Professional Documents

Culture Documents

Geoscan: Indr-Kobelco'S Proprietary Noise and Dust Reduction Technology

Uploaded by

Akhmad SebehOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Geoscan: Indr-Kobelco'S Proprietary Noise and Dust Reduction Technology

Uploaded by

Akhmad SebehCopyright:

Available Formats

Technology

GEOSCAN

Excavator Remote Monitoring System

iNDr—Kobelco’s Remote Monitoring for Peace of Mind GPS

Proprietary Noise and GEOSCAN is the remote monitoring system for Acera Geospec series

Dust Reduction excavators. When a hydraulic excavator is fitted with this system, data

on the machine’s operation, such as operating hours, location, fuel

consumption, and maintenance status can be obtained remotely.

Technology Hydraulic excavator

Base station

Direct access to operational status

Location data

To help operators work effectively even •Accurate realtime location data can be obtained even from sites where

communications are difficult.

in close quarters, Kobelco pursued the Web server

ultimate in quiet operation.

We also aimed for new levels in

KOBELCO service personnel/dealer/customer

reliability and serviceability.

Maintenance data and warning alerts

Latest location Location records Machine maintenance data Warning alerts

•Provides maintenance status of separate •This system triggers an alert if an

machines operating at multiple sites. anomaly is sensed, preventing damage

Operating hours •Maintenance data is also relayed to that could result in machine downtime.

KOBELCO service personnel, for more

•A comparison of operating times of

efficient planning of periodic servicing.

machines at multiple locations shows

which locations are busier and more

profitable.

•Operating hours on site can be accurately

recorded, for running time calculations

needed for rental machines, etc.

Multiple locations

A new design approach leads to a revolutionary single-duct structure Intake air passes

through the iNDr filter

iNDr engine cooling system Structural Diagram Air flow Noise flow Alarm Alarm

draws on Kobelco’s All intake air goes through the iNDr filter Exhaust outlet

proprietary technology Exhaust Status check possible Daily/monthly reports

The engine and the cooling from cell phones

components are positioned in a single Intake •Data can be obtained by e-mail through •Operational data downloaded onto a

duct connecting the air intake to the Work data the Internet, using a computer or cell computer helps in formulating daily and

Engine Daily report

exhaust outlet. This proprietary phone. monthly reports.

structure delivers a range of benefits,

such as reducing noise to the Fuel consumption data Graph of work content

surrounding environment, maintaining Strategically placed sound The engine compartment is sealed,

insulation cuts overall noise except for intake and exhaust ports •Data on fuel consumption and idling •The graph shows how working hours are

machine performance, simplifying times can be used to indicate divided among different operating

maintenance, and more. Offsetting the intake and exhaust ducts eliminates Engine compartment seals noise in

improvements in fuel consumption. categories, including digging, idling,

any direct escape of sound, minimizing overall noise *Not a completely sealed structure

traveling and optional operations (N&B).

The results are exceptional. The big merits:

Daily reports

“Ultimate Low Noise” is Eliminating dust maintains cooling Easy filter maintenance

achieved by minimizing system performance system simplifies cleaning Security system

sound leakage during The high-density 60-mesh filter* blocks out dust in the Daily inspection consists of a visual check of Engine start alarm Area alarm

operation intake air. This prevents clogging of the cooling system

and the air cleaner, which maintains peak performance.

the iNDr filter only. If it looks dirty, it can be

removed and washed without special tools. Fuel consumption Fuel consumption graph

•The system can be set to sound an

alarm if the machine is operated outside

•It can also trigger an alarm if the

machine is moved out of its designated

Noise from the engine and The waveform filter designated time. area to another location.

cooling fan is absorbed by the allows air through

duct, so the machine far the tops of the

surpasses legal requirements. waves while

Kobelco calls this system, which collecting dust at

exceeds all noise standards, the bottom,

“Ultimate Low Noise,” and it ensuring a smooth

reduces noise to 65.8dB at just airflow.

1.5m from the machine. How the filter catches dust

* “60-mesh” means that there are 60 holes formed by horizontal and vertical wires

in every square inch of filter.

Idle hours Work status Engine start alarm outside prescribed Alarm for outside of reset area

9 work time 10

You might also like

- Nexon-BS-VI 543858409905 Rev 00 10.01.20 PDFDocument232 pagesNexon-BS-VI 543858409905 Rev 00 10.01.20 PDFpushkar72No ratings yet

- NESCAFE Marketing CampaignsDocument7 pagesNESCAFE Marketing CampaignsAsif Bin ZamanNo ratings yet

- Project Titles On Arduino - 2023-1Document22 pagesProject Titles On Arduino - 2023-1Ashok SankurathriNo ratings yet

- Fuel Consumption Case Equipment Loaders Dozers ExcavatorsDocument1 pageFuel Consumption Case Equipment Loaders Dozers ExcavatorsazharcatttNo ratings yet

- HariERM WordDocument5 pagesHariERM WordHarichandan PhutanayNo ratings yet

- Siwarex U Quick Guide v3 1Document15 pagesSiwarex U Quick Guide v3 1Chan Kok LamNo ratings yet

- Hulpak BemlDocument34 pagesHulpak BemlrushabhNo ratings yet

- 20170905061501BH60MDocument4 pages20170905061501BH60MRajkumarNo ratings yet

- L2 MANUAL 200-750 kVADocument16 pagesL2 MANUAL 200-750 kVAbalu9999100% (1)

- ZW-5A series wheel loader delivers 10% fuel savings and enhanced controllabilityDocument9 pagesZW-5A series wheel loader delivers 10% fuel savings and enhanced controllabilityallnainggolanNo ratings yet

- Supply Chain AniketDocument55 pagesSupply Chain Aniketamit tapkirNo ratings yet

- D475a 5Document14 pagesD475a 5RasoolKhadibi100% (1)

- Ashok Leyland 193 LHDDocument297 pagesAshok Leyland 193 LHDАлександр Б100% (1)

- BD80 PDFDocument4 pagesBD80 PDFMd Shahnawaz IslamNo ratings yet

- JCB 215 Service Check ListDocument40 pagesJCB 215 Service Check ListDaniel KabungaNo ratings yet

- Komatsu HM400 Articulated Dump Truck SpecsDocument16 pagesKomatsu HM400 Articulated Dump Truck SpecsJorge Reyes AguilarNo ratings yet

- Installation Manual: Automatic TWIN Greasing SystemDocument62 pagesInstallation Manual: Automatic TWIN Greasing SystemWill FrontNo ratings yet

- Table of Contents: MechatronicsDocument45 pagesTable of Contents: MechatronicsFabo Barajas100% (1)

- 7 5 Kva Escorts Silent Generator Set PDFDocument1 page7 5 Kva Escorts Silent Generator Set PDFmanoj_doshi_1No ratings yet

- Manual Hidraulico Excavadora 395Document19 pagesManual Hidraulico Excavadora 395Ramon MontesNo ratings yet

- 345BL II InglésDocument30 pages345BL II InglésAlvaro HSNo ratings yet

- 785 Truck Electrical System: 8GB418-UPDocument2 pages785 Truck Electrical System: 8GB418-UPEdwin Ruiz VargasNo ratings yet

- PM 200Document16 pagesPM 200dioneslealNo ratings yet

- Q-Lok Catalogue v0Document9 pagesQ-Lok Catalogue v0Wisnu NugrohoNo ratings yet

- SAGA400 Side Housing Total Ass'Y CAT 330D: AP' CH' DR' Rev. No Date DescriptionDocument1 pageSAGA400 Side Housing Total Ass'Y CAT 330D: AP' CH' DR' Rev. No Date DescriptionDarwin SupòNo ratings yet

- 400E 200E Configuration Manual 3.10P2Document101 pages400E 200E Configuration Manual 3.10P2Иван ПарлапановNo ratings yet

- Dumper Spec FinalDocument1 pageDumper Spec FinalJackson PhinniNo ratings yet

- 385C and 385C FS Excavator Electrical SystemDocument4 pages385C and 385C FS Excavator Electrical SystemNova kurniawan 34No ratings yet

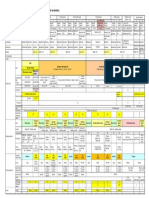

- MPR - April Bagewadi Saundati 2019Document91 pagesMPR - April Bagewadi Saundati 2019Anonymous 9bZXOFUrNo ratings yet

- BH 50M PDFDocument4 pagesBH 50M PDFAnbarasanNo ratings yet

- Brochure, Hitachi, EX1200-6, DKEX1200HT 14-05Document36 pagesBrochure, Hitachi, EX1200-6, DKEX1200HT 14-05Rolando CastilloNo ratings yet

- 01 Technical MapDocument1 page01 Technical MapRian JordanNo ratings yet

- Perkins engines technical bulletinsDocument65 pagesPerkins engines technical bulletinsUTEL CARTERNo ratings yet

- Parts catalog for 20MHB, 25MHB, 20D'03, 25N'03 outboard motorsDocument51 pagesParts catalog for 20MHB, 25MHB, 20D'03, 25N'03 outboard motorsDaniel Barham100% (1)

- RRDocument15 pagesRRYIN YIN HTWENo ratings yet

- Ashok Leyland - India's No. 2 Commercial Vehicle ManufacturerDocument31 pagesAshok Leyland - India's No. 2 Commercial Vehicle ManufacturerAnkur MestryNo ratings yet

- (Approved) DX12 Tappet Replacement ManualDocument34 pages(Approved) DX12 Tappet Replacement ManualLuis Ramón Argüello Real100% (1)

- Komatsu PC850-8R1 Hydraulic Excavator SpecsDocument8 pagesKomatsu PC850-8R1 Hydraulic Excavator SpecsRyanBrandnewdayNo ratings yet

- IMT Submission LBDocument6 pagesIMT Submission LBKrishnendu GhoshNo ratings yet

- 340DL Vs Komatsu PC400 Side by Side Comparison - Update May 11Document31 pages340DL Vs Komatsu PC400 Side by Side Comparison - Update May 11Renan FernandesNo ratings yet

- Rev - B - Asp 5009 FRP SPC 30-10-2020Document139 pagesRev - B - Asp 5009 FRP SPC 30-10-2020Cuong NguyenNo ratings yet

- Grader presentation-OPT-latestDocument34 pagesGrader presentation-OPT-latestJack SonNo ratings yet

- TroubleShooting CP224 274Document23 pagesTroubleShooting CP224 274Alex FreitasNo ratings yet

- The Pizza Food Truck BusinessDocument15 pagesThe Pizza Food Truck BusinessSADHANA KUMARINo ratings yet

- 329 D PDFDocument24 pages329 D PDFCapacitaciones RutasNo ratings yet

- BD50 Crawler Dozer 67kW Engine Spur Gear TransmissionDocument4 pagesBD50 Crawler Dozer 67kW Engine Spur Gear TransmissionAnsh MishraNo ratings yet

- Komatsu Views 2013 No.15 (Ing)Document3 pagesKomatsu Views 2013 No.15 (Ing)Carlos Alfredo LauraNo ratings yet

- Mini Hydraulic ExcavatorDocument8 pagesMini Hydraulic ExcavatorYaroslava YatsukNo ratings yet

- HM400 3M0 PDFDocument20 pagesHM400 3M0 PDFFakhrur RizkyNo ratings yet

- FUSI Aftermarket PricelistDocument24 pagesFUSI Aftermarket PricelistSanjay Kumar BansalNo ratings yet

- Vista Quadrajet PDFDocument516 pagesVista Quadrajet PDFSaadNo ratings yet

- Ayan Corp Exel PDFDocument1 pageAyan Corp Exel PDFmaharaj ( prashant dave)No ratings yet

- PC210 (LC) - 10M0 Sen06701-C0 Engine SystemDocument42 pagesPC210 (LC) - 10M0 Sen06701-C0 Engine SystemdatphuongNo ratings yet

- SOK KPI Management: (Service Operation Kaizen) (Key Performance Index)Document35 pagesSOK KPI Management: (Service Operation Kaizen) (Key Performance Index)Ирина СмирноваNo ratings yet

- Detroitdiesel MHDD A2900174 7d7-5d1 0d20-0d01Document3 pagesDetroitdiesel MHDD A2900174 7d7-5d1 0d20-0d01Erick RodriguesNo ratings yet

- 455zx - Brochure PDFDocument16 pages455zx - Brochure PDFDhru Ti100% (1)

- SK200XDL 10Document2 pagesSK200XDL 10Fendi TriyantoNo ratings yet

- Nautitech Spitfire Brochure 2019Document2 pagesNautitech Spitfire Brochure 2019sreeramk13No ratings yet

- SK200XDL 10Document2 pagesSK200XDL 10AsrinNo ratings yet

- StarLAN Technology ReportFrom EverandStarLAN Technology ReportRating: 3 out of 5 stars3/5 (1)

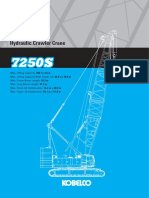

- 7120S Spec 2Document36 pages7120S Spec 2Akhmad SebehNo ratings yet

- SL6000S Spec 3Document34 pagesSL6000S Spec 3Akhmad SebehNo ratings yet

- Configuration Document for Crane SpecificationsDocument5 pagesConfiguration Document for Crane SpecificationsAkhmad SebehNo ratings yet

- 20180830114114HI Multi-Dismantling Machine Update 310818Document6 pages20180830114114HI Multi-Dismantling Machine Update 310818Akhmad SebehNo ratings yet

- Hydraulic Crawler Crane: Model: BMS800Document20 pagesHydraulic Crawler Crane: Model: BMS800Akhmad SebehNo ratings yet

- CraneDocument10 pagesCraneAkhmad SebehNo ratings yet

- 20190904020742HI SK135SR-5 SK140SRLC-5 Tier 4 Final Full BrochureDocument10 pages20190904020742HI SK135SR-5 SK140SRLC-5 Tier 4 Final Full BrochureAkhmad SebehNo ratings yet

- 7250S Spec 2Document37 pages7250S Spec 2Akhmad SebehNo ratings yet

- Bms 1000 SpecDocument20 pagesBms 1000 Spec24x7civilconsultantNo ratings yet

- 7250S Spec 1Document11 pages7250S Spec 1stephen prosserNo ratings yet

- 20160117115809HI Kobelco Generation 10 Concept BookDocument16 pages20160117115809HI Kobelco Generation 10 Concept BookAkhmad SebehNo ratings yet

- CKS BMS 7000S NR5 VF201806Document28 pagesCKS BMS 7000S NR5 VF201806Akhmad Sebeh100% (1)

- CKS BMS 7000S NR5 VF201806Document28 pagesCKS BMS 7000S NR5 VF201806Akhmad Sebeh100% (1)

- 20190904020842HI Kobelco Tier 4 Final SK140SRL BrochureDocument2 pages20190904020842HI Kobelco Tier 4 Final SK140SRL BrochureAkhmad SebehNo ratings yet

- Hydraulic Crawler Crane 80t Max Capacity 54.9m BoomDocument24 pagesHydraulic Crawler Crane 80t Max Capacity 54.9m BoomAkhmad SebehNo ratings yet

- 20150818060113hi SK135SRLC SK210LC SK260LC LongDocument2 pages20150818060113hi SK135SRLC SK210LC SK260LC LongAkhmad SebehNo ratings yet

- KS En178s1 PDFDocument15 pagesKS En178s1 PDFBeny StephenNo ratings yet

- Hydraulic Crawler Crane: Model: CKE1800-1FDocument40 pagesHydraulic Crawler Crane: Model: CKE1800-1FDeny ZeusNo ratings yet

- 5,980 MM 5,880 MM 5,850 MM 2,800 MM: Productivity Examples of OperationDocument2 pages5,980 MM 5,880 MM 5,850 MM 2,800 MM: Productivity Examples of OperationAkhmad SebehNo ratings yet

- Teaching Experimental Design Through a Paper Helicopter ExperimentDocument9 pagesTeaching Experimental Design Through a Paper Helicopter Experimentiangardiner.iow5796No ratings yet

- 5,980 MM 5,880 MM 5,850 MM 2,800 MM: Productivity Examples of OperationDocument2 pages5,980 MM 5,880 MM 5,850 MM 2,800 MM: Productivity Examples of OperationAkhmad SebehNo ratings yet

- ZAXIS-5 series excavator specificationsDocument8 pagesZAXIS-5 series excavator specificationsAkhmad SebehNo ratings yet

- Scrap LoaderDocument2 pagesScrap LoaderAkhmad SebehNo ratings yet

- 2-Piece Boom Demolition Excavator: Zaxis-SeriesDocument12 pages2-Piece Boom Demolition Excavator: Zaxis-SeriesAkhmad SebehNo ratings yet

- Lifting Capacities: Standard EquipmentDocument8 pagesLifting Capacities: Standard EquipmentAkhmad SebehNo ratings yet

- Geoscan: Indr-Kobelco'S Proprietary Noise and Dust Reduction TechnologyDocument1 pageGeoscan: Indr-Kobelco'S Proprietary Noise and Dust Reduction TechnologyAkhmad SebehNo ratings yet

- Hydraulic Crawler Crane 80t Max Capacity 54.9m BoomDocument24 pagesHydraulic Crawler Crane 80t Max Capacity 54.9m BoomAkhmad SebehNo ratings yet

- Locking It All InsideDocument10 pagesLocking It All InsideAkhmad SebehNo ratings yet

- Lifting Capacities: Standard EquipmentDocument8 pagesLifting Capacities: Standard EquipmentAkhmad SebehNo ratings yet

- Way Back To The BibleDocument19 pagesWay Back To The BiblePearlCladelLapidezNo ratings yet

- Kuruk Etra:: Dharma-K Etra Śalya-ParvaDocument1 pageKuruk Etra:: Dharma-K Etra Śalya-ParvaRavinder Khullar100% (1)

- AET Aetna 2017 Investor Day Presentation - Final (For Website) PDFDocument73 pagesAET Aetna 2017 Investor Day Presentation - Final (For Website) PDFAla BasterNo ratings yet

- Seagate WD Hard Drive Price List From Billion HoDocument4 pagesSeagate WD Hard Drive Price List From Billion HoALi RAzaNo ratings yet

- EMAG W01 RodHeatingDocument16 pagesEMAG W01 RodHeatingMiguel Ángel ArizaNo ratings yet

- Introduction to S.G. Iron Casting IndustryDocument30 pagesIntroduction to S.G. Iron Casting Industryavnishchauhan8_46499100% (1)

- DOE V Rhodes College Ammended Motion For TRODocument19 pagesDOE V Rhodes College Ammended Motion For TROSouwesterdocs100% (1)

- Cultural Understanding Impacts Consumer BehaviorDocument10 pagesCultural Understanding Impacts Consumer BehaviorNguyễn Hữu Thảo NguyênNo ratings yet

- Siwarex Cs-En v12Document15 pagesSiwarex Cs-En v12Diego CanoNo ratings yet

- Vedic Healing Through Gems4Document3 pagesVedic Healing Through Gems4gesNo ratings yet

- Clinical Practice Guidelines On Postmenopausal Osteoporosis: An Executive Summary and Recommendations - Update 2019-2020Document17 pagesClinical Practice Guidelines On Postmenopausal Osteoporosis: An Executive Summary and Recommendations - Update 2019-2020Marwa YassinNo ratings yet

- ESBG Financial Systems Difference EU-US PDFDocument12 pagesESBG Financial Systems Difference EU-US PDFDominiqueCarriouNo ratings yet

- Marketing Strategies Audit On Hewlett Packard (HP)Document19 pagesMarketing Strategies Audit On Hewlett Packard (HP)auraNo ratings yet

- Growatt Warranty Procedure - 07-09-2020Document9 pagesGrowatt Warranty Procedure - 07-09-2020Design TeamNo ratings yet

- Earned Value Analysis 8 StepsDocument8 pagesEarned Value Analysis 8 StepsHira RazzaqNo ratings yet

- SMS Security Android AppDocument8 pagesSMS Security Android AppSuman SouravNo ratings yet

- Capstone Presentation 2020Document12 pagesCapstone Presentation 2020api-539629427No ratings yet

- Deutz td2011 l04w Service Manual PDFDocument7 pagesDeutz td2011 l04w Service Manual PDFLuis Carlos RamosNo ratings yet

- Febelfin Academy - Exam RegulationsDocument9 pagesFebelfin Academy - Exam RegulationsGeoff ChapmanNo ratings yet

- Las 4.4 - Hope 4 - Mountaineering (Hiking, Trekking, Camping, Orienteering)Document5 pagesLas 4.4 - Hope 4 - Mountaineering (Hiking, Trekking, Camping, Orienteering)Maricel EsperatNo ratings yet

- CIC-presentation of RP-577 PresentationDocument181 pagesCIC-presentation of RP-577 PresentationIbrahim Eldesoky75% (4)

- Marivy Abella ResearchDocument43 pagesMarivy Abella ResearchRo Gi LynNo ratings yet

- CaracterizacióndeSalpicadurasSMAW Molleda 2007Document5 pagesCaracterizacióndeSalpicadurasSMAW Molleda 2007Tamara Maria Ortiz MendezNo ratings yet

- Engl10 Q4 M1 DistinguishTechnicalTermsUsedinResearch Pagulongan V0-Module-1Document32 pagesEngl10 Q4 M1 DistinguishTechnicalTermsUsedinResearch Pagulongan V0-Module-1Kath Nees67% (3)

- Letter of Request For Brgy. ProfileDocument2 pagesLetter of Request For Brgy. ProfileRhea Mae MacabodbodNo ratings yet

- Brfo193 Radiotherapy Dose Fractionation Third-Edition PDFDocument137 pagesBrfo193 Radiotherapy Dose Fractionation Third-Edition PDFMed MedNo ratings yet

- Novec1230 RoomIntegrityDocument2 pagesNovec1230 RoomIntegritynastyn-1No ratings yet

- Introduction to Pidilite IndustriesDocument8 pagesIntroduction to Pidilite IndustriesAbhijit DharNo ratings yet

- Listado 2 4ghzDocument4 pagesListado 2 4ghzRogerNo ratings yet