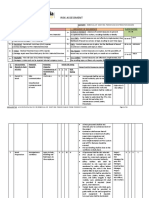

The permit is automatically suspended on activation of the General Alarm or Instruction via Notification Alarm.

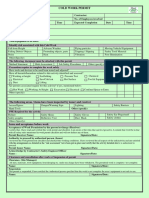

COLD WORK PERMIT

WORK PERMIT NUMBER CWP - PERMIT ISSUED TO SUBCONTRACTOR Yes □ No □

DIVISION / SUBCONTRACTOR NAME MANPOWER

1 A TASK DESCRIPTION

Task/Work Description

Location/Area

Validity Period

Work Shift □ Day Shift □ Night Shift

Days Date From To From To

(Working Duration)

Time From To From To

B HAZARD IDENTIFICATION & RISK ASSESSMENT

Description of Possible Hazards □ Work at Height □ Adjacent Work □ Lifting Operations □ Unauthorized Entry □ Moving Parts □ Rotating Machinery

□ Flying Particles □ Slippery Surface □ Isolations □ Cables / Hoses □ Chemical Handling □ Lifting/Manual Handling

□ Vehicle Movement □ High Noise □ Equipment Hazard □ Spillage □ High Pressure □ High Temperature

□ Others

Attachment required □ HEMP □ Risk Assessment □ Method Statement(MS) □ Drawings □others ______________

CONTROLS

ORIGINATOR / PERFORMING AUTHORITY

C

Required Control measures: Yes No N/A Other Control Measures: Yes No N/A

Safe Access / Work Platform available □ □ □ Cables / Hoses without damage and Safe End Connection □ □ □

Fall Protection System □ □ □ Trolley, Equipment in place for minimizing Manual Handling □ □ □

Hard / Soft Barrier □ □ □ Banksman Assigned to Control Vehicle Movement & Reverse Operation □ □ □

Certified Equipment, Tools and Operator for Lifting Operations □ □ □ Spill Kits Available □ □ □

No Work under suspended load □ □ □ Pipe, Hose and other connections secured for High Pressure □ □ □

Rotating Machinery Guards In Place □ □ □ Heat Stress Control Measure □ □ □

Guards / Shield in place for Preventing Flying Particles □ □ □ Gas Test (if "Yes" go to D) □ □ □

Barrication and Signs for Slippery/Wet Surface □ □ □ Confined Space Entry (if "Yes" go to )F □ □ □

LOTO (Logout/Tagout), if 'Yes' check Isolation work permit □ □ □ Override of HSE Critical devices (if "Yes" go to ) F □ □ □

PPE Required (Check the box if required) ;

Safety Helmet □ □ □ Face shields □ □ □

Safety Goggles □ □ □ Cartridge Respirator □ □ □

Safety Shoe / Boots □ □ □ Hood (□ Welding, □ Blasting, □ Others) □ □ □

Glove s(□ Cotton, □ Leather, □ Nitrile,□ IR) □ □ □ Chemical/Fire Resistant Clothing □ □ □

Full Body Safety Harness and Double lanyard □ □ □ Ear Plug / Ear Muff □ □ □

Actions & Other Precautions:

D GAS TEST ( If additional gas tests are required, use the Additional Gas Tests Form )

Toxic

Gas Test Parameter Flammable Oxygen

Date Time Gas Tester Name H2S CO Ammonia SO2 Others Remarks

Safe Limits < 1% LEL 23.5%<O2> 19.5% < 10 ppm < 35 ppm < 25 ppm < 2 ppm

Test Results

Test Results

Test Results

2

E CROSS REFERENCES & ACKNOWLEDGMENT F PERMITS & CERTIFICATES REQUIRED

ORIGINATOR/AREA

SUPERVISOR

Other permits in area that Yes □ No □ Details: Other Permits or Certificates Required Yes □ No □

could interfere: [SIMOPS] Confined Space Work Permit Number

Acknowledgement from Electrical Work Permit Number

Affected Parties [SIMOPS] Isolation Certificate Number

3 DESCRIPTION PERFORMING AUTHORITY AREA SUPERVISOR ISSUING AUTHORITY HSE TEAM (AOTC)

I understand and accept the above conditions and precautions and accept I declare that all hazards have been identified and all specified control The Permit and any supplementary certificates have been completed. The For check, Compliance and Record

Acknowledgement responsibility for the work and ensure the persons under my control measures are in place and it safe to carry out the work defined control measures defined are in place.

understand and comply with these conditions and precautions

ISSUE

Name

Sign

Date/Time

CHECK

PERFORMING AUTHORITY AREA SUPERVISOR ISSUING AUTHORITY HSE TEAM (AOTC)

CANCELATION

EXTENSION

4

DATE TIME

D NAME SIGN NAME SIGN Name SIGN NAME SIGN

□ □

EXTENSION OR CANCELLATION

□ □

□ □

□ □

□ □

□ □

5 DESCRIPTION PERFORMING AUTHORITY AREA SUPERVISOR ISSUING AUTHORITY HSE TEAM (AOTC)

I declare that the work has been properly performed and that the I have inspected the equipment/work area and declare that the work All copies of Permit & any supplementary certificates collected. The control For check, Compliance and Record

Acknowledgement equipment, plant and apparatus affected by the work have been left in a defined in this permit is complete and that the area is clean and safe. measures put in place for this permit have been removed.

safe, clean condition

COMPLETION

Name

Sign

Date/Time

Document Tag: AOTC-IMS-L4-301-F-001 | Rev:01 | Date: 10-01-2021