Professional Documents

Culture Documents

A-Guide For Selection of Fuses and Wires

A-Guide For Selection of Fuses and Wires

Uploaded by

Avish Shah0 ratings0% found this document useful (0 votes)

20 views4 pagesOriginal Title

A-GUIDE FOR SELECTION OF FUSES AND WIRES

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views4 pagesA-Guide For Selection of Fuses and Wires

A-Guide For Selection of Fuses and Wires

Uploaded by

Avish ShahCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

766 GUIDE FOR SELECTION OF FUSES AND WIRES

relay is essentially a small ferromagnetic cantilevered beam that

bends to make contact under’ the force of a magnetic field.

The control and reed relays are extensively uséd as switching

devices.

Time relays: They find use in automatic and programme con-

trolled machine tools and for star delta switching of motors. They

can be used for switching ON or OFF an electrical circuit after a

lapse of time. The types available include pneumatic, electronic and

motorized time relays.

‘Signal lamps: Signal lamps can be used as visual indication of

functions like supply on, motor running, clamping, etc.

Fuses

Fuses are used to protect electrical equipment against short

circuit. The principle of its function is fusing of easily fusible wire or

strip at a current higher than the nominal current of the fuse itself.

They are provided at the origin of the circuit to be protected.

The characteristics of the fuse and the device to be protected

should be suitably matched electrically. Guide for selection of fuses

is indicated in Table 340.

STARTERS AND CIRCUIT BREAKERS

These are units incorporating within themselves contactors and

overload protector. They provide safety against no-voltage, under

voltage and overload.

Assembly of elements

Assembly and mounting of electrical elements are carried out

with due regard to the factors indicated earlier.

A typical installation scheme of the electrical panel inside the

control console is shown in Fig. 228.

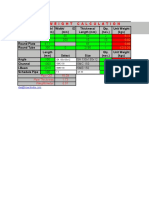

Guide for selection of fuses and wires

Table 340 gives the guidelines for selection of fuses and copper

conductors for induction motors for machine tools. The motors are

tated for 415 V, 3 phase, 50 Hz and are of squirrel cage type suitable

for operation at an ambient of 40°C. HRC fuses correspond to IS

2208, BS 88 or VDE 0660 and this selection is based on a maximum

starting current of 6 times full load current and a maximum starting

time of 5 secs. for direct on line starting and a maximum starting

current of twice the full load current and a maximum starting time of

15 secs. for star delta starting. The full load currents indicated in the

table are applicable for motors of 1500 rpm. For other values

GUIDE FOR SELECTION OF FUSES AND WIRES 767

teference should be made to the motor name plate. Motors with

higher full load current and/or higher starting current and/or longer

starting times as well as motors with higher frequency of operations

may require fuses of a higher rating.

Table 340 Guide for selection of fuses and wires

768 GRAPHICAL SYMBOLS FOR ELECTRICAL CIRCUITS

Mains on-off switch 16 Amps, 500 V

Three position selector switen (1 NO +1 NC) contacts

Triple pole fuse unit 6 Amps (Delayed action)

Air break contactor, 220 V, 2.NO Aux. contacts

ac coil, 50 Hz

Overload relay 3 to 6 Amps. range

Push button switch, mushroom (1. NO +1 NC) contacts

actuator, Red colour

Push button switch, Shrouded (1 NO + 1 NC) contacts

actuator, Green colour

Push button switch, Shrouded (2 NO +2 NC) contacts

actuator, Green colour

Push button switch, Un-shrouded | (1 NO +1 NC) contacts

actuator, Red colour

Auxiliary contactor, open execution,

220V, ac Coil, 50 Hz (4.NO +4 NC) contacts

Time delay relay, 220 V, On-delay, 0-60 secs.

ac coil, 50 Hz

Indicator lamp, yellow colour For rear connection

with 220 V, 7 W bulb.

Glass cartridge 1 Amp

F@ Fuse

Fuse

Fuse

CIRCUIT FUNCTIONS

The circuit is for an electrical coil pressing machine.

The functioning of the circuit is as follows:

1) Switch on S: to connect power to all equipment.

2) Start motor M1 by pressing push button P2 which ener-

gizes contactor K1 and self holds.

3) Select the direction (horizontal, vertical or both) by

switch S2

4) Clamp by pressing push-button P6 which energizes sol-

enoid valve 9A. The coil is pressed.

If a high pressure is desired, press push-button P3. Indi-

cator H1 indicates high pressure.

(Note that after high pressure is selected, the changing of

switch position $2 does not have any effect. This is specifi-

cally provided to avoid damage to hydraulic elements)

5) Press P5 to declamp which is accomplished by the sol-

enoid valve 9B being kept energized for a specified time

selected in pneumatic time delay relay AS.

Note: Necessary no-voltage protection and short circuit protection are provided

for all elements. Pl serves as master stop.

mate STILE

220V, SOHZ

‘MOTOR

=> 15 ww, 1000 RPM

i 2 7 69 0 2

e porkzontas vertican Bowen exc CLAMP _DECLAMP. TIME DELAY VALVE, INDICATOR

it Spunar wie O80 SECS

‘DoveLE SoLENGLvE ounce ‘socenow wive $2? SES uc preseune

ON-CLAMP. ON-DECLAMP on-moH

i. Loe [RO] WS Sees, Pac teune

fue fropne]

{712 elo. [8 [No]Nc]

i EE 7 ra{- wst [21 fra] inst

1 Ee 70) Fae

_ =[= i == = far] pevav

Fg. 29

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- E Weight CalculationDocument20 pagesE Weight CalculationAvish Shah100% (1)

- Radiation Shield ThicknessDocument4 pagesRadiation Shield ThicknessAvish ShahNo ratings yet

- Radiation Shield ThicknessDocument4 pagesRadiation Shield ThicknessAvish ShahNo ratings yet

- Radiography Testing: RT PrincipleDocument6 pagesRadiography Testing: RT PrincipleAvish ShahNo ratings yet

- 2 Wedge Fire Clay RefractoriesDocument2 pages2 Wedge Fire Clay RefractoriesAvish ShahNo ratings yet

- Tjm-Ifb-Series - Eng - Fire Insulation BrickDocument2 pagesTjm-Ifb-Series - Eng - Fire Insulation BrickAvish ShahNo ratings yet

- A-Hydraulic Power SupplyDocument4 pagesA-Hydraulic Power SupplyAvish ShahNo ratings yet

- C-680 AstmDocument15 pagesC-680 AstmAvish ShahNo ratings yet

- C-Hydrostatic TransmissionDocument3 pagesC-Hydrostatic TransmissionAvish ShahNo ratings yet

- D-Control ValvesDocument14 pagesD-Control ValvesAvish ShahNo ratings yet

- B-Graphical Symbols For Electrical CircuitsDocument4 pagesB-Graphical Symbols For Electrical CircuitsAvish ShahNo ratings yet

- Odp OdpsDocument3 pagesOdp OdpsAvish ShahNo ratings yet

- Parameter Annotation Value UnitDocument3 pagesParameter Annotation Value UnitAvish ShahNo ratings yet

- A-Cylindrical Grinding MachineDocument2 pagesA-Cylindrical Grinding MachineAvish ShahNo ratings yet

- B-Hydraulic Fluids and Fluid FlowDocument8 pagesB-Hydraulic Fluids and Fluid FlowAvish ShahNo ratings yet

- UntitledDocument2 pagesUntitledAvish ShahNo ratings yet

- Mechanical Power Transmission Products: +91-9870809150 Mumbai, IndiaDocument10 pagesMechanical Power Transmission Products: +91-9870809150 Mumbai, IndiaAvish ShahNo ratings yet

- LV Motors: IE2 Safe Area: Reliable - Long Las NGDocument16 pagesLV Motors: IE2 Safe Area: Reliable - Long Las NGAvish ShahNo ratings yet

- HDP SERIES - Double Acting JackDocument1 pageHDP SERIES - Double Acting JackAvish ShahNo ratings yet

- Screw Jack, Bevel Gearbox ManufacturerDocument20 pagesScrew Jack, Bevel Gearbox ManufacturerAvish ShahNo ratings yet

- Alm 75Document1 pageAlm 75Avish ShahNo ratings yet

- Cyridrical Shell CalculationDocument2 pagesCyridrical Shell CalculationAvish ShahNo ratings yet