Professional Documents

Culture Documents

Honda Motorcycle Spare Parts Supply With Economic Order Quantitiy (Case Study: CV AHASS MOTOR JAYA 2)

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Honda Motorcycle Spare Parts Supply With Economic Order Quantitiy (Case Study: CV AHASS MOTOR JAYA 2)

Copyright:

Available Formats

Volume 8, Issue 3, March – 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Honda Motorcycle Spare Parts Supply with Economic

Order Quantitiy

(Case Study : CV AHASS MOTOR JAYA 2)

Lisa Anjas Renilaili

Teknik Industri Universitas Bina Darma Teknik Industri Universitas Bina Darma

Palembang, Indonesia Palembang, Indonesia

Ch. Desi Kusmindari

Teknik Industri Universitas Bina Darma

Palembang, Indonesia

Abstract:- Spare parts inventory planning needs to be The problem formulation of this research was how to

done because the company has not been able to do it plan Honda motorcycles spare parts to determine optimal

optimally. Economic Order Quantity (EOQ) is a method supply thus minimize supply shortages.

used in inventory control to determine the optimal

number of orders with a minimum Total Inventory Cost. The aims of this research were to control the planning of

The purpose of this research is to get the optimal number Honda motorcycle spare parts supply and to determine the

of orders with a minimum total cost. The calculation optimal supply at CV AHASS Motor Jaya 2 Palembang.

results for Shoe Set Brake (06430-K44-V80) are 464 units,

Ball Bearings (HB6201RS) are 451 units, Element Comp Supply is materials owned by the company in the form

Air Cleaner (17210-K16-900) are 427 units, Pad Set FR of raw goods, semi-finished goods and finished goods that are

(06455-KVB- T01) of 389 units, Element Comp Air ready to be distributed to consumers. It is very important for

Cleaner (17210-KZR-600) of 341 units, Oring-Fuel Pump the company because with sufficient raw material supply, it

(17572-GGL-J00) of 288 units, Belt Drive Kit (23100-k44- will facilitate the production operations of a company. [2]

BA0) of 284 units, Tire RR (90/90-14FT235 42711-K59-

A12 ) 294 units, Brake Shoe (43130-KZL-930) 292 units, According to Gaspersz (2005), forecasting activity is a

Race Steering Kit (06535-GN5-505) 306 units. business function that seeks to estimate the sales and use of

products so that the products can be made in the right quantity

Keywords:- Economic Order Quantity, Inventory Control, [3]. One method for forecasting is by using linear regression.

Spare Part, Inventory Planning.

Linear regression is a statistical method used to form a

I. INTRODUCTION model or relationship between one or more independent

variables X and a response variable Y. Regression analysis

The advanced era of science and technology has created with one independent variable X is called simple linear

a lot of competition between humans. This will encourage a regression, whereas if there is more than one independent

company to make improvements in its system thus it can meet variable X, it is referred to multiple linear regressions. The

market demand optimally. A system that can help the linear regression formula:[4]

company to meet market demand optimally is the optimal

inventory planning by using Economic Order Quantity.

Y = a + bX ……………….…………….. (1)

The EOQ method will be able to minimize the

occurrence of Out Of Stock so that it does not interfere with 𝑛 (∑ 𝑥𝑦)−(∑ 𝑥)(∑ 𝑌)

b= 2 2 ……………………. (2)

processes within the company and is able to save supply costs 𝑛 (∑ 𝑥 )− (∑ 𝑥)

incurred by the company because of the raw material supply (Σy) 𝑏 (Σx)

efficiency. One of companies that often experiences Out Of a= 𝑛

− 𝑛

………………………... (3)

Stock is CV AHASS Motor Jaya 2.

EOQ method is highly recommended to control the total

Through EOQ or Economy Order Quantity it can find cost of supply. With the forecasting that has been done, the

out how many quantities must be ordered so that the total cost, results show that the company's ordering costs are directly

in this case the sum of ordering costs and storage costs, is proportional to the frequency of orders [5] . The EOQ formula

minimized. [1] is as follow:

IJISRT23MAR1861 www.ijisrt.com 2193

Volume 8, Issue 3, March – 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

2𝑋𝐷𝑋𝑆 kg, Coloring 593 kg, Anti-Damp 1,813 kg, PE AI 2,759 kg. In

Q =√ 𝐻

…………………..(4) 2015 Polytam was 4,740 kg, Calvet was 2,648 kg, Coloring

was 1,054 kg, Anti-Damp was 1,063 kg, PE Al was 2,616 kg,

The safety stock is additional supply held to protect or (4) Jose L Gonzales & Daniel Gonzales [5] by title Analysis

maintain the possibility of materials shortage materials of an Economic Order Quantity and reorder point inventory

(stockout) . [1] The formula for Safety Stock is as follow: control model for company XYZ.

𝑆𝑆=Sd𝑥Z ………………….(5) II. RESEARCH METHOLODOLY

Sofjan Assauri [1] argues that Reorder point (ROP) is A. Research Date and Location

the limit or point of the repurchase number. The formula for This research was taken at CV AHASS Motor Jaya 2

calculating the reorder point (ROP) is as follows: which is a spare part distributor company as well as a service

provider for Honda motorbikes located at JL Captain

ROP= (LT x AU)+Safety stock (SS) ………….(6) Abdullah No.03, Plaju sub-district from August 2021 to

January 2022.

Some previous studies using EOQ are (1) Putri Garneta

[6] according to a study titled Inventory control Mechanical B. Data Collection Methods [9]

parts with the Q method, back order conclusion is obtained to

determine how much is needed optimal ordering, determining Literature Study

safety stock, determining return order point values. Calculate Literature study is a way of solving a problem by

the total inventory issued by the company and provide finding solutions from previous theories.

suggestions for improvements to control category A

mechanical spare parts inventory, (2) Degra Salida Lifie [7] Observation

by title Inventory planning for Toyota Kijang Super car parts Focus in this observation was the maintenance of spare

with economic order quantity, get results Grouping using the parts raw materials in the warehouse up to distribution to

ABC method, forecasting sales for the next 1 year at CV consumers.

Sapari Motor, knowing the value of safety stock and knowing

the total coast (TC), (3) Indrastin Anggraini[8] by title Interview

Analysis of planning and controlling raw material inventory The informant of this interview was the company

with economic order quantity at CV Maju Mapan Lestari employee and owner of CV AHASS Motor Jaya 2.

Palembang get result supplies of raw materials increase and

decrease every year such as polytam, calvet, dyes, moisture C. Data Processing Methods

proof and PE AL. Frequency of purchase of raw materials The data processing methods are as follows:

CV. Maju Mapan Lestari Palembang when using the EOQ is 9

times Polytam, 6 to 7 times Calvet, 3 times Coloring, 5 times Forecasting spare parts sales for the next 12 months

Moisture Anti, 6 times PE Al in one code. Limits or points of Calculating Economic Order Quantitiy (EOQ) standard

ordering raw materials needed by CV. Maju Mapan Lestari Calculating spare parts Safety Stock (SS)

Palembang using the 2013 EOQ of 4,001 kg of Polytam, Calculating spare parts Reorder Point (ROP)

2,352 kg of Calvet, 455 kg of dye, L667 kg of Anti Moisture, Calculating Total Coast (TC)

2,859 kg of PE Al. In 2014 Polytam 3,657 kg, Calvet L974

III. RESULT AND DISCUSSION

A. Forcasting

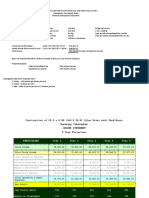

The data used in the study are 10 spare parts items that have the highest levels of inventory shortages. The data used for

forecasting are spare parts sales data in the last 1 year. Spare part sales for the last 1 years describe in tabel 1 below

Table 1 Spare Parts Sales Data for the Last 1 Year

No Part Code Description Item

1 06430-K44-V80 Shoe Set,Brake 1016

2 Hb6201rs Bearing, Ball 1018

3 17210-K16-900 Element Comp., Air Cleaner 902

4 06455-Kvb-T01 Pad Set Fr 803

5 17210-Kzr-600 Element Comp, Air Cleaner 623

6 17572-Ggl-J00 O-Ring, Fuel Pump 686

7 23100-K44-Ba0 Belt Drive, Kit 518

8 42711-K59-A12 Tire Rr (90/90-14 Ft235) 466

9 43130-Kzl-930 Brake Shoe 420

10 06535-Gn5-505 Race Steering Kit 398

Forecasting results using linear regression are obtained as in table 2 below

IJISRT23MAR1861 www.ijisrt.com 2194

Volume 8, Issue 3, March – 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Table 2 Forecasting Result with Linear Regresion

No Part Code Description Item

1 06430-K44-V80 Shoe Set,Brake 1154,94

2 Hb6201rs Bearing, Ball 1093,52

3 17210-K16-900 Element Comp., Air Cleaner 978,53

4 06455-Kvb-T01 Pad Set Fr 813,56

5 17210-Kzr-600 Element Comp, Air Cleaner 624,53

6 17572-Ggl-J00 O-Ring, Fuel Pump 445,33

7 23100-K44-Ba0 Belt Drive, Kit 433,41

8 42711-K59-A12 Tire Rr (90/90-14 Ft235) 462,99

9 43130-Kzl-930 Brake Shoe 456,26

10 06535-Gn5-505 Race Steering Kit 503,73

B. Mean Absolute Persentage Error (MAPE ) Score

MAPE is used to see the percentage of forecasting error against the original data. MAPE for all spare parts data is shown in

table 3 below

Table 3 Mean Absolute Persentage Error (MAPE) Score

No Part Code Description Mape

1 06430-K44-V80 Shoe Set,Brake 6.05 %

2 Hb6201rs Bearing, Ball 4.54%

3 17210-K16-900 Element Comp., Air Cleaner 5.77%

4 06455-Kvb-T01 Pad Set Fr 5.63%

5 17210-Kzr-600 Element Comp, Air Cleaner 19.0%

6 17572-Ggl-J00 O-Ring, Fuel Pump 14.49%

7 23100-K44-Ba0 Belt Drive, Kit 13.52%

8 42711-K59-A12 Tire Rr (90/90-14 Ft235) 7.71%

9 43130-Kzl-930 Brake Shoe 15%

10 06535-Gn5-505 Race Steering Kit 9.42%

Average 10%

C. Economic Order Quantity

The data required for EOQ calculations is shown in the table 4 until 6 below

Table 4 Ordering Cost Data

No Cost Type Amount

1 Administration and Employee Rp. 50.000

2 Electricity, computer, and internet Rp. 25.000

3 Shipping cost Rp. 25.000

Rp 100.000

Source: CV AHASS Motor Jaya 2

The ordering cost above was the amount required to make a one-time order. These costs consisted of administrative and

employee costs, electricity, computer, internet and shipping costs.

Table 5 Storage Cost Data

No Cost Type Amount

1 Administration and Employee Rp. 300.000

2 Electricity and computer Rp. 200.000

3 Warehouse maintenance Rp. 125.000

Rp. 625.000

Source: CV AHASS Motor Jaya 2

The storage cost data in table 4 was the data for one month. Meanwhile, to conduct research by using the economic order

quantity method required annual storage data.

IJISRT23MAR1861 www.ijisrt.com 2195

Volume 8, Issue 3, March – 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Table 6 Storage Cost Data in 1 Year

No Description Per year

1 Administration and Employee Rp. 3.600.000

2 Electricity, computer, and internet Rp. 2.400.000

3 Warehouse maintenance Rp. 1.500.000

Total Rp. 7.500.000

Based on table 5 the total cost per year for the storing cost, the results obtained for ordering costs in one year was 7,500,000

rupias, the total annual cost was divided by the total orders in one year to get the result of storage cost per unit. Lead time for all

item are 15 day/mounth

2𝑥𝐷𝑋𝑆

Equation : 𝐸𝑂𝑄 = √

𝐻

Where

EOQ = The optimal number of orders for the company

D = Number of needs or forecasting (1155)

S = Ordering fee for 1 time order (Rp. 100.000 )

H = Storage cost per product

( Rp. 625.000 x 12 / 6967 = 1.076,5 / unit )

So the economic Order Quantity for all spare part items is described in the table 7 below

Table 7 Calculation of Economic Order Quantitiy

No Part Code Description Eoq

1 06430-K44-V80 Shoe Set,Brake 464

2 Hb6201rs Bearing, Ball 451

3 17210-K16-900 Element Comp., Air Cleaner 427

4 06455-Kvb-T01 Pad Set Fr 389

5 17210-Kzr-600 Element Comp, Air Cleaner 341

6 17572-Ggl-J00 O-Ring, Fuel Pump 288

7 23100-K44-Ba0 Belt Drive, Kit 284

8 42711-K59-A12 Tire Rr (90/90-14 Ft235) 294

9 43130-Kzl-930 Brake Shoe 292

10 06535-Gn5-505 Race Steering Kit 306

From the calculation of the economic order quantity, the results showed in table 7 above. The EOQ score for each spare part

had been obtained so that the company can undertake the optimal order to minimize the company's total cost.

D. Safety Stock

The safety factor for the service level used was 95% = 1.64, then: Safety Stock (SS) = Deviation standard X Safety factor

From safety stock calculation, the safety stock value for the all item is describe on table8 below:

Table 8 Calculation for Safety Stock

No Part Code Description Safety Stock

1 06430-K44-V80 Shoe Set,Brake 6

2 Hb6201rs Bearing, Ball 3

3 17210-K16-900 Element Comp., Air Cleaner 3

4 06455-Kvb-T01 Pad Set Fr 1

5 17210-Kzr-600 Element Comp, Air Cleaner 1

6 17572-Ggl-J00 O-Ring, Fuel Pump 10

7 23100-K44-Ba0 Belt Drive, Kit 4

8 42711-K59-A12 Tire Rr (90/90-14 Ft235) 1

9 43130-Kzl-930 Brake Shoe 2

10 06535-Gn5-505 Race Steering Kit 5

IJISRT23MAR1861 www.ijisrt.com 2196

Volume 8, Issue 3, March – 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

From the table 8 above, the results obtained that total of safety stock values for each spare part varied. The safety stock score

was the total of spare parts that must be available and can be used if the order arrived beyond the lead time to avoid stock

shortages.

E. Reorder Point

ROP = (Daily Average X Lead Time) + Safety Stock

From the calculation above, the Reorder Point score for all item is shown on table 9

Table 9 Calculation of Reorder Point

No Part Code Description Rop

1 06430-K44-V80 Shoe Set,Brake 54

2 Hb6201rs Bearing, Ball 49

3 17210-K16-900 Element Comp., Air Cleaner 44

4 06455-Kvb-T01 Pad Set Fr 35

5 17210-Kzr-600 Element Comp, Air Cleaner 27

6 17572-Ggl-J00 O-Ring, Fuel Pump 29

7 23100-K44-Ba0 Belt Drive, Kit 22

8 42711-K59-A12 Tire Rr (90/90-14 Ft235) 21

9 43130-Kzl-930 Brake Shoe 21

10 06535-Gn5-505 Race Steering Kit 26

From the table 9 above, the results obtained that the number of Reorder Point score for each spare part varied. The Reorder

Point score was the point that determined the supply must be reordered. It aimed to make the received orders according to the

waiting time.

F. Total Cost

𝐷 𝑄

(TC) = (𝑄 ) S + ( 2 ) H

Where:

D = Forecasting demand

Q = EOQ

S = Ordering Cost

H = Storage cost

From the above calculation, the Total Cost for all item spare parts are follows:

Table 10 Calculation of Total Cost

No Part Code Description Total Cost

1 06430-K44-V80 Shoe Set,Brake 498.670

2 Hb6201rs Bearing, Ball 485.322

3 17210-K16-900 Element Comp., Air Cleaner 459.106

4 06455-Kvb-T01 Pad Set Fr 418.633

5 17210-Kzr-600 Element Comp, Air Cleaner 366.827

6 17572-Ggl-J00 O-Ring, Fuel Pump 309.877

7 23100-K44-Ba0 Belt Drive, Kit 305.679

8 42711-K59-A12 Tire Rr (90/90-14 Ft235) 315.727

9 43130-Kzl-930 Brake Shoe 313.674

10 06535-Gn5-505 Race Steering Kit 329.409

From the table 10 above, the results obtained that the Total Cost for each spare part varied. The total cost required to

perform optimal inventory with the minimum total costs incurred.

IV. CONCLUSION set brake (06430-k44-v80) was 464 units, bearing ball

(hb6201rs) was 451 units, element comp air cleaner (17210-

From the calculation result of the economic order k16-900) was 427 units, pad set fr (06455-kvb- t01) was

quantitiy, it was obtained the results of optimal order 389 units, element comp air cleaner (17210-kzr-600) was

number with minimum costs. the calculation results for shoe 341 units, oring-fuel pump (17572-ggl-j00) was 288 units,

IJISRT23MAR1861 www.ijisrt.com 2197

Volume 8, Issue 3, March – 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

belt drive kit (23100-k44-ba0) was 284 units, tirer (90/90-

14ft235 42711-k59-a12 ) was 294 units, brake shoe (43130-

kzl-930) was 292 units, and race steering kit (06535-gn5-

505) was 306 units. Forecasting was good with mape results

of 10% and the accuracy rate of 90%.

REFERENCES

[1]. S. Assauri, “Manajemen pemasaran : dasar, konsep &

strategi / Prof. DR. Sofjan Assauri, M.B.A,” Ed.

Pertama Penerbit. PT. Raja Graf. Persada …, p. 450,

2017, Accessed: Dec. 24, 2022. [Online]. Available:

https://www.rajagrafindo.co.id/produk/manajemen-

pemasaran-dasar-konsep-dan-strategi/.

[2]. “Manajemen persediaan / Agus Ristono | OPAC

Perpustakaan Nasional RI.”

https://opac.perpusnas.go.id/DetailOpac.aspx?id=673

391 (accessed Dec. 24, 2022).

[3]. V. Gasperz, “Total quality menagement / Vincent

Gasperz).” Jakarta : Gramedia Pustaka Utama, 2005,

Accessed: Dec. 24, 2022. [Online]. Available:

http://opac.lib.um.ac.id/index.php?s_data=bp_buku&

s_field=0&id=30907&mod=b&cat=3.

[4]. D. Ps., “Statistik induktif / Djarwanto Ps., Pangestu

Subagyo).” Yogyakarta : BPFE, 2000, Accessed:

Dec. 24, 2022. [Online]. Available:

http://opac.lib.um.ac.id/index.php?s_data=bp_buku&

s_field=0&id=14313&mod=b&cat=3.

[5]. J. L. Gonzalez and D. González, “Analysis of an

Economic Order Quantity and Reorder Point

Inventory Control Model for Company XYZ.”

[6]. P. GARNETA, “Pengendalian Persediaan Suku

Cadang Mekanikal Dengan Metoda Q, Back Order

Di Pt. X,” 2019, [Online]. Available:

http://repository.unpas.ac.id/id/eprint/43922.

[7]. D. S. Lifie, “Perencanaan persediaan suku cadang

mobil Toyota kijang super dengan metode economic

order quantitiy,” Universitas Bina Darma, 2017.

[8]. I. Anggraini, “Analisis Perencanaan Dan

Pengendalian Persediaan Bahan Baku Dengan

Metode EOQ (Economy Order Quantity) Pada Cv.

Maju Mapan Lestari Palembang,” J. Chem. Inf.

Model., vol. 53, no. 9, pp. 1689–1699, 2019.

[9]. Sugiyono, Buku Metode Penelitian Sugiyono | PDF.

2013.

IJISRT23MAR1861 www.ijisrt.com 2198

You might also like

- WIDGB3 Utest Language 2ADocument2 pagesWIDGB3 Utest Language 2ASerge IvNo ratings yet

- Capstone ProjectDocument124 pagesCapstone ProjectLyadallaBharadwajaNo ratings yet

- QWS21111119 - ECON20039 - Economics For ManagersDocument14 pagesQWS21111119 - ECON20039 - Economics For ManagersSwastika PorelNo ratings yet

- There's No Way This Isn't Racist - Daniels2018Document19 pagesThere's No Way This Isn't Racist - Daniels2018elisaNo ratings yet

- Eco-Friendly River Bank Protection Technologies Using Coir GeotextilesDocument8 pagesEco-Friendly River Bank Protection Technologies Using Coir GeotextilesThắng PhạmNo ratings yet

- Connected POC Dashboard User Guide V1.0 (Key Account View)Document24 pagesConnected POC Dashboard User Guide V1.0 (Key Account View)Daniel KrohnNo ratings yet

- 00 Panel DataDocument653 pages00 Panel Dataindrahaning0% (1)

- Chapter - Contemporary Issue.....Document24 pagesChapter - Contemporary Issue.....Nokia PokiaNo ratings yet

- Reports Indices August 2021 Summary Lyst7634Document34 pagesReports Indices August 2021 Summary Lyst7634VeanganNo ratings yet

- CHP 1-4-1Document56 pagesCHP 1-4-1ekundayo ojoNo ratings yet

- Biology Question and AnswersDocument8 pagesBiology Question and AnswersPartha MandalNo ratings yet

- OBP Certification GuideDocument5 pagesOBP Certification Guidedomino akun2No ratings yet

- Soon, 1 Out of Every 15 Points of Light in The Sky Will Be A SatelliteDocument26 pagesSoon, 1 Out of Every 15 Points of Light in The Sky Will Be A SatelliteEnaDumitrascuNo ratings yet

- Homeostasis and Soft Robotics in The Design of Feeling Machines (Damasio)Document7 pagesHomeostasis and Soft Robotics in The Design of Feeling Machines (Damasio)ytr8944No ratings yet

- Box Area: Assignment 2GDocument2 pagesBox Area: Assignment 2GGábor Köles0% (1)

- Share Crme DetectionDocument16 pagesShare Crme DetectionLEX ANN MAY SERAFICONo ratings yet

- BSNL Consumer TrendsDocument108 pagesBSNL Consumer TrendsShahzad SaifNo ratings yet

- The Legend Continues: The Art of ExcellenceDocument162 pagesThe Legend Continues: The Art of ExcellenceJohn BenderNo ratings yet

- Kader Proposal 2 CorectDocument31 pagesKader Proposal 2 CorectKhader Axmed MaxamedNo ratings yet

- HAADStatisticsEng2013 PDFDocument91 pagesHAADStatisticsEng2013 PDFHitesh MotwaniiNo ratings yet

- The Velocity of Ultrasonic Waves in WaterDocument3 pagesThe Velocity of Ultrasonic Waves in WaterSai VardhanNo ratings yet

- Plenary Lecture Given To The CILT Primary Languages Show, 'From The Word To The World', Liverpool, 4 March 2011Document6 pagesPlenary Lecture Given To The CILT Primary Languages Show, 'From The Word To The World', Liverpool, 4 March 2011Billy AslamNo ratings yet

- CGL 2020 GST Inspector, Po & Examiner State Wise VacancyDocument8 pagesCGL 2020 GST Inspector, Po & Examiner State Wise VacancyAmlan DuttaNo ratings yet

- 1.1. Introduction To Embedded SystemsDocument45 pages1.1. Introduction To Embedded SystemsKotagiri AravindNo ratings yet

- Iacovone Exploring DataDocument23 pagesIacovone Exploring DataVictor LugoNo ratings yet

- Physics ProjectDocument18 pagesPhysics ProjectDevansh SinghNo ratings yet

- Englishprojecttt 150230Document17 pagesEnglishprojecttt 150230Heemanth ReddyNo ratings yet

- Bacte Lab PrelimsDocument20 pagesBacte Lab PrelimsEvanka BaguistanNo ratings yet

- Passionweek - Malayalam MaglishDocument252 pagesPassionweek - Malayalam MaglishAaaasidhi MkNo ratings yet

- Magenetic Chip Collector New 2Document27 pagesMagenetic Chip Collector New 2Hemasundar Reddy JolluNo ratings yet

- 2020 Morgan D Annual Review of Matrials ResearchDocument35 pages2020 Morgan D Annual Review of Matrials Researchilyas tarhouchiNo ratings yet

- Government Capital Expenditure and Manufacturing Sector Output in NigeriaDocument20 pagesGovernment Capital Expenditure and Manufacturing Sector Output in NigeriaEditor IJTSRDNo ratings yet

- Irect TataSteel Q2FY23Document8 pagesIrect TataSteel Q2FY23jeff bezozNo ratings yet

- ProposalDocument18 pagesProposalazli100% (1)

- Unit 3Document44 pagesUnit 3LOOPY GAMINGNo ratings yet

- Balochistan Digital Policy Ver 1.4 1Document37 pagesBalochistan Digital Policy Ver 1.4 1baloch47No ratings yet

- MSDS NaOH-D Cell WashDocument10 pagesMSDS NaOH-D Cell Washabi biaNo ratings yet

- Agastya: HPC User ManualDocument73 pagesAgastya: HPC User ManualromNo ratings yet

- Kahramanmaraş - Gaziantep Türkiye M7.7 Earthquake, 6 February 2023 (04:17 GMT+03:00)Document37 pagesKahramanmaraş - Gaziantep Türkiye M7.7 Earthquake, 6 February 2023 (04:17 GMT+03:00)projelerharunNo ratings yet

- Environment Shankar 9th Edition NotesDocument16 pagesEnvironment Shankar 9th Edition NotesSan JayNo ratings yet

- Demetra - Decentralized Metering With User Anonymity On BlockchainDocument48 pagesDemetra - Decentralized Metering With User Anonymity On BlockchainMarioNo ratings yet

- QurbanaKramam English and MalayalamDocument27 pagesQurbanaKramam English and MalayalamdeliriousDenizenNo ratings yet

- Delay RoutineDocument11 pagesDelay RoutineDivya KrishnanNo ratings yet

- Research Article Baphia Nitida Leaves Extract As A Green Corrosion Inhibitor ForDocument11 pagesResearch Article Baphia Nitida Leaves Extract As A Green Corrosion Inhibitor ForHong Giang LeNo ratings yet

- Placement DetailsDocument12 pagesPlacement DetailsTharunNo ratings yet

- Template SPRINGERDocument12 pagesTemplate SPRINGERCSE R. AISHWARYANo ratings yet

- SSR Revised Sept 2016Document195 pagesSSR Revised Sept 2016Invincible HeroNo ratings yet

- SYM - 2017 - FALL 5 Minute Presentation Handouts PDFDocument19 pagesSYM - 2017 - FALL 5 Minute Presentation Handouts PDFNeesha KhatriNo ratings yet

- SPS Section 7 V2 EnglishDocument56 pagesSPS Section 7 V2 EnglishjustinNo ratings yet

- July 4, 2022Document6 pagesJuly 4, 2022Rosenie MalibagoNo ratings yet

- LOS ANGELES - Feasibility StudyDocument4 pagesLOS ANGELES - Feasibility StudyGoldie AnnNo ratings yet

- ISO 841 en - Pdf-DesbloqueadoDocument8 pagesISO 841 en - Pdf-DesbloqueadoJosé Zegarra Calderón0% (1)

- Microprocessors & InterfacingDocument255 pagesMicroprocessors & InterfacingSasi BhushanNo ratings yet

- Impact On FirmsDocument2 pagesImpact On FirmsAyushman AgarwalNo ratings yet

- 2018LLB003 I.P.C Semester 4 Research PaperDocument23 pages2018LLB003 I.P.C Semester 4 Research PaperAishwarya BuddharajuNo ratings yet

- Digitalization of Securities MarketDocument8 pagesDigitalization of Securities Marketmrinal kumarNo ratings yet

- Creating The Innovation Ecosystem For Renewable Energy Via SocialDocument12 pagesCreating The Innovation Ecosystem For Renewable Energy Via SocialLeeKahMunNo ratings yet

- Using - Data - To - Create - Tactics fm23Document31 pagesUsing - Data - To - Create - Tactics fm23Milica StojanovicNo ratings yet

- Doh AuditDocument38 pagesDoh AuditJeremy TurleyNo ratings yet

- Dharamvir Mangal1Document7 pagesDharamvir Mangal1annNo ratings yet

- Sustainable Energy Consumption Analysis through Data Driven InsightsDocument16 pagesSustainable Energy Consumption Analysis through Data Driven InsightsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Vertical Farming System Based on IoTDocument6 pagesVertical Farming System Based on IoTInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Entrepreneurial Creative Thinking and Venture Performance: Reviewing the Influence of Psychomotor Education on the Profitability of Small and Medium Scale Firms in Port Harcourt MetropolisDocument10 pagesEntrepreneurial Creative Thinking and Venture Performance: Reviewing the Influence of Psychomotor Education on the Profitability of Small and Medium Scale Firms in Port Harcourt MetropolisInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Influence of Principals’ Promotion of Professional Development of Teachers on Learners’ Academic Performance in Kenya Certificate of Secondary Education in Kisii County, KenyaDocument13 pagesInfluence of Principals’ Promotion of Professional Development of Teachers on Learners’ Academic Performance in Kenya Certificate of Secondary Education in Kisii County, KenyaInternational Journal of Innovative Science and Research Technology100% (1)

- Ambulance Booking SystemDocument7 pagesAmbulance Booking SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Utilization of Waste Heat Emitted by the KilnDocument2 pagesUtilization of Waste Heat Emitted by the KilnInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Digital Finance-Fintech and it’s Impact on Financial Inclusion in IndiaDocument10 pagesDigital Finance-Fintech and it’s Impact on Financial Inclusion in IndiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Detection and Counting of Fake Currency & Genuine Currency Using Image ProcessingDocument6 pagesDetection and Counting of Fake Currency & Genuine Currency Using Image ProcessingInternational Journal of Innovative Science and Research Technology100% (9)

- An Overview of Lung CancerDocument6 pagesAn Overview of Lung CancerInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Osho Dynamic Meditation; Improved Stress Reduction in Farmer Determine by using Serum Cortisol and EEG (A Qualitative Study Review)Document8 pagesOsho Dynamic Meditation; Improved Stress Reduction in Farmer Determine by using Serum Cortisol and EEG (A Qualitative Study Review)International Journal of Innovative Science and Research TechnologyNo ratings yet

- An Efficient Cloud-Powered Bidding MarketplaceDocument5 pagesAn Efficient Cloud-Powered Bidding MarketplaceInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Designing Cost-Effective SMS based Irrigation System using GSM ModuleDocument8 pagesDesigning Cost-Effective SMS based Irrigation System using GSM ModuleInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Impact of Stress and Emotional Reactions due to the Covid-19 Pandemic in IndiaDocument6 pagesImpact of Stress and Emotional Reactions due to the Covid-19 Pandemic in IndiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Effect of Solid Waste Management on Socio-Economic Development of Urban Area: A Case of Kicukiro DistrictDocument13 pagesEffect of Solid Waste Management on Socio-Economic Development of Urban Area: A Case of Kicukiro DistrictInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Computer Vision Gestures Recognition System Using Centralized Cloud ServerDocument9 pagesComputer Vision Gestures Recognition System Using Centralized Cloud ServerInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Auto Tix: Automated Bus Ticket SolutionDocument5 pagesAuto Tix: Automated Bus Ticket SolutionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Examining the Benefits and Drawbacks of the Sand Dam Construction in Cadadley RiverbedDocument8 pagesExamining the Benefits and Drawbacks of the Sand Dam Construction in Cadadley RiverbedInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- An Industry That Capitalizes Off of Women's Insecurities?Document8 pagesAn Industry That Capitalizes Off of Women's Insecurities?International Journal of Innovative Science and Research TechnologyNo ratings yet

- Forensic Advantages and Disadvantages of Raman Spectroscopy Methods in Various Banknotes Analysis and The Observed Discordant ResultsDocument12 pagesForensic Advantages and Disadvantages of Raman Spectroscopy Methods in Various Banknotes Analysis and The Observed Discordant ResultsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Predictive Analytics for Motorcycle Theft Detection and RecoveryDocument5 pagesPredictive Analytics for Motorcycle Theft Detection and RecoveryInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Comparative Evaluation of Action of RISA and Sodium Hypochlorite on the Surface Roughness of Heat Treated Single Files, Hyflex EDM and One Curve- An Atomic Force Microscopic StudyDocument5 pagesComparative Evaluation of Action of RISA and Sodium Hypochlorite on the Surface Roughness of Heat Treated Single Files, Hyflex EDM and One Curve- An Atomic Force Microscopic StudyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Study Assessing Viability of Installing 20kw Solar Power For The Electrical & Electronic Engineering Department Rufus Giwa Polytechnic OwoDocument6 pagesStudy Assessing Viability of Installing 20kw Solar Power For The Electrical & Electronic Engineering Department Rufus Giwa Polytechnic OwoInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Unmasking Phishing Threats Through Cutting-Edge Machine LearningDocument8 pagesUnmasking Phishing Threats Through Cutting-Edge Machine LearningInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Cyber Security Awareness and Educational Outcomes of Grade 4 LearnersDocument33 pagesCyber Security Awareness and Educational Outcomes of Grade 4 LearnersInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Blockchain Based Decentralized ApplicationDocument7 pagesBlockchain Based Decentralized ApplicationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Smart Health Care SystemDocument8 pagesSmart Health Care SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Visual Water: An Integration of App and Web To Understand Chemical ElementsDocument5 pagesVisual Water: An Integration of App and Web To Understand Chemical ElementsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Parastomal Hernia: A Case Report, Repaired by Modified Laparascopic Sugarbaker TechniqueDocument2 pagesParastomal Hernia: A Case Report, Repaired by Modified Laparascopic Sugarbaker TechniqueInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Factors Influencing The Use of Improved Maize Seed and Participation in The Seed Demonstration Program by Smallholder Farmers in Kwali Area Council Abuja, NigeriaDocument6 pagesFactors Influencing The Use of Improved Maize Seed and Participation in The Seed Demonstration Program by Smallholder Farmers in Kwali Area Council Abuja, NigeriaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Impact of Silver Nanoparticles Infused in Blood in A Stenosed Artery Under The Effect of Magnetic Field Imp. of Silver Nano. Inf. in Blood in A Sten. Art. Under The Eff. of Mag. FieldDocument6 pagesImpact of Silver Nanoparticles Infused in Blood in A Stenosed Artery Under The Effect of Magnetic Field Imp. of Silver Nano. Inf. in Blood in A Sten. Art. Under The Eff. of Mag. FieldInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Reharmonisation (For All Notes & Chord Types) - Sheet1Document9 pagesReharmonisation (For All Notes & Chord Types) - Sheet1Luke Miller100% (2)

- Consolidation of Wholly Owned Subsidiaries Aquired at More Than Book ValueDocument39 pagesConsolidation of Wholly Owned Subsidiaries Aquired at More Than Book ValuejuniarNo ratings yet

- Approaches To The Study of Environment: Carl RitterDocument12 pagesApproaches To The Study of Environment: Carl RitterArshdeep SinghNo ratings yet

- Ester An IntroductionDocument22 pagesEster An IntroductionAnandNo ratings yet

- 75 - Papa v. Mago, 22 SCRA 857Document5 pages75 - Papa v. Mago, 22 SCRA 857gerlie22No ratings yet

- New QuestainerDocument58 pagesNew Questainerbharat sachdevaNo ratings yet

- Quantum Physics Infographics by SlidesgoDocument35 pagesQuantum Physics Infographics by Slidesgo39 Mohit KumarNo ratings yet

- Vice President Human Resources in Louisville KY Resume Christopher LitrasDocument3 pagesVice President Human Resources in Louisville KY Resume Christopher LitrasChristopher LitrasNo ratings yet

- Second Quarter Exam Pe 12Document4 pagesSecond Quarter Exam Pe 12Melegin Raton67% (3)

- Heat Gun ManualDocument15 pagesHeat Gun Manualcharles blairNo ratings yet

- Toad For Oracle Release Notes 2017 r2Document30 pagesToad For Oracle Release Notes 2017 r2Plate MealsNo ratings yet

- 'Tis So Sweet To Trust in JesusADocument1 page'Tis So Sweet To Trust in JesusAEsterlyn BumanlagNo ratings yet

- H. Muhammed Ka Parichay (Kannada)Document96 pagesH. Muhammed Ka Parichay (Kannada)Q.S.KhanNo ratings yet

- Alfamart List Store Aug2020 To June2021Document3 pagesAlfamart List Store Aug2020 To June2021Santi Leo50% (2)

- "The World On The Turtle's Back" by The IroquoisDocument9 pages"The World On The Turtle's Back" by The IroquoisCaleb Morales100% (1)

- Reliance Communications Report - 2Document91 pagesReliance Communications Report - 2Rocker AshwaniNo ratings yet

- Flushing of An Indwelling Catheter and Bladder Washouts KnowbotsDocument5 pagesFlushing of An Indwelling Catheter and Bladder Washouts KnowbotsTanaman PeternakanNo ratings yet

- Abhishek Panchal: Work ExperienceDocument3 pagesAbhishek Panchal: Work ExperienceNitin MahawarNo ratings yet

- International Shoe Size ChartDocument2 pagesInternational Shoe Size Chartlivelife01100% (1)

- The Design of High Efficiency Turbomachinery and Gas Turbines PDFDocument625 pagesThe Design of High Efficiency Turbomachinery and Gas Turbines PDFPhyo ThihabookNo ratings yet

- Sociology 08Document10 pagesSociology 08Lata SinghNo ratings yet

- Debt Collectors - Georgia Consumer Protection Laws & Consumer ComplaintsDocument11 pagesDebt Collectors - Georgia Consumer Protection Laws & Consumer ComplaintsMooreTrustNo ratings yet

- Haramaya University: R.NO Fname Lname IDDocument13 pagesHaramaya University: R.NO Fname Lname IDRamin HamzaNo ratings yet

- ZONE A - Walled City ReportDocument49 pagesZONE A - Walled City ReportAr Vishnu Prakash0% (1)

- Allarco Alberta Statement of Claim OCR PDFDocument12 pagesAllarco Alberta Statement of Claim OCR PDFHoward KnopfNo ratings yet

- Land Colonization of PlantsDocument57 pagesLand Colonization of PlantsSUDHA GUPTANo ratings yet

- Mid-Term Test Part 1: Listening: Time Allowance: 90 MinsDocument4 pagesMid-Term Test Part 1: Listening: Time Allowance: 90 MinsThu Lan HàNo ratings yet

- Socio Cultural Factors Influencing Child Nutrition Among Mothers in Calabar Municipality Cross River State NigeriaDocument34 pagesSocio Cultural Factors Influencing Child Nutrition Among Mothers in Calabar Municipality Cross River State NigeriaTAJUDEEN AZEEZNo ratings yet

- Assignment 33Document4 pagesAssignment 33Imran Khan JunejoNo ratings yet

- LEGAL AND JUDICIAL ETHICS - Final Report On The Financial Audit in The MCTC - AdoraDocument6 pagesLEGAL AND JUDICIAL ETHICS - Final Report On The Financial Audit in The MCTC - AdoraGabriel AdoraNo ratings yet