Professional Documents

Culture Documents

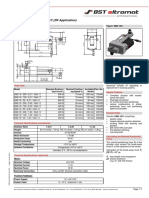

SETEC 624 E 05-2003: - Optional-Cradle Device

Uploaded by

Boudaoud0 ratings0% found this document useful (0 votes)

10 views1 pageThe document describes an automatic fabric spreading machine. It has optional features like a turn table, cradle device, and attachment unit. The standard equipment includes programs for different step and sequential threading. It can store 144 parameters and calculates length and position. The technical details list the table width, maximum roll weight of 80kg, roll diameter of 450mm, speed of 100m/min, and maximum laying height. It has an operation display and electronic software controls.

Original Description:

Original Title

Untitled

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document describes an automatic fabric spreading machine. It has optional features like a turn table, cradle device, and attachment unit. The standard equipment includes programs for different step and sequential threading. It can store 144 parameters and calculates length and position. The technical details list the table width, maximum roll weight of 80kg, roll diameter of 450mm, speed of 100m/min, and maximum laying height. It has an operation display and electronic software controls.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views1 pageSETEC 624 E 05-2003: - Optional-Cradle Device

Uploaded by

BoudaoudThe document describes an automatic fabric spreading machine. It has optional features like a turn table, cradle device, and attachment unit. The standard equipment includes programs for different step and sequential threading. It can store 144 parameters and calculates length and position. The technical details list the table width, maximum roll weight of 80kg, roll diameter of 450mm, speed of 100m/min, and maximum laying height. It has an operation display and electronic software controls.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

SETEC 624 E 05-2003 -optional- Turn table

With a soft finger tip the top carriage including material can be rotated

- optional fully automatic -

SETEC 624 E -optional- Cradle device

The perfect accurate spreading result is achieved by controlled

motors.The angular position of the driving motor and the belt

motor are electronically synchronized.

Variation 1

Variation 2 -optional- Attachment unit

This unit serves your fabric as a receiver. The

fabric can be spread over the roof. Sensors

for the height grope the ply package and

STANDARD EQUIPMENT drive the spreading unit to the optimal

distance.

Short ply programm

Different step ply programm Variation 3

Sequential threading

Spreading device

Threading fully automatically

Cloth bar with accessories The spreading unit with fabric feeding

roll adapts sensor controlled to the

Prism driven top carriage

growing fabric ply.

Programm with fabric specific The low distance from the machine to

parameters the last ply height increases the quality

of lay and fabric utilisation.The dancer

144 parameters can be selected

TECHNICAL DETAILS bar regulates the fabric target, therefore

Metric control with storage even material that is highly sensitive to

Table width:

Calculator for length and position tension, can be spread automatically.

1,80m /2,00m /2,20m /2,40m (up to 3,40m if required)

Programming for up to 50 different Operation display

Max. roll weight:

spreading positions for beginning - end Our robust industry switches do not wear

and number of plies 80kg at standard version out and are easy to understand.

The digital software controls all driving

Linked to SELINK-System Max. roll diameter:

functions electronically.

Fabric feeding roll with top carriage ca. 450mm (larger diameter if required)

Electronical synchronized feeding roll Max. speed:

Cutting

Safety sensors on user and non-user-side 100m/min

The cutting unit is marked by a long life time and

Input of total number of plies and bundle after consumption even a novice can change the unit

Max. Laying height:

Micro processing controlled with screen and keyboard within 20 seconds. No insert of whetstones and

ca. 180mm

therefore no servicing and the average lifespan of a

Prism driven, over tooth bar running, motor elevator with cutting disc can be up to 500 operating hours.

Weight:

integrated dragging roll with automatic lifting

ca. 420kg

Exact length measuring with an encoder toothed belt within the Twist grip

Power supply:

aluminium table profiles Swiss quality potentiometer guarantees up to 6*107 turns.

4 quadrant DC engines, without brake and therefore no wearing parts 220V, 50-60Hz

Changes in construction and execution reserved SETEC Maschinenbau GmbH · Dottinger-Str. 89 · D-72525 Münsingen · Telefon:++49/ (0)7381/189-0 · Fax: 189-44 · www.setec-info.de

You might also like

- Linde EN Ds 131 p50 0206 ADocument6 pagesLinde EN Ds 131 p50 0206 ANadeem AhmedNo ratings yet

- Equipment Features: Electric Tow Tractor With Platform Capacity 3000 KG P30Document6 pagesEquipment Features: Electric Tow Tractor With Platform Capacity 3000 KG P30gananathansNo ratings yet

- SSM XENO-AC enDocument8 pagesSSM XENO-AC enajam.tavNo ratings yet

- Standard Equipment /optional Equipment FeaturesDocument2 pagesStandard Equipment /optional Equipment FeaturesNadeem AhmedNo ratings yet

- 72 Ef 53Document2 pages72 Ef 53Robson belchiorNo ratings yet

- Standard Equipment/Optional Equipment Features: Pedestrian Pallet Stacker Capacity 1400, 1600 and 2000 KG L14, L16, L20Document2 pagesStandard Equipment/Optional Equipment Features: Pedestrian Pallet Stacker Capacity 1400, 1600 and 2000 KG L14, L16, L20Amina ZukićNo ratings yet

- T20 and T24 SP and APDocument2 pagesT20 and T24 SP and APLima PereiraNo ratings yet

- MB 1370Document4 pagesMB 1370azizNo ratings yet

- MR-JE - Safety Installation Manual IB (NA) 0300194E-D (08.13)Document1 pageMR-JE - Safety Installation Manual IB (NA) 0300194E-D (08.13)Puji AntoroNo ratings yet

- Paglierani Fill and Seal Packer ORT1200 BrochureDocument4 pagesPaglierani Fill and Seal Packer ORT1200 BrochureWaleed LemsilkhiNo ratings yet

- EKR500 Digital Touch DatasheetDocument2 pagesEKR500 Digital Touch DatasheetAhmed Selem SyamNo ratings yet

- Linde EN Ds t20 25sr br1154 en A 0517Document2 pagesLinde EN Ds t20 25sr br1154 en A 0517Nadeem AhmedNo ratings yet

- iPTS - Powder Transfer SystemDocument2 pagesiPTS - Powder Transfer SystemJay OzaNo ratings yet

- ZSK Technical Embroidery Systems - 2017 07 - EN - Low PDFDocument16 pagesZSK Technical Embroidery Systems - 2017 07 - EN - Low PDFhuyenthanh1807No ratings yet

- 5110.003.12 PIG-SIG V PI-May2021Document8 pages5110.003.12 PIG-SIG V PI-May2021MORELLI silvioNo ratings yet

- Linde EN Ds w20 br127 04 en B 0111Document2 pagesLinde EN Ds w20 br127 04 en B 0111Nadeem AhmedNo ratings yet

- Application Handbook Application Handbook: LV DC SwitchgearDocument50 pagesApplication Handbook Application Handbook: LV DC SwitchgearVan Luong BuiNo ratings yet

- EN Ds l10 12 br1172 en F 0517Document2 pagesEN Ds l10 12 br1172 en F 0517JankoNo ratings yet

- Product Sheet: EMS 18/C (DF Application)Document1 pageProduct Sheet: EMS 18/C (DF Application)Marcelo SilvaNo ratings yet

- FILE 51 Use of Grinder or Angle GrinderDocument1 pageFILE 51 Use of Grinder or Angle GrinderJonathan BobadillaNo ratings yet

- Unipark GBDocument2 pagesUnipark GBMohammad TammamNo ratings yet

- Dish Motor: Test ReportDocument3 pagesDish Motor: Test ReportAlexander WieseNo ratings yet

- Manual Dewalt DW-292Document5 pagesManual Dewalt DW-292rocha.bestNo ratings yet

- Voyager - New Ins System Navigasi SystemDocument3 pagesVoyager - New Ins System Navigasi SystemDanang PrayogiNo ratings yet

- HF 525plus Equipos RadiológicosDocument2 pagesHF 525plus Equipos RadiológicosVictor RiquelmeNo ratings yet

- Enda Etc Series Pid Temperature Controllers: DimensionsDocument2 pagesEnda Etc Series Pid Temperature Controllers: DimensionsSvetoslav StoimenovNo ratings yet

- 10.6 - UltraSonic ImagerDocument50 pages10.6 - UltraSonic ImagermsvaletNo ratings yet

- Storage Feeder: Constant Yarn Tension, Fewer Knitting FaultsDocument2 pagesStorage Feeder: Constant Yarn Tension, Fewer Knitting FaultscobaNo ratings yet

- Standard Equipment/Optional Equipment Features: Electric Straddle Stacker Capacity 1000 - 1200 KG L10AS, L12ASDocument2 pagesStandard Equipment/Optional Equipment Features: Electric Straddle Stacker Capacity 1000 - 1200 KG L10AS, L12ASIker BasqueAdventureNo ratings yet

- XQG100 DT614VE XF01S ManualDocument2 pagesXQG100 DT614VE XF01S ManualgabrielaNo ratings yet

- DS K1T341A Series Face Recognition Terminal - QSG - V1.0 - 20210730Document2 pagesDS K1T341A Series Face Recognition Terminal - QSG - V1.0 - 20210730Cristian PulidoNo ratings yet

- Linde N20Document6 pagesLinde N20sindyNo ratings yet

- Catalogo Completo PROFESSIONAL - ENGDocument20 pagesCatalogo Completo PROFESSIONAL - ENGMoonsa BlackNo ratings yet

- Standard Equipment/Optional Equipment FeaturesDocument2 pagesStandard Equipment/Optional Equipment FeaturesAndrés RojasNo ratings yet

- Advanced Cutting and Routing Techniques Using The Festool MFS Fence System ReducedDocument57 pagesAdvanced Cutting and Routing Techniques Using The Festool MFS Fence System ReducedxanderNo ratings yet

- Linde EN Ds p30 br132 en B 0411Document6 pagesLinde EN Ds p30 br132 en B 0411Nadeem AhmedNo ratings yet

- Superga - Yarn SingeingDocument4 pagesSuperga - Yarn Singeinglieven.verraest6369No ratings yet

- Model 950A Antenna Control System: Full Featured Inverter Drive ControlDocument2 pagesModel 950A Antenna Control System: Full Featured Inverter Drive ControlAsif SharifNo ratings yet

- Specific Safety Rules Safety Warnings For Drill: 4) Power Tool Use and CareDocument7 pagesSpecific Safety Rules Safety Warnings For Drill: 4) Power Tool Use and CareAlif Rahmat FebriantoNo ratings yet

- Catalogue: Automation For Gates and DoorsDocument104 pagesCatalogue: Automation For Gates and DoorsAndrás TóthNo ratings yet

- C99 Mitsubishi L06055engfDocument40 pagesC99 Mitsubishi L06055engfNguyen Danh HuyNo ratings yet

- Supplementary Instructions For CMS Machines With Weave-In DeviceDocument24 pagesSupplementary Instructions For CMS Machines With Weave-In Devicemich abiNo ratings yet

- NR770HNMO InstructionsDocument1 pageNR770HNMO Instructionswisdom icyNo ratings yet

- Opman MG44 v01Document2 pagesOpman MG44 v01Carlos ArauzNo ratings yet

- Mfm383a User ManualDocument4 pagesMfm383a User ManualNhân Hồ ChíNo ratings yet

- Geoscan: Indr-Kobelco'S Proprietary Noise and Dust Reduction TechnologyDocument1 pageGeoscan: Indr-Kobelco'S Proprietary Noise and Dust Reduction TechnologyAkhmad SebehNo ratings yet

- Professional Ruffles and Pleats: Preparing The Sewing Machine: Attaching Ruffles For Fancy EffectsDocument1 pageProfessional Ruffles and Pleats: Preparing The Sewing Machine: Attaching Ruffles For Fancy EffectsJohn DoverNo ratings yet

- EDM314 Machine Description V2 0 ENDocument21 pagesEDM314 Machine Description V2 0 ENOctavio SierraNo ratings yet

- Standard Equipment/Optional Equipment Features: Pedestrian Double Stacker Capacity 600 KG - 800 KG D06, D08Document2 pagesStandard Equipment/Optional Equipment Features: Pedestrian Double Stacker Capacity 600 KG - 800 KG D06, D08Iker BasqueAdventureNo ratings yet

- APW-194N APW-195N APW-196N: Automatic Pocket Welting MachineDocument6 pagesAPW-194N APW-195N APW-196N: Automatic Pocket Welting MachineRahul Raj100% (1)

- ETR-Series Trolley System EN-GBDocument4 pagesETR-Series Trolley System EN-GBSajith VenkitachalamNo ratings yet

- BookDocument2 pagesBookharry desaiNo ratings yet

- Mode Fiber: Short-Wavelength Transmission On 1300 NM Optimized SingleDocument8 pagesMode Fiber: Short-Wavelength Transmission On 1300 NM Optimized SinglesankhaNo ratings yet

- Productspecificaties Linde H100 H180 Zware HeftrucksDocument2 pagesProductspecificaties Linde H100 H180 Zware HeftrucksJan Hendriks50% (2)

- Standard Equipment/Optional Equipment Features: Electric Tow Tractor Capacity 25000 KG P 250Document2 pagesStandard Equipment/Optional Equipment Features: Electric Tow Tractor Capacity 25000 KG P 250jackson.santosgreentechNo ratings yet

- Peugeot 406 2003 UKDocument13 pagesPeugeot 406 2003 UKjuangutierrezf93No ratings yet

- W504 Part 1Document428 pagesW504 Part 1AndryNo ratings yet

- SmartAlign Brochure 06-12-20Document2 pagesSmartAlign Brochure 06-12-20Faris MahmoodNo ratings yet

- Mutasim Ali Mohamed Saleh Mansour Malaysia, Kulalmpor: Sex - NationalityDocument2 pagesMutasim Ali Mohamed Saleh Mansour Malaysia, Kulalmpor: Sex - Nationalityahmed aliNo ratings yet

- GENERAL CHEMISTRY - Q1 - Mod1 - Properties of Matter PDFDocument17 pagesGENERAL CHEMISTRY - Q1 - Mod1 - Properties of Matter PDFdarmaricric78% (9)

- Headache Orofacial Pain and Bruxism - Selvaratnam PDFDocument377 pagesHeadache Orofacial Pain and Bruxism - Selvaratnam PDFLukas100% (1)

- Chap 3 and 5Document156 pagesChap 3 and 5Richell Mark MiguelNo ratings yet

- Mathematical Argument, Language and Proof: AS/A LEVEL 2017Document4 pagesMathematical Argument, Language and Proof: AS/A LEVEL 2017Florita LagramaNo ratings yet

- Causal Essay OutlineDocument7 pagesCausal Essay Outlinemiwaj0pabuk2100% (2)

- L-G Slideway OilDocument2 pagesL-G Slideway OilAdnanNo ratings yet

- Module Descriptor Structural Mechanics-I (TSM203) - BE2CDocument4 pagesModule Descriptor Structural Mechanics-I (TSM203) - BE2CJampel kun TsheringNo ratings yet

- Hydrodynamic Calculation Howell-Bunger ValveDocument34 pagesHydrodynamic Calculation Howell-Bunger Valvemet-calcNo ratings yet

- Zorlu Zemin Şartlarında EPB TBM Tünelciliği: Ataköy - İkitelli Metro Tünelinde Örnek Bir Çalışma, TürkiyeDocument7 pagesZorlu Zemin Şartlarında EPB TBM Tünelciliği: Ataköy - İkitelli Metro Tünelinde Örnek Bir Çalışma, TürkiyecemalbalciNo ratings yet

- Student Exploration: Cat and Mouse (Modeling With Linear Systems)Document7 pagesStudent Exploration: Cat and Mouse (Modeling With Linear Systems)brooklynNo ratings yet

- BAF003048 SY (A) Managing The Infrastructure of HospitalDocument22 pagesBAF003048 SY (A) Managing The Infrastructure of Hospitalshubham hanbarNo ratings yet

- Analytical Balance SOPDocument2 pagesAnalytical Balance SOPdivine productionNo ratings yet

- CLPWDocument13 pagesCLPWRoselyn Lictawa Dela CruzNo ratings yet

- EJPB - Volume 26 - Issue 2 - Pages 279-296Document18 pagesEJPB - Volume 26 - Issue 2 - Pages 279-296Mourad TaibiNo ratings yet

- Mechanism and Mechanical Vibration (Lab Work) Teaching PlanDocument8 pagesMechanism and Mechanical Vibration (Lab Work) Teaching PlanBelia NomeNo ratings yet

- Variable Frecuency Drives (VFDS)Document17 pagesVariable Frecuency Drives (VFDS)Waldir GavelaNo ratings yet

- NPJH50681Document3 pagesNPJH50681BlueShoterNo ratings yet

- 0450 - Volume V.4Document47 pages0450 - Volume V.4Billy MakoyNo ratings yet

- How To Retire Happy Wild and FreeDocument3 pagesHow To Retire Happy Wild and Freeruth.aduncan2014No ratings yet

- Chapter-1 FinalDocument8 pagesChapter-1 FinalHazel NutNo ratings yet

- KJ 117 o en Sac 00 Zme 0301Document1 pageKJ 117 o en Sac 00 Zme 0301Abdullah ObeidatNo ratings yet

- BilaanDocument1 pageBilaanVelante IrafrankNo ratings yet

- Applications: Mathematics and ArtDocument2 pagesApplications: Mathematics and ArtJohn Kenneth BentirNo ratings yet

- 1 Formation EvaluationDocument26 pages1 Formation EvaluationMostafa IbrahimNo ratings yet

- Sistem Informasi Pemantauan Status Gizi Balita: Khasnur Hidjah, Helna Wardhana, Heroe Santoso, Anthony AnggrawanDocument5 pagesSistem Informasi Pemantauan Status Gizi Balita: Khasnur Hidjah, Helna Wardhana, Heroe Santoso, Anthony AnggrawanZahra FahmiNo ratings yet

- Urban MorphologyDocument10 pagesUrban MorphologyAnchal kumariNo ratings yet

- Aero Structures-Basic ElasticityDocument86 pagesAero Structures-Basic ElasticityFaryal BatoolNo ratings yet

- The Cure For BoredomDocument3 pagesThe Cure For BoredomNarette SolanoyNo ratings yet

- Ocean Engineering: Ali Mahrooghi, Esmail LakzianDocument17 pagesOcean Engineering: Ali Mahrooghi, Esmail LakzianAlmir RodriguesNo ratings yet