Professional Documents

Culture Documents

Brochures

Uploaded by

משה אביסדריסCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Brochures

Uploaded by

משה אביסדריסCopyright:

Available Formats

IRIZAR HEAVY INDUSTRIES INC

Head Office: 1512 Adamson View, Edmonton, Alberta T6W 0V4, Canada

Factory: 464014 RR 235, County of Wetaskiwin, AB, T0C 1Z0, Canada

Phone: 1 780 450 6695, Fax: 1 780 485 6677

Email: jirizar@jirizar.com Website: www.jirizar.com

PRODUCT CATALOG

July 2017. Irizar Welding Rotator Model WR 1200

At Nuclear Construction Site in Georgia Power Plant Vogtle, USA

Westinghouse Nuclear Power Generator AP 1000 PWR

IRIZAR HEAVY INDUSTRIES INC

Revision: March 26, 2019

© 2019 Irizar Heavy Industries Inc. All rights reserved

Exceeding International Standards since 1999 ` 1|P a g e

IRIZAR HEAVY INDUSTRIES INC

Head Office: 1512 Adamson View, Edmonton, Alberta T6W 0V4, Canada

Factory: 464014 RR 235, County of Wetaskiwin, AB, T0C 1Z0, Canada

Phone: 1 780 450 6695, Fax: 1 780 485 6677

Email: jirizar@jirizar.com Website: www.jirizar.com

PRODUCT RANGE

Irizar Heavy Industries Inc is proudly a

Canadian Company with headquarters in

1. Conventional Welding Rotators: From 1 to 2,000 MT

Edmonton, Canada.

2. Anti-Drift (Anti-Creep) Turning Rolls: From 250 to 3,000 MT

3. Self Aligned Rotators: From 5 to 500 MT

INDUSTRIAL SEGMENT

4. Chain Welding Rotators: 20 MT

5. Pipe Rotators: From 1 to 25 MT

Our products have been used among others

6. Welding Positioners: From 0.3 to 100 MT

industries: Oil & Gas, Power Generation,

7. Head & Tail Stock: From 1 to 100 MT

Nuclear, Aerospace, Pipes and Pressure

8. Welding Manipulators: From 2 x 2 m to 8 x 6 m (vertical x horizontal)

Vessels, Onshore & Offshore Wind

9. Girth Welders: AGW-1, AGW-2, LNG AGW-1 & Motorized Baskets

Towers and Monopiles, Rail Tanks,

10. Tank Lifting Jacks: Up to 3,000 MT tank weight lifting capacity. Jacks with load

Defense Industry, Mining, and Food

capacity of 12 MT & 25 MT. Applicable on Field Erected Tanks API-650, LNG

Industry.

API 620 Welded Tanks, Grain Bins, and Smooth Wall Bolted Tanks.

DESIGN: Our products are Designed & Engineered in Canada; and, made by our own Factory in China. We are proud to own

The World Largest Stock of Welding Positioning Equipment and Tank Lifting Jacks. Our warehouse it’s located in Wetaskiwin

Alberta Canada in a thirty acres lot; at thirty-five minutes from the Edmonton International Airport. Welcome to visit our Show

Room, large inventory, and spare parts stock.

EXPORTATION: We have exported over sixty countries, among them: Angola, Argentina, Australia, Belgium, Bahamas,

Bolivia, Brazil, Canada, Chad, Chile, China, Colombia, Costa Rica, Cote D’ Ivoire, Denmark, Ecuador, Egypt, France, Germany,

Greece, Guatemala, India, Indonesia, Iran, Ireland, Italy, Japan, Jordan, Kuwait, Madagascar, Martinique & Guadeloupe, Mexico,

Morocco, Netherlands, New Zealand, Nigeria, Norway, Oman, Pakistan, Panama, Paraguay, Peru, Philippines, Poland, Romania,

Russia Federation, Saudi Arabia, Singapore, South Africa, Spain, Tanzania, Taiwan (China), Thailand, Ukraine, United Arab

Emirates, United Kingdom, Uruguay, USA and Venezuela.

OUR GOALS: To Build State of art High-Tech Products; to Exceed International-Standards; to provide Top-Quality and Safety

Products; to provide First-Class Service; to offer the Most Competitive-Price; to Deliver within the Shortest-Time; and to Build a Long-

Term Business Relationship with our customers. Our company produces finished products; but there is more to it. Passionate employees

in every department which captivate what we stand for, to great ideas and true commitment; to do our best. Research & Development:

Everything start from the research for the perfect materials tested by extensive and rigorous testing methods. With our state-of-the-art

testing and measurement equipment, we regularly rise the bar again and again. Our design engineers only aim for the best. Production and

Logistics: Quality comes first. With constant quality control immersed within the production process, we guaranty prestige products for

our clients. Each product is pack and ship in premium packaging. Sales & Marketing: Our multinational team covers more than fifty

countries all over the World. Technical Support: Our trust, know how, integrity, as well as, our fast and flexible service is always

appreciated.

Page CONTENTS

3 The World Largest Stock

4 Conventional Tank Turning Rolls WR Series

6 Anti-Drift Turning Rolls AD-WR Series

7 Self-Aligned Tank Turning Rolls SAR Series

9 Chain Welding Rotators

9 Custom Built Rotators

10 Fit Up Rolls Growing Line

11 Pipe Rotators PR & PP Series

12 Welding Positioners WP Series

14 Welding Positioners CWP Series Anti-Drift Welding Rotator Model WR 3000

15 Welding Positioners PL Series 3000 MT (6,600,000 #) load and rotation capacity

15 Head & Tail Stock HT Series

15 Turn-Tables TT Series

Notes: The information contained on this brochure is intended to be

16 Welding Manipulators WM Series

accurate. However, the manufacturer reserves the right to make

18 Automatic Girth Welders AGW Series

changes in design which may not be included

20 Linear Oscillator Welding Tractor

20 Irizar Magnetic Device

21 Tank Jacking TJ Series Limited Warranty

22 Jack Selection Software Terms and Conditions of Sale

© 2019 Irizar Heavy Industries Inc. All rights reserved

Exceeding International Standards since 1999 ` 2|P a g e

IRIZAR HEAVY INDUSTRIES INC

Head Office: 1512 Adamson View, Edmonton, Alberta T6W 0V4, Canada

Factory: 464014 RR 235, County of Wetaskiwin, AB, T0C 1Z0, Canada

Phone: 1 780 450 6695, Fax: 1 780 485 6677

Email: jirizar@jirizar.com Website: www.jirizar.com

The World Largest Stock

ROTATORS FOR SPECIAL APPLICATIONS

Vessel/Pipe

Capacity

We are proud to own The World Largest Stock of Model Diameter

MT

(mm)

Welding Positioning Equipments and Tank Lifting

Jacks. In stock over 3,000 pieces of equipment. Below Chain Rotator CWR 20 20 2000-5000

Pipe Positioner PP 3 3 50-800

is the current equipment in stock; nevertheless, we can

Pipe Rotator PR 5 5 50-600

custom-built or make any other model available in this

brochure.

WELDING MANIPULATORS

DELIVERY TIME: a) In Canada: 3 to 5 business days; b)

Boom Expansion

In USA & US-Mexican border: One week; c) In Latino Model Vertical x Horizontal

America: 4 weeks; d) World-Wide: 5 to 6 weeks (m)

WM 3030 w motorized trolley 3.0 x 3.0

CONVENTIONAL WELDING ROTATORS WM 4040 w motorized trolley 4.0 x 4.0

WM 5050 w motorized trolley 5.0 x 5.0

WM 6060 w motorized trolley 6.0 x 6.0

Vessel

Capacity

Model Diameter

MT

(mm)

WELDING POSITIONERS

PR 1 1 20-1000

WR 3 3 150-2500 Load & Rotation

WR-5 5 150-3200 Model

Capacity

WR-10 10 250-4800

WR 20 20 250-4800 WP 0.30 300 kilos @ 200 mm GC

WR 40 40 250-4800 WP 0.60 600 kilos @ 200 mm GC

WR 60 60 300-5200 WP 1 1 MT @ 250 mm GC

WR 80 80 300-5200 WP 3 3 MT @ 300 mm GC

WR 100 100 350-7800 WP 5 5 MT @ 300 mm GC

WR 150 150 350-7800 WP 10 10 MT @ 400 mm GC

WR 250 250 350-7500

WR 250 250 550-9000

WR 400 400 550-9000 TURN TABLES

WR 600 600 550-9000

WR 1200 1200 1100-12000

Load & Rotation

WR 1600 1600 1100-12000 Model

Capacity

TT 1 1 MT

ANTI-DRIFT WELDING ROTATORS TT 3 3 MT

TT 5 5 MT

Vessel TT 10 10 MT

Capacity

Model Diameter

MT

(mm)

AUTOMATIC GIRTH WELDERS

AD - WR 800 800 2000-9000

AD - WR 1000 1000 2000-9000

AD - WR 1200 1200 2000-9000 Model

AD - WR 1600 1600 2000-9000

Girth Tank Welder Model AGW-1

Girth Tank Welder Model AGW-1-C

SELF ALIGNED WELDING ROTATORS Girth Tank Welder Model AGW-2

Girth Tank Welder LNG AGW-1

Motorized Basket

Vessel MIG Oscillator Welding Tractor

Capacity

Model Diameter Irizar Magnetic Device

MT

(mm)

SAR 5 5 250-2300

SAR 10 10 350-2800 TANK JACKING

SAR 20 20 500-3500

SAR 40 40 900-5200

Model

SAR 60 60 750-4800

SAR 80 80 850-5000 12 MT Jacks with trestle for 1.20 m plate

SAR 100 100 1000-5500 12 MT Jacks with trestle for 3.00 m plate

SAR 100 100 1000-6800 25 MT Jack with trestles for 3.00 m plate

SAR 150 150 1100-6000 Power Pack 10 HP

SAR 250 250 1800-8000 Power Pack 20 HP

SAR 500 500 1800-8000 Power Pack 40 HP

Power Pack 80 HP

RENTALS IN CANADA AND USA

© 2019 Irizar Heavy Industries Inc. All rights reserved

Exceeding International Standards since 1999 ` 3|P a g e

IRIZAR HEAVY INDUSTRIES INC

Head Office: 1512 Adamson View, Edmonton, Alberta T6W 0V4, Canada

Factory: 464014 RR 235, County of Wetaskiwin, AB, T0C 1Z0, Canada

Phone: 1 780 450 6695, Fax: 1 780 485 6677

Email: jirizar@jirizar.com Website: www.jirizar.com

Conventional Tank Turning Rolls, WR Series

Conventional Welding Rotators, also known as: Tank Rollers, Welding Rollers, Tank Rotators, Weld Rotators, Pipe

Rotators, Welding Rolls, Welding Rotators, Vessel Rollers, Tank Rolls and Turning Rolls

Irizar Model WR 1200

Load & Wheel Dimensions

Rotation Vessel (mm) L*W*H (mm)

Rotation Power Torque Weight

Model speed Diameter

Capacity (kW) (Nm) (MT)

(mm/min) (mm) Diam Width Power Roll Idler Roll

(MT)

WR 3 3 100-1000 2*0.25 1200 150-2500 200 112 1900*500*450 1350*300*450 0.35

WR 5 5 100-1000 2*0.37 2200 150-3200 250 140 2000*500*480 1600*380*480 0.80

WR 10 10 100-1000 2*0.55 4000 250-4800 300 170 2440*610*550 2320*450*550 1.00

WR 20 20 100-1000 2*1.10 9250 250-4800 350 180 3000*675*600 2500*500*600 1.50

WR 40 40 100-1000 2*1.50 14400 250-4800 400 200 3100*700*650 2610*700*650 2.30

WR 60 60 100-1000 2*2.20 23750 300-5200 450 220 3450*820*830 3000*820*830 2.40

WR 80 80 100-1000 2*3.00 26400 300-5200 500 240 4380*900*890 3400*700*890 2.90

WR 100 100 100-1000 2*3.00 36000 350-7800 500 260 4380*970*980 3800*760*980 4.80

WR 150 150 100-1000 2*4.00 48000 350-7800 500 260 4210*1000*980 3800*800*980 5.50

WR 250 250 100-1000 2*5.50 87000 550-9000 660 260 4900*1060*1100 4380*920*1100 10.00

WR 400 400 100-1000 2*5.50 92000 550-9000 700 300 5900*1140*1180 5500*920*1180 17.50

WR 600 600 100-1000 2*7.50 162000 550-9000 900 360 6900*1300*1600 6000*1200*1600 27.50

WR 800 800 100-1000 2*11.0 237000 550-9000 900 380 7100*1400*1600 6500*1260*1600 35

WR 1000 1000 100-1000 2*11.0 360000 1100-12000 1000 400 7500*1600*1700 7000*1320*1700 40.

WR 1200 1200 100-1000 2*11.0 360000 1100-12000 1000 450 8500*1600*1800 7500*1320*1800 48

WR 1600 1600 100-1000 2*18.5 NA 1100-12000 1200 600 8500*2320*2800 11000*2028*2800 110

WR 2000 2000 100-1000 2*25.9 NA 1100-12000 1200 600 8500*2320*2800 11000*2028*2800 140

Features:

Standard Package: 1. One Power Roll with Control Box

and Remote Control Box with 12 m cable, 2. One Idler

3D Model 3D Model

Photos/Video Roll, 3. Operation Manual with Electric Diagram, 4. One

WR 3 - WR 400 WR 600 - WR 1200

year Warranty

a. Designed and Engineered in Canada Optional:

b. Prototype static and dynamic tested at full capacity by Canadian Testing a. Foot Pedal. Control: Forward/Stop/Reverse

Laboratory b. Wireless Remote Control: With 60 m reach and 128

c. Rotators wheels from WR 3 to WR 100 are made of Cast Iron; covered with heavy channels. Control: Forward/Stop/Reverse/Variable speed

duty rubber HSA80, and two steel rings at the side. Rotators wheels for WR 150 and adjustment with digital display in mm/min

larger are made of Cast Steel ASTM 80-40 or equivalent; Then, quenched and c. Turning rolls mounted idler or motorized bogies.

tempered at 43 ~ 45 HRC (Rockwell C). Options: Constant speed of 1.5 m/minute, or variable

d. Remote Control Box with 12 m cable. Control: Forward/Stop/Reverse/Variable speed from 0.15 to 1.5 m/minute

speed adjustment with digital display in mm/min d. Screw Device (manual or motorized) for adjust center to

e. Center to center distance between wheels adjustable by means of bolts and nuts center wheel distance. Available for models up to WR

f. Angle between wheel’s center and vessel center must be on the range of 45° to 110°. 150

Never use less than 45° since produce un-safe condition. For increase traction use e. Anti-Drift Turning Rolls: Minimize the screw effect

angles from 90° to 110° (longitudinal displacement) while vessel is rotating.

g. Increase power rotation capacity up to 50% more by adding extra idler; table sheet Axial vessel accuracy of ± 3.0 mm; Available in rollers

next page. Valid only when: a) Vessel has no eccentricity loads, b) Each rotator from 500 to 2000 MT.

takes one third of the vessel weight f. Brake Motors for vessels with large “eccentricity”. It

h. Quality: 1. Gearbox’s shells made of cast iron ASTM-A48-A48M or equivalent; 2. means, large GC offset from the tank rotation center line.

Open gears made of Q235 steel or equivalent; 3. Shafts made of ANSI-1045 or g. Rotator’s wheels covered with polyurethane HSA95.

equivalent; 4. Motors and control box with IP 54 protection against dust and heavy Ideal for construction of stainless-steel tanks. Available

rain; 5. Frequency driver made by TECO Westinghouse; 6. Shot blasted to ensure for rotators up to WR 150.

the paint holds longer h. Rotators for shot blasting and painting with explosion

proof on both motors and main control box

Notes: 1. Rentals: Available in Canada & USA, 2. Custom-built welding rotators i. Synchronized Device: Synchronize rotation speed of two

available. 3. The information contained in this brochure is intended to be accurate. power rotators

However, the manufacturer reserves the right to make changes in design which may not be j. CE Mark

included. Latest revision available online

© 2019 Irizar Heavy Industries Inc. All rights reserved

Exceeding International Standards since 1999 ` 4|P a g e

IRIZAR HEAVY INDUSTRIES INC

Head Office: 1512 Adamson View, Edmonton, Alberta T6W 0V4, Canada

Factory: 464014 RR 235, County of Wetaskiwin, AB, T0C 1Z0, Canada

Phone: 1 780 450 6695, Fax: 1 780 485 6677

Email: jirizar@jirizar.com Website: www.jirizar.com

Max Load & Rotation

Vessel Ø Capacity (MT)

Model

(mm)

1 Power + 1 Idler 1 Power + 2 Idlers (*)

WR 3 150-2500 3 4.5

WR 5 150-3200 5 7.5

WR 10 250-4800 10 15

WR 20 250-4800 20 30

WR 40 250-4800 40 60

WR 60 300-5200 60 90

WR 80 300-5200 80 120

WR 100 350-7800 100 150

WR 150 350-7800 150 225

WR 250 350-9000 250 375

WR 400 350-7500 400 600

WR 600 550-9000 600 900

WR 800 550-9000 800 1200

WR 1000 1100-12000 1000 1500

WR 1200 1100-12000 1200 1800

WR 1600 1100-12000 1600 2400

Irizar Welding Rotator Model WR 1200

WR 2000 1100-12000 2000 3000

Engineered in Canada. Load & Rotation Capacity: 1,200 MT

At Work in USA, Spain & China

(*) Valid only if vessel has no eccentric loads

Irizar Model WR 1200

1200 MT Load and Rotation Capacity

Irizar Power Welding Rotator Model WR 1200

Engineered in Canada. Load Capacity: 600 MT, Rotation Capacity: 1200 MT

Tested at C-FER, Canandian Laboratory in Edmonton, AB

March 2013. Irizar Welding Rotator Model WR 1200

At Nuclear Construction Site in Haiyang, Shandong, China

January 2017. Irizar Welding Rotator Model WR 1200 Westinghouse Nuclear Power Generator AP 1000 PWR

At Nuclear Construction Site in VC Summer, South Carolina USA

Westinghouse Nuclear Power Generator AP 1000 PWR March 2014. Irizar Welding Rotator Model WR 1200

At Nuclear Construction Site CNNC in Sanmen, Tazhou Zhejang, China

The world’s first AP1000 third-generation nuclear unit

© 2019 Irizar Heavy Industries Inc. All rights reserved

Exceeding International Standards since 1999 ` 5|P a g e

IRIZAR HEAVY INDUSTRIES INC

Head Office: 1512 Adamson View, Edmonton, Alberta T6W 0V4, Canada

Factory: 464014 RR 235, County of Wetaskiwin, AB, T0C 1Z0, Canada

Phone: 1 780 450 6695, Fax: 1 780 485 6677

Email: jirizar@jirizar.com Website: www.jirizar.com

Anti-Drift Turning Rolls, AD-WR Series

Anti-Drift Turning Rolls: Also known as Anti-Creep Rotators.

Minimize the screw effect (longitudinal displacement) while vessel is

rotating. Axial vessel accuracy of ± 3.0 mm. Anti-Drift Welding Rotators

from 100 to 3000 MT

Standard Package:

1. One Power Roll with Control Box and Remote-Control Box

2. One Idler Roll with up/down servo motor on both wheels

3. In/Out Drift Sensor with Stand

4. PLC Controlled or Electric Manual Controlled

5. Operation Manual with Electrical Diagram

6. One year Warranty

3000 MT, Irizar Anti-Drift Welding Rotator Model AD-WR 3000

Video 3000 MT (6,600,000 #) Load and Rotation capacity

Load & Wheel

Rotation Vessel (mm)

Rotation Power Dimensions Weight

Model speed Diameter

Capacity (kW) L*H*W1*W2 (mm) (MT)

(mm/min) (mm) Diam Width

(MT)

AD WR 100 100 100-1000 2*3.0 1000-8000 500 260 5300*1070*1000*600 6.24

AD WR 150 150 100-1000 2*4.0 1000-8000 500 260 5700*1140*1050*650 7.15

AD WR 250 250 100-1000 2*5.5 1000-9000 660 260 5700*1250*1140*700 13.00

AD WR 400 400 100-1000 2*5.5 1200-9000 700 300 6600*1450*1320*830 22.75

AD WR 600 600 100-1000 2*7.5 1500-9000 900 360 7200*1845*1650*1000 35.75

AD WR 800 800 100-1000 2*11.0 2000-9000 900 380 7900*1845*2000*1300 45.50

AD WR 1000 1000 100-1000 2*11.0 2000-9000 1000 400 7900*1860*2100*1500 52.00

AD WR 1200 1200 100-1000 2*11.0 2000-9000 1000 450 7900*1860*2150*1600 62.40

AD WR 1600 1600 100-1000 2*20.00 2000-9000 1200 600 7900*1860*2400*1800 143.00

AD WR 2000 2000 100-1000 2*24.0 2000-9000 1200 600 8500*1960*2560*1900 182.00

AD WR 3000 3000 100-1000 2*24 + 30 2000-4000 1500 800 10000*2695*3210*2440 300.00

500 MT, Irizar Model WR 500 with Anti-Drift 3000 MT, Irizar Anti-Drift Welding Rotator Model AD-WR 3000

1600 MT, Irizar Model Anti-Drift Power WR 1600

1600 MT, Irizar Model Anti-Drift Idler IR 1600

© 2019 Irizar Heavy Industries Inc. All rights reserved

Exceeding International Standards since 1999 ` 6|P a g e

IRIZAR HEAVY INDUSTRIES INC

Head Office: 1512 Adamson View, Edmonton, Alberta T6W 0V4, Canada

Factory: 464014 RR 235, County of Wetaskiwin, AB, T0C 1Z0, Canada

Phone: 1 780 450 6695, Fax: 1 780 485 6677

Email: jirizar@jirizar.com Website: www.jirizar.com

Self-Aligned Tank Turning Rolls, SAR Series

Self Aligned Rotators also known as: Self Aligning (Adjusted, Alignment, Adjustment) Rollers

Wheel Dimensions

Load & (mm) L*W*H (mm)

Rotation Vessel

Rotation Power Torque Weight

Model speed Diameter

Capacity (kW) (Nm) (MT)

(mm/min) (mm) Diameter Width Power Roll Idler Roll

(MT)

SAR 5 5 100-1000 0.75 3188 250 140 1620*690*700 1380*380*700 0.85

SAR 10 10 100-1000 1.10 7652 300 170 1880*780*820 1454*390*820 1.20

SAR 20 20 100-1000 1.50 13093 350 180 2150*960*850 1700*480*850 2.00

SAR 40 40 100-1000 3.00 20405 400 200 2600*1000*1100 2200*500*1100 3.00

SAR 60 60 100-1000 4.00 30608 Chart 450 220 3000*1100*1150 2500*540*1150 4.00

SAR 80 80 100-1000 4.00 34009 Next Page 500 240 3200*1200*1200 2700*620*1200 4.50

SAR 100 100 100-1000 5.50 46800 500 260 3500*1200*1400 3000*750*1400 5.50

SAR 150 150 100-1000 3.0*2 51900 500 220 3500*1200*1400 3000*750*1400 6.00

SAR 250 250 100-1000 5.5*2 93600 660 260 5010*1200*1600 3800*790*1600 12.00

SAR 500 500 100-1000 7.5*2 124000 800 300 5800*1400*2000 5000*1000*2000 28.00

Features:

Standard Package: 1. One Power Roll with Control Box

and Remote Control Box with 12 m cable, 2. One idler roll,

3D Model 3D Model

Photos/Video 3. Operation Manual with Electric Diagram, 4. One year

SAR 5 - SAR 100 SAR 150 - SAR 500

Warranty

a. Designed and Engineered in Canada

Work Pieces with Eccentric Loads ≥ 25 inches of GC.

b. Prototype static and dynamic tested at full capacity by Canadian Testing

Select the Rotator Model: Rotation Capacity (MT) ≥ 5 x

Laboratory

Vessel Weight (MT) x GC (inches) / Vessel Radius (inches).

c. Rollers align itself with the vessel diameter. Enable weight distribution in four

In addition, Brake’s motor may be required if: Vessel

idler wheels on idler roll and four motorized wheels on power rotator

Radius (inches) x 0.7 ≥ GC (inches)

d. Rotators wheels from SAR 5 up to SAR 100 are made of Cast Iron; covered with

heavy duty rubber HSA80, and two steel rings at the side. Rotators wheels from

SAR 150 up to SAR 150 are made of Cast Steel ASTM 80-40 or equivalent; Optional:

then, quenched and tempered at 43 ~ 45 HRC (Rockwell C)

a. Foot Pedal. Control: Forward/Stop/Reverse

e. Remote Control Box with 12 m cable. Control: Forward/Stop/Reverse/ Variable

b. Wireless Remote Control: With 60 m reach and 128

speed adjustment with digital display in mm/min

channels. Control: Forward/Stop/Reverse/Variable speed

f. Increase power rotation capacity up to 50% more by adding extra idler; table

adjustment with digital display in mm/min

sheet next page. Valid only when: a) Vessel has no eccentricity loads, b) Each

c. Turning rolls mounted over idler or motorized bogie.

rotator takes one third of the weight

Options: Constant speed of 1.5 m/min, or variable speed

g. Quality: 1. Gearbox’s shells made of cast iron ASTM-A48-A48M or equivalent;

from 0.15 to 1.5 m/minute

2. Open gears made of Q235 steel or equivalent; 3. Shafts made of ANSI-1045

d. Brake Motors for vessels with large “eccentricity”. It

or equivalent; 4. Motors and control box with IP 54 protection against dust and

means, large GC offset from the tank rotation center line

heavy rain; 5. Frequency driver made by TECO Westinghouse; 6. Shot blasted to

e. Rotator’s wheels covered with polyurethane HSA95.

ensure the paint holds longer

Ideal for construction of stainless-steel tanks. Available

for rollers up to SAR 150.

Notes: 1, Rentals: Available in Canada & USA, 2. Custom-built welding rotators

f. Synchronized Device: Synchronize rotation speed of two

available, 3. The information contained in this brochure is intended to be accurate.

power rotators

However, the manufacturer reserves the right to make changes in design which may

g. CE Mark

not be included. Latest revision available online.

© 2019 Irizar Heavy Industries Inc. All rights reserved

Exceeding International Standards since 1999 ` 7|P a g e

IRIZAR HEAVY INDUSTRIES INC

Head Office: 1512 Adamson View, Edmonton, Alberta T6W 0V4, Canada

Factory: 464014 RR 235, County of Wetaskiwin, AB, T0C 1Z0, Canada

Phone: 1 780 450 6695, Fax: 1 780 485 6677

Email: jirizar@jirizar.com Website: www.jirizar.com

Workpiece sits in Four Wheels

Vessel Ø Max Load and Rotation Capacity (MT)

Model

(mm) 1 Power + 1 Idler 1 Power + 2 Idlers (*)

SAR 5 770-2300 5 7.5

SAR 10 920-2800 10 15

SAR 20 1170-3500 20 30

SAR 40 1400-5200 40 60

SAR 60 1550-4800 60 90

SAR 80 1730-5000 80 120

SAR 100 2010-5500 100 150

SAR 150 2810-6000 150 225

SAR 250 2810-8000 250 375

SAR 500 3110-8000 500 750

(*) Valid only if vessel has no eccentric loads

Workpiece sits only on Two Wheels

Vessel Ø Max Load and Rotation Capacity (MT)

Model

(mm)

1 Power + 1 Idler 1 Power + 2 Idlers (*)

SAR 5 250-760 3.75 5.62

SAR 10 320-910 7.50 11.25

SAR 20 500-1160 15.00 22.50

SAR 40 900-1390 30.00 45.00

SAR 60 750-1540 45.00 67.50

SAR 80 850-1720 60.00 90.00

SAR 100 1000-2000 75.00 112.50

SAR 150 1100-2800 112.50 168.75

SAR 250 1800-2800 187.50 281.25

SAR 500 1800-3100 375.00 562.50

(*) Valid only if vessel has no eccentric loads

500 MT, Irizar Model SAR 500 at work in UAE

Welding Rotator Model SAR 100

Engineered in Canada, Tested at C-FER, Canandian Laboratory

500 MT, Irizar Model SAR 500 500 MT Irizar Model SAR 500 at work in Saudi Arabia

© 2019 Irizar Heavy Industries Inc. All rights reserved

Exceeding International Standards since 1999 8|P a g e

IRIZAR HEAVY INDUSTRIES INC

Head Office: 1512 Adamson View, Edmonton, Alberta T6W 0V4, Canada

Factory: 464014 RR 235, County of Wetaskiwin, AB, T0C 1Z0, Canada

Phone: 1 780 450 6695, Fax: 1 780 485 6677

Email: jirizar@jirizar.com Website: www.jirizar.com

Photos/Video

Chain Welding Rotator, CWR Series

Application: For light gage vessels or fiberglass tanks

Design for vessel to sit on chain rollers; never touches the rotator’s wheels

Standard Package: 1. One Power Roll with Control Box and Remote-Control

Box with 12 m cable. Control: Forward/Stop/Reverse/Variable speed adjustment

with digital display in mm/min, 2. One Idler Roll, 3. Operation Manual, 4. Electric

Diagram, 5. One year Warranty

Optional: Foot Pedal. Control: Forward/Stop/Reverse

At Work in Las Vegas, Nevada & Salt Lake City, USA

Rotation Load Vessel Wheel Dimensions

Speed Power (mm) L*W*H (mm) Weight

Model Capacity Capacity Diameter

(mm/min) (kW) (MT)

(MT) (MT) (mm) Diameter Width Power Roll Idler Roll

CWR-20 20 20 100-1000 2 @ 1.50 2000 – 5000 420 240 3450*1030*658 3450*600*658 3.50

Features: Notes:

a. Power Rotator with main control box and remote-control box with 12 1. Features: Vessel sits on a chain covered with heavy duty rubber.

m cable. Rotation Capacity: 20 MT. Load Capacity: 10 MT. Variable Work piece never touches the rotator’s wheels to avoid

speed: From 100 up to 1,000 mm/min indentation, scratches or any other damage due to its thin wall.

b. Idler Rotator: Load Capacity: 10 MT Adjust middle wheel for reach diameter vessel required.

c. Idler Bogies on both, power and idler rotators

Center to center distance between wheels: 2,350 mm 2. Fit Up Process: First shell sits on one power and one idler;

d. Protection class IP54 against dust and heavy rain on electric control Second shell sits on two idlers. Since Rotators have idler bogies

box and motors the vessel mounted on rollers can move along a rail.

Custom Built Rotator

Anti-Drift Turning Rolls

Bed Rollers

Concrete Drum Welding Positioner

Cone Rotators

Fit Up Rolls

1B

Beam Rotator Dodecagon Power Pole Rotator

I Beam Rotators

Large Diameter Rotators

Lifting Scissor Rollers

Pipe Rotator PR-1

2B

Power Pole Rotators

3B

Rotators with Bogies

Rotators with Screw Device Adjustment

Shot Blasting & Painting Rotators

Turbine Rotator

Welding Rotator Model WR 100 with Bogies Concrete Drum Positioner

At work in Calgary, AB, Canada

Double Rubber Wheel Self Aligned SAR 40

Use when large friction is required: For

example, construction of Wind Turbine

Blades

Certificates

CE Mark Bed Rolles

WR 1200 Certificate

© 2019 Irizar Heavy Industries Inc. All rights reserved

Exceeding International Standards since 1999 9|P a g e

IRIZAR HEAVY INDUSTRIES INC

Head Office: 1512 Adamson View, Edmonton, Alberta T6W 0V4, Canada

Factory: 464014 RR 235, County of Wetaskiwin, AB, T0C 1Z0, Canada

Phone: 1 780 450 6695, Fax: 1 780 485 6677

Email: jirizar@jirizar.com Website: www.jirizar.com

Fit Up Rolls Growing Line

Fit Up Rotator:

• Max Load Capacity: 600 MT @ 2 units = 1,200 MT

APPLICATION: Designed for assemble shell-shell or section- • Diameter Range: From 2 to 12 m

section. Ideal for construction of Monopiles and Transition Pieces • Hydraulic lifting cylinder of 300 MT @ 2 units = 600 MT

which serve as foundation piles for Offshore Wind Turbines. The • Hydraulic fit up cylinder of 200 MT @ 2 units = 400 MT

growing line can also be used for the construction of large and • Rotation speed: NA (No apply)

heavy vessels up to: 1,750 MT weight, from 2 to 12 m diameter, • Bogie speed: From 1 to 10 m/minute

and 120 m length. Available custom-built production lines for

lighter applications.

INSPECTION & REPAIRS

MONOPILE

Composed of Irizar Welding Rotator Model WR 1200

(Two Powers Rotators + Two Idlers Rotators)

Power Rotator:

• Max Rotation Capacity: 1200 MT@ 2 units = 2,400 MT

• Max Load Capacity: 600 MT @ 2 units = 1,200 MT

• Diameter Range: From 2 to 12 m

• Rotation speed: From 0.4 to 4 m/minute

• Bogie speed: From 1 to 10 m/minute

Idler Rotator:

• Max Load Capacity: 600 MT @ 2 units = 1,200 MT

Wind Power Offshore Magazine

• Diameter Range: From 2 to 12 m

GROWING LINE • Rotation speed: NA (No apply)

• Bogie speed: NA

Composed of Irizar Welding Rotator Model WR 1200 (Two • One Idler rotator with standard size

Power Rotators + Two Idler Rotators + Two Fit-Up Rotators) • One Idler rotator with bolted bench

Power Rotator:

BLASTING & PAINTING

• Max Rotation Capacity: 1200 MT @ 2 units = 2,400 MT

Same as above with:

• Max Load Capacity: 600 MT @ 2 units = 1,200 MT

• Diameter Range: From 2 to 12 m • Explosion proof on motors, main control box & remote-

• Hydraulic lifting cylinder: 600 MT control

• Rotation speed: From 0.4 to 4 m/minute • Enclose sealed cabin for motor protection

• Bogie speed: From 1 to 10 m/minute

• Speed wireless control (forward/stop/reverse) for both rotation and

bogie Features: Variable speed adjustment; reach up to 65 m and

digital display in m/minute

Idler Rotator:

• Max Load Capacity: 600 MT @ 2 units = 1,200 MT

• Diameter Range: From 2 to 12 m

• Hydraulic lifting cylinder: 600 MT

• Rotation speed: NA (No apply)

• Bogie speed: From 1 to 10 m/minute

• Speed wireless control: Same as above

Offshore Wind Tower Farm

© 2019 Irizar Heavy Industries Inc. All rights reserved

Exceeding International Standards since 1999 10 | P a g e

IRIZAR HEAVY INDUSTRIES INC

Head Office: 1512 Adamson View, Edmonton, Alberta T6W 0V4, Canada

Factory: 464014 RR 235, County of Wetaskiwin, AB, T0C 1Z0, Canada

Phone: 1 780 450 6695, Fax: 1 780 485 6677

Email: jirizar@jirizar.com Website: www.jirizar.com

Pipe Rotator,Series

Pipe Rotator Model PR 1

Wheel Diameter: 200 mm

Load and Rotation Capacity: 1 MT

Wheel Width: 30 mm

Pipe Diameter: From 20 up to 1,000 mm

Foot Control: Included

Linear Speed: From 80-2,400 mm/minute

Power (L*W*H): 300*250*370 mm

Input Power: 110 V, 50/60 Hz, 1 P

Idler (L*W*H): 500*200*370 mm

Power: 0.18 kW

1 MT, Irizar Pipe Rotator Model PR 1 Weight: 65 kilos

Torque: 1000 Nm

PR Series Pipe Rotator PR Series, also known as Pipe Spool Rotator. It is used for pipe spool

fabrication with long pipes with high eccentric loads. It has an assisting pressure column for

pipe clamping.

Technical Information: a) Manual screw adjustment device to modify center to center wheel

distance in both power and idler rolls, b) Column turning: ± 90° (manual), c) Working height

(floor to roll wheels): Approx. 650 mm

Standard Package: 1. One Power Roll with assisting pressure column. Remote Control Box

with 12 m cable. Control: Forward/Stop/Reverse/Variable speed adjustment with digital display

in mm/minute, 2. One Idler Roll, 3. Operation Manual, 4. Electric Diagram, and 5. One year

Warranty

Optional: a) Foot Pedal: Forward/Stop/Reverse, b) Wireless Remote Control: Up to 60 m reach.

Control: Forward/Stop/Reverse/Variable speed adjustment with digital display in mm/min

Photos/Video

Load & Column

Rotation Dimensions

Rotation Pipe Diameter Assisting Lifting Power Weight

Model Speed L*W*H

Capacity (mm) Pressure Speed (kW) (MT)

(mm/min) (mm)

(MT) (kg) (mm/min)

PR-5 5 100-1000 50-600 ≤ 450 145 1500*1200*1800 0.75 1.30

PR-5L 5 70-1700 100-1200 ≤ 450 145 1500*1200*2300 0.75 1.50

PR-10 10 70-1700 50-600 ≤ 450 145 1700*1300*1800 1.10 2.50

PR-10L 10 70-1700 100-1200 ≤ 450 145 1700*1300*2300 1.10 2.70

PR-25 25 70-1700 100-1500 ≤ 450 500 1900*1500*3000 3.00 3.00

PP Series Pipe Rotator PP Series is used for pipe spool fabrication with short pipes with high eccentric

loads. It has a tilt angle of ± 45º, and an assisting pressure column for pipe clamping.

Technical Information: a) Manual adjustment for modifying center to center wheel distance, b)

Dimensions and weight subject to change without notice.

Standard Package: 1. Power Roll with Remote Control Box with 12 m cable. Control:

Forward/Stop/Reverse/Variable speed adjustment with digital display in mm/minute, 2.

Operation Manual, 3. Electric Diagram, 4. One year Warranty

Optional: a) Foot Pedal. Control: Forward/Stop/Reverse, b) Idler support with adjustable height

mounted over manual bogies, c) Wireless Remote Control: Up to 60 m reach. Control:

Forward/Stop/Reverse/Variable speed adjustment digital display in mm/min

Photos/Video

Load & Column

Rotation Pipe Dimensions

Rotation Tilt Power Weight

Model Speed Diameter Assisting Lifting Speed L*W*H

Capacity Angle (kW) (MT)

(mm/min) (mm) Pressure (kg) (mm/min) (mm)

(MT)

PP-1 1 70-1700 ± 45º 50-426 ≤ 450 300 1200*800*1800 0.75 1.00

PP-2 2 70-1700 ± 45º 50-630 ≤ 450 300 1200*800*1800 1.10 1.40

PP-3 3 70-1700 ± 45º 50-800 ≤ 450 300 1300*800*1800 1.10 1.50

© 2019 Irizar Heavy Industries Inc. All rights reserved

Exceeding International Standards since 1999 11 | P a g e

IRIZAR HEAVY INDUSTRIES INC

Head Office: 1512 Adamson View, Edmonton, Alberta T6W 0V4, Canada

Factory: 464014 RR 235, County of Wetaskiwin, AB, T0C 1Z0, Canada

Phone: 1 780 450 6695, Fax: 1 780 485 6677

Email: jirizar@jirizar.com Website: www.jirizar.com

Welding Positioners, WP Series

WP Series, Fixed height Irizar Model WP 5 AH-WP Series, Adjustable height 100 MT @ 1,200 mm GC, Irizar Model WP 100

Max Gravity Center

Power Table Torque

Max Eccentricity

Max Work Piece

Dia. @ 90° Tilt

Tilt Angle (°)

(kW) (Nm)

rotation ç (mm)

Speed (RPM)

Load Dimensions

(mm)

(mm)

(mm)

Weight

Diameter

Surface

Model Cap L*W*H

(mm)

Rotation

Rotation

Rotation

(MT)

(MT) (mm)

Tilt

Tilt

Tilt

WP 0.3 0.30 0.37 N/A 200 150 0.10~1.0 N/A 150 600 800 1286 N/A 0-90° 930*660*720 0.3

WP 0.6 0.60 0.75 0.75 200 150 0.10~1.0 1.09 210 1000 1500 2600 2676 0-90° 1200*900*850 0.7

WP 1 1 1.10 1.50 250 200 0.05~0.5 0.80 240 1200 2000 8345 7257 0-120° 1400*1200*1200 1.0

WP 3 3 1.50 2.20 300 200 0.05~0.5 0.23 250 1400 2100 8519 37617 0-120° 2100*1500*1350 2.5

WP 5 5 2.20 3.00 300 200 0.05~0.5 0.16 280 1500 2500 14913 71119 0-120° 2200*1500*1450 3.7

WP 10 10 3.00 5.50 400 200 0.05~0.2 0.24 280 2000 3200 71720 91029 0-120° 2700*2000*1850 5.8

WP 20 20 4.00 7.50 450 200 0.05~0.5 0.10 290 2300 3200 90000 315000 0-135° 3300*2230*2000 11

WP 30 30 7.50 11.0 500 200 0.05~0.5 0.10 290 3000 3400 120000 420000 0-135° 3675*3000*2750 18

WP 40 40 11.0 11.0 500 200 0.05~0.5 0.10 300 3500 3400 142000 500000 0-135° 4000*3000*3300 22

WP 50 50 11.0 15.0 500 200 0.05~0.5 0.10 300 3500 4200 163000 550000 0-135° 4525*3500*4100 27

Standard Package: 1. Welding Positioner with

Features: Control Box and Remote Control Box with 12 m

cable, 2. Operation Manual with Electric Diagram, 3.

3D Model 3D Model One year Warranty

Photos Video

WP 0.6 - WP 1 WP 3 - WP 10

Optional:

a. Designed and Engineered in Canada

b. Main Control Box controls tilt rotation (*): Forward/Stop/Reverse a. Foot Pedal. Control table rotation:

c. Remote Control Box with 12 m cable. Control: Forward/Stop/ Reverse/Variable Forward/Stop/Reverse

speed adjustment on table rotation. Digital display in mm/min is included b. Tilt variable speed

d. Tilt break through gear reducer motor or motor with electric break c. Wireless remote control: With 60 m reach and

e. “T” shaped channels on table surface 128 channels. Control table rotation:

f. Octagonal Tables of WP 30 and larger. Octagon size has an inscribed Forward/Stop/Reverse/

circumference of 2.3 m Ø. Variable speed adjustment with digital display

g. Quality: 1. Gearbox’s shells made of cast iron ASTM-A48-A48M or equivalent; d. Table extension arms for reach larger work

2. Open gears made of Q235 steel or equivalent; 3. Shafts made of ANSI 1045 or pieces on WP 30 and larger. Max work piece

equivalent; 4. Motors and control box with IP 54 protection against dust and diameter in red color table above

heavy rain; 5. Frequency driver made by TECO Westinghouse; 6. Shot blasted: e. Synchronized Device: Synchronize rotation

Ensure the paint holds longer speed of two WP. Increase rotation capacity

h. Safety: WP 20 and larger adopt double motor and double gear on tilt 100% when both positioners are placed one in

front of other and work piece is loaded on tables

(*) Variable speed on tilt: Optional at 90° (vertical position)

f. CE mark

Max

Work Piece Gravity Center (mm)* vs Load Capacity (kg or MT) **

Model Eccentricity Notes:

(mm) 200 250 300 350 400 450 500 600 700 800 900 1000 1200 1400 1600 1800 (mm)

WP 0.3 Kgs 300 240 200 171 150 133 120 100 150 (*) The maximum

WP 0.6 Kgs 600 480 400 342 300 266 240 200 150 gravity center measured

WP 1 Kgs 1000 833 714 625 555 500 416 357 312 277 200

from the table surface

WP 3 Kgs 3000 2571 2250 2000 1800 1500 1285 1125 1000 200

WP 5 Kgs 5000 4285 3750 3333 3000 2500 2142 1870 1666 200

WP 10 MT 10 8.8 8 6.6 5.7 5 4.4 4 3.3 2.8 2.5 2.2 200 (**) The maximum load

WP 20 MT 20 17.1 15 13.3 12 10 8.5 7.5 6.6 200 capacity when the

WP 30 MT 30 25.7 22.5 20 18 15 12.8 11.2 10 200 positioner’s table is at

WP 40 MT 40 35 31.1 28 23.3 20 17.5 15.5 200 90° tilt

WP 50 MT 50 44.4 40 33.3 28.5 25 22.2 200

© 2019 Irizar Heavy Industries Inc. All rights reserved

Exceeding International Standards since 1999 12 | P a g e

IRIZAR HEAVY INDUSTRIES INC

Head Office: 1512 Adamson View, Edmonton, Alberta T6W 0V4, Canada

Factory: 464014 RR 235, County of Wetaskiwin, AB, T0C 1Z0, Canada

Phone: 1 780 450 6695, Fax: 1 780 485 6677

Email: jirizar@jirizar.com Website: www.jirizar.com

Notes:

1. Custom-built Welding Positioners available

2. Rental: Available in Canada and USA

3. Concrete Drum Positioner

4. The information contained in this brochure is intended to be accurate.

However, the manufacturer reserves the right to make changes in

design which may not be included

1 MT (2,200 #) @ 250 mm GC, Irizar Model WP 1

0.6 MT (1,320 #) @ 200 mm GC, Irizar Model WP 0.6 5 MT (11,000 #) @ 300 mm GC, Irizar Model WP 5

20 MT (44,000 #) @ 600 mm GC, Irizar Model WP 20

0 MT (22,000 #) @ 400 mm GC, Irizar Model WP 10

At Work in Edmonton, AB, Canada Shipped to Topeka, Kansas USA & Tatsumo, Japan

40 MT @ 1,200 mm GC, Irizar Model CWP 40 88,000 # @ 47.25” GC, Irizar Model CWP 40

At work Portland, Oregon, USA At work Portland, Oregon, USA

© 2019 Irizar Heavy Industries Inc. All rights reserved

Exceeding International Standards since 1999 13 | P a g e

IRIZAR HEAVY INDUSTRIES INC

Head Office: 1512 Adamson View, Edmonton, Alberta T6W 0V4, Canada

Factory: 464014 RR 235, County of Wetaskiwin, AB, T0C 1Z0, Canada

Phone: 1 780 450 6695, Fax: 1 780 485 6677

Email: jirizar@jirizar.com Website: www.jirizar.com

Welding Positioners, CWP Series

60 MT @ 1,800 mm GC, Irizar Model CWP 60 132,000 # @ 70.86” GC, Irizar Model CWP 60 60 MT @ 1,800 mm GC, Irizar Model CWP 60

Table

Power Torque

Max Gravity Center

Max Eccentricity

Max Work Piece

Dia. @ 90° Tilt

(kW) (N-m)

Tilt Angle (°)

Speed (RPM)

Table Surface to

rotation ç (mm)

Load Dimensions

(mm)

(mm)

(mm)

Weight

Model Cap L*W*H

(MT)

Rotation

Rotation

Rotation

(MT) (mm)

Tilt

Tilt

Tilt

CWP 30 30 11 2*5.5 1200 400 200 4000 120000 420000 0-90° 6370*2800*2300 33

CWP 40 40 11 2*7.5 1200 400 200 4000 142000 500000 0-90° 6370*2800*2300 34

CWP 50 50 15 2*7.5 1200 400 350 4000 163000 550000 0-90° 6370*2800*2300 35

0.02 ~ 0.2

0.01 ~ 0.1

CWP 60 60 18.50 2*11 1800 300 400 5500 195000 670000 0-90° 8100*4000*3100 65

CWP 70 70 22 2*11 1800 300 450 5500 250000 950000 0-90° 8100*4000*3100 67

CWP 80 80 22 2*15 1800 300 500 5500 335000 1460000 0-90° 8100*4000*3100 68

CWP 90 90 2*15 2*18.5 2000 300 500 6000 425000 1700000 0-90° 9300*4300*3500 72

CWP 100 100 2*15 2*18.5 2000 300 550 6000 470000 1900000 0-90° 9300*4300*3500 75

Features: Standard Package:

3D Model Photos/Video

a. Designed in Canada 1. Welding Positioner with Control Box and

b. Control Box with emergency stop Remote-Control Box with 24 m cable

c. Remote Control Box with 24 m cable. Control: Forward/Stop/Reverse/Variable speed 2. Operation Manual with Electric Diagram

adjustment on table rotation and tilt. Digital display in RPM 3. One year Warranty

d. Rotation variable speed from 0.02 to 0.20 RPM

e. Tilt variable speed from 0.01 to 0.10 RPM

f. Self lock worm gear boxes with electric brake to prevent table tilt when motor stop

g. Octagon table within an inscribed circumference from 2.20 up to 3.00 m Ø.

Include “T” shaped channels at 45° on table surface

h. Quality:

✓ Gearbox’s shells made of cast iron ASTM-A48-A48M or equivalent

✓ Open gears made of Q235 steel or equivalent

✓ Shafts made of ANSI-1045 or equivalent

✓ Motors and control box with IP 54 protection against dust and heavy rain Optional:

✓ Frequency driver made by TECO Westinghouse

✓ Shot blasted to ensure the paint holds longer a. Table extension arms to reach larger work

pieces. Arm’s length: work piece OD + 0.70 m

i. Safety tilt device composed of a gas cylinder support on gear to prevent table tilt in case a b. Tilt angle from 0° to 135° forward

gear box brake c. CE mark

Max

Work Piece Gravity Center (mm)* vs. Load Capacity (MT)**

Model Eccentricity

Notes:

(mm) 1200 1400 1600 1800 2000 2200 2400 2600 2800 3000 (mm)

CWP 30 MT 30.0 25.7 22.5 20,0 18.0 16.3 15.0 13.8 12.8 12.0 400 (*) Maximum gravity center measured from the

CWP 40 MT 40.0 34.2 30.0 26.6 24.0 21.8 20.0 18.4 17.1 16.0 400

table surface

CWP 50 MT 50.0 42.8 37.5 33.3 30.0 27.2 25.0 23.0 21.4 20.0 400

CWP 60 MT 60.0 54.0 49.0 45.0 41.5 38.5 36.0 300

CWP 70 MT 70.0 63.0 57.2 52.5 48.4 45.0 42.0 300 (**) Maximum load capacity when the

CWP 80 MT 80.0 72.0 65.4 60.0 55.3 51.4 48.0 300 positioner’s table is at 90 tilt

CWP 90 MT 90.0 81.8 75.0 69.2 64.2 60.0 300

CWP 100 MT 100.0 91.0 83.3 76.9 71.4 66.6 300

© 2019 Irizar Heavy Industries Inc. All rights reserved

Exceeding International Standards since 1999 14 | P a g e

IRIZAR HEAVY INDUSTRIES INC

Head Office: 1512 Adamson View, Edmonton, Alberta T6W 0V4, Canada

Factory: 464014 RR 235, County of Wetaskiwin, AB, T0C 1Z0, Canada

Phone: 1 780 450 6695, Fax: 1 780 485 6677

Email: jirizar@jirizar.com Website: www.jirizar.com

Welding Positioner, PL Series

Load Table Height Rotation Elevation Max Max

Power Weight

Model Cap. Diameter Adjustment Speed Speed GC Eccentricity

(kW) (MT)

(MT) (mm) (mm) (RPM) (m/min) (mm) (mm)

PL 1.0 1.00 900 800~1,900 0.15~1.50 1.00 300 200 3.50 1.50

PL 2.5 2.50 900 800~1,900 0.15~1.50 1.00 300 200 4.00 2.50

PL 5.0 5.00 1,200 800~1,900 0.02~0.20 0.45 300 200 8.00 3.50

PL 7.5 7.50 1,800 820~2,300 0.02~0.20 0.45 300 200 12.00 4.50

PL 10.0 10.0 1,800 820~2,300 0.02~0.20 0.45 300 200 18.50 5.50

Photos Head & Tail Stock, HT Series

Load Table Rotation Rotation Elevation Max

Torque Power Weight

Model Cap. Diameter Center Speed Speed Eccentricity

(Nm) (kW) (MT)

(MT) (mm) (mm) (RPM) (m/min) (mm)

HT 1 1.0 800 800~1,500 0.15~1.50 1.0 200 2100 0.75 1.50

HT 3 3.0 800 800~1,500 0.15~1.50 1.0 150 6400 1.50 3.20

HT 5 5.0 800 800~1,500 0.15~1.50 0.6 150 9000 1.50 5.10

HT 10 10 1000 800~1,500 0.10~1.00 0.6 100 13500 2.20 10.0

HT 15 15 1000 800~1,500 0.10~1.00 0.6 100 18000 3.00 13.0

HT 25 25 1000 800~1,500 0.08~0.80 0.6 100 35000 3.50 14.0

HT 50 50 1500 1,000~2,000 0.04~0.40 0.6 100 60000 4.00 23.0

HT 75 75 1500 1,000~2,000 0.02~0.20 0.5 100 90000 4.75 24.5

HT 100 100 1500 1,000~2,000 0.02~0.20 0.5 100 120000 5.50 26.0

Photos-Video Turntables, TT Series

Load Table Rotation Max Dimensions

Torque Power Weight

Model Cap. Diameter Speed Eccentricity L*W*H

(Nm) (kW) (MT)

(MT) (mm) (RPM) (mm) (mm)

TT 0.5 0.5 800 0.10~1.00 200 800*800*400 80 0.18 0.90

TT 1 1 1000 0.10~1.00 200 1000*1000*500 100 0.25 1.00

TT 3 3 1500 0.05~0.50 200 1500*1500*600 400 0.55 1.10

TT 5 5 1500 0.05~0.50 200 1500*1500*650 600 0.75 1.30

TT 10 10 1800 0.05~0.50 200 1800*1800*650 1200 1.10 1.50

TT 20 20 2000 0.02~0.20 200 2000*2000*750 2400 1.50 2.50

TT 50 50 2500 0.015~0.15 200 2500*2500*750 6000 2.20 4.50

TT 75 75 2800 0.015~0.15 200 2600*2600*850 9000 3.00 6.00

TT 100 100 2800 0.010~0.10 200 2800*2800*1000 12000 4.00 7.80

Features:

Standard Package: a) Welding Positioner PL or Head & Tail Stock

a. Designed and Engineered in Canada

or Turntable, b) Control Box and Remote Control Box, c) Operation

b. Head & Tail Stock with adjustable rotation center Configuration: 1) Head

Manual with Electric Diagram, d) One year Warranty

Stock fixed to the floor; 2) Tail Stock mounted over idler bogies for adjust

work piece length

Optional: a) Foot control pedal. Control: Forward/Stop/Reverse, b)

c. Remote Control Box with 12 m cable length:

Extension arms on Turntable for increase table diameter, c) CE mark

On Welding Positioner Model PL. Includes: Variable speed on table

rotation: Forward / Stop / Reverse; Digital display in RPM; and, tilt speed

control, and height adjustment: Up / Down

On Head Stock Model HT. Includes: Variable speed on table rotation:

Forward / Stop / Reverse; Digital display in RPM; and, adjustable center

rotation height: Up / Down

On Turntable Model TT: Variable speed on table rotation: Forward / Stop /

Reverse; Digital display in RPM

d. Quality: a) Gearbox’s shells made of cast iron ASTM-A48-A48M or

equivalent, b) Shafts made of ANSI 1045 or equivalent, c) Motors and HT 25

control box with IP 54 protection against dust and heavy rain, d) Frequency

driver made by TECO Westinghouse, e) Shot blasted: Ensure paint holds

longer Sold to a Chinese Company

e. “T” shaped channels on table surface

© 2019 Irizar Heavy Industries Inc. All rights reserved

Exceeding International Standards since 1999 15 | P a g e

IRIZAR HEAVY INDUSTRIES INC

Head Office: 1512 Adamson View, Edmonton, Alberta T6W 0V4, Canada

Factory: 464014 RR 235, County of Wetaskiwin, AB, T0C 1Z0, Canada

Phone: 1 780 450 6695, Fax: 1 780 485 6677

Email: jirizar@jirizar.com Website: www.jirizar.com

Welding Manipulators, WM Series

Manufacture Welding Manipulators, also known as: Welding Booms and Welding Columns

IRIZAR 3D Model WM 4040 & SAR 40

Boom Column Trolley or SS (Self Stand)

(B) Horizontal expansion (m)

Max load at boom extremity

(A)

Up–Down speed (m/min)

Estimated Packing Dim.

Colum-Boom (L*W*H)

Vertical

Rotation Angle ± 180º

In–Out speed (m/min)

Model Expansion

Dimensions D*E*H

(F) Rail ç to ç (mm)

Traveling Precision

Estimated Packing

(Kilos @ 12” GC)

(m)

WM YYXX

speed (m/min)

(C) height (m)

Weight (MT)

Power (kW)

Speed (%)

Net Min-Max

(m)

(m)

SS WM 1530 1.5 0.53~2.03 3.0 1.00 200 manual 3.20 N/A N/A N/A 2.75 3.50*1.40*0.60 2.00

WM 3030 3.0 0.75~3.75 3.0 1.00 200 motorized 5.50 2.40*1.90*0.5 1600 1.50 2.75 5.50*1.40*0.70 3.00

0.12 to 1.20

WM 4040 4.0 0.75~4.75 4.0 1.00 200 motorized 6.50 2.40*1.90*0.5 1600 1.50 2.75 6.50*1.50*0.80 4.00

± 2%

WM 5050 5.0 1.10~6.10 5.0 0.90 300 motorized 7.80 2.40*2.10*0.5 1798 1.50 3.35 7.80*1.60*0.90 5.00

WM 6060 6.0 1.10~7.10 6.0 0.90 300 motorized 9.00 2.40*2.10*0.5 1798 1.50 3.35 9.80*1.70*1.0 6.50

SS WM 7060 7.0 1.20~8.20 6.0 0.90 300 motorized 10.00 3.20*2.40*0.5 2200 1.50 4.25 10.80*1.70*1.1 11.00

SS WM 8060 8.0 1.20~9.20 6.0 0.90 300 motorized 11.00 3.20*2.40*0.5 2200 1.50 4.25 11.80*1.70*1.2 13.00

Standard Package: 1) Welding Manipulator mounted on motorized trolley; 2) k. Quality:

Control Box & Remote-Control Box, 3) Operation Manual with Electrical ✓ Gearbox’s shells made of cast iron ASTM-A48-A48M or equivalent

Diagram. 4) One year Warranty ✓ Open gears made of Q235 steel or equivalent

✓ Shafts made of ANSI 1045 or equivalent

Features: ✓ Motors and control box with IP 54 protection against dust and heavy

3D Model Photos Videos

rain

✓ Frequency driver made by TECO Westinghouse

a. Designed and Engineered in Canada ✓ Stress Relieved on Column and Boom

b. Boom expansion speed (in-out): From 0.12 to 1.20 m/min ✓ Shot Blasted to ensure the paint holds longer

c. Boom lifting (up-down) speed: Constant l. Safety

d. Trolley motorized travel speed: 1.5 m/minute • Boom anti-fall safety device on WM 3030 and up

e. Column rotation angle: ± 180º

• Trolley anti-fall safety device

f. Column rotation speed: Approx. 0.30 RPM

• Limit switches in all directions

g. Main Control Box fixed on trolley: Control column rotation:

m. Set up at Job Site: Erection Supervision, On site Commissioning,

Forward/Stop/Reverse.

Operation, and Training

h. Remote Control Box with 12 m cable length. Control: Variable speed

on boom in-out: Forward/Stop/Reverse. Digital display in mm/min

Welding Manipulator Guide Selection:

Also control boom lifting: Up/Stop/Down

i. Boom Features:

1. Determine the largest tank diameter to be fabricated

• Standard: For Min 1.50 m ID.

2. Determine the largest longitudinal seam to be welded

• Custom Built: Min 20” ID using WM 3030 3. Select the WM YYXX

• Counter weight system to ensure smooth vertical travel Y = Maximum effective boom vertical expansion (up-down) in m

• Cable organizer: Included X = Maximum effective boom horizontal expansion (in-out) in m

j. Power Source Platforms: Available on Trolley. Max load capacity of 4. Check if column height of the selected WM fits below your overhead

1.5 MT. Platforms can handle: Lincoln Power Waves AC/DC 1000, or crane; otherwise, we can custom built column height

DC-1500/AC-1200, or equivalent

© 2019 Irizar Heavy Industries Inc. All rights reserved

Exceeding International Standards since 1999 16 | P a g e

IRIZAR HEAVY INDUSTRIES INC

Head Office: 1512 Adamson View, Edmonton, Alberta T6W 0V4, Canada

Factory: 464014 RR 235, County of Wetaskiwin, AB, T0C 1Z0, Canada

Phone: 1 780 450 6695, Fax: 1 780 485 6677

Email: jirizar@jirizar.com Website: www.jirizar.com

Boom Configuration for Longitudinal and Circumferential

(SAW) Submerged Arc Welding

3D Model

Optional:

a. Submerged Arc Welding Equipment: Idealarc Lincoln Power

Source DC 1000. Include: NA3S Lincoln Head Controller

(1.1), Wire Reel (1.2), Flux Hopper (1.3), NA3S Lincoln Wire

Feeder (1.4)

b. Cross Slide options:

• Manual Cross Slide for Single Head

Max load capacity: 50 kilos @ 12” GC. Stroke 80 x 80 mm

• Manual Cross Slide for Tandem Head (only by order)

Max load capacity: 100 kilos @ 12” GC. Stroke: 80 x 80

• Motorized Cross Slide for Single Head

Max load capacity: 50 kilos @ 12” GC. Stroke: 80 x 80 mm

Max load capacity: 50 kilos @ 12” GC. Stroke: 200 x 200

c. Seam Tracker Model 100: For SAW Max capacity of 100

kilos @ 14.5” GC. Stroke: 200 mm on X & Z. Accuracy: ±

0.25 mm. Include: Main control (2.1), Left/Right control slide

(2.2), Up/Down control slide (2.3), Finger Probe (2.4), Cables

for standard configuration. Approx. set weight of 32 kilos

d. Flux Recovery Model FRU-80

Flux Delivery (3.1), Flux Recovery (3.2) Irizar Brackets, Wire

reel bracket (4.1), Seam Tracker bracket (4.2), Flux Recovery

& Finger Probe bracket (4.3)

e. Irizar Manual horizontal slide (5.1): 36” stroke

f. Irizar 90° Swivel (5.2). Required in WM which apply both

longitudinal and circumferential seams welding

Note: All components above are sold separately. Assembling

set up to the manipulator’s boom is not included; require some

drilling and tapping.

g. Trolley variable speed: From 0.15 up to 1.50 m/minute

h. Trolley built to apply longitudinal seams welds while the

manipulator is moving. Include: Ultra-fine precision

transmission with variable speed from 0.15 up to 1.50 m/min.

Applicable on long longitudinal seams on shells or I beams

i. Column variable rotation speed: From 0.03 up to 0.30 RPM

j. Wireless Remote Control: With 60 m reach and 128 channels.

Control Boom (in-out): Forward/Stop/Reverse/Variable speed

Irizar Welding Manipulator with SAW Lincoln Welding Head and Controller; Wire

Reel, Seam Tracker Model 100 & Flux Recovery Model FRU-80. Minimum ID 25” adjustment

(63.5 mm) with boom efective horizontal stroke from 3 up to 6 m (10’ up to 20’) k. CE Mark

IRIZAR 3D Model WM 4040 & WR 40

Custom Built:

a. Self Stand Welding Manipulators (Fixed base): SS WM

b. WM 4040 for welding Steel Box Columns

c. For TIG applications: 1. WM with linear drive. 2. welding

rotator with servomotors, 3. Arc Length Controller

d. Welding Gantry

Notes:

The information contained in this brochure is intended to be

accurate. However, the manufacturer reserves the right to

make changes in design which may not be included. Latest

revision available online

© 2019 Irizar Heavy Industries Inc. All rights reserved

Exceeding International Standards since 1999 17 | P a g e

IRIZAR HEAVY INDUSTRIES INC

Head Office: 1512 Adamson View, Edmonton, Alberta T6W 0V4, Canada

Factory: 464014 RR 235, County of Wetaskiwin, AB, T0C 1Z0, Canada

Phone: 1 780 450 6695, Fax: 1 780 485 6677

Email: jirizar@jirizar.com Website: www.jirizar.com

Automatic Girth Welder, AGW Series

Girth Welders, also known as: Tank Welder and 3 O’ Clock Welder

The AGW is a self-propelled frame designed to apply efficient horizontal seam welds by means of the Submerged Arc Welding (SAW) Process. The AGW

rides along the upper edge of a large diameter field storage tank while applying inside and/or outside welding. Compared with conventional techniques, the

AGW reduces the construction rate 25 times and cuts welding time by 2.

Model AGW-1 AGW-2 AGW-1- C LNG AGW-1 Motorized Basket

Application TM & TJ TM TM, TJ, LNG Tanks TM TM & TJ (Insp/Repairs)

Type Single Side Double Side Single Side Single Side Single Side

Speed (mm/min) 200 to 2,900 200 to 2,900 200 to 2,900 200 to 2,900 2,900

Plate Height (m) 1.80 to 3.20 1.80 to 3.20 Min 0.80 m (*) 1.80 to 3.20 1.80 to 3.20

Tank Diameter (m) Min 5.0 Min 8.0 Min 3.0 Min 8.0 Min 5.0

Plate Thickness (mm) 8 to 50 8 to 50 6 to 50 8 to 50 8 to 50

Weight Fixture (kgs) 680 1,360 208 580 380

Weight Power Storage & Cables (kgs) 150 + 70 = 220 150 @ 2 + 140 = 440 150 + 180 + 70 = 400 150 + 70 = 220 NA

Total Weight (**) 900 1,800 608 800 380

Fixture Dim. W*D*H (m) 1.55 x 1.20 x 2.80 3.10 x 2.50 x 2.80 1.10 x 0.62 x 1.73 1.55 x 0.85 x 2.80 1.55 x 0.85 x 2.80

Power Source Dim. L*W*H (m) 1.30 x 1.10 x 1.30 1.30 x 1.10 x 1.30 @ 2 1.30 x 1.10 x 1.30 1.30 x 1.10 x 1.30 NA

Input Power (V, Hz, P) 240/60/3 or 380/50/3 240/60/3 or 380/50/3 240/60/3 or 380/50/3 240/60/3 or 380/50/3 240/60/3 or 380/50/3

Power (kW) 0.19 0.19 0.19 0.19 0.19

Notes: TM (Traditional Method), TJ (Tank Jacking), NA (Not apply), (*) Restriction only on first/top shell, (**) Lincoln Power Source weigth not included

3D Model 3D Model AGW-1 3D Model 3D Model Welding Tractor Irizar Magnetic Device

AGW-1 Set up for Lifting Jacks AGW-1- C AGW-2 & Video 3D Model & Video

Features: 1) Designed and Engineered in Canada, 2) Control Box: Forward/Stop/Reverse & Digital display with

variable speed; Flux recovery: On/Off; Four plug in of 110 V, 50/60 HZ, 1 P or 220 V, 50/60 HZ, 1P; and,

Emergency Stop; 3) Quality: a) Motors and control box with IP 54 protection against dust and heavy rain, b)

Frequency Driver made by TECO Westinghouse or Panasonic

Application: a) AGW-1: It is compatible with the Traditional Construction Method (down-top) driving hunged

on the upper edge of the tank. It is also compatible with Tank Jacking Method (top –down) driving at ground

level on a rail outside and around the tank; b) For LNG Double Wall Tank building with Traditional Method use

LNG AGW-1. This unit fits on 1.0 m space between inner & outer tanks. c) Use our AGW-1-C for welding inside

/ outside the tank with Tank Jacking or with LNG Tanks. This unit fits on 850 mm space; this unit drives on a flat

bar of ½”thickness x 4” (W) hanged on brakets supports.

Note: Welding Procedure Specifications (WPS), Procedure Qualifications Records (PQR) and Welder

Qualification Test (WQT) must be prepared and qualified in accordance with the applicable Codes and Standards

and Project Specifications; and, remain full responsibility of the buyer.

AGW-1 AGW-2 AGW-1-C

Item Standard Package Composed Single Double Single Side

Side Side Compact

Lincoln Electric Power Source FlexTec 650 X or DC-1000. Including

1.

Lincoln NA3S Welding Head Controller, Lincoln NA3S Wire Feeder, 1 set 2 sets 1 set

Lincoln Wire Reel, brackets & cables.

2. Heavy duty motorized carriage 1 unit 1 unit 1 unit

Control Box: Forward/Stop/Reverse/Speed Adjustment with display in

3. 1 unit 1 unit 1 unit

mm/min. Four plugs in of 110 V, 50/60 HZ, 1 P or 220 V, 50/60 HZ, 1P

Flux recovery & delivery system; flux belt assembly included. Flux

4. 1 set 2 sets 1 set

capacity: 25 kg on AGW-1/AGW-2; and, 20 kg on AGW-1-C

5. Manual welding head cross slide: 50 kg @ 12” GC. Stoke: 6”x 6” 1 unit 2 units 1 unit

6. Operator seat with tool box 1 unit 2 units N/A

7. TECO Westinghouse frequency driver 1 unit 1 unit 1 unit

8. Power source storage steel box 1 unit 2 units 1 unit

Welding cable 120 mm²: 1 wire of 60 m length

9. Power cable 2.5 mm²: 4 wire of 60 m length 1 set 2 sets 1 set Irizar Magnetic Device (optional):

Control cable 1.5 mm²: 10 wires of 60 m length Apply horizontal IF Submerged Arc

10. Electric control panel 1 unit 1 unit 1 unit Welding (SAW) fillets, outside/inside

11. Operation Manual & Electric Diagram 1 set 1 set 1 set the Annular Plate to the Tank Bottom,

by means of a Lincoln LT-7 Tractor

12. Warranty 1 year 1 year 1 year

© 2019 Irizar Heavy Industries Inc. All rights reserved

Exceeding International Standards since 1999 18 | P a g e

IRIZAR HEAVY INDUSTRIES INC

Head Office: 1512 Adamson View, Edmonton, Alberta T6W 0V4, Canada

Factory: 464014 RR 235, County of Wetaskiwin, AB, T0C 1Z0, Canada

Phone: 1 780 450 6695, Fax: 1 780 485 6677

Email: jirizar@jirizar.com Website: www.jirizar.com

AGW-1 (Traditional Method) AGW-2 (Traditional Method) AGW-1 (Compatible with Lifting Jacks)

Circumferential Welding for Outside the Tank Circumferential Seam Inside/Outside simultaneously Circumferential Welding for Outside the Tank

AGW-1-C (Compact)

AGW-1 (Compatible with Lifting Jacks) AGW-2 (Traditional Method)

AGW-1 (Traditional Method) Running outside on rail at floor level Electric Winch is not included

Driving hung on the upper edge

Electric Winch is not included

© 2019 Irizar Heavy Industries Inc. All rights reserved

Exceeding International Standards since 1999 19 | P a g e

IRIZAR HEAVY INDUSTRIES INC

Head Office: 1512 Adamson View, Edmonton, Alberta T6W 0V4, Canada

Factory: 464014 RR 235, County of Wetaskiwin, AB, T0C 1Z0, Canada

Phone: 1 780 450 6695, Fax: 1 780 485 6677

Email: jirizar@jirizar.com Website: www.jirizar.com

Linear Oscillator Welding Tractor Irizar Magnetic Device

Linear Oscillator Welding Tractor: Apply Vertical-Up & Circumferential

Irizar Magnetic Device: Useful to apply inside & outside Submerged Arc

MIG/MAG Seam Welds.

Welding (SAW) fillets on Annular Plate vs Tank Bottom; specially, when

the annular plate is not wide enough, and one of the two rear wheels of the

Specifications:

Lincoln LT-7 Tractor is floating.

✓ On/Off Switch

Included: Irizar Device (only)

✓ Quick Clamping Torch Holder for MIG/MAG welding gun

✓ Forward/Reverse Travel Switch

Not included: Lincoln LT-7 Tractor, Lincoln Power Source, cables, etc.

✓ Interface Welding Machine Switch

✓ Variable Speed Knob: From 100 to 1040 mm/minute (4 - 41 IPM)

Specifications:

✓ Oscillation Weaving Knob: From 0 - 2 seconds

✓ Oscillation Stroke Knob (crown width): 0 - 34 mm (± 17)

✓ Minimum OD Tank: 5 m (16.4’)

✓ Oscillation Left Time Knob: 0 – 2 seconds

✓ Minimum Outside Annular Plate: 50.8 mm (2”)

✓ Oscillation Right Time Knob: 0 – 2 seconds

✓ Magnetic Device can roll over a crown of 3 mm (1/8”) maximum

✓ Origin Location Knob (Left, Zero, Right)

✓ Packing (m): 0.60 (L) x 0.40 (W) x 0.28 (H) @ 17 kg

✓ Oscillation Pattern Selection Knob: Five types

✓ Power Supply: AC 110 V, 50/60 HZ, single

✓ Flexible Rail Track: Two of 1,800 mm length each; plus, twelve magnets 3D Model Video

Video

SAW Lincoln LT-7 Welding Tractor

With Irizar Magnetic Device (red color)

Packing:

Tractor: 500 mm (L) x 400 mm (W) x 250 mm (H) @ 11 kg

Tracks: 2000 mm (L) x 50 mm (W) x 50 mm (H) @ 8 kg

Magnets: 500 mm (L) x 200 mm (W) x 200 mm (H) @ 25 kg

© 2019 Irizar Heavy Industries Inc. All rights reserved

Exceeding International Standards since 1999 20 | P a g e

IRIZAR HEAVY INDUSTRIES INC

Head Office: 1512 Adamson View, Edmonton, Alberta T6W 0V4, Canada

Factory: 464014 RR 235, County of Wetaskiwin, AB, T0C 1Z0, Canada

Phone: 1 780 450 6695, Fax: 1 780 485 6677

Email: jirizar@jirizar.com Website: www.jirizar.com

Tank Jacking, TJ Series

Tank Jacking, also known as: Tank Erection, Hydraulic Tank Jacks, and Tank Lifting Jacks

• Large cranes: No longer required; roof is built over the first

course.

• Scaffolding: Minimized

• Tank shell plates: Fed at floor level

6. Personal work inside the tank under roof cover at a maximum

height of 6.50 m: For tank shell plate assembling, tack welding,

inside circumferential and longitudinal welding, welding

inspections, and repairs.

7. Personal work outside the tank at a maximum height of 3.50 m:

Corpus Christi Texas USA, 40 m OD. SS Tank For outside circumferential and longitudinal welding, welding

inspections, and repairs.

Applications:

Tank Construction Jacks for Welded Tanks:

1. API 650 Welded Tanks for Oil Storage Jack Model Jack Model

Description

2. API 620 Welded Low-Pressure Storage Tanks 12 MT - 3000 25 MT - 3000

3. LNG Double Wall API 620 Tanks

Working capacity (metric tons) 12 25

4. Grain Bin or Corrugated Bolted Tanks

Tested load (metric tons) 18 37.5

5. Smooth Wall Bolted Tanks

Double action jack Yes Yes

Minimum outside tank diameter (m) 3.35 3.35

Tank Repairs & Modifications / Alterations Minimum shell thickness (mm) 3.175 (1/8”) 3.175 (1/8”)

Shell height (mm) Up to 3,000 Up to 3,000

1. Tank Dismantling & Removal Arc-distance between jacks (m) 1.50 - 3.0 1.50 - 3.0

2. Tank Floor & Annular Plate Replacement Jack unitary climb (mm/stroke) 100 100

Lifting time per shell (min) Approx. 30 to 45 30 to 45

3. Tank Bottom Shell Replacement

4. Tank Capacity Expansion

Jack weight (kg) 64 90

Trestle & Stay Pipes weight (kg) 250 410

Industry Segment Used: Oil refineries, petrochemical plants, fertilizer Approx. weight/set (kg) 314 540

plants, power generating stations, petroleum product installations & Packing weight (kg) 40 40

depots, and liquid storage terminals ports.

Notes:

Experience: Irizar lifting jacks have been used for worldwide

construction of over five thousand field erected tanks. Maximum lifting 1. Standard trestle can accommodate up to 3.0 m shell plate. Custom

built trestles can reach up to 4.0 m shell plate

up to 2,650 MT.

2. Tank supports of 0.5 m height can provide personal entrance/exit, air

ventilation flow, power cables and tools access all around the tank.

Standard Package: 1. Jacks with Trestles, 2. Power Pack, 3. Operation

Manual and Electrical Diagram, 4. One year Warranty

Jacks for Bolted Tanks:

Welcome to visit:

(*) Get password access by Grain Bins Smooth Wall Smooth Wall

(*) Video

6B

3D Model requesting to jirizar@jirizar.com

7B

Description Jack Model Jack Model Jack Model

12 MT - 1200 12 MT - 1800 12 MT - 3000

Working capacity (metric tons) 12 12 12

Tested load (metric tons) 18 18 18

Key Features:

Double action jack Yes Yes Yes

Minimum outside tank diameter (m) 5.0 5.0 5.0

1. Designed and Engineered in Canada Minimum shell thickness (mm) 1.75 1.75 1.75

2. Constructing Procedure: Tank erection from top course Shell height (inch) 46” 70” 120”

downwards. Arc-distance between jacks (m) Max 5.0 Max 5.0 Max 5.0

3. Erection Safe: The lifted tank will be hold in place -will not slide Jack unitary climb (mm/stroke) 100 100 100

Lifting time per shell (min) Approx. 12 – 18 18 - 27 30 - 45

down-, even in the case of power pack failure/removal, electrical

power shutdown, or hydraulic hose burst; since the tank is hold

Jack weight (kg) 64 64 64

mechanically. Trestle & Stay Pipes weight (kg) 110 180 250

4. Flexible: The Tank Jacking can be split for erection of smaller Approx. weight/set (kg) 174 244 314

tanks; or expand, by adding extra jacks for erection of larger Packing weight (kg) 40 40 40

tanks.

5. Cost- Effectiveness

© 2019 Irizar Heavy Industries Inc. All rights reserved

Exceeding International Standards since 1999 21 | P a g e

IRIZAR HEAVY INDUSTRIES INC

Head Office: 1512 Adamson View, Edmonton, Alberta T6W 0V4, Canada

Factory: 464014 RR 235, County of Wetaskiwin, AB, T0C 1Z0, Canada

Phone: 1 780 450 6695, Fax: 1 780 485 6677

Email: jirizar@jirizar.com Website: www.jirizar.com

Power Packs Specifications: Irizar Double Action Jacks has been tested at job sites at extreme

temperatures from: Minus 30 up to plus 45 Celsius degrees.

Tank Pump Working

Weight

Description

(Kilos)

Capacity Flow Pressure Quality:

(Liters) (LPM) (PSI)

Power Pack for Jack Model 12 1. Ball Valves: Easy operation (close/open) only with 90-degree turn;

10 HP, Max 34 jacks 350 350 22 1,750 instead, the needle valves require eight full turns.

20 HP, Max 65 jacks 375 350 45 1,750 2. Trestle Box Indentations: Made to match the jack’s grip jaw pitch;

40 HP, Max 115 jacks 575 500 96 1,750

which is the mechanism that holds the tank weight mechanically

80 HP, Max 230 jacks 1,150 1000 192 1,750

3. Grip Jaws: Heat treated with 48 to 50 RC hardness; avoid

Power Pack for Jack Model 25

premature wearing

20 HP, Max 20 jacks 350 350 22 2,400

40 HP, Max 38 jacks 375 350 45 2,400 4. Finishing: Shot blasted at SA 1½ before been prime and painted.

80 HP, Max 65 jacks 575 500 96 2,400 Coating thickness is 150 microns minimum on trestles & stay

pipes; 250 microns minimum on jacks & power packs.

Note: Oil heater is required for power packs working subzero temperatures

Jack’s Test Certificate: We provide a Test Certificate for each

Jack Selection Software

purchase order; include the jack’s serial number.

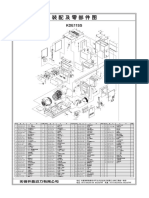

Spare Parts can be ordered by using 3-D Exploded Solid Works

For selection of jack model and the number of jacks per tank, Irizar Drawing available in our Operation Manual. Spare Parts are in stock.

Heavy Industries has developed a sophisticate and unique software Payment can be made by Wire Transfer or Credit Card (Visa, Master or

which assure the lifting jacking system will withstand: tank load, snow American Express). Parts are usually shipped within 24 hours by FedEx.

load, wind load, and seismic load for a specific construction site. The

following factors are considered: 1) Tank Diameter (m), 2) Tank Height Packing: Irizar Products are professionally packaged. It provides

(m), 3) Tank Weight (MT) not including bottom shell, neither base plate. protection during storage, transportation, loading and un-loading.

4) Number of roof column(s) support (if applicable) & roof weight, 5) Packaging also minimizes the floor space required for storage &

Construction site location, 6) Snow Load (MT), 7) 3-Second Gust Wind transport. All packages have lifting lugs and forks access. Steel crates

Speed (Km/h). In accordance with ASCE 7-10 or the National Building for jacks & accessories have pallet jack access.

Code, 8) Seismic Geometric Data from USGS or the National Building

Code. Stock: The Largest World-Wide inventory is available in Canada;

ready for shipping as per buyer input power request

Before lifting a tank obtain written approval from our engineering

department. Our company is not liable for any misuse or accident caused Notes:

by inappropriate selection.

Training: We offer: a) Tutorial Lifting Jacks Set up Video, b) Tutorial

Attributes: Lifting Jacks Operation Video, c) Training in our Alberta Canadian

Facility, and d) Training at Jobsite Worldwide.

Laboratory Tested: Irizar Lifting Jacks has been tested and found

satisfactory at full load capacity plus fifty percent of safety factor by C- Technical Support: Available 24 Hours in WhatsApp

FER Technologies, a well-known Canadian Laboratory. The test

includes: a) Test of the jack along with its structural parts, b) Test of the Delivery Time: a) In North America, Canada & USA: We can deliver

hydraulic lifting system, and c) Test of mechanical load holding system. at buyer’s shop floor at the latest in five business days; b) In South

Test Report is available under request. Large number of job sites request America: Delivery takes four to five weeks at any Container’s Sea Port;

a third-party testing report. c) Word Wide: Delivery takes five to six weeks at the most important

Container’s Sea Ports. Also, we can ship Word-Wide by air cargo.

Plate Fit Up Tools Devices: Shell Vertical Fit Up Video; Shell

Horizontal Fit Up Video; Floor Plate Fit Up Video; Plate Fit Up Tools

Supplier

Welding Equipment:

1. SAW Irizar Tank Welder Model AGW-1-C for inside/outside

circumferential seams

2. SAW Irizar Tank Welder Model AGW-1 for outside circumferential

3. MIG/MAG Irizar Linear Welding Oscillation Tractor for longitudinal

Power Packs come with high-end Motor Starter, Safety Release Valve,

seams

and Electric Diagram. Wireless Control is an optional. It has sixty-

meter reach and control: Motor on/off & oil flow in/out. Advantage: One

operator can lift/lower the tank

© 2019 Irizar Heavy Industries Inc. All rights reserved

Exceeding International Standards since 1999 22 | P a g e

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Israel Standart-4295Document8 pagesIsrael Standart-4295משה אביסדריסNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- A Ultra REX DUO PLUSDocument34 pagesA Ultra REX DUO PLUSמשה אביסדריסNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- סוגי ברגיםDocument4 pagesסוגי ברגיםמשה אביסדריסNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shore Durometer Conversion ChartDocument1 pageShore Durometer Conversion Chartמשה אביסדריסNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Adhesion-in-Peel of Elastomeric Joint Sealants: Standard Test Method ForDocument4 pagesAdhesion-in-Peel of Elastomeric Joint Sealants: Standard Test Method Forמשה אביסדריסNo ratings yet

- Work Breakdown StructureDocument8 pagesWork Breakdown StructurerenshagullNo ratings yet

- Trina 440W Vertex-S+ DatasheetDocument2 pagesTrina 440W Vertex-S+ DatasheetBrad MannNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Bcom (HNRS) Project Final Year University of Calcutta (2018)Document50 pagesBcom (HNRS) Project Final Year University of Calcutta (2018)Balaji100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Department of Education: Template No. 1 Teacher'S Report On The Results of The Regional Mid-Year AssessmentDocument3 pagesDepartment of Education: Template No. 1 Teacher'S Report On The Results of The Regional Mid-Year Assessmentkathrine cadalsoNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Mathmatcs Joint Form TwoDocument11 pagesMathmatcs Joint Form TwoNurudi jumaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Debate ReportDocument15 pagesDebate Reportapi-435309716No ratings yet

- Galgotias University Uttar Pradesh School of Computing Science & Engineering B.Tech. (CSE) 2018-19 Semester Wise Breakup of CoursesDocument2 pagesGalgotias University Uttar Pradesh School of Computing Science & Engineering B.Tech. (CSE) 2018-19 Semester Wise Breakup of CoursesRohit Singh BhatiNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hockney-Falco Thesis: 1 Setup of The 2001 PublicationDocument6 pagesHockney-Falco Thesis: 1 Setup of The 2001 PublicationKurayami ReijiNo ratings yet

- Song Book Inner PagesDocument140 pagesSong Book Inner PagesEliazer PetsonNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- 2Document8 pages2Eduardo Antonio Comaru Gouveia75% (4)