Professional Documents

Culture Documents

V Light

Uploaded by

Ale MuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

V Light

Uploaded by

Ale MuCopyright:

Available Formats

®

ION™ V-Series™ Surface Mount Lighthead

www. .com

ENGINEERING COMPANY INC.

51 Winthrop Road

Chester, Connecticut 06412-0684

Phone: (860) 526-9504

Sales Email:autosale@whelen.com

Canadian Sales:canadiansales@whelen.com

Customer Service:custserv@whelen.com

Safety First: This document provides all the necessary information to allow your Whelen product to be properly and safely installed. Before beginning the installation and/or operation

of your new product, the installation technician and operator must read this manual completely. Important information is contained herein that could prevent serious injury or damage.

• Proper installation of this product requires the installer to have a good understanding of • If this product uses a remote device to activate or control this product, make sure that this

automotive electronics, systems and procedures. control is located in an area that allows both the vehicle and the control to be operated

• Whelen Engineering requires the use of waterproof butt splices and/or connectors if that safely in any driving condition.

connector could be exposed to moisture. • Do not attempt to activate or control this device in a hazardous driving situation.

• Any holes, either created or utilized by this product, should be made both air- and • This product contains either strobe light(s), halogen light(s), high-intensity LEDs or a

watertight using a sealant recommended by your vehicle manufacturer. combination of these lights. Do not stare directly into these lights. Momentary blindness

• Failure to use specified installation parts and/or hardware will void the product warranty! and/or eye damage could result.

• If mounting this product requires drilling holes, the installer MUST be sure that no vehicle • Use only soap and water to clean the outer lens. Use of other chemicals could result in

components or other vital parts could be damaged by the drilling process. Check both premature lens cracking (crazing) and discoloration. Lenses in this condition have

sides of the mounting surface before drilling begins. Also de-burr any holes and remove significantly reduced effectiveness and should be replaced immediately. Inspect and

any metal shards or remnants. Install grommets into all wire passage holes. operate this product regularly to confirm its proper operation and mounting condition. Do

not use a pressure washer to clean this product.

• Do not install this product or route any wires in the deployment area of your air bag.

Equipment mounted or located in the air bag deployment area will damage or reduce the • WARNING! All customer supplied wires that connect to the positive (+) terminal of the

effectiveness of the air bag, or become a projectile that could cause serious personal battery must be sized to supply at least 125% of the maximum operating current and

injury or death. Refer to your vehicle owner's manual for the air bag deployment area. The FUSED “at the battery” to carry that load. DO NOT USE CIRCUIT BREAKERS WITH THIS

User/Installer assumes full responsibility to determine proper mounting location, based PRODUCT!

on providing ultimate safety to all passengers inside the vehicle. • FAILURE TO FOLLOW THESE PRECAUTIONS AND INSTRUCTIONS COULD RESULT IN

• For this product to operate at optimum efficiency, a good electrical connection to chassis DAMAGE TO THE PRODUCT OR VEHICLE AND/OR SERIOUS INJURY TO YOU AND YOUR

ground must be made. The recommended procedure requires the product ground wire to PASSENGERS!

be connected directly to the NEGATIVE (-) battery post.

Mounting Alley Light (WHT/BLK) - Extend the WHT/BLK wire to +12VDC via an SP/ST

IMPORTANT! BEFORE MOUNTING READ ALL THE ABOVE WARNINGS FOR switch. (fuse @ 3 amps).

MOUNTING, VEHICLE DAMAGE AND WIRE ROUTING.

Puddle Light (WHT/RED) - Extend the WHT/RED wire to +12VDC via an SP/ST

1. Using the mounting dimensions below, mark the mounting and wire hole

switch. (fuse @ 1 amp).

locations onto the proposed mounting surface.

Scan-Lock™ (WHT/VIO) - Extend the WHT/VIO wire to +12VDC via a momentary

2. Drill two .250" diameter mounting holes and a 5/8" (minimum) wire access hole switch (fuse @ 1 amp). Refer to the Scan-Lock section for operational information.

into the mounting surface.

GREY - SYNC: To SYNC 2 lightheads, configure both lightheads to display the same

3. Place the gasket into position on the mounting surface then place the Phase 1 (Simultaneous) pattern. Turn power off and connect the GREY wire from

lighthead/flange assembly in position on the gasket while feeding the wires each lighthead together. Activate the lightheads and their patterns will be

through the wire hole. synchronized. To configure 2 lightheads to alternate their patterns, advance either

lighthead to Phase 2 (Alternating) of the current pattern.

4. Insert the two supplied screw grommets through the lighthead/flange assembly

and gasket and all the way into the mounting surface. NOTE: ALL SWITCHES AND FUSES ARE CUSTOMER SUPPLIED

5. With the assembly in position, insert the two supplied #8 sheet metal screws Scan-Lock

through the flange mounting holes and into the screw grommets. Tighten the Note: In order to change flash patterns, the lighthead must be on.

mounting screws until the lighthead assembly is drawn firmly against the

mounting surface. A torque value of 12 in-lb. (max.) is typically required. DO NOT TO CHANGE PATTERNS: To advance to the next pattern apply +12VDC to the

OVER TIGHTEN! WHT/VIO wire for less than 1 second and release. To cycle back to the previous

pattern apply +12VDC to the WHT/VIO wire for more than 1 second and release.

6. Using appropriately sized wires (minimum 22 AWG), extend the wires to their

designated connections. Refer to the diagram below for wiring and fusing TO CHANGE THE DEFAULT PATTERN: When the desired pattern is displayed,

information. allow it to run for more than 5 seconds. The lighthead will now display this pattern

when initially activated.

Wiring

TO RESTORE THE FACTORY DEFAULT PATTERN: This will reset all patterns

IMPORTANT! BEFORE WIRING READ ALL THE ABOVE WARNINGS FOR WIRE

back to their default settings. With the light turned off, apply power to the WHT/VIO

SIZE AND THE ROUTING OF WIRES.

wire. With power applied to the WHT/VIO wire, turn light on. Allow the unit to run for

3 seconds before removing power from the WHT/VIO wire.

Ground (BLK) - Extend the BLK wire to Chassis Ground.

Warning Light (RED) - Extend the RED wire to +12VDC via an SP/ST switch. Fuse

@ 3 AMPS.

MOUNTING DIMENSIONS Flash Patterns Flash Patterns

4-3/4" (SYNC Capable) (REGULAR)

GASKET - Use gasket on 1. SignalAlert™ 75 / phase 1 15. SingleFlash 60

5/8 INCH

smooth flat surfaces only WIRE HOLE 2. SignalAlert™ 75 / phase 2 16. SingleFlash 90

1/8"

WIRING DIAGRAM

3. CometFlash® 75 / phase 1 17. SingleFlash 120

4. CometFlash® 75 / phase 2 18. SingleFlash 300

SURFACE

1 Amp

WHT/VIO (Scan-Lock) To +12VDC 5. DoubleFlash 75 / phase 1 19. DoubleFlash 150

LIGHTHEAD Mom. SW

6. DoubleFlash 75 / phase 2 20. ComAlert™ 150

3 Amp

WHT/BLK (Alley) To +12VDC 7. SingleFlash 75 / phase 1 21. ActionFlash™ 50

SP/ST

1 Amp 8. SingleFlash 75 / phase 2 22. ActionFlash™ 150

Light WHT/RED (Puddle) To +12VDC 9. ComAlert™ 75 / phase 1 23. ModuFlash™

SP/ST

MOUNTING

3 Amp 10. ComAlert™ 75 / phase 2 24. ActionScan™

RED (Warning) To +12VDC

SP/ST 11. LongBurst™ 75 / phase 1 25. Steady

#8 x 1" BLK To Chassis Ground 12. LongBurst™ 75 / phase 2

PPHSMS 13. PingPong™ 75 / phase 1

SCREW GROMMET GRY To SYNC wire of other SYNC capable light 14. PingPong™ 75 / phase 2

Waterproof butt splices and/or connectors are required if that

connection could be exposed to moisture. Any unused wires

must be sealed (waterproofed) to prevent moisture infiltration.

©2013 Whelen Engineering Company Inc.

Form No. 14706B (012219) For warranty information regarding this product, visit www.whelen.com/warranty

Warnings to Installers

Whelen’s emergency vehicle warning devices must be properly mounted and wired in order to be effective and safe.

Read and follow all of Whelen’s written instructions when installing or using this device. Emergency vehicles are often

operated under high speed stressful conditions which must be accounted for when installing all emergency warning

devices. Controls should be placed within convenient reach of the operator so that he can operate the system without

taking his eyes off the roadway. Emergency warning devices can require high electrical voltages and/or currents.

Properly protect and use caution around live electrical connections.Grounding or shorting of electrical connections can

cause high current arcing, which can cause personal injury and/or vehicle damage, including fire. Many electronic

devices used in emergency vehicles can create or be affected by electromagnetic interference. Therefore, after

installation of any electronic device it is necessary to test all electronic equipment simultaneously to insure that they

operate free of interference from other components within the vehicle. Never power emergency warning equipment from

the same circuit or share the same grounding circuit with radio communication equipment. All devices should be mounted

in accordance with the manufacturer’s instructions and securely fastened to vehicle elements of sufficient strength to

withstand the forces applied to the device. Driver and/or passenger air bags (SRS) will affect the way equipment should

be mounted. This device should be mounted by permanent installation and within the zones specified by the vehicle

manufacturer, if any. Any device mounted in the deployment area of an air bag will damage or reduce the effectiveness of

the air bag and may damage or dislodge the device. Installer must be sure that this device, its mounting hardware and

electrical supply wiring does not interfere with the air bag or the SRS wiring or sensors. Mounting the unit inside the

vehicle by a method other than permanent installation is not recommended as unit may become dislodged during

swerving; sudden braking or collision. Failure to follow instructions can result in personal injury. Whelen assumes no

liability for any loss resulting from the use of this warning device. PROPER INSTALLATION COMBINED WITH

OPERATOR TRAINING IN THE PROPER USE OF EMERGENCY WARNING DEVICES IS ESSENTIAL TO INSURE

THE SAFETY OF EMERGENCY PERSONNEL AND THE PUBLIC.

Warnings to Users

Whelen’s emergency vehicle warning devices are intended to alert other operators and pedestrians to the presence and

operation of emergency vehicles and personnel. However, the use of this or any other Whelen emergency warning

device does not guarantee that you will have the right-of-way or that other drivers and pedestrians will properly heed an

emergency warning signal. Never assume you have the right-of-way. It is your responsibility to proceed safely before

entering an intersection, driving against traffic, responding at a high rate of speed, or walking on or around traffic lanes.

Emergency vehicle warning devices should be tested on a daily basis to ensure that they operate properly. When in

actual use, the operator must ensure that both visual and audible warnings are not blocked by vehicle components (i.e.:

open trunks or compartment doors), people, vehicles, or other obstructions. It is the user’s responsibility to understand

and obey all laws regarding emergency warning devices. The user should be familiar with all applicable laws and

regulations prior to the use of any emergency vehicle warning device. Whelen’s audible warning devices are designed to

project sound in a forward direction away from the vehicle occupants. However, because sustained periodic exposure to

loud sounds can cause hearing loss, all audible warning devices should be installed and operated in accordance with the

standards established by the National Fire Protection Association.

You might also like

- Rubric AutocadDocument2 pagesRubric Autocadros maria100% (6)

- Seiwa SFW 412 Operation Manual - R09Document80 pagesSeiwa SFW 412 Operation Manual - R09Bernie Wire100% (1)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- GX Deloitte 2017 TMT PredictionsDocument60 pagesGX Deloitte 2017 TMT PredictionsMontevideo PortalNo ratings yet

- Edu 637 Lesson Plan Gallivan TerryDocument11 pagesEdu 637 Lesson Plan Gallivan Terryapi-161680522No ratings yet

- Level 5 Diploma in Business Management: Assignment BriefsDocument22 pagesLevel 5 Diploma in Business Management: Assignment BriefsyehashaNo ratings yet

- V23RTPBDocument2 pagesV23RTPBAle MuNo ratings yet

- Manual TocadiscosDocument8 pagesManual TocadiscosimmavNo ratings yet

- Panasonic SC-PM25 PDFDocument28 pagesPanasonic SC-PM25 PDFdoru_gabriel_stanNo ratings yet

- 151XST InstructionsDocument19 pages151XST InstructionsfraustovictorNo ratings yet

- JVC GR-AXM1U Camcorder ManualDocument56 pagesJVC GR-AXM1U Camcorder Manualmdavidson22No ratings yet

- Instruction Manual Mode D'Emploi Manual de Instrucciones: Register OnlineDocument20 pagesInstruction Manual Mode D'Emploi Manual de Instrucciones: Register OnlineLauraNo ratings yet

- Kac 8403Document20 pagesKac 8403Manuel Olmos RabagoNo ratings yet

- JVC Gr-Sxm515uDocument68 pagesJVC Gr-Sxm515uedcorraNo ratings yet

- Manual de PionnerDocument72 pagesManual de PionnerAnthony T. RiveraNo ratings yet

- Abbeon Cal, Inc.: Model Bd-50E High Frequency Generator Operating ManualDocument7 pagesAbbeon Cal, Inc.: Model Bd-50E High Frequency Generator Operating ManualdanielvillagrapNo ratings yet

- BMRX ManualDocument10 pagesBMRX ManualIbarra Diego ONo ratings yet

- Camera JVC GRAXM25UDocument56 pagesCamera JVC GRAXM25Umattedi_rjNo ratings yet

- Panasonic - Ag-Mx70 Av MixerDocument172 pagesPanasonic - Ag-Mx70 Av MixerMalay K GhoshNo ratings yet

- Instruction Manual: Model BN-86Document5 pagesInstruction Manual: Model BN-86Sonny WicaksonoNo ratings yet

- MT610i MT6100i MT8100i Installation 101028Document8 pagesMT610i MT6100i MT8100i Installation 101028ali jafariNo ratings yet

- Gr-dvm70 JVC CamcorderDocument112 pagesGr-dvm70 JVC Camcorderjt_scribdNo ratings yet

- KAC-7252 KAC-7202: Instruction Manual Mode D'Emploi Manual de InstruccionesDocument20 pagesKAC-7252 KAC-7202: Instruction Manual Mode D'Emploi Manual de Instruccionesroberto carlos martinez narvaezNo ratings yet

- AKA304 (Akai-S3200XL) PDFDocument318 pagesAKA304 (Akai-S3200XL) PDFJh CtNo ratings yet

- CX-2 User ManualDocument24 pagesCX-2 User ManualGimenez RicardoNo ratings yet

- 131ST 131DST-instructionsDocument16 pages131ST 131DST-instructionsfraustovictorNo ratings yet

- JBL KX180 UserManual en 092017Document16 pagesJBL KX180 UserManual en 092017loc nguyenNo ratings yet

- LG j10hd Owner S ManualDocument39 pagesLG j10hd Owner S ManualZdravko Lučić100% (1)

- Complete Equalization & Loudspeaker Management System: User ManualDocument83 pagesComplete Equalization & Loudspeaker Management System: User ManualAdrianm MzrtinezNo ratings yet

- Powered Speaker Optimizer: User ManualDocument48 pagesPowered Speaker Optimizer: User ManualMatej PavlešićNo ratings yet

- HW-Q60R Q60RS ZF FullManual 02 ENG FRA ITA POR SPA 190410 PDFDocument192 pagesHW-Q60R Q60RS ZF FullManual 02 ENG FRA ITA POR SPA 190410 PDFRob55RaNo ratings yet

- HW-Q60R Q60RS EN FullManual 02 ENG BUL CRO CZE DEU EST FRA GRE HUN ITA LAT LTU POL ROM SER SLK SLV 190410 PDFDocument648 pagesHW-Q60R Q60RS EN FullManual 02 ENG BUL CRO CZE DEU EST FRA GRE HUN ITA LAT LTU POL ROM SER SLK SLV 190410 PDFCatalin B.No ratings yet

- MT-8000 Series MT-8104iH: Installation InstructionDocument8 pagesMT-8000 Series MT-8104iH: Installation Instructionbassit82No ratings yet

- KAC-8452 KAC-8402: Instruction Manual Mode D'Emploi Manual de InstruccionesDocument20 pagesKAC-8452 KAC-8402: Instruction Manual Mode D'Emploi Manual de InstruccionesEDUARDONo ratings yet

- LG BH7220BDocument125 pagesLG BH7220Bdanielradu27100% (1)

- Luna Manual 2011 PDFDocument28 pagesLuna Manual 2011 PDFAnonymous lfw4mfCmNo ratings yet

- MT6070iH ManualDocument8 pagesMT6070iH ManualFranco Cossio RamirezNo ratings yet

- Aiwa AV-X100 User ManualDocument0 pagesAiwa AV-X100 User Manualsteves0118No ratings yet

- 112D User GuideDocument86 pages112D User GuideSimon MeierNo ratings yet

- HW-R450 ZF FullManual 01 ENG FRA ITA POR SPA 190304Document182 pagesHW-R450 ZF FullManual 01 ENG FRA ITA POR SPA 190304Jo ZemostNo ratings yet

- 05 Warning Light O&M 121S (English & Spanish)Document16 pages05 Warning Light O&M 121S (English & Spanish)BENJY SULLA TICONANo ratings yet

- Ah68-03026g-03 HW-N400 ZF Eng Fra Ita Por Spa 180418 PDFDocument127 pagesAh68-03026g-03 HW-N400 ZF Eng Fra Ita Por Spa 180418 PDFAlejandro CamargoNo ratings yet

- ZP2 SeriesDocument2 pagesZP2 SeriesMaheshkumarNo ratings yet

- 10307628-User Manual-Hdl 35-AsDocument28 pages10307628-User Manual-Hdl 35-AsDEISY MARLENY GUINEA GUINEANo ratings yet

- Manual Pioneer A390Document72 pagesManual Pioneer A390Jorge Flores0% (2)

- MT6070iH 8070ih MT607i Installation 101028Document8 pagesMT6070iH 8070ih MT607i Installation 101028Kelechi H. HenryNo ratings yet

- Body Electrical SystemDocument59 pagesBody Electrical SystemLeonardo Gómez Berniga100% (1)

- Dewalt Table Saw Dw745Document52 pagesDewalt Table Saw Dw745Pablo DNo ratings yet

- Operator's Manual: WarningDocument156 pagesOperator's Manual: WarningMiguelAngelOrtizNo ratings yet

- MX-T50 XA FullManual 01 L04 200910Document118 pagesMX-T50 XA FullManual 01 L04 200910Pablo Maria Peralta LorcaNo ratings yet

- MT6050i 8050i Installation 101102Document8 pagesMT6050i 8050i Installation 101102gabyNo ratings yet

- Instruction 10197765Document512 pagesInstruction 10197765Vasilii LupascoNo ratings yet

- Hw-n300 ZP Fullmanual 00 Eng Spa 180713Document62 pagesHw-n300 ZP Fullmanual 00 Eng Spa 180713NIVARDO ÑAUPA MOROCCONo ratings yet

- LST-3410A Service ManualDocument135 pagesLST-3410A Service ManualzlrigNo ratings yet

- MT-8000 Series: MT-8056T/ MT-6056T Installation Instruction 1.0 Installation and Startup GuideDocument8 pagesMT-8000 Series: MT-8056T/ MT-6056T Installation Instruction 1.0 Installation and Startup GuideVicente SantillanNo ratings yet

- User ManualDocument27 pagesUser ManualMark PostlesNo ratings yet

- Full Manual: Imagine The PossibilitiesDocument157 pagesFull Manual: Imagine The Possibilitiesangar777No ratings yet

- Samsung+CL21Z50MQ3XXAO+Chassis K16C (N) ValiantDocument77 pagesSamsung+CL21Z50MQ3XXAO+Chassis K16C (N) ValiantBLENO TECLASNo ratings yet

- Akai S3200XL Owners ManualDocument318 pagesAkai S3200XL Owners ManualdodNo ratings yet

- LG BH5140S PDFDocument109 pagesLG BH5140S PDFboroda2410100% (5)

- GSP1101 Manual 18-0474-C OriginalDocument64 pagesGSP1101 Manual 18-0474-C OriginalJisoo KimNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- ALW - Bolt Pattern TemplateDocument1 pageALW - Bolt Pattern TemplateAle MuNo ratings yet

- Vertex LightDocument2 pagesVertex LightAle MuNo ratings yet

- 40N en Full PDFDocument6 pages40N en Full PDFSehend MorsaliNo ratings yet

- Blue Strobe LightDocument2 pagesBlue Strobe LightAle MuNo ratings yet

- UntitledDocument1 pageUntitledAle MuNo ratings yet

- 42 Investors Awareness Towards Mutual FundsDocument8 pages42 Investors Awareness Towards Mutual FundsFathimaNo ratings yet

- HboDocument126 pagesHboKunal ChaudhryNo ratings yet

- Acctg 14 - MidtermDocument5 pagesAcctg 14 - MidtermRannah Raymundo100% (1)

- FFA Test CHP INV and 16Document8 pagesFFA Test CHP INV and 16zainabNo ratings yet

- Aga 11Document7 pagesAga 11elijbbNo ratings yet

- Making The Quantum LeapDocument22 pagesMaking The Quantum LeapRJ DeLongNo ratings yet

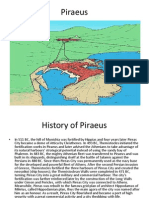

- PiraeusDocument9 pagesPiraeusBen JamesNo ratings yet

- 21S18052 - Joshua Partogi Hutauruk - Review BUSNOV - Umbrella - WarsDocument5 pages21S18052 - Joshua Partogi Hutauruk - Review BUSNOV - Umbrella - WarsJoshua HutaurukNo ratings yet

- COURT CLERK NoticeDocument10 pagesCOURT CLERK NoticeED Curtis100% (3)

- Euroleague Basketball: Change Pays Off ForDocument36 pagesEuroleague Basketball: Change Pays Off ForNikos TagalnikNo ratings yet

- Types of TrianglesDocument5 pagesTypes of Trianglesguru198319No ratings yet

- HD785-7 Fault Codes SEN05900-01-3Document16 pagesHD785-7 Fault Codes SEN05900-01-3ISRAEL GONZALESNo ratings yet

- Prime Time FeaturesDocument15 pagesPrime Time FeaturesPruthwish PatelNo ratings yet

- AWS Solution Architect SampleDocument3 pagesAWS Solution Architect SamplepandiecNo ratings yet

- Fly The Maddog X User Manual MSFS 2020Document15 pagesFly The Maddog X User Manual MSFS 2020KING OF NOOBSNo ratings yet

- Plewa2016 - Reputation in Higher Education: A Fuzzy Set Analysis of Resource ConfigurationsDocument9 pagesPlewa2016 - Reputation in Higher Education: A Fuzzy Set Analysis of Resource ConfigurationsAlice ChenNo ratings yet

- Subject: Industrial Marketing Topic/Case Name: Electrical Equipment LTDDocument4 pagesSubject: Industrial Marketing Topic/Case Name: Electrical Equipment LTDRucha ShirudkarNo ratings yet

- SD HospitalDocument2 pagesSD HospitalSam PowelNo ratings yet

- JD Data Analyst CapgeminiDocument2 pagesJD Data Analyst CapgeminiShivansh KansalNo ratings yet

- Contracts Act, 2010Document59 pagesContracts Act, 2010Sam KNo ratings yet

- Penn State: The Dickinson School of LawDocument88 pagesPenn State: The Dickinson School of LawHafiz UmmarNo ratings yet

- TVS 1 PDFDocument24 pagesTVS 1 PDFPooja PreetiNo ratings yet

- Annexure - IV (SLD)Document6 pagesAnnexure - IV (SLD)Gaurav SinghNo ratings yet

- Cbjessco 13Document3 pagesCbjessco 13Fawaz ZaheerNo ratings yet

- Activity 2.1 Test Your Food Safety IQDocument3 pagesActivity 2.1 Test Your Food Safety IQAustin PriceNo ratings yet

- 20-21 Ipads Shopping GuideDocument1 page20-21 Ipads Shopping Guideapi-348013334No ratings yet