Professional Documents

Culture Documents

The Erection of The Hoist

The Erection of The Hoist

Uploaded by

Vedad SaletovicOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Erection of The Hoist

The Erection of The Hoist

Uploaded by

Vedad SaletovicCopyright:

Available Formats

6.

THE ERECTION OF THE HOIST

6.1 Preparing the Erection ........................................................3

6.1.1 The Weights of some Hoist Components......................4

6.1.2 The Foundation Slab for a Single SCXX32 Hoist ...........5

6.1.2.1 Reinforcement ....................................................6

6.1.3 The Foundation Slab for a Double SCXX32 ..................8

6.1.3.1 The Foundation Slab for a Double XX32 Hoist10

6.1.3.2 Reinforcement ..................................................11

6.1.4 The Foundation Slab for a Single SCXX37 Hoist .........13

6.1.4.1 Reinforcement ..................................................14

6.1.5 The Foundation Slab for a Double SCXX37 ................16

6.1.5.1 The Foundation Slab for a Double SCXX37 ....18

6.1.5.2 Reinforcement ..................................................19

6.1.6 Supporting Forces Directed to the Ground ................21

6.1.6.1 Single Hoist without the Concrete ..................21

6.1.6.2 Single Hoist with the Concrete Foundation ...22

6.1.6.3 Double Hoist without the Concrete Found....23

6.1.6.4 Double Hoist with the Concrete Fondation...24

6.1.7 Mounting the Single Hoist, Freestanding ....................25

6.1.8 Mounting the Double Hoist, Freestanding ..................26

6.1.9 Lifting the Hoist ..............................................................27

6.1.9.1 Top Part ..............................................................27

6.1.9.2 Lifting the Cage ................................................27

6.1.9.3 Lifting th Ground Station and the Cage ........29

6.1.9.4 Lifting the Lifting Mechanism ...........................30

6.1.9.5 Lifting the Mast ..................................................32

6.2 Anchoring the Mast to the Façade..............................33

6.2.1 HD Anchoring ...............................................................34

6.2.1.1 HD Anchor Spacing ..........................................34

6.2.1.2 Anchor Force Tables for HD Anchors .............35

6.2.1.3 Wall Panel Anchor Bolt Force Tables

for HD Anchors ..................................................39

6.2.1.4 Support Pipe Lengths .......................................43

V16C_11.2006 Erection SC-hoist Pos 6

1

6. THE ERECTION OF THE HOIST

6.2.2 LD Anchoring ................................................................46

6.2.2.1 LD Anchor Spacing ..........................................46

6.2.2.2 Anchor Force Tables for LD Anchors ..............47

6.2.2.3 Wall Panel Anchor Bolt Force Tables

for LD Anchors ...................................................51

6.3 Mounting the Basic Unit ...................................................56

6.4 Mounting the Mast .............................................................61

6.5 Mounting the Pipe Line .....................................................64

6.6 Anchoring .............................................................................66

6.7 Cable Guides ............................................................ 68

6.7.1 Installation of the Cable Guides .................................69

6.8 Landings ................................................................................70

6.8.1 Installing the Double Doors .........................................70

6.8.2 Installing the Sliding Doors...........................................70

6.8.3 Installing the Gate ........................................................70

6.8.4 Installing the Set of Electrical Components ...............72

6.9 Access Bridges according to the Regulations ........73

6.10 Mast Limit Switch Rigid Rails ...........................................74

6.10.1 General Information .....................................................74

6.10.2 The Bottom Limit Rigid Rail ...........................................74

6.10.2.1 The Relay Control ...........................................74

6.10.2.2 The Logic Control............................................74

6.10.3 The Top Limit Rigid Rail .................................................74

6.10.3.1 The Relay Control ...........................................74

6.10.3.2 Logiikkaohjaus .................................................74

6.10.4 The Safety Limit Rigid Rails ...........................................75

6.10.5 The Rigid Rails on the Landings ...................................75

6.10.5.1 The Relay Control ...........................................75

6.10.5.2 The Logic Control............................................76

6.10.6 Dimensional Drawing ...................................................77

SC-hoist Pos 6 Erection V16C_11.2006

2

6.11 Inspections............................................................................78

6.11.1 General .........................................................................78

6.11.2 The Start-up Inspection ................................................78

6.11.3 The Erection Inspection ...............................................78

6.11.4 The Maintenance Inspection ......................................78

6.11.5 Points of Inspection ......................................................79

6.11.5.1 The Erection Inspection Form ........................80

6.11.5.2 The Maintenance Inspection Form...............81

6.11.6 The Weather Conditions...............................................82

6. THE ERECTION OF THE HOIST

6.1 Preparing the Erection

Prior to delivering the hoist to the site one holes for the cotter bolts on the vault and

must make an erection plan including, in what places if the hoist is to be anchored

among other things, the selection of the to the base as well.

place for erecting the hoist, a plan for the

mast anchoring and landing placements When the hoist is erected directly on the

as well as a calculation of the components ground or when it is mounted on a founda-

needed for the hoist erection. tion slab, the ground must be compacted

and levelled before the mounting. When

Before starting the erection of the hoist making the foundation on the ground take

choose a place for the erection. This is care also of the drainage so that no wa-

when you make a decision whether to ter remains standing on the erection site.

erect the hoist directly on a concrete base, Also the possible frost susceptibility has to

for example on a vault or compact ground, be taken into account and prevented.

or to mount it on a cast concrete founda- The foundation slab is cast, reinforced and

tion slab. The foundation slab should be equipped with the mast anchoring frame

cast in good time before starting the erec- according to the dimensional drawings.

tion so that the slab has time to dry and When making the foundation slab note that

harden properly. screw heads of the anchoring frame should

not protrude from the concrete, but on the

When the hoist is erected, for instance on contrary, are placed a few millimetres be-

a vault, the contractor should give an ap- low the concrete surface. The concrete sur-

proval of the vault’s load capacity. The dy- face has to be even and smoothed. In ad-

namic forces caused by the hoist and the dition it is recommended to fix lifting brack-

load should also be taken into account in ets on the slab edges, from which the slab

the load capacity calculations. Also one can later easily be lifted.

has to find out whether it is possible to drill

V16C_11.2006 Erection SC-hoist Pos 6

3

6.1.1 The Weights of Some Hoist Components

The following weights can be used for calculating the forces influencing the foundation.

Hoist cage 1600 kg

Ground station 1250 kg

Lifting mechanism 470 kg

Mast section 1,5 m incl. bolts 127 kg

Vertical pipe 3 m 24 kg

Pipe support 20 kg

Wall tie set 1,6 - 2,7 m 155 kg

Landing bar, long 19 kg

Landing gate incl. electric equipment 12 kg

SC-hoist Pos 6 Erection V16C_11.2006

4

6.1.2 The Foundation Slab for a Single SCXX32 Hoist

2

1 Reinforcement

2 Concrete volume V=4,0 m

Weight: 8930 kg quality B25 F25 (PN-EN 206-1)

����

� � ���

�� �

���

���

� �

����

����

���

���

��

��

����

���

V16C_11.2006 Erection SC-hoist Pos 6

5

6.1.2.1 Reinforcement

�

� �

� �

Weight: 520,5 kg

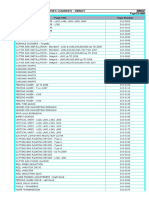

Pos Number, pcs Description Scancode

1 1 Mounting frame PG104971

2 46 Reinforcement, corrugated bar I see the picture

3 4 Lifting eye PG109645

4 2 Fastening plate PG109649

5 34 Reinforcement, corrugated bar II see the picture

Pos. 2 Reinforcement, corrugated bar I, bending instruction

��

��������

���

�������

��

Material: S235J2G3

Length: L= 2922 mm

���

SC-hoist Pos 6 Erection V16C_11.2006

6

�����������

���

���

���

���

��

���

�����������

����

����

���

���

����

���

��

� ��

���

���

��

��� a4

Pos. 4 Fastening plates are attached to the reinforcement

����������������������������������������������������

by welding =>

Pos. 5 Reinforcement, corrugated bar II

���

Material: S235J2G3

��

���� ����

V16C_11.2006 Erection SC-hoist Pos 6

7

6.1.3 The Foundation Slab for a Double SCXX32

Pos Number, pc’s Description Scancode

1 1 Foundation slab for a single hoist

2 1 Foundation slab for a double hoist

3 4 Screw M30x80-8.8 PN EN ISO 4017 A4J 89038812

4 4 Nut M30-8 PN EN 24032 A4J 89211810

5 8 Washer 31 HV DIN 6916 89105102

SC-hoist Pos 6 Erection V16C_11.2006

8

���� ����

���

����

��� ����

� �

� �

���

����

� � � �

V16C_11.2006 Erection SC-hoist Pos 6

9

6.1.3.1 The Foundation Slab for a Double XX32 Hoist

1 Reinforcement

2 Concrete volume V = 2.75 m3

Weight: 5700 kg quality B25 F25 (PN-EN 206-1)

����

����

����

� �

���

��

���

���

��

����

���

SC-hoist Pos 6 Erection V16C_11.2006

10

6.1.3.2 Reinforcement

� �

Paino: 287,5 kg

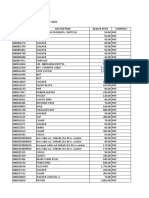

Pos Number pcs Description Scancode

1 4 Lifting eye PG109645

2 2 Fastening plate PG109649

3 42 Reinforcement, corrugated bar I see the picture

4 18 Reinforcement, corrugated bar II see the picture

Pos. 3 Reinforcement, corrugated bar II, bending instruction

��

��������

��

���

�

�������

Material: S235J2G3

��

Length: L= 2022 mm

�

��

���

V16C_11.2006 Erection SC-hoist Pos 6

11

����

�����

���

���

�����������

� � ��

� ���

����

���

� ��

���

���

��

��� ���

a4

Pos. 2 Fastening plates are attached to the reinforcement

����������������������������������������������������

by welding

Pos. 4 Reinforcement, corrugated bar II

���

��

��������

Material: S235J2G3

SC-hoist Pos 6 Erection V16C_11.2006

12

6.1.4 The Foundation Slab for a Single SCXX37 Hoist

2

1

1 Reinforcement

2 Concrete volume V=4,5 m³

Weight: 9930 kg quality B25 F25 (PN-EN 206-1)

����

� �

� ��

���

���

���

� �

����

�� � �

���

��

���

���

��

����

����

V16C_11.2006 Erection SC-hoist Pos 6

13

6.1.4.1 Reinforcement �

�

�

� �

Weight: 557 kg

Pos Number pcs Description Scancode

1 1 Mounting frame PG104971

2 50 Reinforcement, corrugated bar I see the picture

3 34 Reinforcement, corrugated bar II see the picture

4 4 Lifting eye PG109645

5 2 Fastening plate PG109649

Pos. 2 Reinforcement, corrugated bar I

��

��������

���

�������

��

Material: S235J2G3

Length: L= 2922 mm

���

SC-hoist Pos 6 Erection V16C_11.2006

14

�����������

���

���

���

� ��

��

���

�����������

����

����

����

���

���

���

���

��

���

� ��

���

��

���

���

a4

Pos. 5 Fastening plates are attached to the reinforcement by

����������������������������������������������������

welding =>

Pos. 3 Reinforcement, corrugated bar II

���

��

��������

Material: S235J2G3

V16C_11.2006 Erection SC-hoist Pos 6

15

6.1.5 The Foundation Slab for a Double SCXX37

Pos Number, pcs Description Scancode

1 1 Foundation slab for a single hoist

2 1 Foundation slab for a double hoist

3 4 Screw M30x80-8.8 PN EN ISO 4017 A4J 89038812

4 4 Nut M30-8 PN EN 24032 A4J 89211810

5 8 Washer 31 HV DIN 6916 89105102

SC-hoist Pos 6 Erection V16C_11.2006

16

� ���� ����

���

����

��� ����

� �

���

����

� � �

�

�

V16C_11.2006 Erection SC-hoist Pos 6

17

6.1.5.1 The Foundation Slab for a Double SCXX37 Hoist

1 Reinforcement

2 Concrete volume V=3,0 m³

Weight: 6660 kg quality B25 F25 (PN-EN 206-1)

����

� �

���

����

����

� �

��

���

���

���

��

����

SC-hoist Pos 6 Erection V16C_11.2006

18

6.1.5.2 Reinforcement

Weight: 309 kg

Pos Number, pcs Description Scancode

1 18 Reinforcement, corrugated bar II see the picture

2 4 Lifting eye PG109645

3 2 Fastening plate PG109649

4 46 Reinforcement, corrugated bar II see the picture

Pos. 4 Reinforcement, corrugated bar II, bending

��

��������

��

���

�

�������

��

�

�� Material: S235J2G3

Length: L= 2022 mm

���

V16C_11.2006 Erection SC-hoist Pos 6

19

����

�����

���

���

����

����

����

����

���

���

���

���

��

���

���

a4

Pos. 3 Fastening plates are attached to the reinforcement

����������������������������������������������������

by welding=>

Pos. 1 Reinforcement, corrugated bar II, bending instruction

���

��

��������

Materiaali: S235J2G3

SC-hoist Pos 6 Erection V16C_11.2006

20

6.1.6 Supporting Forces Directed to the Ground

6.1.6.1 Single Hoist without the Concrete

The forces directed to the base through the outriggers

- steel frame without the concrete foundation slab

- pipeline and landings mounted

- single hoist

Mast Supporting forces [kN] Max. number

height F1 F2 F3 F4 Fcp Ftotal of landings

[m]

10 21.9 29.0 21.9 29.0 44.9 73.4 1

20 30.1 37.2 30.1 37.2 54.2 94.5 5

30 30.1 37.2 30.1 37.2 63.5 113.8 8

40 30.1 37.2 30.1 37.2 72.8 134.8 12

50 30.1 37.2 30.1 37.2 82.1 155.9 16

60 33.8 38.7 30.1 37.2 91.4 175.2 19

70 40.0 44.2 30.1 37.2 100.7 196.2 23

80 46.2 49.8 30.1 37.2 110.0 217.3 27

90 52.4 55.3 30.1 37.2 119.3 238.3 31

100 57.5 60.2 30.1 37.2 128.6 257.6 34

V16C_11.2006 Erection SC-hoist Pos 6

21

6.1.6.2 Single Hoist with the Concrete Foundation

The forces directed to the base through the outriggers

- hoist mounted on the concrete foundation

- pipeline and landings mounted

- single hoist

Mast Supporting forces [kN] Max. number

height F1 F2 F3 F4 Fcp Ftotal of landings

[m]

10 21.9 29.0 21.9 29.0 44.9 73.4 1

20 30.1 37.2 30.1 37.2 54.2 94.5 5

30 30.1 37.2 30.1 37.2 63.5 113.8 8

40 30.1 37.2 30.1 37.2 72.8 134.8 12

50 30.1 37.2 30.1 37.2 82.1 155.9 16

60 33.8 38.7 30.1 37.2 91.4 175.2 19

70 40.0 44.2 30.1 37.2 100.7 196.2 23

80 46.2 49.8 30.1 37.2 110.0 217.3 27

90 52.4 55.3 30.1 37.2 119.3 238.3 31

100 57.5 60.2 30.1 37.2 128.6 257.6 34

SC-hoist Pos 6 Erection V16C_11.2006

22

6.1.6.3 Double Hoist without the Concrete Foundation

The forces directed to the base through the outriggers

- steel frame without the concrete foundation slab

- pipeline and landings mounted

- double hoist

Mast Supporting forces [kN] Max. no.

height F1 F2 F3 F4 F5 F6 Fcp Ftotal of landings

[m]

10 21.9 29.0 21.9 29.0 21.9 21.9 92.6 131.6 1

20 30.1 37.2 30.1 37.2 30.1 30.1 103.6 161.6 5

30 30.1 37.2 30.1 37.2 30.1 30.1 114.7 188.6 8

40 30.1 38.0 30.1 37.2 30.1 30.1 125.7 218.6 12

50 30.1 46.3 30.1 37.2 30.1 30.1 136.7 248.6 16

60 33.8 53.3 30.1 37.2 30.1 30.1 147.7 275.6 19

70 40.0 61.6 30.1 37.2 30.7 30.1 158.7 305.6 23

80 46.2 69.9 30.1 37.2 35.2 30.1 169.8 335.6 27

90 52.4 78.2 30.1 37.2 39.6 30.1 180.8 365.6 31

100 57.5 85.3 30.1 37.2 43.4 30.1 191.8 392.6 34

V16C_11.2006 Erection SC-hoist Pos 6

23

6.1.6.4 Double Hoist with the Concrete Foundation

The forces directed to the base through the outriggers

- steel frame with the concrete foundation slab

- pipeline and landings mounted

- double hoist

Mast Supporting forces [kN] Max . no.

height F1 F2 F3 F4 F5 F6 Fcp Ftotal of landings

[m]

10 21.9 29.0 21.9 29.0 21.9 21.9 92.6 131.6 1

20 30.1 37.2 30.1 37.2 30.1 30.1 103.6 161.6 5

30 30.1 37.2 30.1 37.2 30.1 30.1 114.7 188.6 8

40 30.1 38.0 30.1 37.2 30.1 30.1 125.7 218.6 12

50 30.1 46.3 30.1 37.2 30.1 30.1 136.7 248.6 16

60 33.8 53.3 30.1 37.2 30.1 30.1 147.7 275.6 19

70 40.0 61.6 30.1 37.2 30.7 30.1 158.7 305.6 23

80 46.2 69.9 30.1 37.2 35.2 30.1 169.8 335.6 27

90 52.4 78.2 30.1 37.2 39.6 30.1 180.8 365.6 31

100 57.5 85.3 30.1 37.2 43.4 30.1 191.8 392.6 34

SC-hoist Pos 6 Erection V16C_11.2006

24

6.1.7 Mounting the Single Hoist, Freestanding

MAX. ALLOWED LIFTING AND MAST HEIGHT WITH VARIOUS FOUNDATIONS

- wind velocity max. 20 m/s both during the operation and the mounting

and dismounting

Outriggers Concrete foundation

Ground station without the Ground station + out- Ground station attached

foundation slab and outriggers riggers without the to the concrete foundation

V16C_11.2006 Erection SC-hoist Pos 6

25

6.1.8 Mounting the Double Hoist, Freestanding

MAX. ALLOWED LIFTING AND MAST HEIGHT WITH VARIOUS FOUNDATIONS

- wind velocity max. 20 m/s both during the operation and the mounting

and dismounting

Concrete foundation

Ground station without the Ground station attached to the

foundation slab concrete foundation

SC-hoist Pos 6 Erection V16C_11.2006

26

6.1.9 Lifting the Hoist

When lifting the hoist and its parts the giv- strong and able to resist the forces influenc-

en instructions must be followed strictly. ing it during its use.

The hoist is manufactured with sheet metal

technology, which as a construction is very

6.1.9.1 Top Part

The top part is an auxiliary device used to ral fastening points for the lifting rope for va-

help lift the hoist. The top part is attached rious loading situations (picture 6.1.4).

to the mast top with four mast bolts. The top

part is equipped with a lifting rod with seve-

6.1.9.2 Lifting the Cage

The cage alone can be lifted either with a with the lifting rope and take care that the

forklift by the pockets placed on the lower ropes are long enough. If the cage is lifted

edge of the cage (picture 6.1.1) or by the without the supporting bars and/or with too

brackets on the cage roof (pictures 6.1.2 A, short ropes the cage constructions are in-

b and C). When lifting by the brackets on fluenced by compressive forces that may

the cage roof one must use supporting bars damage the cage construction.

1000 KG - EMPTY CAGE

2200 KG - CAGE WITH 8 MAST SECTIONS

T2-999005

Picture 6.1.1 Lifting the cage by the

V16C_11.2006 Erection SC-hoist Pos 6

27

1000 KG - EMPTY CAGE

2200 KG - CAGE WITH 8 MAST SECTIONS

SUPPORTING BAR

B C

T2-999004

Picture 6.1.2 Lifting the cage by the brackets (A, B, C)

SC-hoist Pos 6 Erection V16C_11.2006

28

6.1.9.3 Lifting the Ground Station and the Cage

The ground station and the cage can be

lifted and transported as one whole. Use

the top part attached to the mast top to

☞ Lifting the ground station and the

cage together by the brackets

on the cage roof is strictly forbid-

help with the lifting (picture 6.1.3). den.

T2-999001

Picture 6.1.3 Lifting the ground station and the cage

V16C_11.2006 Erection SC-hoist Pos 6

29

Ground station, cage and lifting

mechanism

Ground station and cage without lifting

mechanism

Lifting mechanism and mast section

Picture 6.1.4 Top part

6.1.9.4 Lifting the Lifting Mechanism

The hoist lifting mechanism is a unit, which

is removed from the hoist during the trans-

portation. The lifting mechanism is lifted

and stored together with the mast section

it is clamped to. When lifting the mech-

anism (picture 6.1.5) use the top part at-

tached to the mast top.

SC-hoist Pos 6 Erection V16C_11.2006

30

T2-999002

Picture 6.1.5 Lifting the lifting mechanism

V16C_11.2006 Erection SC-hoist Pos 6

31

6.1.9.5 Lifting the Mast

The top part also may be used in situations

when several mast sections have been

joined together on the ground, and the

mast has to be erected as a whole (picture

6.1.6). However, the length of the mast lift-

ed as a whole must not exceed the length

of the mast anchoring interval or the whole

length of the freestanding mast.

T2-999003

Picture 6.1.6 Lifting the mast

SC-hoist Pos 6 Erection V16C_11.2006

32

6.2 Anchoring the Mast to the Façade

The hoist cage, the load in the cage and In table a.b are shown maximum values for

wind cause forces influencing the mast. anchoring forces. L is the distance from the

Due to these forces the hoist has to be sup- mast’s centre to the building’s façade. In

ported at fixed intervals to the building be- the table are given also the forces influenc-

side which it is erected. The forces influenc- ing the mast V,x and V,y. With these maxi-

ing the mast are taken into account in ac- mum values the supporting forces can be

cordance with the standards and regula- determined in proportion to shorter distanc-

tions, and on their basis the wall ties are di- es.

mensioned to comply with these regula-

tions.

The mast is anchored to the building’s

façade at certain intervals. The anchoring

interval depends on the means of the hoist’s

foundation, the mast height, the used an-

chor model and the wind conditions.

V16C_11.2006 Erection SC-hoist Pos 6

33

6.2.1 HD Anchoring

6.2.1.1 HD Anchor Spacing

The following values are based on HD anchor types with a 21

meter interval between the anchors.

Single Double Single Double

Max. allowed overhang with

double top anchors

WALL ANCHORS:

Max. allowed overhang with double top anchors:

S1 = 12 m hoist without outriggers and concrete foundation

S1 = 19 m hoist with outriggers without concrete

foundation

S1 = 25 m steel frame tied to concrete foundation

Spacing to next anchor max. S2 = S1 + 1.5 m, but not greater

than 21 m. Spacing in general max. 21 m.

PIPE SUPPORTS:

- first support, max. height 3.5 m

- spacing max. Ps = 3.0 m

MAST OVERHANG:

1. Standard top anchor::

Oh_max = 7,5 m, single cage

Oh_max = 3,0 m, double cage

2. Double top anchor:

Oh_max = 15,0 m, single cage

Oh_max = 10,5 m, double cage

MAST HEIGHT:

Hmax_single cage = 200 m, hoist without concrete foundation

Hmax_single cage = 300 m, hoist on concrete foundation

Hmax_double cage = 130 m, hoist without concrete foundation

Hmax_double cage = 300 m, hoist on concrete foundation

SC-hoist Pos 6 Erection V16C_11.2006

34

6.2.1.2 Anchor Force Tables for HD Anchors

• support pipe wall panels symmetrically placed with respect to the mast

• spacing to the next anchor max. 21.0 m

• wind velocity max. 12.5 m/s during mounting and dismounting

• wind velocity max. 20.0 m/s during operation

• combinations indicated in Table xxx are forbidden

Following the European Storm wind Height [m] A/B C D E

Map (EN 12159 Appendix A) with Eu-

0<H<=10 21 21 21 21

rope divided into zones A to E, the

10<H<=20 21 21 21 18

spacing between anchors must not

exceed the values given in Table 20<H<=50 21 21 19 15

6.2.1. 50<H<=100 21 21 16 13

Table 6.2.1

V16C_11.2006 Erection SC-hoist Pos 6

35

Force F2 [kN]

B [mm] 900 1000 1100 1200 1300 1400 1600

A [mm]

400 *** 33.7 30.5 27.9 25.7 23.8 20.7

500 *** *** 32.1 29.4 27.0 25.0 21.8

600 *** *** 33.7 30.8 28.4 26.3 22.9

800 *** *** *** 33.7 31.0 28.7 25.0

1000 *** *** *** *** 33.7 31.2 27.2

1200 *** *** *** *** *** 33.7 29.4

1500 *** *** *** *** *** *** 32.6

2000 *** *** *** *** *** *** ***

2500 *** *** *** *** *** *** ***

3000 *** *** *** *** *** *** ***

3500 *** *** *** *** *** *** ***

4500 *** *** *** *** *** *** ***

B[mm] 1800 2000 2500 3000 4000 5000 6000

A[mm]

400 *** *** *** *** *** *** ***

500 19.3 *** *** *** *** *** ***

600 20.3 18.2 *** *** *** *** ***

800 22.2 19.9 15.9 *** *** *** ***

1000 24.1 21.6 17.2 *** *** *** ***

1200 26.0 23.3 18.6 15.4 *** *** ***

1500 28.9 25.9 20.6 17.1 *** *** ***

2000 33.7 30.2 24.0 20.0 14.9 *** ***

2500 *** *** 27.5 22.8 17.0 13.6 ***

3000 *** *** *** 25.7 19.2 15.3 12.7

3500 *** *** *** 28.5 21.3 17.0 14.1

4500 *** *** *** *** 25.5 20.4 17.0

SC-hoist Pos 6 Erection V16C_11.2006

36

Force F1a [kN]:

B[mm] 900 1000 1100 1200 1300 1400 1600

A[mm]

400 *** -2.5 2.3 6.3 9.6 12.4 17.0

500 *** *** 1.9 5.1 7.8 10.1 13.8

600 *** *** 1.6 4.3 6.6 8.6 11.8

800 *** *** *** 3.5 5.3 6.9 9.4

1000 *** *** *** *** 4.5 5.9 8.0

1200 *** *** *** *** *** 5.2 7.1

1500 *** *** *** *** *** *** 6.3

2000 *** *** *** *** *** *** ***

2500 *** *** *** *** *** *** ***

3000 *** *** *** *** *** *** ***

3500 *** *** *** *** *** *** ***

B[mm] 1800 2000 2500 3000 4000 5000 6000

A[mm]

400 *** *** *** *** *** *** ***

500 16.7 *** *** *** *** *** ***

600 14.2 16.2 *** *** *** *** ***

800 11.3 12.9 15.6 *** *** *** ***

1000 9.7 11.0 13.4 *** *** *** ***

1200 8.6 9.8 11.9 13.3 *** *** ***

1500 7.6 8.6 10.4 11.7 *** *** ***

2000 6.5 7.4 9.0 10.1 11.4 *** ***

2500 *** *** 8.2 9.2 10.3 11.0 ***

3000 *** *** *** 8.5 9.6 10.3 10.7

3500 *** *** *** 8.1 9.2 9.8 10.2

V16C_11.2006 Erection SC-hoist Pos 6

37

Force F1b [kN]:

B[mm] 900 1000 1100 1200 1300 1400 1600

A[mm]

400 *** 19.3 14.5 10.5 7.2 4.4 -0.2

500 *** *** 14.9 11.7 9.0 6.7 3.0

600 *** *** 15.2 12.5 10.2 8.2 5.0

800 *** *** *** 13.3 11.5 9.9 7.4

1000 *** *** *** *** 12.3 10.9 8.8

1200 *** *** *** *** *** 11.6 9.7

1500 *** *** *** *** *** *** 10.5

2000 *** *** *** *** *** *** ***

2500 *** *** *** *** *** *** ***

3000 *** *** *** *** *** *** ***

3500 *** *** *** *** *** *** ***

B[mm] 1800 2000 2500 3000 4000 5000 6000

A[mm]

400 *** *** *** *** *** *** ***

500 0.1 *** *** *** *** *** ***

600 2.6 0.6 *** *** *** *** ***

800 5.5 3.9 1.2 *** *** *** ***

1000 7.1 5.8 3.4 *** *** *** ***

1200 8.2 7.0 4.9 3.5 *** *** ***

1500 9.2 8.2 6.4 5.2 *** *** ***

2000 10.3 9.4 7.8 6.7 5.4 *** ***

2500 *** *** 8.6 7.7 6.5 5.8 ***

3000 *** *** *** 8.3 7.2 6.5 6.1

3500 *** *** *** 8.7 7.7 7.0 6.6

4500 *** *** *** *** 8.3 7.7 7.3

SC-hoist Pos 6 Erection V16C_11.2006

38

6.2.1.3 Wall Panel Anchor Bolt Force Tables for HD Anchors

• support pipe wall panels symmetrically placed with respect

to the mast

• forces directed to the anchor bolts are deduced from the

anchor force tables produced in Chapter 6.2.1.2 Anchor

Force Tables for HD Anchors

Force Fao [kN]:

B [mm] 900 1000 1100 1200 1300 1400 1600

A [mm]

400 *** 17.6 16.6 15.8 15.2 14.6 13.7

500 *** *** 17.4 16.4 15.6 14.9 13.7

600 *** *** 18.2 17.1 16.1 15.3 14.0

800 *** *** *** 18.5 17.4 16.4 14.8

1000 *** *** *** *** 18.7 17.5 15.7

1200 *** *** *** *** *** 18.8 16.7

1500 *** *** *** *** *** *** 18.3

2000 *** *** *** *** *** *** ***

2500 *** *** *** *** *** *** ***

3000 *** *** *** *** *** *** ***

3500 *** *** *** *** *** *** ***

4500 *** *** *** *** *** *** ***

5420 *** *** *** *** *** *** ***

B [mm] 1800 2000 2500 3000 4000 5000 6000

A [mm]

400 *** *** *** *** *** *** ***

500 12.8 *** *** *** *** *** ***

600 13.0 12.2 *** *** *** *** ***

800 13.6 12.6 10.8 *** *** *** ***

1000 14.3 13.2 11.2 *** *** *** ***

1200 15.2 13.9 11.7 10.3 *** *** ***

1500 16.6 15.1 12.6 10.9 *** *** ***

2000 19.0 17.3 14.2 12.2 9.7 *** ***

2500 *** *** 15.9 13.6 10.7 8.9 ***

3000 *** *** *** 15.0 11.7 9.7 8.4

3500 *** *** *** 16.4 12.8 10.6 9.1

4500 *** *** *** *** 14.9 12.3 10.5

5420 *** *** *** *** *** *** ***

V16C_11.2006 Erection SC-hoist Pos 6

39

Force Fai [kN]:

B [mm] 900 1000 1100 1200 1300 1400 1600

A [mm]

400 *** 17.6 15.2 13.2 11.5 10.1 7.8

500 *** *** 16.1 14.1 12.5 11.1 8.8

600 *** *** 16.9 15.0 13.4 12.0 9.7

800 *** *** *** 16.6 14.9 13.5 11.2

1000 *** *** *** *** 16.4 14.9 12.5

1200 *** *** *** *** *** 16.3 13.8

1500 *** *** *** *** *** *** 15.6

2000 *** *** *** *** *** *** ***

2500 *** *** *** *** *** *** ***

3000 *** *** *** *** *** *** ***

3500 *** *** *** *** *** *** ***

4500 *** *** *** *** *** *** ***

B [mm 1800 2000 2500 3000 4000 5000 6000

A [mm]

400 *** *** *** *** *** *** ***

500 7.1 *** *** *** *** *** ***

600 8.0 6.6 *** *** *** *** ***

800 9.4 8.0 5.5 *** *** *** ***

1000 10.7 9.2 6.6 *** *** *** ***

1200 11.8 10.3 7.5 5.7 *** *** ***

1500 13.5 11.8 8.8 6.8 *** *** ***

2000 16.1 14.2 10.8 8.5 5.7 *** ***

2500 *** *** 12.6 10.1 7.0 5.1 ***

3000 *** *** *** 11.7 8.2 6.1 4.7

3500 *** *** *** 13.2 9.3 7.1 5.5

SC-hoist Pos 6 Erection V16C_11.2006

40

Force Fbi [kN]:

B [mm] 900 1000 1100 1200 1300 1400 1600

A [mm]

400 *** 22.1 18.9 16.3 14.1 12.2 9.2

500 *** *** 20.2 17.6 15.4 13.5 10.5

600 *** *** 21.5 18.8 16.6 14.7 11.6

800 *** *** *** 21.2 18.9 16.9 13.6

1000 *** *** *** *** 21.1 18.9 15.5

1200 *** *** *** *** *** 21.0 17.3

1500 *** *** *** *** *** *** 20.0

2000 *** *** *** *** *** *** ***

2500 *** *** *** *** *** *** ***

3000 *** *** *** *** *** *** ***

3500 *** *** *** *** *** *** ***

B [mm] 1800 2000 2500 3000 4000 5000 6000

A [mm]

400 *** *** *** *** *** *** ***

500 8.2 *** *** *** *** *** ***

600 9.3 7.4 *** *** *** *** ***

800 11.1 9.2 5.7 *** *** *** ***

1000 12.8 10.8 7.0 *** *** *** ***

1200 14.5 12.3 8.3 5.7 *** *** ***

1500 16.9 14.4 10.1 7.2 *** *** ***

2000 20.7 17.9 12.9 9.6 5.5 *** ***

2500 *** *** 15.7 11.9 7.3 4.6 ***

3000 *** *** *** 14.2 9.0 6.0 4.0

3500 *** *** *** 16.5 10.7 7.3 5.1

4500 *** *** *** *** 14.1 10.1 7.4

V16C_11.2006 Erection SC-hoist Pos 6

41

Force Fbo [kN]:

B [mm] 900 1000 1100 1200 1300 1400 1600

A [mm]

400 *** 13.5 13.2 13.0 12.8 12.6 12.3

500 *** *** 13.6 13.3 12.9 12.7 12.2

600 *** *** 14.1 13.6 13.2 12.8 12.3

800 *** *** *** 14.3 13.8 13.3 12.6

1000 *** *** *** *** 14.4 13.9 13.0

1200 *** *** *** *** *** 14.5 13.5

1500 *** *** *** *** *** *** 14.3

2000 *** *** *** *** *** *** ***

2500 *** *** *** *** *** *** ***

3000 *** *** *** *** *** *** ***

3500 *** *** *** *** *** *** ***

B [mm] 1800 2000 2500 3000 4000 5000 6000

A[mm]

400 *** *** *** *** *** *** ***

500 11.8 *** *** *** *** *** ***

600 11.8 11.4 *** *** *** *** ***

800 12.0 11.5 10.7 *** *** *** ***

1000 12.3 11.8 10.8 *** *** *** ***

1200 12.8 12.1 11.0 10.2 *** *** ***

1500 13.4 12.7 11.4 10.6 *** *** ***

2000 14.7 13.8 12.2 11.2 9.9 *** ***

2500 *** *** 13.1 11.9 10.4 9.4 ***

3000 *** *** *** 12.6 10.9 9.8 9.1

3500 *** *** *** 13.4 11.5 10.3 9.5

SC-hoist Pos 6 Erection V16C_11.2006

42

6.2.1.4 Support Pipe Lengths

• support pipe wall panels symmetrically placed

with respect to the mast

Pipe length 1

B [mm] 900 1000 1100 1200 1300 1400 1600

A [mm]

400 343 336 336 343 358 378 433

500 441 436 436 441 453 469 515

600 540 536 536 540 549 563 602

800 739 735 735 739 746 756 785

1000 938 935 935 938 943 951 975

1200 *** 1135 1135 1137 1142 1148 1168

1500 *** *** 1435 1437 1440 1446 1461

2000 *** *** *** *** 1939 1943 1954

2500 *** *** *** *** *** 2441 2450

3000 *** *** *** *** *** *** 2948

3500 *** *** *** *** *** *** ***

B [mm] 1800 2000 2500 3000 4000 5000 6000

A [mm]

400 *** *** *** *** *** *** ***

500 574 *** *** *** *** *** ***

600 653 715 *** *** *** *** ***

800 825 875 1032 *** *** *** ***

1000 1007 1049 1183 *** *** *** ***

1200 1195 1230 1347 1496 *** *** ***

1500 1483 1512 1608 1735 *** *** ***

2000 1971 1992 2066 2167 2433 *** ***

2500 2464 2481 2541 2623 2847 3135 ***

3000 2959 2973 3023 3093 3285 3538 3839

3500 *** 3468 3511 3571 3738 3962 4234

4500 *** *** 4494 4541 4674 4855 5079

V16C_11.2006 Erection SC-hoist Pos 6

43

• support pipe wall panels symmetrically placed with

respect to the mast

Pipe length 2

B [mm] 900 1000 1100 1200 1300 1400 1600

A [mm]

400 343 336 336 343 358 378 433

500 441 436 436 441 453 469 515

600 540 536 536 540 549 563 602

800 739 735 735 739 746 756 785

1000 938 935 935 938 943 951 975

1200 *** 1135 1135 1137 1142 1148 1168

1500 *** *** 1435 1437 1440 1446 1461

2000 *** *** *** *** 1939 1943 1954

2500 *** *** *** *** *** 2441 2450

3000 *** *** *** *** *** *** 2948

3500 *** *** *** *** *** *** ***

4500 *** *** *** *** *** *** ***

B [mm] 1800 2000 2500 3000 4000 5000 6000

A [mm]

400 *** *** *** *** *** *** ***

500 574 *** *** *** *** *** ***

600 653 715 *** *** *** *** ***

800 825 875 1032 *** *** *** ***

1000 1007 1049 1183 *** *** *** ***

1200 1195 1230 1347 1496 *** *** ***

1500 1483 1512 1608 1735 *** *** ***

2000 1971 1992 2066 2167 2433 *** ***

2500 2464 2481 2541 2623 2847 3135 ***

3000 2959 2973 3023 3093 3285 3538 3839

3500 *** 3468 3511 3571 3738 3962 4234

4500 *** *** 4494 4541 4674 4855 5079

SC-hoist Pos 6 Erection V16C_11.2006

44

• support pipe wall panels symmetrically placed

with respect to the mast

Pipe length 3

B [mm] 900 1000 1100 1200 1300 1400 1600

A [mm]

400 901 949 997 1045 1093 1141 1238

500 938 983 1030 1076 1123 1170 1265

600 983 1027 1071 1116 1161 1207 1299

800 1096 1135 1175 1216 1258 1300 1386

1000 1231 1266 1302 1339 1377 1416 1495

1200 *** 1413 1445 1479 1513 1549 1621

1500 *** *** 1682 1711 1741 1772 1836

2000 *** *** *** *** 2160 2185 2237

2500 *** *** *** *** *** 2629 2672

3000 *** *** *** *** *** *** 3127

3500 *** *** *** *** *** *** ***

4500 *** *** *** *** *** *** ***

B [mm] 1800 2000 2500 3000 4000 5000 6000

A [mm]

400 *** *** *** *** *** *** ***

500 1361 *** *** *** *** *** ***

600 1392 1486 *** *** *** *** ***

800 1474 1563 1791 *** *** *** ***

1000 1577 1660 1877 *** *** *** ***

1200 1697 1775 1979 2192 *** *** ***

1500 1903 1973 2158 2355 *** *** ***

2000 2293 2351 2508 2680 3056 *** ***

2500 2719 2768 2903 3052 3387 3759 ***

3000 3166 3209 3326 3457 3756 4094 4463

3500 *** 3665 3768 3884 4152 4461 4801

4500 *** *** 4687 4781 5001 5260 5552

V16C_11.2006 Erection SC-hoist Pos 6

45

6.2.2 LD Anchoring

6.2.2.1 LD Anchor Spacing

The following values are based on LD anchor types using 76/76

scaffold joints. The spacing between the anchors is 10.5 m.

Single Double

WALL ANCHORS:

First anchor max. height:

S1 = 10,5 m

Spacing to next anchor max:

S2 = S1 + 1,5 m, but not greater than 10.5 m.

Max. spacing between anchors S2 = 10.5 m.

MAST OVERHANG:

Oh_max = 1,5 m, single cage

Oh_max = 0,8 m, double cage

☞ The topmost anchor always must be a

double top anchor.

Spacing between anchors max. 0.8 m.

MAST HEIGHT:

Hmax_single cage = 200 m, hoist without concrete foundation

Hmax_single cage = 300 m, hoist on concrete foundation

Hmax_double cage = 200 m, hoist without concrete foundation

Hmax_double cage = 300 m, hoist on concrete foundation

SC-hoist Pos 6 Erection V16C_11.2006

46

6.2.2.2 Anchor Force Tables for LD Anchors

• 76/76 scaffold joints used with support pipes

• support pipe wall panels symmetrically placed with respect to the

mast

• spacing to the next anchor max. 10.5 m

• wind velocity max. 12.5 m/s during mounting and dismounting

• wind velocity max. 20.0 m/s during operation

• combinations indicated in Table xxx are forbidden

Following the European Stormwind Height [m] A/B C D E

Map (EN 12159 Appendix A) with Eu-

0<H<=10 10,5 10,5 10,5 10,5

rope divided into zones A to E, the

spacing between anchors must not

10<H<=20 10,5 10,5 10,5 9,0

exceed the values given in Table 20<H<=50 10,5 10,5 9,5 7,5

6.2.2. 50<H<=100 10,5 10,5 8,0 6,5

Table 6.2.2

V16C_11.2006 Erection SC-hoist Pos 6

47

Force F2 [kN]:

B [mm] 800 900 1000 1100 1200 1300 1400

A [mm]

400 21.2 *** *** *** *** *** ***

500 22.3 19.8 *** *** *** *** ***

600 *** 20.7 18.7 *** *** *** ***

800 *** 22.6 20.3 18.5 *** *** ***

1000 *** *** 22.0 20.0 18.3 16.9 ***

1200 *** *** *** 21.5 19.7 18.2 16.9

1500 *** *** *** *** 21.8 20.2 18.7

2000 *** *** *** *** *** *** 21.7

2500 *** *** *** *** *** *** ***

3000 *** *** *** *** *** *** ***

3500 *** *** *** *** *** *** ***

B [mm] 1600 1800 2000 2500 3000 3500 4000

A [mm]

400 *** *** *** *** *** *** ***

500 *** *** *** *** *** *** ***

600 *** *** *** *** *** *** ***

800 *** *** *** *** *** *** ***

1000 *** *** *** *** *** *** ***

1200 *** *** *** *** *** *** ***

1500 16.4 *** *** *** *** *** ***

2000 19.0 16.9 15.2 *** *** *** ***

2500 21.6 19.2 17.3 13.8 *** *** ***

3000 *** 21.5 19.4 15.5 12.9 *** ***

3500 *** *** 21.5 17.2 14.3 *** ***

SC-hoist Pos 6 Erection V16C_11.2006

48

Force F1a [kN]:

B [mm] 800 900 1000 1100 1200 1300 1400

A [mm]

400 1.2 *** *** *** *** *** ***

500 1.0 3.1 *** *** *** *** ***

600 *** 2.7 4.1 *** *** *** ***

800 *** 2.1 3.3 4.2 *** *** ***

1000 *** *** 2.8 3.6 4.3 4.8 ***

1200 *** *** *** 3.2 3.8 4.3 4.7

1500 *** *** *** *** 3.3 3.8 4.1

2000 *** *** *** *** *** *** 3.6

2500 *** *** *** *** *** *** ***

3000 *** *** *** *** *** *** ***

3500 *** *** *** *** *** *** ***

4000 *** *** *** *** *** *** ***

B [mm] 1600 1800 2000 2500 3000 3500 4000

A [mm]

400 *** *** *** *** *** *** ***

500 *** *** *** *** *** *** ***

600 *** *** *** *** *** *** ***

800 *** *** *** *** *** *** ***

1000 *** *** *** *** *** *** ***

1200 *** *** *** *** *** *** ***

1500 4.8 *** *** *** *** *** ***

2000 4.1 4.5 4.8 *** *** *** ***

2500 3.7 4.1 4.4 4.9 *** *** ***

3000 *** 3.8 4.1 4.6 4.9 *** ***

3500 *** *** 3.9 4.4 4.7 *** ***

V16C_11.2006 Erection SC-hoist Pos 6

49

Force F1b [kN]:

B [mm] 800 900 1000 1100 1200 1300 1400

A [mm]

400 7.2 *** *** *** *** *** ***

500 7.4 5.3 *** *** *** *** ***

600 *** 5.8 4.4 *** *** *** ***

800 *** 6.3 5.2 4.2 *** *** ***

1000 *** *** 5.6 4.8 4.2 3.6 ***

1200 *** *** *** 5.2 4.6 4.1 3.7

1500 *** *** *** *** 5.1 4.7 4.3

2000 *** *** *** *** *** *** 4.8

2500 *** *** *** *** *** *** ***

3000 *** *** *** *** *** *** ***

3500 *** *** *** *** *** *** ***

4000 *** *** *** *** *** *** ***

B [mm] 1600 1800 2000 2500 3000 3500 4000

A [mm]

400 *** *** *** *** *** *** ***

500 *** *** *** *** *** *** ***

600 *** *** *** *** *** *** ***

800 *** *** *** *** *** *** ***

1000 *** *** *** *** *** *** ***

1200 *** *** *** *** *** *** ***

1500 3.7 *** *** *** *** *** ***

2000 4.3 3.9 3.6 *** *** *** ***

2500 4.7 4.3 4.0 3.5 *** *** ***

3000 *** 4.6 4.3 3.8 3.5 *** ***

3500 *** *** 4.5 4.1 3.8 *** ***

SC-hoist Pos 6 Erection V16C_11.2006

50

6.2.2.3 Wall Panel Anchor Bolt Force Tables for LD Anchors

• 76/76 scaffold joints used with support

pipes

• support pipe wall panels symmetrically

placed with respect to the mast

• forces directed to the anchor bolts are

deduced from the anchor force tab-

les produced in Chapter 6.2.1.2 An-

chor Force Tables for HD Anchors

Force Fao [kN]:

B [mm] 800 900 1000 1100 1200 1300 1400

A [mm]

400 10.8 *** *** *** *** *** ***

500 11.3 10.5 *** *** *** *** ***

600 *** 10.9 10.1 *** *** *** ***

800 *** 11.7 10.8 10.0 *** *** ***

1000 *** *** 11.5 10.7 10.0 9.4 ***

1200 *** *** *** 11.4 10.6 9.9 9.3

1500 *** *** *** *** 11.5 10.8 10.1

2000 *** *** *** *** *** *** 11.5

2500 *** *** *** *** *** *** ***

3000 *** *** *** *** *** *** ***

3500 *** *** *** *** *** *** ***

B [mm] 1600 1800 2000 2500 3000 3500 4000

A [mm]

400 *** *** *** *** *** *** ***

500 *** *** *** *** *** *** ***

600 *** *** *** *** *** *** ***

800 *** *** *** *** *** *** ***

1000 *** *** *** *** *** *** ***

1200 *** *** *** *** *** *** ***

1500 9.1 *** *** *** *** *** ***

2000 10.3 9.3 8.5 *** *** *** ***

2500 11.5 10.4 9.5 7.8 *** *** ***

3000 *** 11.5 10.5 8.6 7.4 *** ***

3500 *** *** 11.5 9.4 8.0 *** ***

V16C_11.2006 Erection SC-hoist Pos 6

51

Force Fai [kN]:

B [mm] 800 900 1000 1100 1200 1300 1400

A [mm]

400 10.4 *** *** *** *** *** ***

500 11.0 9.4 *** *** *** *** ***

600 *** 9.9 8.6 *** *** *** ***

800 *** 10.9 9.6 8.5 *** *** ***

1000 *** *** 10.5 9.4 8.4 7.6 ***

1200 *** *** *** 10.2 9.2 8.4 7.6

1500 *** *** *** *** 10.3 9.4 8.6

2000 *** *** *** *** *** *** 10.2

2500 *** *** *** *** *** *** ***

3000 *** *** *** *** *** *** ***

3500 *** *** *** *** *** *** ***

B [mm] 1600 1800 2000 2500 3000 3500 4000

A [mm]

400 *** *** *** *** *** *** ***

500 *** *** *** *** *** *** ***

600 *** *** *** *** *** *** ***

800 *** *** *** *** *** *** ***

1000 *** *** *** *** *** *** ***

1200 *** *** *** *** *** *** ***

1500 7.3 *** *** *** *** *** ***

2000 8.8 7.6 6.7 *** *** *** ***

2500 10.2 8.9 7.9 6.0 *** *** ***

3000 *** 10.1 9.0 6.9 5.6 *** ***

3500 *** *** 10.1 7.8 6.3 *** ***

4000 *** *** *** 8.7 7.1 5.9 ***

SC-hoist Pos 6 Erection V16C_11.2006

52

Force Fbo [kN]:

B [mm] 800 900 1000 1100 1200 1300 1400

A [mm]

400 11.9 *** *** *** *** *** ***

500 12.5 10.9 *** *** *** *** ***

600 *** 11.4 10.1 *** *** *** ***

800 *** 12.5 11.1 10.0 *** *** ***

1000 *** *** 12.0 10.9 9.9 9.1 ***

1200 *** *** *** 11.7 10.7 9.9 9.1

1500 *** *** *** *** 11.9 10.9 10.1

2000 *** *** *** *** *** *** 11.7

2500 *** *** *** *** *** *** ***

3000 *** *** *** *** *** *** ***

3500 *** *** *** *** *** *** ***

4000 *** *** *** *** *** *** ***

B [mm] 1600 1800 2000 2500 3000 3500 4000

A [mm]

400 *** *** *** *** *** *** ***

500 *** *** *** *** *** *** ***

600 *** *** *** *** *** *** ***

800 *** *** *** *** *** *** ***

1000 *** *** *** *** *** *** ***

1200 *** *** *** *** *** *** ***

1500 8.9 *** *** *** *** *** ***

2000 10.3 9.2 8.3 *** *** *** ***

2500 11.7 10.4 9.4 7.6 *** *** ***

3000 *** 11.6 10.5 8.5 7.1 *** ***

3500 *** *** 11.6 9.3 7.9 *** ***

V16C_11.2006 Erection SC-hoist Pos 6

53

Force Fbi [kN]:

B [mm] 800 900 1000 1100 1200 1300 1400

A[mm]

400 9.3 *** *** *** *** *** ***

500 9.8 8.9 *** *** *** *** ***

600 *** 9.3 8.6 *** *** *** ***

800 *** 10.2 9.2 8.5 *** *** ***

1000 *** *** 10.0 9.1 8.4 7.8 ***

1200 *** *** *** 9.8 9.0 8.4 7.8

1500 *** *** *** *** 10.0 9.3 8.6

2000 *** *** *** *** *** *** 10.0

2500 *** *** *** *** *** *** ***

3000 *** *** *** *** *** *** ***

3500 *** *** *** *** *** *** ***

B [mm] 1600 1800 2000 2500 3000 3500 4000

A [mm]

400 *** *** *** *** *** *** ***

500 *** *** *** *** *** *** ***

600 *** *** *** *** *** *** ***

800 *** *** *** *** *** *** ***

1000 *** *** *** *** *** *** ***

1200 *** *** *** *** *** *** ***

1500 7.5 *** *** *** *** *** ***

2000 8.7 7.8 7.0 *** *** *** ***

2500 10.0 8.8 7.9 6.3 *** *** ***

3000 *** 10.0 8.9 7.1 5.9 *** ***

3500 *** *** 9.9 7.9 6.5 *** ***

4000 *** *** *** 8.7 7.2 6.1 ***

SC-hoist Pos 6 Erection V16C_11.2006

54

A-A L B[m]

L[m]

max 2700 1873 From To

2,37 1,34 1,66

A

3,47 1,34 1,66

max 1660

min 1340

F Vx

3,87 1,34 1,66

B

F

Vy 4,57 1,34 1,66

kN Vx Vy F A

In use 1,3 9,3 14,1 2,8

max 9000

Not in use 9,4 9,5 38,7 8,5

V = Wall anchor

A A

The first wall tie max 13 m

The distance between the wall ties

max 13200

max 13 m

Intermediate support R every 3 m (except

for the wall anchoring points)

H Cross support every 3 m

F Freestanding section after the mast’s

top anchor max. 9 m

max 13200

max 3016

V16C_11.2006 Erection SC-hoist Pos 6

55

6.3 Mounting the basic unit

Read carefully chapter 2 SAFETY INSTRUCTIONS in this Instruction Manual before starting

the mounting operations.

☞ Prior to the mounting operations

protect the hoist area and its

surroundings with a fence. Put out

☞ Always use safety harness during

the mounting operations and

when working on the cage roof.

also warning signs giving a There is always the risk of falling

warning of falling items. down.

During the mounting the wind velocity

should not exceed 12.5 m/s.

When the hoist’s foundation work is finished

one can start mounting the basic unit. The

basic unit consists of the ground station

with the railing, two mast sections and the

cage.

Mount the basic unit to the chosen place

for erection, either directly on the ground

or on a concrete base depending on the

means of foundation. See Chapter 6.1.9 Lift-

ing the Hoist. Adjust the basic unit straight

with the help of the support screws placed

in its corners.

Mount the lifting mechanism on the basic

unit together with a mast section which is

used for transporting the lifting mechanism.

☞

Prior to the lifting operation remo-

ve the brake casings from the lifting

motors (pos. 1) – picture 6.3.1.

Picture 6.3.1 Removing the brake casings

SC-hoist Pos 6 Erection V16C_11.2006

56

Remove the protective cover (pos. 2) from the cage roof and the

➩

mounting pins (pos. 3) from the brackets of the lifting mechanism

– picture 6.3.2. A and B.

B

A

Picture 6.3.2 Removing the protective cover (A) and the mounting pins (B)

165

Also remove the bottom limit rigid

rails (pos. 4) of the mast – picture

6.3.3.

☞

4 4

140

470

240

Picture 6.3.3 Removing the bottom

limit rigid rails of the mast

V16C_11.2006 Erection SC-hoist Pos 6

57

Lift the lifting mechanism on the hoist with cage with two locking pins (pos. 3) – pic-

the help of the top part. Fasten the lifting ture 6.3.4.

rope into the inner hole (pos. 5) on the top

part lifting rod. Lower the lifting mecha- For joining the mast sections use

nism carefully on top of the hoist so that M24x245/10.9 bolts and self-retaining ”NY-

the hooks of the lifting mechanism and of LOC” nuts. The tightening torque for the

the cage brackets (pos. 6 and 7) are inter- mast bolts is 300 Nm. All four mast bolts

locked. The mast sections are fastened to needed for fastening one mast section are

each other with four mast bolts, and the screwed and tightened carefully at one

lifting mechanism is fastened to the hoist time.

Picture 6.3.4 Lifting the lifting mechanism on top of the hoist

SC-hoist Pos 6 Erection V16C_11.2006

58

The lifting mechanism can be

lowered carefully by releasing

the motor brakes from the levers

(pos. 10 and 11) so that the lock-

☞

ing pins go to their places – pic-

ture 6.3.5.

The lifting motor cables are connected to

the motors link boxes with bayonet connec-

tors.

Mount the brake casings of the motors, the

protective cover removed from the cage

roof and the bottom limit rigid rails of the

mast back to their places.

Connect also the bayonet connector of Picture 6.3.5 Lowering the lifting mechanism

the roof control box cable.

After this the hoist can be connected to

the mains. The supply cable cross-section

has to be 5x16mm2, so the cable is to have

☞ Prior to opening the service door

and entering the railing switch

off the supply voltage from the

five conductors: 3 phase conductors, neu- disconnecting switch!

tral and protective ground. In case the sup-

ply cable is long, the recommended cross-

section is 25 mm2 for minimizing voltage

drop. Always try to connect the hoist sup- of the lifting mechanism.

ply cable directly to the site’s main distri-

bution board. Also mark the board outlet Mount another two mast sections so that

supplying the hoist clearly. The voltage for the cage can be run to about two meters.

the hoist’s board is switched on from the Through the service door there is an ac-

ground station disconnecting switch. Do cess to underneath the hoist cage, where

not forget to check the correct phase se- the buffer springs can be fastened to the

quence! Read the operating instructions in mast’s front part.

chapter 3.

.

If you use a mast erecting crane and a

winch to mount the mast sections, install

them as well. The mast crane stand is fas-

tened to the brackets placed on the sides

V16C_11.2006 Erection SC-hoist Pos 6

59

☞ Prior to working under the cage

put in the safety rod

The safety rod is made of 76 mm tube, yel- install it to its place under the hoist. The lo-

low, and usually kept attached to the mast wer end of the safety rod is fastened to the

side inside the ground station fence. Re- buffer spring holder and the upper end to

move the safety rod from its clamps and the mast section’s cross bar.

Picture 6.3.6 Safety rod

SC-hoist Pos 6 Erection V16C_11.2006

60

6.4 Mounting the Mast

In general there are two methods used for mounting the mast:

a) a mobile crane or a tower crane

b) a mast erecting crane placed on the cage roof and its winch

If a mobile or a tower crane is available 4

to 8 mast sections can be joined already on

the ground. These are lifted as one piece

☞ To join the mast sections use

bolts M24x245/10.9 and self-re-

taining “NYLOC” nuts. The tight-

on the mast and immediately fastened ening torque for the mast bolts is

with four mast bolts. In this case the cage is 300 Nm.

already run to the mast top, and the mast

bolts can easily be screwed and tightened

at breast height. The number of the mast

sections piled together depends on the dis-

tance of the last support. Mast sections can

be added by only a number corresponding

one support interval at a time on the pre-

vious support, and after that the mast must

be supported again before adding more

mast sections.

The erection of the mast using a mast

erecting crane and a winch is carried out

with one mast section at a time. A suitable

number of mast sections is loaded in the

cage and the cage is run up to the mast

top. Lift the mast sections through the roof

gate using the mast erecting crane and

the winch. Fasten the metal rod used as a

lifting tool to the winch hook and lower it

inside the mast as shown in the picture. Lift

the mast section with the winch, sway it on

the mast with the mast erecting crane and

put it carefully down on top of the mast.

Fasten the mast section with four bolts and

tighten them to the right torque. When the

mast section is fastened, detach the crane

from it and sway the crane off the mast.

Install the following mast sections similarly.

Continue this way one support interval at a Picture 6.4.1 Mounting the mast

time, until the mast has reached the need-

ed height.

V16C_11.2006 Erection SC-hoist Pos 6

61

When erecting the mast use only masts on the joints and that the gear rack is not

of the same “generation”. Mast sections left to bear the weight. The weight of the

of different generations differ in their ten- mast must not lie on the gear rack. The mast

sile properties and should not be mixed to- sections should be installed so that on both

gether. ends is left a small air slot. This air slot should

be so small that when during the hoist’s op-

When installing the mast sections make sure eration the pinion crosses the mast sections

that the mast pipes are tightly connected there must not be any jerks.

☞ DANGER! Do not lean beyond the railings while the cage is moving! Keep

your head, feet and hands inside the railings. Do not run the cage beyond

the mast top!

☞ Always finish every working phase before starting a new one!

☞ Do not run the cage unnecessarily! Make sure that the working phases are

finished and check the screw tightening once more before moving the cage

to the next phase!

☞ Use a safety harness when working on the cage roof! There is

always the risk of falling down.

SC-hoist Pos 6 Erection V16C_11.2006

62

It is extremely important that the basic unit

(the mast and the pipe line) be installed

perpendicularly right from the start. The

perpendicularity can be checked after a

few mast sections have been mounted.

To check the perpendicularity use a long

builder’s level or a plummet line. To straight-

en the mast or the pipe line later is very dif-

ficult.

Richtlineal When the mast has been erected to the

stage that the wall tie can be attached,

the next phase is to continue also the pipe

line to the tie height.

Richtlineal

(Richtlinear builder's level, plummet line)

Richtlineal

V16C_11.2006 Erection SC-hoist Pos 6

63

6.5 Mounting the Pipe Line

The pipe scaffolding consists of three verti-

cal pipes, two of which are parallel to the

mast pipes and the third one is placed to

the side in relation to the first two. The pipes

are joined together using the so called pipe

couplings, which are pressed to the pipe’s

inner surface. Place the pipe coupling in-

side the lower pipe. Lift the second pipe on

it with the notched end down so that the

pipe coupling’s tension screw is placed in-

to the notch of the upper pipe. When tight-

ening the pipe coupling make sure that the

pipe ends are placed exactly end to end.

Support the vertical pipes at every 3m with

a so called light pipe tie binding the pipe

line to the mast, and with a cross tie bind-

ing the vertical pipes to each other. Attach

the pipe tie to the cross bar placed be-

tween the mast pipes. The pipe tie must be

placed exactly on the mast’s center line so

that the outer vertical pipe runs in line with

the mast pipes.

5

Attach the first pipe tie in 3 m from the

ground and the next ones max. every 3 m.

When building the wall ties the heavy an-

chor tie replaces the lighter pipe tie.

SC-hoist Pos 6 Erection V16C_11.2006

64

The purpose of the cross bars is to bind the When building the landing attach a wood-

vertical pipes to each other. At the same en plank for example of 50x50mm or

time the cross bars are used as supports 50x100mm between the forks on the cross

for the landings to be built on each floor. bar. The bridge deck itself can then be

Attach the first cross bar in 3m from the attached to this plank. See chapters 6.8

ground and the next ones max. every 3m. LANDINGS and 6.9 ACCESS BRIDGES AC-

CORDING TO THE REGULATIONS.

When installing the cross bar take into ac-

count the landing to be built on each floor. So each vertical 3 m long pipe section con-

The cross bars are installed on such a height sists of one light pipe tie and a cross bar.

in relation to the landing that the bridge to

be built onto the landing will be horizon- Continue the pipe line about 3 m above

tal or slope slightly down towards the land- the top landing. Attach a light pipe tie and

ing. If the distance between the floors is less a bridge bar to the end of the pipe line.

than three meters additional cross bars are Their purpose is to support the top landing

not needed. and also to secure the functioning of the

door locking.

The cross bar is attached inside the pipe

line to three vertical pipes with the clamps

fixed to the bar. Attach the cross bar first

to one vertical pipe with the clamp, then

place the bar exactly horizontally using a

builder’s level, and tighten the two remain-

ing clamps to the vertical pipes.

V16C_11.2006 Erection SC-hoist Pos 6

65

6.6 Anchoring

The wall tie set consists of a so called heavy

anchor tie, two support pipes, a brace

placed between the support pipes, wall

panels (2pcs) and 76mm scaffold joints

(4pcs).

The heavy anchor tie is fastened to the

mast with bolts. The two pipe lines running

parallel with the mast pipes are fastened

to the clamps placed in the end of the an-

chor tie.

Attach the wall panels to certain points (sup-

porting points) on the building’s façade.

The panels are attached to the wall with

anchor bolts sufficiently strong to resist the

forces directed to them. The volume of the

supporting forces depends on, for exam-

ple the mast’s distance from the building’s

façade, the mutual distance between the

supporting points, the mast height, the

wind conditions etc. The biggest support-

ing forces occur in a storm when the use of

the equipment is forbidden. The supporting

forces are shown in table c.d.

The anchor bolts should be zinc or cad-

mium covered and have a strength of 8.8

or10.9.

Picture 6.6.1, 2 ja 3 Anchoring bolts

SC-hoist Pos 6 Erection V16C_11.2006

66

The “fork end” of the support pipes is at- vents its sidewise movement. Fasten the di-

tached to the brackets on the wall panels agonal pipe with a 76 mm scaffold joint al-

with a bolt included in the set. The other so to the “inner” support pipe’s wall side

end of the support pipes is fastened to the end and the other pipe end to the outer

vertical pipe with a 76mm scaffold joint, di- vertical pipe directly above or below the

rectly above or below the anchor tie. Final- anchor tie. Finally, make sure that all joints

ly, install the so called diagonal pipe or the and screws are properly tightened.

brace, which stiffens the support and pre-

Picture 6.6.4 Wall tie set

V16C_11.2006 Erection SC-hoist Pos 6

67

6.7 Cable guides

The hoist’s cable guiding system consists of

a cable basket with the cable or cables in

case if separate motor and guiding cables

are used. The cable basket is attached to

the hoist’s ground station frame.

To the cage is attached also a cable hold-

er, from which the cable(s) hang(s) down

and which also guides the cable through

the cable guides. The cable should hang

from the holder so that it goes down free-

ly in the middle of the basket. The cable(s)

should also be fastened to the holder so

that it cannot slip in its strain relief clamp.

The cable guides guiding the cable’s run-

ning and preventing it sideways move-

ment are attached at certain intervals to

the mast. The cable holder attached to

the hoist cage leads the cable(s) through

the cable guide. The cable holder “cuts”

through the flexible diverters of the cable

guide and leads the cable into the guide

during the hoist’s upward movement. Cor-

respondingly, during the hoist’s downward

movement the cable holder leads the ca-

ble out of the guide’s eye.

The hoist cable is put in the basket so that

during the hoist’s downward movement

the cable always coils a full turn and the

turns are piled on each other. Correspond-

ingly, during the hoist’s upward movement

the cable uncoils from the basket one turn

at a time. When the cage moves down

with the cables each full counter clockwise

turn, the cable’s free end should also coil

one turn counter clockwise round its axle.

In this case the turns settle on each other

in the basket in good order and the cable

runs safely through the guides.

SC-hoist Pos 6 Erection V16C_11.2006

68

6.7.1 Installation of the Cable Guides

The cable guides are fastened to the cross The cable itself must not be oiled, because

support bar of the mast section with screws oiling may corrode the cable’s insulation

and self-retaining nuts so that the free- material and it also gathers dirt. As for the

ly hanging cable runs in the middle of the cable holder, its surfaces running through

guide. Fasten the first cable guide about the cable guide can be lightly greased.

1m above the cable basket, practically to The friction of the cable can be decreased

the first possible place. Fasten the next ca- by powdering its surfaces with talc.

ble guide 1,5 to 3m above the first one. This

makes one or two mast section lengths. The cable(s) used is a special cable, which

Fasten the third cable guide 3 to 4,5 m must not be replaced with another con-

above the previous one. The following ca- struction.

ble guides can be fastened at intervals of

4,5 to 6m one after the other. In windy con-

ditions it is recommended to keep the dis-

tance in 4,5m so that the wind does not

press the cable to the cage or other con-

structions.

V16C_11.2006 Erection SC-hoist Pos 6

69

6.8 Landings

On the landings can be used two different door systems. The first option is a so called

landing gate, which is quite light and simple by its structure. The other option is a landing

door system, which means that on every landing there is about 2,1 m high fully protect-

ed double door.

6.8.1 Installing the Double doors

On the bridge beams there are ready made time lower the rack end on the doors side

cantilever brackets with holes for hinge above so that the upper hinge pin blocks

pins. Before putting the doors in their plac- the door to its place. Leave a space of 1 to

es install a rack between the vertical pipes 2mm between the door’s upper edge and

about 50 mm above the upper edge of the the rack. Install the other door leaf in the

doors. This rack has the upper hinge holes same way. When both door leaves are in-

for the doors, the cross door bolt locking stalled, tighten the rack to its place.

the doors as well as the door locking and

unlocking device and the limit switches. Lift After the installation check the functioning

one door leaf into its place so that the low- of the doors and locking bolt, and grease

er hinge pin goes into its hole. At the same the sliding surfaces and the hinges.

6.8.2. Installing the Sliding Doors

The sliding doors are put into place and fas- spect with the landing level and the clamps

tened to the vertical pipes as one whole are tightened to the torque 100 Nm. An ac-

(see page 71???). cess bridge is extended from the building’s

side with its end on the hoist’s side support-

The doors are attached to the vertical pipes ed to the lower bar. There is a groove on

with the Æ 76 mm clamps placed on the the lower bar, where a wooden plank of

upper and lower bars. The threshold level 50 to 50 cm can be installed and which the

of the doors is checked to be suitable in re- bridge deck can be attached to.

6.8.3 Installing the Gate

Fasten the landing gate between the ver- limit switch. The limit switch should discon-

tical pipes with the clamps attached to nect the hoist’s safety circuit when the gate

the gate’s supports. Check that the gate is opened and keep it disconnected when-

is placed horizontally. In lower position the ever the gate is not in closed position.

gate’s height should be 1000 to1100mm

from the access bridge surface. After the installation check the functioning

of the gate and grease the sliding surfaces

When installing the gate check and if and the hinges.

necessary adjust the position of the gate’s

SC-hoist Pos 6 Erection V16C_11.2006

70

W 3

Torque 100 Nm

5

1. Sliding doors

2. Locking device

3. Ø 76 mm clamp

4. Access bridge

5. Manual door opening

V16C_11.2006 Erection SC-hoist Pos 6

71

6.8.4 Installing the Set of Electrical Components

Fasten the landing’s push button box, multi- et at the ground station control center bot-

pole socket and limit switch with screws to tom. Fasten the connection cables to the

the landing gate or to the mounting panel vertical pipe with binders or adhesive tape

placed on the door edge. The connection so that the cage does not when moving by

cable of the electrical set is always con- grip the cable. On the top landing a cable-

nected to the multi-pole socket of the pre- less plug closing (short circuiting) the land-

vious landing. The standard cable length ing circuit is put into the multi-pole socket.

of 5m is sufficient for normal floor height. In Test the landing circuits immediately after

case the floor-to-floor height is bigger ex- their installation. When lifting the gate or

tension cables can be used. A set of elec- opening the door the limit switch should im-

trical components with a connection cable mediately disconnect the hoist control and

is installed between the ground station and keep it disconnected, until the gate is put

the first landing. A set of electrical compo- down to its lower position or the door is fully

nents with a 12 m connection cable is in- closed. Test also the landing call and “stop

stalled between the ground station and the next floor” buttons one by one.

first landing. Connect the cable to the sock-

☞ The plug closing the landing cir-

cuit should always be either at

the ground station or on the top

floor. Otherwise it is not possible

to run the hoist the safety circuit

being disconnected.

SC-hoist Pos 6 Erection V16C_11.2006

72

6.9 Access Bridges according to the Regulations

The issues concerning occupational safe- The horizontal space between the access

ty are regulated with many different rules. bridge and the cage threshold when the

On a construction site the site’s foreman cage is standing on the landing must not

and the safety representative are respon- exceed 50 mm.

sible for the occupational safety issues. In

the end it is every employee’s duty to re- The access bridge is to be equipped with

port discovered defects and faults. solid railings of 1100 to1200mm height with

at least one intermediate bar in the middle

The landing access bridges are structures and a 150mm high kick plate at the lower

usually included in the duties of the con- end of the railings.

structor.

The access bridge deck must be of mate-

As mentioned earlier in chapter 6.5 MOUNT- rial as rough as possible so that it prevents

ING THE PIPE LINE, the bridge cross bars slipping in rain and frost.

should be installed to such height that the

bridge is placed horizontally or better still Keep the access bridges free and clean of

slopes slightly towards the building. snow and ice.

The landing access bridge structure must In case the hoist is used during evenings or

be dimensioned to comply with the maxi- night time or the illumination conditions oth-

mum load permissible to the hoist. Also the erwise are poor, the lighting of all the land-

point load directed to the bridge structures ings must be taken care of.

has to be taken into account when design-

ing the bridge structures. The access bridge from the landing to the

hoist as well as the landing gate and door

must be totally illuminated.

V16C_11.2006 Erection SC-hoist Pos 6

73

6.10 Mast Limit Switch Rigid Rails

6.10.1 General Information

There are three mechanical limit switch- bottom limit switches for some reason do

es on the cage’s mast side wall, top lim- not stop the cage.

it (S14), bottom limit (S13) and safety lim-

it (S18), which determine the extreme limits The limit switches react when the cage

of the hoist’s movement range. The bottom reaches the rigid rails attached to the

limit switch stops the cage at the ground mast. The rigid rail turns the lever on the lim-

station, and the top limit switch on the top it switch shaft, and the limit switch contact

landing. The safety limit switch disconnects opens.

the control voltage circuit if the top or the

6.10.2 The Bottom Limit Rigid Rail

6.10.2.1 The Relay Control

Fasten the bottom limit rigid rail to the mast

and adjust it so that the empty cage stops

at about 30...40mm above the ground sta-

tion threshold level.

☞

6.10.2.2 The Logic Control

Fasten the bottom limit rigid rail to the mast The ground station rigid rails have

and adjust it so that the cage stops exactly been pre-assembled at the fac-

on the ground station threshold level. tory, but their correct assembling

height in relation to the mast must

be checked by test-running the

hoist!

6.10.3 The Top Limit Rigid Rail

6.10.3.1 The Relay Control

Fasten the top limit rigid rail to the mast and

adjust it so that the empty cage stops at

about 30...40 mm above the top landing

threshold level.

6.10.3.2 The Logic Control

Fasten the top limit rigid rail to the mast and The cage can be run to the top limit only

adjust it so that the cage during the au- by manual control when operated from the

tomatic control when stopping on the top cage or the cage roof.

landing does not reach the top limit at all.

SC-hoist Pos 6 Erection V16C_11.2006

74

6.10.4. The Safety Limit Rigid Rails

Fasten the safety limit rigid rails so that the

safety limit switch stops the cage only if the

top or bottom limit switch for some reason

☞ The ground station rigid rails have

been assembled at the facto-

ry, but their correct assembling

does not work. Adjust the safety limit rigid height in relation to the mast must

rails so that at the ground station the safe- be checked by test-running the

ty rigid rail becomes about 140mm below hoist!

the bottom limit rigid rail. Correspondingly,

on the top landing the safety limit rigid rail

should be about 130mm above the top lim-

it rigid rail.

6.10.5. The Rigid Rails on the Landings

6.10.5.1 The Relay Control

The rigid rails on the landings determine If the cage does not stop by the plates at-

the cage’s stopping place when the cage tached to the rigid rails check the distance

reaches the landing. On the mast side of the inductive limit switch from the rigid

cage wall there is an inductive switch (B1). rail plates. The distance between the in-

This limit switch triggers the cage’s stopping ductive limit switch and the rigid rail plate

circuit if the push button “Stop next land- must not exceed 10mm so that the induc-

ing” has been pushed in the cage, at the tive limit switch is able to identify the plate.

ground station or on any landing. Fasten to The distance of the inductive limit switch

the limit switch rigid rail one or two plates can be adjusted by unscrewing the nuts,

so that the cage without load stops when with which the limit switch is attached to

moving upwards or downwards at about the cage wall. The inductive limit is a ful-

30…40 mm above the landing threshold ly threaded metal cylinder, and therefore

level. it is easy to regulate its distance by screw-

ing and unscrewing the nuts around it (see

the picture).

V16C_11.2006 Erection SC-hoist Pos 6

75

6.10.5.2 The Logic Control

The logic control system stops the cage au- If the cage door locking on the landing

tomatically on a desired landing according side is not unlocked and the control system

to the call. The landings are programmed gives the error message F13 “Door locking

in the control system’s memory so that a error” it means that the system does not

certain number of impulses is equivalent to identify the landing limit stopper. Check

a landing. The cage is stopped on the land- that the landing limit stopper is by the in-

ing by the program. On the mast side cage ductive limit and that its distance from the

wall there is an inductive limit switch (B1). stop plate is not too big. The distance be-

This limit switch secures that the cage hast tween the inductive limit switch and the

stopped on the landing, and at the same stop plate must not exceed 10mm so that

time it allows the unlocking of the landing the inductive limit switch is able to identify

door. the plate. The distance of the inductive limit

switch can be adjusted by unscrewing the

Fasten to the limit switch rigid rail one stop nuts, with which the limit switch is attached

plate so that when the cage is by the land- to the cage wall. The inductive limit is a ful-

ing the inductive limit switch (B1) is activat- ly threaded metal cylinder, and therefore