pair potential εii, εjj, εij and εji in the three models are constants values,

which meaning of the mean value of the pair potential and can be solved according to the g1ij(r)

and ε1jj(r).

g ij1 r g r ln g r dr

1 1

ij 1 1

g 1 r dr r dr kT

ij ij

1

(19)

ij g r dr

ij

kT kT 1

ij

Similarly, the expressions of εii, εjj and εji can be obtained. substituting Eqs.(19) into Eqs.(17),

(18) obtain the energy parameters of the model.

3 Results and discussion

3.1 AIMD reproduces the partial pair distribution function gij(r)

The three type gij(r) of the four liquid alloys obtained by AIMD are shown in Fig.3. The

Eqs.(20) was used to calculate the SD(standard deviation) of gij(r) in literature and AIMD, in

order to evaluate the performance of AIMD, The SD are listed in Table 3. Usually, when the SD

less than 0.01, they are overlap and indistinguishable. The SD in Table 3 range from 0.04 to 0.24

show the gij(r) obtained under the small atoms model and short time simulation condition

consistent with the gij(r) in the literature. It can be known from Fig.3 there is a significant

difference between the gij(r) from AIMD and the gij(r) from literature. The difference mainly

caused by the deviation on the right side of the peak, and there is a significant difference between

the peak and valley. Actually, the subsequent study will use g1ij(r), not gij(r). The g1ij(r)

construction method in paper have the effect of weakening the right side trend and peak valley

inconsistency, and the consistent g1ij(r) can be constructed from two incompletely coincident

g1ij(r).

Electronic copy available at: https://ssrn.com/abstract=4121941

10

i-i j-j i-j Present work

Korkmaz

Korkmaz

8 Liu Dan

Roik

K0.5Na0.5

Cs0.5K0.5

6

Mg0.6Si 0.4

Al0.5Sn0.5

0

2 4 6 8 2 4 6 8 2 4 6 8

r/Å r/Å r/Å

Fig.3 Partial pair distribution function gii(r), gjj(r), gij(r) for the liquid alloys K0.5Na0.5, Al0.5Sn0.5,

Cs0.5K0.5, Mg0.6Si0.4

Table 3 The standard deviation of gij(r) calculated by AIMD are compared with gij(r)

in literature for four alloys

K0.5Na0.5 Cs0.5K0.5

r0 /Å r1 /Å SD r0/ Å r1 /Å SD

i-i 3.365 4.431 0.239 3.849 5.162 0.144

j-j 2.755 3.613 0.168 3.426 4.503 0.108

i-j 3.117 4.043 0.146 3.698 4.842 0.175

Mg0.6Si0.4 Al0.5Sn0.5

r0 /Å r1 /Å SD r0 /Å r1 /Å SD

i-i 2.368 3.16 0.044 2.053 2.495 0.146

j-j 2.011 2.434 0.077 2.465 3.136 0.098

i-j 2.162 2.743 0.103 2.193 2.822 0.222

r1

1

g r gijliterature r

2

SD AIMD

ij

(20)

N r r0

3.2 Calculation of thermodynamic model parameters

Solving the five models parameters only need a set of g1ij(r) in arbitrary alloys component. In

order to make the AIMD(g1ij(r))/(MIVM, RSM, Wilson, NRTL) has strong adaptability and

representativeness in the whole liquid alloy component, the average parameters values under each

component as the final input parameters. Dorini calculated parameters ω and β by regression,

without the average value[8]. Table 4 show the corresponding alloy model parameters of each

model.

Electronic copy available at: https://ssrn.com/abstract=4121941

Table 4 the model parameter for five models

model parameter K-Na Cs-K Mg-Si Al-Sn

𝑤

RSM 0.510 0.498 1.966 2.115

𝑘𝑇

Zc 0.005 0.202 5.650 0.855

Z0 9.485 10.244 10.228 8.104

QCM

𝜔

0.460 0.251 1.403 0.577

𝑘𝑇

Bij(Λij) 0.761 0.854 0.802 1.154

Bji(Λji) 1.174 1.125 2.041 0.616

∆εij(τij) 0.020 0.013 0.372 0.003

MIVM ∆εji(τji) 0.186 0.110 0.012 0.413

NRTL Zi[25] 10.500 10.500 10.900 11.500

Wilson Zj[25] 10.400 10.400 6.400 10.900

Vi[26] 47.211 73.059 18.428 11.388

Vj[26]

24.920 47.211 11.911 17.692

cm3/mol

Haghtalab and Flemer respectively pointed out that the models parameters and components

of liquid alloys has function relation. Haghtalab fitted the parameters of NRTL, Wilson,

UNIQUAC with the components of mixtures by using third order polynomials. Fig.4 is the

relation between liquid alloys components and the models parameters, the parameters fluctuate

significantly. It is difficult to obtain the accurate relation only through to observe Fig.4, thus

correlation analysis is necessary. The correlation values that calculated by Eqs.(21) are listed in

Table 5. The change of correlation values in Table 5 are complex, the same parameters are

significantly different in different liquid alloys, only describe the overall characteristics of each

model parameter, in next analysis. The w and ω are analyzed together due to both they are

interchange energy, among the 8 values, only the ρw of Cs-K is 0.132 belong to weak correlation,

while the other seven’s are greater than 0.6 belong to strong correlation. Basically, it can be

conclude that the exchange energy parameter calculated based on g1ij(r) is function of

components, which consists with Haghtalab's work. That the ρZ of K-Na, Cs-K and Al-Sn are

0.007, 0.284, 0.497 respectively, indicates ρZ is weak correlation. The ρZ of Mg-Si is 0.99 belong

to strong correlation, because the gij(r) of Mg-Si affected by both temperature and components,

and the ρZ tend to reflect the relation of Z and T. There are a weak correlation between the Z and

the components of alloys, and the Z can be considered is characterize of differ type alloy. The ρBij,

ρBji of K-Na, Cs-K and Mg-Si are moderate correlation, while the value of Al-Sn is weakly

correlated. correlation analysis combine with e, f in Fig.4 can known that Al-Sn Bij relative to the

other three alloy, and obvious fluctuations in the components of regularity, that could be gij(r) and

the accuracy of numerical calculation method of swings, in a follow up study is required to ensure

that obtaining more accurate g1ij(r) cases for further study. The correlation of ∆εij and ∆εji of

MIVM is obvious, the correlation coefficient values are generally greater than 0.8, but in Mg-Si

and Al-Sn, one value is strongly correlated, the other value is weak correlation. For example in

Mg-Si, ∆εji, ∆εij are 0.779, 0.019 respectively. theoretically, it is unlikely that indexes with the

Electronic copy available at: https://ssrn.com/abstract=4121941

same meaning are extreme in the same system. Combined with g and h in Fig.4, it can be seen that

the ∆εij, ∆εji of Mg-Si and Al-Sn fluctuates obviously, the ∆εij fluctuation decreases and then

increases and ∆εji drops monotonically in Mg-Si, the ∆εij drops monotonically and ∆εji drops and

increases again in Al-Sn,which results show that ∆εji and ∆εij are affected by the components in

Mg-Si and Al-Sn, the correlation value is low due to non-monotone variation. By analyzing the

correlation of each model parameter in four alloys, it can be found that each parameter has

abnormal value in a certain alloy, which makes the correlation of description parameters

uncertain. The exact value of the correlation is affected by numerical calculations methods, but the

overall trend should be related to the gij(r) of the different components of the alloy when the

numerical calculation methods are stable enough, the Mg-Si ρZ is 0.99 obviously different from

that of other alloys due to the influence of temperature. Similarly, the correlation between the

MIVM parameters of Al-Sn and the other four alloys is obviously different. It can be used to

check whether the variation trend of Al-Sn alloy g1ij(r) is consistent with the other three alloys

under the influence of components which can be used to verify the accuracy of numerical

calculation. The correlation analysis of parameters and components provide very useful

information for us to realize the characteristic changes between parameters and components and

the possible problems of the proposed method, which should be pay attention to in our work.

11 0.6 1.6 2.5

(a):Z K-Na K-Na

(b):w Cs-K (e):B ij (f):Bji

10 Cs-K

0.4 Mg-Si 1.4 2 Mg-Si

Al-Sn Al-Sn

9

0.2 1.2 1.5

8

Bij

Bji

w

Z

0 1 1

7

6 -0.2 0.8 0.5

1.4

5 -0.45 0.6

0.4 0.8

0

(d):ω (g):Δε ij (h):Δε

(c):β ji

1.2 0.2 0.6

0 0.4

1 0

Δεij

Δεji

0.2

ω

β

0.8 -5 -0.2

0

0.6 -0.4 -0.2

-10

0.4 -0.6 -0.4

0 0.5 1 0 0.5 1 0 0.5 1 0 0.5 1

x2 x2 x2 x2

Fig.4 The relation between Model parameters and alloys component

Table 5 Model parameter correlation for five models

Mode Parameter K-Na Cs-K Mg-Si Al-Sn

𝑤

RSM 0.651 0.132 0.675 0.706

𝑘𝑇

Z 0.007 0.284 0.990 0.497

QCM

𝜔

0.868 0.891 0.917 0.736

𝑘𝑇

Bij(Λij) 0.909 0.567 0.619 0.265

MIVM Bji(Λji) 0.618 0.613 0.737 0.411

(Wilson

∆εij(τij) 0.967 0.923 0.019 0.885

NRTL)

∆εji(τji) 0.959 0.845 0.779 0.241

weak correlation 0~0.4;medium correlation 0.4~0.6; strong correlation 0.6~0.8; high strong

Electronic copy available at: https://ssrn.com/abstract=4121941

correlation 0.8~1.

n

X i X Yi Y

Y i 1

(21)

n n

X X . Yi Y

2 2

i

i 1 i 1

Although the relation between the models parameters and the components of mixture are

analyzed on above, constructing specific function expression for parameter not mature enough,

and the models parameters as constant value are convenience. It is necessary to do discrete

analysis when treating a variable values as constant values, treating as constant value is

appropriate, if the lower discrete degree, otherwise, the effect is poor. It is inappropriate to use SD

as the index of discrete degree when there are orders of magnitude differences between sets of

data. using coefficient of variation CV represent discrete degree. Coefficient of variation is the

ratio of standard deviation to the mean, CV= STD(Y)/mean(Y), the CV values of models

parameters listed in table 6. That the CVw values of the four alloys in the range from 0.20 to 0.9

belong to strong variation. It can known that the w changed significantly with the component,

which as constant value are not a beast choice. The CVZ values of K-Na, Cs-K and Al-Sn were

2%, 1.9% and 5.8%, respectively, belong to weak variation, the CVZ values of Mg-Si is 19% at

medium variation. The correlation coefficient analysis show that the ρZ were weakly correlated,

and the CV of Z was also low, which further proved that the Z treatment as constant values is

appropriate,Z have the potential to be an essential characteristic of the liquid alloy. That the CVω

range of the four alloys range from 2 to 104 are strong variation, the ω treatment as constant value

not conform the actual situation, also contrary to the constant treatment of Dorini, the Dorini’s

method need further study. The values of CV∆εij and CV∆εji of the four alloys all have a significant

difference,one value in the range of moderate variation and another value is strong variation. The

universality of this result are difficult to explain at present, and the basic information shown by it

can be judged whether the treatment as a constant is the best choice under the condition that the

components of ∆εij and ∆εij are obviously affected by the components and the dispersion is large.

The coefficient of variation shows that the discrete of Z,

Table 6 The Coefficient of variation for five model parameter

Mode Parameter K-Na Cs-K Mg-Si Al-Sn

𝑤

RSM 0.204 0.321 0.466 0.888

𝑘𝑇

Z 0.021 0.019 0.205 0.058

QCM

ω 103.721 15.282 2.065 4.75

Bij(Aij) 0.036 0.027 0.054 0.096

MIVM Bji(Aji) 0.045 0.023 0.109 0.197

(Wilson NRTL) ∆εij(τij) 2.866 3.101 0.208 70.663

∆εji(τji) 0.412 0.452 12.2 0.383

Electronic copy available at: https://ssrn.com/abstract=4121941

Coefficient of variation division: <0.1 weak variation; 0.1~1 Medium variation; Strong

variation >1.

Bij, Bji are small, and the constant treatment is appropriate for the whole component. The model

parameters, ω, ∆εij, ∆εji, belong to strong variation, and the constant treatment does not conform to

the actual situation. The coefficient of variation table in Table 6 is given to realize that the

constant treatment needs mathematical basis in the calculation of thermodynamic model. The

larger the CV, the more problems will be caused by constant treatment.

3.3 Estimate thermodynamic values

The excess Gibbs energy of K-Na, Cs-K, Mg-Si, Al-Sn are estimated by to substitute the

parameters in Table 4 into the excess Gibbs energy modes. Fig.5 show the estimation and

experimental of four liquid alloys, the estimation trend of MIVM, RSM and experimental value

are relatively close, while the QCM, Wilson and NRTL can only estimate the general trend. The

RSM ,MIVM, NRTL use the same method calculating pair potential, that the estimation of RSM

and MIVM are better than NRTL indicate that pair potential method is reasonable and the problem

of NRTL theory and the parameter calculation method not fully reasonable. Prausnitz think that

the parameters of NRTL were similar to Wilson's and in Haghtalab's thesis ,the parameter of

Wilson and NRTL are consistent[4, 27]. The preliminary experimental of this work is showed that

when both NRTL and Wilson used volume parameters, NRTL estimation is worse. The Wilson,

NRTL, MIVM compare with together, the MIVM contains two term, the volume term form as

same as Wilson and the energy term form similar to NRTL, while MIVM estimation are best,

because the structure theory of MIVM is more prefect than the Wilson and NRTL, MIVM

naturally has two contributions of excess entropy and excess enthalpy in the process of model

derivation. The RSM and QCM compare with together, theoretically,the QCM derived from RSM

more realistic physical structure, but the RSM estimation better than QCM. One of reasons is

obtaining parameter method different. In table 3, the parameter values of two model are different,

and the preliminary experiments show that the two model parameter methods cannot be used

interchangeably, which means that two models relation need deep research. Calculating model

Electronic copy available at: https://ssrn.com/abstract=4121941

800

300 quasi-chemical

(a):K-Na (b):Cs-K MIVM

250 regular solution

600 Wilson

200 NRTL

experiment

400

G

150

K-Na:Hultgren

100 Cs-K:SGTE

200 Al-Sn:Hultgren

50 Mg-Si:SGTE

4000

0 0

(c):Al-Sn

-2000

3000

-4000

2000 -6000

G

-8000

1000

-10000

(d):Mg-Si

0 -12000

0 0.2 0.4 0.6 0.8 1 0 0.2 0.4 0.6 0.8 1

x2 x2

Fig.5 Excess Gibbs energy in the estimated and experimental contrast diagram for K-Na[28],Cs-

K[29],Al-Sn[28],Mg-Si[29]

parameters from structural parameters enlarge the advantages and disadvantages of the model,

which the regression method can not do it.

The excess Gibbs energy describe the energy changing follow with components mixture, the

fluid phase balance also needs to know the activity. The activity of each alloy is calculated

according to Eqs.(22). It should be mentioned that the parameters β and Z of the QCM are

components function, and require do partial derivatives. In order to keep the formula simple in the

practical application, the technicians treat the variable coefficients in the model as constants, the

methods will make the γi and γi cannot keep the thermodynamic consistency with GE. In the case

of known analytic formula of coefficient and component, the calculation should be carried out in

strict accordance with the rule of derivation. This paper does not suggest simplifying the variable

coefficient in theoretical research. Fig.5 is the activity of experiment and estimationfor four liquid

alloys. The estimation of MIVM and RSM are reasonable in all system, QCM is poor performance

in Al-Sn, Wilson ans NRTL estimation worse than the first three models, and have reasonable

estimation only in K-Na and Cs-K system. The activity estimation used Wilson have the

characteristic,that estimation value of i and j is significantly different, the aj was within a

reasonable range in Al-Sn and Mg-Si system, while the ai is abnormal, and In K-Na and Cs-K, the

ai estimation result is better than aj.

ln i

GiE GmE GmE RT

xi

GmE RT

;ai x i i

RT RT xi xi

(22)

G E G E GmE RT

ln j 2 m xj

GmE RT

;a j x j j

RT RT x j x j

Electronic copy available at: https://ssrn.com/abstract=4121941

1

quasi-chemical

0.8 MIVM

Quasi-lattice

Activity 0.6 Wilson

NRTL

0.4 Experiment

K-Na:Hultgren

0.2 (a):K-Na (b):Cs-K Cs-K:SGTE

10

Al-Sn:Hultgren

Mg-Si:SGTE

0.8

Activity

0.6

(d):Mg-Si

0.4

0.2 (c):Al-Sn

0

0 0.2 0.4 0.6 0.8 01 0.2 0.4 0.6 0.8 1

x2 x2

Fig.6 activity in the estimated and experimental contrast diagram for AlSn,CsK,KNa,MgSi

In order to further analyze the estimation performance for four liquid alloys,Table 7 lists the

average relative deviation of activity and excess Gibbs energy. The QCM, MIVM and RSM

estimability at the same level and, the ARD of Wilson and NRTL for excess Gibbs energy are

larger. The ARD of excess Gibbs energy generally bigger than the ARD of activity

relative,because the free energy and activity are different orders of magnitude cause the ARD

amplifier. The ARD indicates that the excess Gibbs energy and activity of QCM, MIVM and

RSM all have estimability, and the follows are: RSM, MIVM, QCM. When the g1ij(r)/model

parameters methods are extended to Wilson and NRTL, both of them perform worse than the first

three methods, but the RAD of the K-Na, Cs-K and Al-Sn is 5.5~22 mean that both of them also

have the estimability. RSM, MIVM, Wilson and NRTL can jointly demonstrate the rationality of

the g1ij(r)/model parameters presented in this paper.

Table7 The RAD for five model parameter

QCM MIVM RSM Wilson NRTL

Alloy

Energy Activity Energy Activity Energy Activity Energy Activity Energy Activity

K-Na 43.37 11.64 23.18 6.57 15.16 4.44 74.98 18.48 67.65 16.87

Cs-K 22.87 2.93 34.03 3.40 50.99 4.93 72.35 11.20 55.52 5.55

Mg-Si 16.14 13.42 39.65 21.88 21.09 18.92 54.34 136.71 65.21 63.85

Al-Sn 49.06 17.88 20.99 10.14 12.04 6.77 65.04 21.93 57.60 20.18

average 32.86 11.47 29.46 10.50 24.82 8.76 66.68 47.08 61.49 26.61

(24)

1 Ypre Yexp

ARD%

N

Yexp

*100%

Except for QCM, the excess energy and activity RAD of the others four models in Mg-Si

system are abnormal compared with other alloys’s, the Wilson RAD of activity is 136.7%,

obviously incomprehensible, needs to be explained. Examining the experimental data of excess

Gibbs energy and activity coefficient of the four alloys and the results find out the experimental

data in Mg-Si and Al-Sn literatures did not fully accord with each other. Fig.7 and 8 are activity

Electronic copy available at: https://ssrn.com/abstract=4121941

and excess energy data verification of Mg-Si and Al-Sn respectively. In Fig.7, the experimental

activity coefficient of Mg-Si and excess Gibbs energy do not meet the relation of molar and partial

molar. In Fig.8, the activity coefficient does not meet the Gibbs-Duhem equation. We have the

reason to suspect that the estimation performance of Mg-Si and Al-Sn are affected by the accuracy

of experimental values, and the inconsistency between Mg-Si activity and free energy is quite

significant. From finding abnormal estimation of Mg-Si to checking problems in experimental

data of Mg-Si, the scientific of AIMD(g1ij(r))/(MIVM, RSM, Wilson, NRTL,QCM) and it’s

ability to provide guidance for thermodynamic research are proved.

Mg-Si: Consistency test of molar and partial molar Mg-Si:Activity coefficient consistency test

0 2

1.5

-5000

-10000

0.5

-15000 0

0 0.2 0.4 0.6 0.8 1 0 0.2 0.4 0.6 0.8 1

Fig.7 Consistency test of Thermodynamic data of Mg-Si

Al-Sn: Consistency test of molar and partial molar Al-Sn:Activity coefficient consistency test

3000 0.4

2500 0.2

2000 0

1500 -0.2

1000 -0.4

500 -0.6

0 -0.8

0 0.2 0.4 0.6 0.8 1 0 0.2 0.4 0.6 0.8 1

Fig.8 Consistency test of Thermodynamic data of Al-Sn

4 Conclusions

In this study, the model parameters of MIVM and RSM are calculated by using the only input

parameter gij(r) to predict the excess Gibbs energy and activity of of liquid alloys,the ARD of

excess Gibbs energy and activity is less than ± 30%, and the ARD of activity is less than ±

20%. The g1ij(r)/parameter methods extended to Wilson and NRTL estimability are not good as

MIVM and RSM, but the RAD still at reasonable range. Dorini’s gij(r)/QCM as contrast methods

compare with our work, the RAD of excess energy and activity of four QCM systems is ±32.862%

Electronic copy available at: https://ssrn.com/abstract=4121941

and ±11.468%, respectively. gij(r)/QCM estimability at same level with gij(r)/(MIVM, RSM).

It is also necessary to further improve the calculation performance and reduce the prediction

deviation. At present, the reasons for the large RAD of estimation is that research have point out

models parameters is the function of liquid alloys components, but still consider as constant

values, because the accurate function relation cannot be accurately described. The order of

magnitude of model parameters are small, and the gij(r) of alloy and the numerical fluctuation

caused by the numerical processing method have a significant influence on the parameter values.

The gij(r) obtained by AIMD should enough accurate and the numerical processing methods

should enough stable, only satisfy the above two requirements can to reflect the (gij(r))/(QCM,

MIVM, RSM) real estimability. The inconsistency between thermodynamic model theory and the

g1ij(r) structure theory also is an important reason to influence estimability. The comparison

between the RSM and QCM, MIVM and Wilson, NRTL, both of them clearly show that the

theoretical deficiencies of the models can make estimation worse, Changing the models theory.

Modifying model appropriately based on model theory and g1ij(r) may be one the research

direction to improve the estimability In liquid computer simulation experiments, the suitable

molecular pair potential function is an important issues. Using the g1ij(r) to express ε1ij(r) are

reasonable in practical application, but from the theoretical point of view that the expression is

quite rough, which possible a the important reason affecting the model estimability. In general, the

estimation accuracy of AIMD(g1ij(r))/(QCM, MIVM, RSM) can be further improved, and it is

possible to achieve the consistent accuracy of thermodynamic data obtained in laboratory.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China

under Grant (No. 51464022).

Appendix

The equation parameter of g1ii(r), g1jj(r), g1ij(r) in four alloys Table 1, 2, 3, 4

Table 1 K-Na

component xk

parameter

0.1 0.2 0.3 0.4 0.5 0.5(cal) 0.6 0.7 0.8 0.9

i-i 4.423 4.448 4.464 4.458 4.442 4.567 4.437 4.453 4.577 4.528

rm/Å i-j 4.047 4.030 4.025 4.075 4.065 4.133 4.047 4.039 4.077 4.117

j-j 3.650 3.644 3.647 3.656 3.644 3.604 3.644 3.601 3.641 3.611

i-i 2.716 2.676 2.617 2.638 2.639 2.376 2.630 2.612 2.706 2.533

g(rm) i-j 2.503 2.554 2.608 2.707 2.673 2.241 2.737 2.768 2.961 2.769

j-j 2.730 2.846 2.961 3.263 3.173 3.591 3.307 3.491 3.737 3.884

i-i 0.264 0.306 0.326 0.297 0.294 0.368 0.267 0.273 0.330 0.333

v i-j 0.230 0.213 0.205 0.261 0.258 0.302 0.223 0.212 0.208 0.270

j-j 0.188 0.192 0.197 0.215 0.214 0.188 0.208 0.170 0.201 0.183

i-i 0.401 0.356 0.341 0.393 0.361 0.644 0.430 0.440 0.360 0.460

u i-j 0.338 0.349 0.363 0.283 0.289 0.416 0.347 0.361 0.357 0.343

j-j 0.291 0.275 0.258 0.236 0.233 0.368 0.234 0.265 0.195 0.270

Electronic copy available at: https://ssrn.com/abstract=4121941

Table 2 Cs-K

component xCs

parameter

0.1 0.2 0.3 0.4 0.5 0.5(cal) 0.6 0.7 0.8 0.9

i-i 5.155 5.176 5.152 5.167 5.206 5.299 5.179 5.182 5.226 5.199

rm/Å i-j 4.840 4.870 4.864 4.873 4.886 4.955 4.858 4.892 4.910 4.877

j-j 4.525 4.551 4.565 4.555 4.522 4.561 4.531 4.535 4.567 4.518

i-i 2.497 2.410 2.392 2.379 2.368 2.373 2.373 2.350 2.313 2.317

g(rm) i-j 2.320 2.366 2.387 2.404 2.418 2.476 2.463 2.464 2.417 2.440

j-j 2.450 2.572 2.548 2.575 2.747 2.813 2.810 2.881 2.686 3.004

i-i 0.465 0.444 0.425 0.449 0.502 0.456 0.445 0.454 0.502 0.447

v i-j 0.370 0.401 0.387 0.368 0.405 0.365 0.382 0.419 0.421 0.410

j-j 0.322 0.356 0.350 0.342 0.328 0.327 0.342 0.332 0.354 0.345

i-i 0.587 0.628 0.701 0.693 0.638 0.508 0.722 0.764 0.818 0.839

u i-j 0.667 0.551 0.659 0.681 0.616 0.378 0.626 0.591 0.717 0.746

j-j 0.584 0.457 0.569 0.594 0.504 0.437 0.488 0.509 0.681 0.510

Table 3 Mg-Si

component xMg

parameter

0.1 0.2 0.3 0.4 0.47 0.6 0.6(cal) 0.67 0.8 0.9

i-i 3.243 3.178 3.190 3.214 3.216 3.162 3.291 3.143 3.084 5.155

rm/Å i-j 2.769 2.785 2.797 2.764 2.785 2.735 2.861 2.741 2.713 4.840

j-j 2.448 2.454 2.461 2.431 2.449 2.461 2.468 2.466 2.444 4.525

i-i 1.498 1.420 1.459 1.639 1.811 1.910 1.897 1.892 2.204 2.497

g(rm) i-j 1.851 2.143 2.311 2.556 2.713 2.708 2.581 2.889 3.091 2.320

j-j 2.239 2.328 2.517 2.641 2.713 2.696 2.195 2.507 2.172 2.450

i-i 0.253 0.213 0.228 0.220 0.206 0.185 0.271 0.196 0.151 0.465

v i-j 0.099 0.108 0.115 0.088 0.099 0.077 0.146 0.082 0.076 0.370

j-j 0.060 0.057 0.058 0.038 0.050 0.056 0.057 0.058 0.048 0.322

i-i 0.494 0.552 0.516 0.488 0.370 0.368 0.372 0.402 0.328 0.587

u i-j 0.426 0.293 0.244 0.254 0.223 0.226 0.241 0.194 0.158 0.667

j-j 0.125 0.129 0.088 0.093 0.072 0.085 0.126 0.057 0.074 0.584

Table 4 Al-Sn

parameter component xAl

Electronic copy available at: https://ssrn.com/abstract=4121941

0.25 0.5 0.5(cal) 0.65 0.8 0.87 0.92 0.97

i-i 2.509 2.517 2.539 2.501 2.535 2.658 2.707 2.767

rm/Å i-j 2.781 2.805 2.903 2.941 2.898 2.957 2.898 2.903

j-j 3.13 3.13 3.194 3.103 3.136 3.117 3.119 3.094

i-i 2.177 1.998 2.107 2.011 1.876 1.921 2.015 2.371

g(rm) i-j 1.614 1.644 1.808 1.567 1.805 2.399 2.695 3.056

j-j 2.268 2.603 2.509 2.893 3.343 3.539 3.526 3.785

i-i 0.079 0.083 0.082 0.079 0.093 0.172 0.15 0.139

v i-j 0.133 0.148 0.155 0.198 0.121 0.09 0.083 0.058

j-j 0.131 0.1 0.126 0.084 0.108 0.077 0.102 0.092

i-i 0.273 0.292 0.178 0.428 0.488 0.269 0.287 0.189

u i-j 0.433 0.393 0.416 0.326 0.297 0.232 0.188 0.174

j-j 0.36 0.327 0.272 0.275 0.351 0.3 0.154 0.109

The models parameters solved by g1ij(r) under the multicomponent for four alloys Table 5, 6,

7, 8

Table 5 K-Na

component xK

parameter

0.1 0.2 0.3 0.4 0.5 0.5(cal) 0.6 0.7 0.8 0.9

Zii 1.572 2.86 4.011 5.1 5.709 6.917 6.685 7.563 8.598 8.777

local

Zij 10.03 8.392 6.918 5.874 4.475 4.428 3.444 2.494 1.694 0.786

Coordiantion

Zji 1.114 2.098 2.965 3.916 4.475 4.428 5.166 5.818 6.775 7.07

number

Zjj 8.171 7.083 5.783 5.039 3.817 4.849 2.947 2.203 1.39 0.72

ε 𝒌𝑻

ii -0.5 -0.485 -0.464 -0.471 -0.474 -0.366 -0.468 -0.461 -0.55 -0.5

𝜀

ε 𝒌𝑻

ij -0.406 -0.439 -0.452 -0.507 -0.493 -0.308 -0.508 -0.519 -0.586 -0.519

𝑘𝑇

ε𝒋j 𝒌𝑻 -0.488 -0.55 -0.586 -0.683 -0.655 -0.779 -0.697 -0.751 -0.834 -0.858

Z 9.517 9.595 9.403 9.762 9.323 9.524 9.323 9.446 9.867 9.385

RSM

𝒘 𝒌𝑻 0.84 0.756 0.687 0.686 0.671 0.265 0.693 0.827 1.041 1.497

σ 0.194 0.332 0.427 0.476 0.486 0.434 0.459 0.391 0.298 0.165

QCM β 0.851 0.928 0.967 1.015 1.056 1.305 1.093 1.147 1.151 1.186

𝝎 𝒌𝑻 -6.889 -1.177 -0.384 0.149 0.511 2.744 0.859 1.511 2.019 3.543

Bij 0.709 0.734 0.739 0.768 0.758 0.641 0.773 0.769 0.788 0.806

Bji 1.227 1.185 1.196 1.166 1.181 0.9132 1.169 1.132 1.218 1.092

MIVM

∆εij 0.094 0.046 0.012 -0.036 -0.019 0.058 -0.04 -0.057 -0.036 -0.02

∆εji 0.082 0.111 0.134 0.176 0.175 0.471 0.189 0.233 0.247 0.339

Table 6 Cs-K

parameter component xCs

Electronic copy available at: https://ssrn.com/abstract=4121941

0.1 0.2 0.3 0.4 0.5 0.5(cal) 0.6 0.7 0.8 0.9

Zii 1.351 2.619 3.791 4.881 8.011 5.524 6.545 7.752 8.778 9.149

local

Zij 10.056 8.446 7.602 6.336 2.791 4.389 3.867 2.793 0.965 0.894

Coordiantion

Zji 1.117 2.112 3.258 4.224 6.512 4.389 5.800 6.517 3.859 8.044

number

Zjj 8.745 7.387 6.588 5.624 2.563 4.56 3.527 2.563 1.226 0.832

ε 𝒌𝑻

ii -0.416 -0.381 -0.373 -0.368 -0.267 -0.365 -0.299 -0.302 -0.340 -0.339

𝜀

ε 𝒌𝑻

ij -0.338 -0.362 -0.371 -0.379 -0.385 -0.407 -0.402 -0.403 -0.221 -0.465

𝑘𝑇

ε𝒋j 𝒌𝑻 -0.397 -0.445 -0.426 -0.447 -0.511 -0.548 -0.534 -0.560 -0.479 -0.605

Z 10.016 9.812 10.310 10.395 9.938 9.64 9.978 6.132 8.811 9.926

RSM

𝒘 𝒌𝑻 0.685 0.502 0.296 0.291 0.041 0.049 0.144 0.170 1.665 0.074

σ 0.190 0.331 0.432 0.483 0.488 0.471 0.472 0.616 0.231 0.171

QCM β 0.894 0.936 0.945 0.986 1.049 1.122 1.036 0.363 1.770 1.109

𝝎 𝒌𝑻 -4.113 -1.048 -0.699 -0.149 0.478 1.079 0.365 1.087 1.567 1.866

Bij 0.827 0.806 0.860 0.865 0.835 0.7945 0.886 0.813 0.440 0.879

Bji 1.150 1.143 1.154 1.127 1.112 0.9621 1.096 1.089 0.787 1.075

MIVM

∆εij 0.078 0.019 0.002 -0.012 -0.016 -0.042 -0.103 -0.044 0.120 -0.126

∆εji 0.059 0.083 0.055 0.068 0.126 -0.141 0.132 0.157 0.258 0.141

Table 7 Mg-Si

component xMg

parameter

0.1 0.2 0.3 0.4 0.47 0.6 0.6(cal) 0.67 0.8 0.9

local Zii 1.054 1.857 2.759 4.070 4.722 6.071 6.955 7.099 8.119 8.909

Coordia- Zij 7.343 6.153 5.600 4.918 4.561 3.261 3.727 2.659 1.510 0.758

ntion Zji 0.816 1.538 2.400 3.279 4.044 4.891 5.591 5.399 6.039 6.825

number Zjj 3.931 3.453 2.883 2.384 2.061 1.696 1.613 1.175 0.612 0.358

εii 𝒌𝑻 0.089 0.148 0.134 0.001 -0.097 -0.149 -0.141 -0.142 -0.291 -0.345

𝜀

εij 𝒌𝑻 0.029 -0.263 -0.342 -0.439 -0.503 -0.494 -0.448 -0.554 -0.619 -0.665

𝑘𝑇

ε𝒋j 𝒌𝑻 -0.003 -0.345 -0.411 -0.472 -0.509 -0.497 -0.287 -0.432 -0.276 -0.638

Z 5.112 5.595 6.206 6.993 7.599 8.233 9.292 8.708 9.033 9.419

RSM

𝒘 𝒌𝑻 -0.067 -0.917 -1.264 -1.426 -1.524 -1.405 -0.234 -2.329 -3.032 -1.635

σ 0.242 0.400 0.519 0.566 0.582 0.507 0.52 0.454 0.307 0.166

QCM β 0.487 0.599 0.618 0.695 0.712 0.895 0.947 0.950 1.084 1.174

𝝎 𝒌𝑻 —— —— -4.122 -2.700 -2.595 -0.959 -1.621 -0.511 1.097 3.379

Bij 0.774 0.833 0.870 0.806 0.856 0.806 0.803 0.761 0.744 0.766

Bji 1.868 1.778 1.943 2.063 2.213 1.923 2.310 2.263 2.467 2.117

MIVM

∆εij -0.206 -0.410 -0.476 -0.440 -0.407 -0.345 -0.307 -0.413 -0.328 -0.320

∆εji 0.190 0.083 0.069 0.032 0.005 0.003 -0.161 -0.122 -0.343 -0.027

Table 8 Al-Sn

component xAl

parameter

0.25 0.5 0.5(cal) 0.65 0.8 0.87 0.92 0.97

local Zii 1.286 2.673 2.322 4.438 5.76 6.119 7.266 8.321

Electronic copy available at: https://ssrn.com/abstract=4121941

Coordia- Zij 4.336 3.429 3.971 2.209 1.452 1.252 0.74 0.308

ntion Zji 1.445 3.429 3.971 4.103 5.806 8.378 8.51 9.967

number Zjj 7.188 5.708 5.397 4.198 3.289 2.102 0.965 0.397

εii 𝒌𝑻 -0.279 -0.192 -0.246 -0.2 -0.13 -0.156 -0.201 -0.368

𝜀

εij 𝒌𝑻 0.018 0.001 -0.093 -0.076 -0.094 -0.371 -0.492 -0.613

𝑘𝑇

ε𝒋j 𝒌𝑻 -0.326 -0.458 -0.421 -0.563 -0.708 -0.767 -0.767 -0.832

Z 7.881 7.62 7.954 7.226 7.588 7.776 8.124 8.682

RSM

𝒘 𝒌𝑻 0.321 0.272 0.268 0.426 0.334 0.083 -0.012 -0.019

σ 0.318 0.469 0.524 0.389 0.289 0.252 0.157 0.064

QCM β 1.356 1.134 0.909 1.339 1.217 0.798 0.877 0.833

𝝎 𝒌𝑻 2.956 0.958 0.762 2.264 2.125 -6.344 -6.275 ——

Bij 1.124 1.283 1.709 0.925 1.008 1.369 1.171 1.198

Bji 0.603 0.601 0.735 0.526 0.441 0.596 0.767 0.777

MIVM

∆εij 0.297 0.193 0.153 0.124 0.037 -0.215 -0.291 -0.245

∆εji 0.344 0.459 0.327 0.487 0.614 0.396 0.275 0.22

The consistency test of thermodynamic data in literature for four alloys Table 9, 10, 11, 12

Table 9 K-Na, T=773K

GmE RTΣxilnγi d ln i d ln j

xi xj ai aj γi γj xi xj

(J/mol) (J/mol) dxi dx j

1 0 1 0 1 2.438 0 0 -0.004 0

0.9 0.1 0.907 0.211 1.008 2.107 293 295 -0.143 -0.142

0.8 0.2 0.826 0.367 1.033 1.835 514 515 -0.266 -0.266

0.7 0.3 0.755 0.484 1.078 1.615 665 664 -0.368 -0.368

0.6 0.4 0.689 0.575 1.148 1.437 749 750 -0.442 -0.442

0.5 0.5 0.625 0.648 1.25 1.295 770 769 -0.482 -0.482

0.4 0.6 0.557 0.711 1.393 1.186 728 727 -0.483 -0.483

0.3 0.7 0.478 0.772 1.592 1.103 628 627 -0.441 -0.44

0.2 0.8 0.374 0.837 1.87 1.046 469 471 -0.35 -0.348

0.1 0.9 0.226 0.91 2.26 1.012 260 261 -0.204 -0.204

0 1 0 1 2.816 1 0 0 0 -0.008

Table 10 Cs-K, T=773K

GmE RTΣxilnγi d ln i d ln j

xi xj ai aj γi γj xi xj

(J/mol) (J/mol) dxi dx j

Electronic copy available at: https://ssrn.com/abstract=4121941

1 0 1 0 1 1.595 0 0 -0.001 0

0.9 0.1 0.906 0.139 1.007 1.394 111 112 -0.124 -0.12

0.8 0.2 0.821 0.251 1.026 1.253 185 186 -0.188 -0.186

0.7 0.3 0.738 0.347 1.056 1.156 226 231 -0.208 -0.208

0.6 0.4 0.652 0.436 1.087 1.09 239 239 -0.195 -0.197

0.5 0.5 0.562 0.523 1.124 1.046 229 229 -0.16 -0.163

0.4 0.6 0.464 0.612 1.159 1.02 201 200 -0.113 -0.115

0.3 0.7 0.357 0.704 1.189 1.006 159 159 -0.064 -0.063

0.2 0.8 0.242 0.8 1.208 1 108 107 -0.022 -0.020

0.1 0.9 0.121 0.9 1.213 1 53 55 0.003 0.004

0 1 0 1 1.199 1 0 0 0 -0.005

Table 11 Mg-Si, T=2200K

GmE RTΣxilnγi d ln i d ln j

xi xj ai aj γi γj xi xj

(J/mol) (J/mol) dxi dx j

1 0 1 0 1 0.059 0 0 0.001 0

0.9 0.1 0.983 0.021 0.984 0.078 -3031 -4931 0.353 0.354

0.8 0.2 0.869 0.054 0.914 0.117 -5628 -9164 0.898 0.893

0.7 0.3 0.69 0.11 0.781 0.186 -7599 -12394 1.429 1.423

0.6 0.4 0.496 0.2 0.607 0.297 -8810 -14361 1.796 1.794

0.5 0.5 0.324 0.334 0.431 0.452 -9185 -14959 1.910 1.915

0.4 0.6 0.195 0.509 0.285 0.633 -8708 -14202 1.746 1.751

0.3 0.7 0.108 0.704 0.183 0.805 -7421 -12096 1.339 1.338

0.2 0.8 0.055 0.877 0.119 0.93 -5425 -8848 0.791 0.779

0.1 0.9 0.022 0.986 0.085 0.989 -2875 -4691 0.267 0.261

0 1 0 1 0.072 1 0 0 0 0.052

Table 12 Al-Sn, T=973K

GmE RTΣxilnγi d ln i d ln j

xi xj ai aj γi γj xi xj

(J/mol) (J/mol) dxi dx j

1 0 1 0.001 1 6.639 0 0 0.352 0

Electronic copy available at: https://ssrn.com/abstract=4121941

0.9 0.1 0.925 0.384 1.028 3.845 12932 1290 -0.527 -0.471

0.8 0.2 0.883 0.511 1.104 2.553 21598 2156 -0.769 -0.697

0.7 0.3 0.853 0.569 1.219 1.894 2670 2671 -0.757 -0.765

0.6 0.4 0.821 0.61 1.368 1.526 2888 2888 -0.689 -0.738

0.5 0.5 0.779 0.65 1.558 1.301 2858 2857 -0.633 -0.659

0.4 0.6 0.714 0.698 1.784 1.163 2607 2606 -0.575 -0.553

0.3 0.7 0.615 0.756 2.049 1.080 2176 2176 -0.469 -0.430

0.2 0.8 0.473 0.823 2.365 1.029 1578 1577 -0.289 -0.289

0.1 0.9 0.274 0.902 2.744 1.002 832 831 -0.077 -0.124

0 1 0.0001 1 2.706 1.000 0 0 0 0.077

Estimating the Excess Gibbs energy and component activities by own’s AIMD g1ij(r)

800 600 K-Na:Hultgren

(a):K-Na (b):Cs-K

Cs-K:SGTE

500

600 Al-Sn:Hultgren

400 Mg-Si:SGTE

400 quasi-chemical

G

300

MIVM

200 Quasi-lattice

200 Wilson

100 NRTL

experiment

30000 0

(c):Al-Sn

2000

-5000

1000

G

0

-10000

-1000

(d):Mg-Si

-2000 -15000

0 0.2 0.4 0.6 0.8 1 0 0.2 0.4 0.6 0.8 1

x2 x2

Fig.1 Excess Gibbs energy in the estimated and experimental contrast diagram for K-Na,Cs-

K,Al-Sn,Mg-Si

Electronic copy available at: https://ssrn.com/abstract=4121941

1 K-Na:Hultgren

Cs-K:SGTE

Al-Sn:Hultgren

Activity

Mg-Si:SGTE

0.5 quasi-chemical

MIVM

Quasi-lattice

(a):K-Na (b):Cs-K

Wilson

0

1 NRTL

Experiment

Activity

0.5 (d):Mg-Si

(c):Al-Sn

0

0 0.2 0.4 0.6 0.8 1

0 0.2 0.4 0.6 0.8 1

x2 x2

Fig.2 activity in the estimated and experimental contrast diagram for AlSn, CsK, KNa, MgSi

Table13 The RAD of Energy and Activity for five model parameter

QCM MIVM RSM Wilson NRTL

Alloy

Energy Activity Energy Activity Energy Activity Energy Activity Energy Activity

Mg-Si 12.556 11.317 64.577 29.427 13.974 13.795 46.766 150.13 61.163 58.229

K-Na 35.183 9.707 16.838 4.903 11.617 3.458 71.130 19.025 66.940 16.731

Cs-K 53.531 5.06 34.033 7.793 49.242 4.762 24.885 7.7304 55.52 5.539

Al-Sn 66.544 22.489 3.748 3.603 8.301 5.035 96.565 27.746 57.6 21.001

average 41.9535 12.1433 29.799 11.431 20.783 6.762 59.157 51.157 60.305 25.375

Reference

[1]A. K. Sum, S. I. Sandler, Use of Ab Initio Methods to Make Phase Equilibria Predictions Using

Activity Coefficient Models, Fluid Phase Equilibr., 158 (1999) 375-380.

[2]G. Raabe, J. Koehler, Use of Ab Initio Interaction Energies for the Prediction of Phase Equilibria

in the System Nitrogen-Ethane, Phys. Chem. Chem. Phys., 4 (2002) 926-930.

[3]M. Neiman, H. Cheng, A Critical Assessment On Two Predictive Models of Binary Vapor Iquid

Equilibrium, Phys. Chem. Chem. Phys., 6 (2004) 3474-3483.

[4]A. Haghtalab, J. B. R, Y. Seyf, A New Insight to Validation of Local Composition Models in

Binary Mixtures Using Molecular Dynamic Simulation, AIChE J., 1 (2015) 275-286.

https://doi.org/10.1002.

[5]A. Guggenheim E., The Theory of the Equilibrium Properties of some Simple Classes of Mixtures,

Solutions and Alloys., 1979.

[6]A. Ravichandran, R. Khare, C. Chen, Predicting NRTL Binary Interaction Parameters From

Molecular Simulations, AIChE J., 64 (2018) 2758-2769.

https://doi.org/https://doi.org/10.1002/aic.16117.

[7]A. Ravichandran, H. Tun, R. Khare, C. C. Chen, Prediction of Thermodynamic Properties of

Organic Mixtures: Combining Molecular Simulations with Classical Thermodynamics, Fluid

Phase Equilibr., 523 (2020) 1-10.

Electronic copy available at: https://ssrn.com/abstract=4121941

[8]T. T. Dorini, L. Eleno, Liquid Bi–Pb and Bi–Li Alloys: Mining Thermodynamic Properties From

Ab-Initio Molecular Dynamics Calculations Using Thermodynamic Models, Calphad, 67 (2019)

1-9.

[9]Korkmaz, S. D. Korkmaz, Structure and Inter-Diffusion Coefficients of Liquid NaxK1x Alloys,

Journal of Phase Equilibria & Diffusion, 31 (2010) 15-21.

[10]S. D. Korkmaz, Korkmaz, A Study for Structure and Inter-Diffusion Coefficient of Liquid K1−X

Cs X Metal Alloys, Phys. Chem. Liq., 49 (2011) 801-810.

[11]D. Liu, X. Zhu, First-Principles Study of Chemical and Topological Short-Range Orders in the

MgSi Liquid Alloys, Metals - Open Access Metallurgy Journal, 6 (2016) 1-10.

[12]O. S. Roik, O. M. Yakovenko, V. P. Kazimirov, V. E. Sokol'Skii, N. V. Golovataya, Y. O.

Kashirina, Structure of Liquid AlSn Alloys, J. Mol. Liq., 330 (2021) 1-9.

[13]M. Parrinello, R. Car, Unified Approach for Molecular Dynamics and Density-Functional Theory,

Phys. Rev. Lett., 55 (1985) 2471-2474. https://doi.org/10.1103/PhysRevLett.55.2471.

[14]A. Gk, B. Jf, Efficiency of Ab-Initio Total Energy Calculations for Metals and Semiconductors

Using a Plane-Wave Basis Set, Comp. Mater. Sci., 6 (1996) 15-50.

[15]G. Kresse, D. Joubert, From Ultrasoft Pseudopotentials to the Projector Augmented-Wave Method,

Physical Review B, 59 (1999) 1758-1775.

[16]John, P., Perdew, Kieron, Burke, Matthias, Ernzerhof, Generalized Gradient Approximation Made

Simple, Phys. Rev. Lett., 77 (1997) 3865-3868.

[17]N. Shuichi, A Unified Formulation of the Constant Temperature Molecular Dynamics Methods,

The Journal of chemical physics, 81 (1984) 511-519.

[18]P. T. Dong, A New Model of Thermodynamics of Liquid Mixtures and its Application to Liquid

Alloys, Thermochim. Acta, 363 (2000) 105-113.

[19]H. Dai, T. D. Ping, A Statistical Thermodynamic Model with Strong Adaptability for Liquid

Mixtures, Fluid Phase Equilibr., 0378 (2018) 154-165.

[20]J. H. Hildebrand, Solubility. Xii. Regular Solutions1, J.am.chem.soc, 51 (1929) 66-80.

[21]Wilson, M. Grant, Vapor-Liquid Equilibrium. XI. A New Expression for the Excess Free Energy

of Mixing, J.am.chem.soc, 86 (2012) 127-130.

[22]H. Renon, J. M. Prausnitz, Local Composition Thermodynamic Excess Functions for Liquid

Mixtures, AIChE J., 14 (1968) 135-144.

[23]Guggenheim, A. E., Statistical Thermodynamics of Co-Operative Systems (A Generalization of the

Quasi-Chemical Method), Transactions of the Faraday Society, 44 (1948) 263-271.

[24]M. D. Johnson, P. Hutchinson, N. H. March, Ion-Ion Oscillatory Potentials in Liquid Metals,

Proceedings of the Royal Society A, 282 (1964) 283-302.

[25]Y. Waseda, The Structure of Non-Crystalline Materials : Liquids and Amorphous Solids, McGraw-

Hill International Book Co., (1980).

[26]T. Iida, R. Guthrie, The Physical Properties of Liquid Metals, Oxford University Press (1988).

[27]J. M. Prausnitz, R. N. Lichtenthaler, E. Azevedo, Molecular Thermodynamics of Fluid-Phase

Equilibria, 1999.

[28]R. R. Hultgren, Selected Values of the Thermodynamic Properties of Binary Alloys, American

Society for Met (1973).

[29]P. Franke, Neusch, Binary Systems. Part 3: Binary Systems From CsK to Mg-Zr, Binary systems.

Electronic copy available at: https://ssrn.com/abstract=4121941

Part 3: Binary Systems from CsK to Mg-Zr, 2005.

Electronic copy available at: https://ssrn.com/abstract=4121941

You might also like

- NaIonSpmManuscript PreprintDocument17 pagesNaIonSpmManuscript PreprintJustine Marie AbarroNo ratings yet

- 1 s2.0 S2772427122000201 MainDocument11 pages1 s2.0 S2772427122000201 MainAPOORVA R GNo ratings yet

- Methodology! Preliminary Results & Conclusions: Gaurav Gyawali, Arjun Sharma, Amber C. Carpenter, Steven W. RickDocument1 pageMethodology! Preliminary Results & Conclusions: Gaurav Gyawali, Arjun Sharma, Amber C. Carpenter, Steven W. RickGaurav GyawaliNo ratings yet

- 2126 1 OnlineDocument16 pages2126 1 Onlinenazua auliaNo ratings yet

- Z Factor CalculationDocument9 pagesZ Factor Calculationzeeshantariq320No ratings yet

- New Correlation For Z-Factor Using Genet PDFDocument9 pagesNew Correlation For Z-Factor Using Genet PDFFreddy Mendoza CoronelNo ratings yet

- Draft 75 Applications of Inverse Gas Chromatography in The Study of Liquid Crystalline Stationary PhasesDocument36 pagesDraft 75 Applications of Inverse Gas Chromatography in The Study of Liquid Crystalline Stationary PhasesberkahNo ratings yet

- 2015 RefinedDummyMgmodel Jiang Zhang Feng TanDocument12 pages2015 RefinedDummyMgmodel Jiang Zhang Feng TanalejandraNo ratings yet

- Prediction of The Hydration Properties of Diamondoids From Free Energy and Potential of Mean Force CalculationsDocument5 pagesPrediction of The Hydration Properties of Diamondoids From Free Energy and Potential of Mean Force CalculationscleitonmacielNo ratings yet

- Linear Programming and The Simplex MethodDocument10 pagesLinear Programming and The Simplex MethodHugo Poma FernándezNo ratings yet

- Chemical Physics LettersDocument7 pagesChemical Physics LettersJohn Justine VillarNo ratings yet

- 95 Sigma Profile Database 2006Document27 pages95 Sigma Profile Database 2006NafferNo ratings yet

- Density and Molar Volume Predictions Using COSMO-RS For Ionic Liquids. An Approach To Solvent DesignDocument8 pagesDensity and Molar Volume Predictions Using COSMO-RS For Ionic Liquids. An Approach To Solvent DesignCristian GonzálezNo ratings yet

- 1 s2.0 S0016236118307725 MainDocument11 pages1 s2.0 S0016236118307725 MainUser UserNo ratings yet

- 2016 Jiang Zhang AnotherdummysDocument11 pages2016 Jiang Zhang AnotherdummysalejandraNo ratings yet

- Ag2-22 Mckee2017Document11 pagesAg2-22 Mckee2017ht117No ratings yet

- 01.modification of Van Laar Activity Coeff - Model PDFDocument12 pages01.modification of Van Laar Activity Coeff - Model PDFqwerasdfNo ratings yet

- HDS Reactor ModelDocument4 pagesHDS Reactor Modelpcyadav8No ratings yet

- Rapid Solidification of Cu-25at.% Ni Alloy: Molecular Dynamics Simulations Using Embedded Atom MethodDocument7 pagesRapid Solidification of Cu-25at.% Ni Alloy: Molecular Dynamics Simulations Using Embedded Atom MethodThanh DinhNo ratings yet

- Comparison of Simple Potential Functions For Simulating Liquid WaterDocument11 pagesComparison of Simple Potential Functions For Simulating Liquid WaterAdarsh PNo ratings yet

- Large Eddy Simulation of Low Reynolds Number Turbulent Hydrogen Jets - Modelling Considerations and Comparison With Detailed ExperimentsDocument15 pagesLarge Eddy Simulation of Low Reynolds Number Turbulent Hydrogen Jets - Modelling Considerations and Comparison With Detailed Experimentsxaviera07No ratings yet

- Research Article Numerical Analysis of Flash Calculation Using Soave Redlich-Kwong Equation of State With MatlabDocument13 pagesResearch Article Numerical Analysis of Flash Calculation Using Soave Redlich-Kwong Equation of State With MatlabManuel ChNo ratings yet

- Leclaire-2012-Numerical Evaluation of Two RecoDocument16 pagesLeclaire-2012-Numerical Evaluation of Two Reco旭康 鲁No ratings yet

- Quantitative Structure-Retention Relationships of Antimicrobial Hydrazides Evaluated by Reverse-Phase Liquid ChromatographyDocument5 pagesQuantitative Structure-Retention Relationships of Antimicrobial Hydrazides Evaluated by Reverse-Phase Liquid ChromatographyvaldisreinNo ratings yet

- The Effect of Tray Geometry On The Sieve Tray EfficiencyDocument9 pagesThe Effect of Tray Geometry On The Sieve Tray EfficiencyDr Mohammed AzharNo ratings yet

- Fa Yazi 2014Document10 pagesFa Yazi 2014ekeneNo ratings yet

- An Assessment of Drag Models in Eulerian-Eulerian CFD Simulation of Gas-Solid Flow Hydrodynamics in Circulating Fluidized Bed RiserDocument19 pagesAn Assessment of Drag Models in Eulerian-Eulerian CFD Simulation of Gas-Solid Flow Hydrodynamics in Circulating Fluidized Bed RiserSAI Khalid HichamNo ratings yet

- Metals 09 00568 PDFDocument16 pagesMetals 09 00568 PDFGNo ratings yet

- Link To Publication in University of Groningen/UMCG Research DatabaseDocument18 pagesLink To Publication in University of Groningen/UMCG Research DatabaseUpendar SiliveruNo ratings yet

- Hybrid Reynolds-Averaged/Large-Eddy Simulations of A Coaxial Supersonic Free-Jet ExperimentDocument36 pagesHybrid Reynolds-Averaged/Large-Eddy Simulations of A Coaxial Supersonic Free-Jet ExperimentmyskyshepherdNo ratings yet

- Volumes of Mixing in Aluminosilicate Garnets: Solid Solution and Strain BehaviorDocument5 pagesVolumes of Mixing in Aluminosilicate Garnets: Solid Solution and Strain BehaviorHeidi ParkerNo ratings yet

- Relativistic Effects On Geometry and Electronic Structure of Small PD Species N 1, 2, 4Document12 pagesRelativistic Effects On Geometry and Electronic Structure of Small PD Species N 1, 2, 4Lata DeshmukhNo ratings yet

- Steven Miller Et Al - Infrared Emissions of H3 + in The Atmosphere of Jupiter in The 2.1 and 4.0 Micron RegionDocument20 pagesSteven Miller Et Al - Infrared Emissions of H3 + in The Atmosphere of Jupiter in The 2.1 and 4.0 Micron RegionPassammNo ratings yet

- G4.Experimental Study and Thermodynamic Calculation PDFDocument14 pagesG4.Experimental Study and Thermodynamic Calculation PDFJeanVillanuevaNo ratings yet

- Alternative Cycles Based On Carbon Dioxide For Central Receiver Solar Power PlantsDocument13 pagesAlternative Cycles Based On Carbon Dioxide For Central Receiver Solar Power PlantsfaizaNo ratings yet

- A Generalized Correlation For The Prediction of Phase Behaviour in Supercritical SystemsDocument7 pagesA Generalized Correlation For The Prediction of Phase Behaviour in Supercritical SystemsMario Ricardo Urdaneta ParraNo ratings yet

- Analysis of Rietveld Method Application For Gyrolite Crystal Structure RefinementDocument6 pagesAnalysis of Rietveld Method Application For Gyrolite Crystal Structure Refinementtensai no tenshiNo ratings yet

- 7 Synthesis and Characterization of La0.75Sr0.25Mn0.5Cr0.2Ti0.3O3 Anodes For SOFCsDocument6 pages7 Synthesis and Characterization of La0.75Sr0.25Mn0.5Cr0.2Ti0.3O3 Anodes For SOFCsafif03.m21No ratings yet

- Journal of Physics: Conference Series: What Is The Structure of Liquid Bismuth?Document11 pagesJournal of Physics: Conference Series: What Is The Structure of Liquid Bismuth?Guy MakovNo ratings yet

- Simulation of NH Temperature-Programmed Desorption Curves Using An Ab Initio Force FieldDocument7 pagesSimulation of NH Temperature-Programmed Desorption Curves Using An Ab Initio Force FieldImran KhanNo ratings yet

- PHMM1226Document11 pagesPHMM1226Marina PiermannNo ratings yet

- Renon1969 PDFDocument7 pagesRenon1969 PDFMohammad ShahidNo ratings yet

- A Priori Phase Equilibrium Prediction From A Segment Contribution Solvation Model - Lin and SandlerDocument15 pagesA Priori Phase Equilibrium Prediction From A Segment Contribution Solvation Model - Lin and SandlerErick David Ravello SaldañaNo ratings yet

- Sauer 1989Document18 pagesSauer 1989manojrnpNo ratings yet

- 1973 Szekely ChemEngSci StructuralModelGas ExpStudyREDUCTIONofPorousNickelOcidePelletswthHydrogenDocument15 pages1973 Szekely ChemEngSci StructuralModelGas ExpStudyREDUCTIONofPorousNickelOcidePelletswthHydrogenAndres CamposNo ratings yet

- Keaveny jcp123Document10 pagesKeaveny jcp123RoronoaNo ratings yet

- SPE-184287-MS Compressibility Factor Correlation For The Niger Delta GasDocument15 pagesSPE-184287-MS Compressibility Factor Correlation For The Niger Delta GasekeneNo ratings yet

- Thermodynamics and Equilibrium Solubility of Carbon Dioxide in Diglycolamine/ Morpholine/WaterDocument10 pagesThermodynamics and Equilibrium Solubility of Carbon Dioxide in Diglycolamine/ Morpholine/WaterDonatas BertasiusNo ratings yet

- Physica E: Low-Dimensional Systems and Nanostructures: SciencedirectDocument7 pagesPhysica E: Low-Dimensional Systems and Nanostructures: SciencedirectFadjar MulyaNo ratings yet

- 1996 - Dasgupta Et Al. - Crystal Structures and Properties of Nylon Polymers From TheoryDocument11 pages1996 - Dasgupta Et Al. - Crystal Structures and Properties of Nylon Polymers From TheoryymiyazyNo ratings yet

- Acs Iecr 5b00563 PDFDocument13 pagesAcs Iecr 5b00563 PDFAssis RochaNo ratings yet

- Structure and Dynamics of Polar Liquids: A Molecular Dynamics Investigation of N, N-Dimethyl FormamideDocument6 pagesStructure and Dynamics of Polar Liquids: A Molecular Dynamics Investigation of N, N-Dimethyl FormamideYashonathSubramanianNo ratings yet

- The Pka Prediction ModuleDocument23 pagesThe Pka Prediction ModulePav GloNo ratings yet

- A Compatible Finite Element Multi-Material ALE Hydrodynamics AlgorithmDocument12 pagesA Compatible Finite Element Multi-Material ALE Hydrodynamics AlgorithmMichael ClarkNo ratings yet

- Thermophysical Behavior of Mercury-Lead Liquid Alloy: N. Panthi, I. B. Bhandari, I. KoiralaDocument11 pagesThermophysical Behavior of Mercury-Lead Liquid Alloy: N. Panthi, I. B. Bhandari, I. KoiralaLakshita DasNo ratings yet

- A Rhodium/silicon Co-Electrocatalyst Design Concept To Surpass Platinum Hydrogen Evolution Activity at High OverpotentialsDocument7 pagesA Rhodium/silicon Co-Electrocatalyst Design Concept To Surpass Platinum Hydrogen Evolution Activity at High OverpotentialsDada GiltronNo ratings yet

- 1 s2.0 0013794479901103 MainDocument4 pages1 s2.0 0013794479901103 MainHicham FaridNo ratings yet

- Computational Pharmaceutical Solid State ChemistryFrom EverandComputational Pharmaceutical Solid State ChemistryYuriy A. AbramovNo ratings yet

- Hybrid Nanomaterials: Advances in Energy, Environment, and Polymer NanocompositesFrom EverandHybrid Nanomaterials: Advances in Energy, Environment, and Polymer NanocompositesSuneel Kumar SrivastavaNo ratings yet

- Steel Rebar Sizes and Weights ChartsDocument2 pagesSteel Rebar Sizes and Weights ChartsNadiah Abdul RahamanNo ratings yet

- 6th Grade Health Lesson Plan - Portfolio - BloomsDocument3 pages6th Grade Health Lesson Plan - Portfolio - Bloomsapi-475320683No ratings yet

- Outline PatentsDocument37 pagesOutline Patentspbp613No ratings yet

- Z370 AORUS Gaming 3: User's ManualDocument48 pagesZ370 AORUS Gaming 3: User's ManualAtrocitus RedNo ratings yet

- IBS Site Survey ReportDocument101 pagesIBS Site Survey ReportSyed Zahid ShahNo ratings yet

- KentecDocument22 pagesKentecPoposki Sinisa100% (1)

- Healthcare Mobility SecuirtyDocument23 pagesHealthcare Mobility SecuirtyDavid AntelizNo ratings yet