Professional Documents

Culture Documents

FSES Full en Us Letter

Uploaded by

Abo FatmaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FSES Full en Us Letter

Uploaded by

Abo FatmaCopyright:

Available Formats

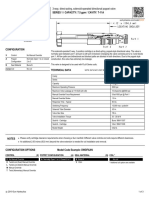

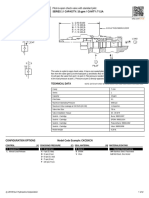

MODEL Synchronizing, flow divider-combiner valve

FSES SERIES 3 / CAPACITY: 6 - 30 gpm / CAVITY: T-33A

snhy.com/FSES

Synchronizing flow divider/combiners are sliding-spool, pressure-compensated devices used to split flow in one

direction and combine flow in the opposite direction. With a sychronizing feature, these valves can be used to allow

two hydraulic cylinders to fully stroke and synchronize at the end of the stroke. When the first cylinder has reached

the end of its stroke, a pressure-compensated, reduced flow is metered to or from the second cylinder until it also

reaches the end of its stroke.

TECHNICAL DATA

Maximum Operating Pressure 5000 psi

Divisional Accuracy at Minimum Input Flow 50% ±4.5%

Divisional Accuracy at Max Input Flow 50% ±2.5%

Pressure Drop at Minimum Rated Input Flow 30 psi

Pressure Drop at Maximum Rated Input Flow 350 psi

Seal kit - Cartridge Buna: 990-033-007

Seal kit - Cartridge Polyurethane: 990-033-002

Seal kit - Cartridge Viton: 990-033-006

CONFIGURATION OPTIONS Model Code Example: FSESXAN

CONTROL (X) FLOW SPLIT (A) SEAL MATERIAL (N) MATERIAL/COATING

X Not Adjustable A 50/50 N Buna-N Standard Material/Coating

V Viton /AP Stainless Steel, Passivated

TECHNICAL FEATURES

All flow divider and divider/combiner cartridges are physically interchangeable (i.e. same flow path, same cavity for a given frame size).

Operating characteristics cause the leg of the circuit with the greatest load to receive the higher percentage of flow in dividing mode. If a rigid mechanism is used to

tie actuators together, the lead actuator may pull the lagging actuator and cause it to cavitate.

In combining mode, compensating characteristics will cause the leg of the circuit with the lowest load to receive the higher percentage of flow. If a synchronization

feature is not included, an additive accuracy error will be experienced with each full stroke of the actuator.

In applications involving rigid mechanisms between multiple actuators, operating inaccuracy will cause the eventual lock-up of the system. If the mechanical structure

is not designed to allow for the operating inaccuracy inherent in the valve, damage may occur.

In motor circuits, rigid frames or mechanisms that tie motors together, and/or complete mechanical synchronized motion of the output shaft of the motors, either by

wheels to the pavement or sprockets to conveyors, will contribute to cavitation, lock-up and/or pressure intensification.

Variations in speed and lock-up can be attributed to differences in motor displacement, motor leakage, wheel diameter variance and friction of wheels on the driving

surface.

Extreme pressure intensification can occur on multiple wheel drive vehicles.

The synchronization feature provides bi-directional static error correction.

Synchronization flow is approximately 15% of minimum rated input flow.

Divisional and combining accuracy are equal.

Created on 06/17/2015 c 2015 Sun Hydraulics Corporation

See www.sunhydraulics.com for detailed product information 1 of 2

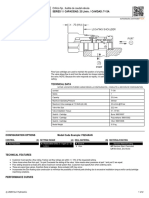

The synchronizing feature only comes into play when any one of the 3 ports is blocked. At that time, flow may occur between the other two ports.

Below the minimum flow rating there is not enough flow for the valve to modulate. It is effectively a tee. If flow starts at zero and rises, there will be no dividing or

combining control until the flow reaches the minimum rating.

Incorporates the Sun floating style construction to minimize the possibility of internal parts binding due to excessive installation torque and/or cavity/cartridge

machining variations.

PERFORMANCE CURVES

Created on 06/17/2015 c 2015 Sun Hydraulics Corporation

See www.sunhydraulics.com for detailed product information 2 of 2

You might also like

- Model Synchronizing, Flow Divider-Combiner Valve: Series 2 / Capacity: 3 - 15 GPM / Cavity: T-32ADocument2 pagesModel Synchronizing, Flow Divider-Combiner Valve: Series 2 / Capacity: 3 - 15 GPM / Cavity: T-32AHamza ChenakerNo ratings yet

- Model Closed Center, Flow Divider-Combiner Valve: Series 2 / Capacity: 3 - 15 GPM / Cavity: T-32ADocument2 pagesModel Closed Center, Flow Divider-Combiner Valve: Series 2 / Capacity: 3 - 15 GPM / Cavity: T-32AAnurag JainNo ratings yet

- Model Flow Divider Valve: Series 2 / Capacity: 3 - 15 GPM / Cavity: T-32ADocument2 pagesModel Flow Divider Valve: Series 2 / Capacity: 3 - 15 GPM / Cavity: T-32AErasmo LimaNo ratings yet

- Flow Divider and Flow Divider/Combiner Valves: ApplicationsDocument5 pagesFlow Divider and Flow Divider/Combiner Valves: ApplicationsmohitNo ratings yet

- TT US FlowDividerDocument5 pagesTT US FlowDividerxxshNo ratings yet

- TT US FlowDividerDocument5 pagesTT US FlowDividerLeonardo FigueroaNo ratings yet

- TTM FlowDivider PDFDocument5 pagesTTM FlowDivider PDFColinNo ratings yet

- Model Fully Adjustable Pressure Compensated Flow Control Valve With Reverse Flow CheckDocument2 pagesModel Fully Adjustable Pressure Compensated Flow Control Valve With Reverse Flow CheckRajan BediNo ratings yet

- Jahns HydraulicDocument14 pagesJahns HydraulicsatphoenixNo ratings yet

- CKBDXCV_APDocument2 pagesCKBDXCV_APŁukasz OlszewskiNo ratings yet

- FlowCon A AB ABV BrochureDocument4 pagesFlowCon A AB ABV BrochureDenon EvonNo ratings yet

- 5hp19 1-2 Shi̇ftDocument8 pages5hp19 1-2 Shi̇ftCatalin IordacheNo ratings yet

- CXHAXAN - Full - en - Metric - Letter BorbetDocument2 pagesCXHAXAN - Full - en - Metric - Letter BorbetRonaldNo ratings yet

- Pilot-to-open check valve technical detailsDocument2 pagesPilot-to-open check valve technical detailsVEERAMANINo ratings yet

- Variable Displacement Axial Piston Pumps: Edition: 04/01.2012 Replaces: MVP 03 T ADocument64 pagesVariable Displacement Axial Piston Pumps: Edition: 04/01.2012 Replaces: MVP 03 T AGERALD SIMONNo ratings yet

- Produkte PowerStromteiler Datenbl EnglDocument16 pagesProdukte PowerStromteiler Datenbl EnglCarlos Augusto100% (1)

- Model Pilot-To-Open Check Valve With Sealed Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11ADocument2 pagesModel Pilot-To-Open Check Valve With Sealed Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11AVignesh PandiyanNo ratings yet

- CKEB_full_en_metric_letterDocument2 pagesCKEB_full_en_metric_letterRafalNo ratings yet

- Screw Pump Series ALLFUEL AFI: GB/2013.11 - Ident-No. 488087Document8 pagesScrew Pump Series ALLFUEL AFI: GB/2013.11 - Ident-No. 488087Eugenio LombardiNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity, Loadadaptive™ Counterbalance ValveDocument1 pageModel 3:1 Pilot Ratio, Standard Capacity, Loadadaptive™ Counterbalance ValveAlexis PeñaNo ratings yet

- Model Pilot-To-Open Check Valve With Standard Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11ADocument2 pagesModel Pilot-To-Open Check Valve With Standard Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11AAnurag JainNo ratings yet

- PCPMCV 116Document17 pagesPCPMCV 116Bambang0% (1)

- IH RedukDocument14 pagesIH RedukPioneer PaperboyNo ratings yet

- CVGV Full en Metric LetterDocument2 pagesCVGV Full en Metric LetterRonaldNo ratings yet

- Counterbalance, Vented Guided Poppet Type, Counterclockwise Adjustment Sun Cavity Interchange, T-11ADocument2 pagesCounterbalance, Vented Guided Poppet Type, Counterclockwise Adjustment Sun Cavity Interchange, T-11Afik schaNo ratings yet

- Pressure Reducing - Relieving Valve PRFBDocument3 pagesPressure Reducing - Relieving Valve PRFBkocho79No ratings yet

- FREA Full en Us A4Document2 pagesFREA Full en Us A4Rodrigo LisboaNo ratings yet

- DMBF Full en Metric LetterDocument4 pagesDMBF Full en Metric LetterRonaldNo ratings yet

- TT US Circuit-SaverDocument7 pagesTT US Circuit-SaverLeonardo FigueroaNo ratings yet

- Normally closed balanced poppet valveDocument2 pagesNormally closed balanced poppet valvejuampacervantesNo ratings yet

- Dresser Mooney Regulators Flowgrid PCVDocument12 pagesDresser Mooney Regulators Flowgrid PCVElias ElHossariNo ratings yet

- CDAP Full en Us LetterDocument2 pagesCDAP Full en Us LetterDaniel CringusNo ratings yet

- 045924X47ZDocument1 page045924X47ZIrina VarzouNo ratings yet

- DWDFXAN Full en Us LetterDocument3 pagesDWDFXAN Full en Us LetterPartagon PowNo ratings yet

- Flow Divider Designs: HydraulikDocument40 pagesFlow Divider Designs: HydraulikHugo Muñoz ValdiviaNo ratings yet

- 81460229single Accumulator Charging ValveDocument8 pages81460229single Accumulator Charging ValveCésar Cusi LazoNo ratings yet

- Model Pilot-To-Open Check Valve With Standard Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11ADocument2 pagesModel Pilot-To-Open Check Valve With Standard Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11AErasmo LimaNo ratings yet

- Data Sheet S7 - 2020 - ENG - Light - CavagnaDocument12 pagesData Sheet S7 - 2020 - ENG - Light - CavagnaWND PRTMNo ratings yet

- Pilot-To-Open Check Valve With Standard Pilot and Delrin SeatDocument2 pagesPilot-To-Open Check Valve With Standard Pilot and Delrin SeatDaniel TostaNo ratings yet

- Seprador de MaterialesDocument2 pagesSeprador de MaterialesJulio CNo ratings yet

- Flow fuse cartridge technical detailsDocument2 pagesFlow fuse cartridge technical detailsSara SaritaNo ratings yet

- PLD 03 T ADocument24 pagesPLD 03 T ADomingo DottpattNo ratings yet

- Pump Unload Pilot Valve SUN QPABDocument2 pagesPump Unload Pilot Valve SUN QPABankesh_ghoghariNo ratings yet

- Model 50%, Accumulator Sense, Pump Unload Valve - Pilot CapacityDocument2 pagesModel 50%, Accumulator Sense, Pump Unload Valve - Pilot CapacityleosignareNo ratings yet

- Dual Counterbalance With Brake Release Port: DescriptionDocument2 pagesDual Counterbalance With Brake Release Port: DescriptionPhilNo ratings yet

- Free-flow nose-to-side check valve technical detailsDocument2 pagesFree-flow nose-to-side check valve technical detailssnsnagarajanNo ratings yet

- Flow-Divider-DesignsDocument38 pagesFlow-Divider-DesignssalesNo ratings yet

- Series N Hydro Pneumatic Press Cylinder PDFDocument11 pagesSeries N Hydro Pneumatic Press Cylinder PDFranjith sanNo ratings yet

- Steering ObrtitolDocument52 pagesSteering ObrtitolJose FigueroaNo ratings yet

- 99-0337-REV D CC ManifoldDocument3 pages99-0337-REV D CC Manifoldtdyhgt tdjhgyfytNo ratings yet

- Flow DividerDocument2 pagesFlow DividerAnil JindalNo ratings yet

- Model Free Flow Nose To Side Check Valve With Bypass OrificeDocument2 pagesModel Free Flow Nose To Side Check Valve With Bypass OrificeRenjithSivaNo ratings yet

- Automatic Line Flush Valves Product SheetDocument2 pagesAutomatic Line Flush Valves Product SheetmanishdgNo ratings yet

- Modelo Totalmente Ajustable Compensado Por Presión Control de Caudal Válvula Con Anti-Retorno de Caudal InversoDocument2 pagesModelo Totalmente Ajustable Compensado Por Presión Control de Caudal Válvula Con Anti-Retorno de Caudal InversoErasmo LimaNo ratings yet

- Pilot-to-close check valve technical detailsDocument2 pagesPilot-to-close check valve technical detailscesar5984No ratings yet

- Tucson CBVDocument2 pagesTucson CBVSridhar PillaNo ratings yet

- Shuttle Valve - Tuscon - 5-710Document2 pagesShuttle Valve - Tuscon - 5-710Rajan BediNo ratings yet

- LOGIC CARTRIDGE LODCXDN - Full - en - Us - LetterDocument2 pagesLOGIC CARTRIDGE LODCXDN - Full - en - Us - LetterHassan KhattabNo ratings yet

- FA2 FA2.5 FA5 SpecsDocument8 pagesFA2 FA2.5 FA5 SpecsAbo FatmaNo ratings yet

- Revision November 2009 IDocument8 pagesRevision November 2009 IAnibal Jose Cruz Larez100% (1)

- 2.JC50DB-06 Drawworks Parts ListDocument17 pages2.JC50DB-06 Drawworks Parts ListAbo FatmaNo ratings yet

- Mud Pump Emsco Fc2200 C&oDocument121 pagesMud Pump Emsco Fc2200 C&oAbo Fatma100% (2)

- TQ340-35 Power Casing Tong Operation & Maintenance ManualDocument18 pagesTQ340-35 Power Casing Tong Operation & Maintenance ManualAbo FatmaNo ratings yet

- Ekiti Subeb Past Questions and AnswersDocument41 pagesEkiti Subeb Past Questions and AnswersSandra Gkbchall0% (1)

- C-Zone SDN BHD: WWW - Czone.myDocument2 pagesC-Zone SDN BHD: WWW - Czone.myFirman SyahNo ratings yet

- Agile vs Waterfall: Which Project Methodology is BestDocument29 pagesAgile vs Waterfall: Which Project Methodology is BestAhmad Adeniyi SharafudeenNo ratings yet

- Lufthansa Technical Training Troubleshooting Fundamentals CourseDocument160 pagesLufthansa Technical Training Troubleshooting Fundamentals CourseBELISARIONo ratings yet

- Seminar: Predictive AnalyticsDocument10 pagesSeminar: Predictive Analyticssamiksha ingoleNo ratings yet

- CIO 100 2011 - Google Apps For Business-Keval Shah-SumariaDocument9 pagesCIO 100 2011 - Google Apps For Business-Keval Shah-SumariaCIOEastAfricaNo ratings yet

- JL-03-November-December The Strutted Box Widening Method For Prestressed Concrete Segmental BridgesDocument18 pagesJL-03-November-December The Strutted Box Widening Method For Prestressed Concrete Segmental BridgesVivek PremjiNo ratings yet

- Physical Optics: Multiple Choice QuestionsDocument9 pagesPhysical Optics: Multiple Choice QuestionsHammadiqbal12No ratings yet

- Finding The Right International MixDocument3 pagesFinding The Right International MixКсения БорисоваNo ratings yet

- Shale ProblemsDocument12 pagesShale ProblemsShirley Hernandez JimenezNo ratings yet

- Osy Chapter 3Document19 pagesOsy Chapter 3NNo ratings yet

- Experimental Phonetics 311Document7 pagesExperimental Phonetics 311Ebinabo EriakumaNo ratings yet

- Hybrid Pile Foundations IPWE SeminarDocument22 pagesHybrid Pile Foundations IPWE Seminarrohit100% (1)

- Advantages of I/O Device Management On Operating SystemDocument4 pagesAdvantages of I/O Device Management On Operating SystemIbrahim HasanNo ratings yet

- Femi-Akala Omotola H Computer Science Group B 19/1509 Data Communications and Computer Networks-COSC 335Document3 pagesFemi-Akala Omotola H Computer Science Group B 19/1509 Data Communications and Computer Networks-COSC 335Femi-Akala Hamzat OmotolaNo ratings yet

- Chapter - 2: Basic Computer Organization and DesignDocument74 pagesChapter - 2: Basic Computer Organization and Designketulmp0% (1)

- Earthing Calculation: A General Design DataDocument14 pagesEarthing Calculation: A General Design Dataمحمد الأمين سنوساوي100% (1)

- Modelica03 AdvancedTutorialDocument34 pagesModelica03 AdvancedTutorialWuberestNo ratings yet

- 06na NW Parts BreakdownDocument14 pages06na NW Parts BreakdownAmaurys Centeno100% (6)

- E176 PDFDocument20 pagesE176 PDFAhmad Zubair RasulyNo ratings yet

- E-Mobility LD DIDACTICDocument12 pagesE-Mobility LD DIDACTICromauli100% (1)

- Transformer Training (SNC Lavalin - District Cooling Project) - R01Document174 pagesTransformer Training (SNC Lavalin - District Cooling Project) - R01MohammedNo ratings yet

- 1623917396609-Model Qsns On Comp - GroundDocument10 pages1623917396609-Model Qsns On Comp - Groundrupakdutta158No ratings yet

- Civil Engineering PG StudiesDocument8 pagesCivil Engineering PG StudiesnitintkattiNo ratings yet

- Sample - Table - Literature ReviewDocument11 pagesSample - Table - Literature ReviewKeyur KevadiyaNo ratings yet

- Organizational Structure TypeDocument7 pagesOrganizational Structure TypechaimaNo ratings yet

- Wireless Sensor Network Security A Critical Literature ReviewDocument4 pagesWireless Sensor Network Security A Critical Literature Reviewea6xrjc4No ratings yet

- Non Faculty Application FormDocument6 pagesNon Faculty Application FormBharat KumarNo ratings yet

- Centrifugal Compressors in Ethylene PlantsDocument5 pagesCentrifugal Compressors in Ethylene PlantsForcus onNo ratings yet

- Journal of Energy StorageDocument14 pagesJournal of Energy StorageLuis Antonio CNo ratings yet