Professional Documents

Culture Documents

Securite Work Public

Securite Work Public

Uploaded by

Bensmat0 ratings0% found this document useful (0 votes)

4 views9 pagesOriginal Title

securite work public

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views9 pagesSecurite Work Public

Securite Work Public

Uploaded by

BensmatCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 9

200K 2: PIPELINE

FACILITIES

Eeuenwce

Purpose

‘Scope

Related Standards

Responsibilties

Requirements

STANDARD

Orr

‘sa |

‘Safeguarding Workers and Public

“To prteet the safety of workers and the public when operating

mechanized excavation equipment, or other below grade zctivity withthe

Potential for damage, takes place near company facilites,

This applies to setvities supervised by company employees. Ths does

not apply where contractors or contractor personnel supervise the work.

Company

Book 2: Safety

© 03-02-01 Safe Work Permit — Hazard Assessment

Book 3 Pipeline Facilites

© 04-02-02 Damage Prevention

‘Company Representative

AWARNING: A company representative must remain onsite to

continually monitor any mechanized excavation, or ater activity with

the potential for damage, that takes place within 3 m (10 8) ofa

company failty, or for ENB (Athabasca) within 5 m (16.58) of @

company facility, whether located above or below grade.

‘The company representative, who must be a competent worker, is

responsible for ensuring:

activities involving mechanized equipment are adequately

supervised

‘© company facilites inthe work area are surface located

‘+ necessary safety precautions are taken considering the unique

aspests of the work

‘© workers and facilites are adequately protected in acoordance with

this stardard

+ work sts if there isa concern for safety, pipeline integrity, oF

damage to company equipment o facilities

‘exposed pipes, conduits, and cables are not damaged, confirmed by

visual inspection inthe ditchvexcavation before backfiling

‘A hazard assessment mast be completed by company employees any

time activity takes place rear company facilities.

Inspections

‘A competent worker must conduct daly inspections of excavations,

adjacent areas, and protective equipment:

before starting work

Th oar ens cot taney ONE ste Pie Say Cans See we,

04-02-01

‘Safeguarding Workers and Public BOOK 3

‘© as neoded throughout the shift

‘after rainstorms or other occurrence that could create a hazard

Inspections must look fr:

‘situations that could result in eave-ns

indications of failure of protective systems

‘+ hazardous atmospheres or ther hazardous condition

NOTE: When a hazardous atmosphere may be expected, emergency

rescue equipment, including breathing apparatus and rescue harness and

Tine, must be available.

Excavations must be lange enough in all dimensions for safe and easy

‘working conditions

‘Scrape all loose materials from the sides of an excavation and from

walking and working areas where workers willbe present

‘Spoil Piles, Materials, Tools, and Equipment

Store spol piles, materials, tools, vehicles, and equipment atleast 1m (3

£8) (CAN) ora least 0.6 m (2) (USA) from the edge ofan excavation,

trench, or borehole

A.CAUTION: Mechanized equipment must rot operate closer than 1 m

(CAN) or 2 ft (USA) from the edge of an excavation.

Slope spoil piles next to excavations, trenches, or boreholes at an angle

not less than 45° to the vertical

‘Thoroughly remove all lumps and stones from walking and working

surfaces, and from excavated spoil

Entrances/Exits

For excavations greater than 1.2m (4 ft) deep, provide atleast 2

+1

Bel cn tment

AAWARNING: Where a portion of an excavation greater than 41 (1.2

1m) deep is constructed with vertical walls, use warning signs attached to

barricades or ropes, or other appropriate methods to prevent workers

from entering that porion of the excavation,

FES sa [If workers are required to work on iter side ofthe pipe, provide an exit

| on each side ofthe pipe

ee —eeeeeseesese—eiee

"hanes Ca ay OLN stn seen ee Salty Comes ot aa

e

BOOK 3

E+E can

04.02.01

Safeguarding Workers and Public

Locate entrances/eits so that no worker travels more than 8 m (25 8) in

either direction to exit the trench

Entrances/xits must be ladders, steps, or sloped walkways of not more

than 1:3 slope

Side rails of ladders must extend I m (3 A) out ofthe trench oe

excavation,

Water Accumulation

Keep all excavations, trenches, and boreholes fre of accumul

water where workers are present.

sof

‘A competent worker must monitor water removal equipment,

‘Water pumped from excavation should be discharged into an energy

dissipation or erosion contol device locate in adjacent upland areas ot

‘other well-vgetated areas.

NOTE: A permit may be required depending on the amount of

pumped from the excavation. For more information, contact Safety &

Environment

Sloping

Slope the walls ofthe excavation when (a) the excavation is rete than

1.2m (4 deep, and () shoring oa teach box snot used

Ifa worker must lie dovm or kneel ina trench without an approved

temporary protective structure, slope the trench wall fom the bottom of

the excavation inthe area where the work will occur.

Soil Analysis:

‘A competent worker must examine the type of sol in an excavation or

trench to ensure the stability of sloping used for excavations and

trenches. The angle of sloping must not be less than required by

provincial regulations.

“Treat frozen soil conditions the same as unfrozen sol conditions.

NOTE: Stable rock is comprised of solid mineral matter and does not

require sloping

(Classification of Soll and Rock

‘A competent worker must classify each soil and rock deposit before and

‘during excavation as one ofthe following soil types:

‘+ Type A—clay and cemented soils

‘+ Type B—angular gravel, silt loam, crushed rock, ete.

Type C—grave, sand, submerged soil, ete

C

04.02.01

Safeguarding Workers and Public BOOK 3

a

usa

NOTE: Whenever excavation work is inside the fenced area of a pomp

station or rightof-way (ROW), the soil shouldbe treated as Type C,

since there isa good chance it was previeusly disturbed. A competent

(pares mest spite My Scamp ee eee eee

A competent worker must classify sol types using the following tests:

‘© visual tes to determine:

qualitative information regarding the excavation site in general

~ soll properties next tothe excavation

soll properties forming the sides of the opening excavation

soll properties taken as samples from excavated material

manual est to determine quantitative as well as qualitative

‘properties of sl, and to provide more information for classitying

sol property, Manual tests include:

~ plasticity test

ary strength

~ thumb penetration

othe strength tests (eg, pocket penetrometer ex hand-operated

shearvane)

‘Sloping and Benching Systems

Use one ofthe following options when designing slopes and benching

systems of excavations under the direction of competent worker:

Option 4: Slope or bench the excavation at an angle not steeper than one

and one-half hrizontal to one vertical (342 measured from the

horizontal)

‘Option 2: Have a competent worker classify the sol using manvsl and

visual tests anda slope a maximum of

+ Type av 3)

+ Types E145")

+ Typec: a G4)

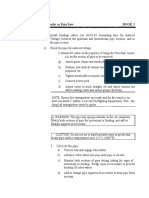

NOTE: Fora sample bench system for Type B sol, see Figure I.

Option 3: Install shoring or use a trench box.

Option 4: Have a registered professional engineer design a support,

system for the excavation

“hE toame rate ns od iC Cay OP Uren vid one Pein Cogins oc

€

e

04.02.01

BOOK 3 Safeguarding Workers and Public

she ype sr 059

anf Le 4

Figure 1

‘Sample Bench System for Type B Soll

Fences and Barricades

Within Fenced Areas

Barricade or ence off unattended excavations, trenches, and boreholes

‘within fenced areas (@., stations, valve sites) as appropriate depending,

‘location ofthe excavation

‘© worker/public access or exposure tothe excavation

+ size ofthe excavation (, depth, length)

‘potential for workers othe public falling into the excavation

+ potential for drowning

+ number of exits, ifany

. ‘of the excavation (e.g. wet, muddy)

. will be unattended

cond

length of time the excav

Barricades must be:

‘© manufactured type (wood, plastic, or metal construction)

+ approximately 1m (3) high

+ secured in place

In addition to barricades/fences, ase suitable warming devices (e.,

reflective signs or ashing light) to provide advance warning of

excavations, trenches, oF boreholes that may presenta hazard to night

traffic,

Pam

“hs cae ere ns or tn oa Cy OL ar ee ew ne Pa Salty Cone Stag ee

BOOK

Along the ROW

‘Guard unattended excavations on the ROW from unintentional entry

‘using bihly visible material (e.g, orange snow fencing). In addition, use

barbed wire where livestock are present

Support the fencing at spacing of appreximately 3 m (10 f), and secure

the fencing to each support (eg. using wire or rope).

Erect barricades or fences approximately 1 m (3 ft) from the excavation

to maintain an adequate walkway around the excavation.

‘Temporary Protective Structures

Consult registered professional engineer to review the stability of any

structure or foundation tat may be affected by an excavation or tench,

[f required, design, construct, and instal a temporary protective sirclute

to support the structure or foundation in accordance with the

specifications of a registered professional engines.

Shoring

‘Timber shoring used in trenches and excavations must be in accordance

with Table 1

Assemble and install hydraulic shoring in accordance withthe

rmamicturer’s instructions.

‘When installing stringer and brace components ina shoring system,

work downward from the surface using a ladder o install each brace in

descending order. Use the reverse ofder fo remove components, unless

conditions make it unsafe for workers to enter the excavation. In such

‘eases, use an alternate method of removal that proteets workers from

injury.

Shoring must extend a minimum of 600 mm (2) above the surface of

the ground or vertical trench walls

A professional engineer must design any support system used in a

excavation greater than 6 m (20 f) deep.

Trench Boves

Install trench boxes in excavations before workers enter, and place

‘egress ladders inside the tench box.

‘Trench boxes must be (a) designed by a professional engineer, and (b)

constructed, inspected, and maietained in accordance with the

engineering or manufacturer's specifications

Before installing a trench box, a Copy ofthe Engineering Certfieate or a

stamped Engineering Drawing must be provided

&

BOOK3

04.02.01

‘Safeguarding Workers and Public

‘Trench boxes stacked in deep excavations must be adequately secured

‘one another,

‘Trench boxes must have continuous sides and st extend a minimum of

{600 mm (24 in) above the vertical wall of the excavation.

A professional engineer must design and approve hoisting hook-up and

drag points. Where a trench box will be dragged forward, protect,

workers in the box gains rigging failure by suitable protective

sorecning or other means.

‘Workers must remain inside the box as long as they are inthe trench, and

rust leave ifthe trench box will be lifted to be moves.

Excavation must be done to minimize the space berween the trench box

and the excavation ‘wal inorder to allow closer access tthe top ofthe

box and to limit soil movement in case of eave-ins:

‘+ Low ground pressure (LGP) tracked equipment exerting .80 psi ot

less ground pressure, the depth of cover is no less than 0.9 1m (36

in) of consolidated cle sol, and repeated crossings are not

requited (¢., acrossing by & D6 with 30 in, of larger track width,

‘ora DS with 24 in, or larger track width),

‘+The depth of cover is, ors noreased to, 13 m (S2 in.) or greater,

the vehicle axe loading is highway legal, conditions are dry, and &

‘company representative is onsite when vehicles are crossing the

Pipeline.

rage rat

"hs ae teaser rans i Cae Cy NP rater and on HE Sy Cane SMR we

pn nts yn as ey cpm Rap i pp mu a sm PINS AEG,

eeu

= fs le

peas one

ren | suomi eunnorntea | tes

soypuas, BoHo4S

Toa.

‘aulgnd pue S180) Burpienl

r

Waste Management - Liquids

Scope of work

‘The scope of this section is to ensure that the liquids potentially generated in

association with the repair of the pipeline are handiea and disposed of with proper

procedures as set forth in the various relevant Enbridge documents and plans as

selerenced below.

‘The potential liquid waste streams associated with the repair include crude oil impacted

water associated with dewatering the repait excavation and stormwater run-off

associated with disturbed soils. The outfall of the dewatering discharge stream will be

‘0 on site fractionation tanks for short term storage and future disposal as coordinated

by Enbridge’s Environment Department, The potential stormwater run-off will be

mitigated via the best management practices set forth on the attached figures.

Regulatory Requirements

‘The relevant Enbridge plans and procedures currently in effect to handle liquid waste

streams were created to be compliant with the Clean Water Act as promulgated in

40CFR Protection of the Environment and adopted by Michigan’s Department of Natural

Resources and Environment. Attached are the relevant portions of Enbridge’s

Operations and Maintenance Plan, and supporting documentation specific to the repair

associated with Line 6B.

Company Standards (see attached)

‘Book 3 02-01-01 ~ Overview of Environmental Protection

Book 3 02-02-01 ~ Environmental Permits/Licenses/Approvals

Book 3 02-02-02 ~ Erosion Central

Book 3 02-02-08 - Stormwater Management

Book 3 02-02-08 — Environmental Records

Book 3 02-02-09 — Refueling Tanks, Equipment and Containers

Exceptions to standards or specific site requirements- None

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Fasc Conception Des Postes Gaz 27 11 2022Document93 pagesFasc Conception Des Postes Gaz 27 11 2022BensmatNo ratings yet

- WPS BoumerdesDocument13 pagesWPS BoumerdesBensmatNo ratings yet

- Fascicule 1 Spécifications Techniques Des Équipements Poste Corrigé 13072021 RH - GFDocument213 pagesFascicule 1 Spécifications Techniques Des Équipements Poste Corrigé 13072021 RH - GFBensmatNo ratings yet

- Fascicule 2 SPECIFICATIONS TECHNIQUES CONCEPTION POSTES GAZ GN - RH - GFDocument108 pagesFascicule 2 SPECIFICATIONS TECHNIQUES CONCEPTION POSTES GAZ GN - RH - GFBensmatNo ratings yet

- Tinywow - 1-45 PDF ANG - 20037352 - 5Document1 pageTinywow - 1-45 PDF ANG - 20037352 - 5BensmatNo ratings yet

- Tinywow - 1-45 PDF ANG - 20037352 - 7Document1 pageTinywow - 1-45 PDF ANG - 20037352 - 7BensmatNo ratings yet

- Cutting The Pipe With Wachs or Fein Saw Book 3Document2 pagesCutting The Pipe With Wachs or Fein Saw Book 3BensmatNo ratings yet

- AIM - LIMITE DES PERIMETRES DE CONSTRUCTION Du 14.06.2011Document8 pagesAIM - LIMITE DES PERIMETRES DE CONSTRUCTION Du 14.06.2011BensmatNo ratings yet

- Tinywow - 1-45 PDF ANG - 20037352 - 10Document1 pageTinywow - 1-45 PDF ANG - 20037352 - 10BensmatNo ratings yet

- Réglem Interieur CPHSEDocument6 pagesRéglem Interieur CPHSEBensmatNo ratings yet

- Tinywow - 1-45 PDF ANG - 20037352 - 1Document1 pageTinywow - 1-45 PDF ANG - 20037352 - 1BensmatNo ratings yet

- Réglem Interieur CPHSUDocument6 pagesRéglem Interieur CPHSUBensmatNo ratings yet

- Procedure S Cutting The Pipe With Wachs or Fein Saw: CompanyDocument3 pagesProcedure S Cutting The Pipe With Wachs or Fein Saw: CompanyBensmatNo ratings yet

- Sechage R0Document13 pagesSechage R0BensmatNo ratings yet

- Procedure de Communication R0Document10 pagesProcedure de Communication R0BensmatNo ratings yet

- Cups-13 A Method To Determine The Minimum Stack HeightDocument46 pagesCups-13 A Method To Determine The Minimum Stack HeightBensmatNo ratings yet

- Procedure de Traitement de Tubes R1Document8 pagesProcedure de Traitement de Tubes R1BensmatNo ratings yet

- Procedure de Vidange D'un Oleoduc R0Document12 pagesProcedure de Vidange D'un Oleoduc R0BensmatNo ratings yet

- Procedure de Revêtement R1Document10 pagesProcedure de Revêtement R1BensmatNo ratings yet

- Procedure Mise en Fouille R0Document8 pagesProcedure Mise en Fouille R0BensmatNo ratings yet

- Procédure Essais Hydro R1Document23 pagesProcédure Essais Hydro R1BensmatNo ratings yet

- How A Burner Management System WorksDocument12 pagesHow A Burner Management System WorksBensmatNo ratings yet

- Procedure de Mise en Gaz Antenne Ø 8'' Centrale Brezina W. El BayadhDocument9 pagesProcedure de Mise en Gaz Antenne Ø 8'' Centrale Brezina W. El BayadhBensmatNo ratings yet

- HST Et Doc Histoire D Oran Par Le General L. Didier 1501 1550Document410 pagesHST Et Doc Histoire D Oran Par Le General L. Didier 1501 1550BensmatNo ratings yet

- Procedure de Mise en Gaz Antenne Ø 8'' Centrale Brezina W. El BayadhDocument8 pagesProcedure de Mise en Gaz Antenne Ø 8'' Centrale Brezina W. El BayadhBensmatNo ratings yet

- La Rentabilite Des Investissement 2016Document7 pagesLa Rentabilite Des Investissement 2016BensmatNo ratings yet

- Safe Separation Distances From Natural Gas PipelinesDocument19 pagesSafe Separation Distances From Natural Gas PipelinesBensmatNo ratings yet

- Gestion Des InvestissementsDocument206 pagesGestion Des InvestissementsBensmatNo ratings yet

- Article & Guide D'imputation - 2Document20 pagesArticle & Guide D'imputation - 2BensmatNo ratings yet

- Les Ressources Externes de Financement Cba 02/2016Document6 pagesLes Ressources Externes de Financement Cba 02/2016BensmatNo ratings yet