Professional Documents

Culture Documents

Untitled

Uploaded by

Alan Ooi0 ratings0% found this document useful (0 votes)

6 views1 pageThe document outlines 13 operations for machining a part including: parting, facing, turning, milling, engraving, inserting helicoils, lapping, deburring, cleaning, and packaging. Key steps include clamping the part for turning and facing operations, finishing the outer and inner diameters within tolerance, cutting grooves and steps to specified depths, engraving identification and drilling side holes using a macro program, inserting helicoils and checking them with a torque wrench, lapping and cleaning the part, and final packaging after quality control.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

TXT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document outlines 13 operations for machining a part including: parting, facing, turning, milling, engraving, inserting helicoils, lapping, deburring, cleaning, and packaging. Key steps include clamping the part for turning and facing operations, finishing the outer and inner diameters within tolerance, cutting grooves and steps to specified depths, engraving identification and drilling side holes using a macro program, inserting helicoils and checking them with a torque wrench, lapping and cleaning the part, and final packaging after quality control.

Copyright:

© All Rights Reserved

Available Formats

Download as TXT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views1 pageUntitled

Uploaded by

Alan OoiThe document outlines 13 operations for machining a part including: parting, facing, turning, milling, engraving, inserting helicoils, lapping, deburring, cleaning, and packaging. Key steps include clamping the part for turning and facing operations, finishing the outer and inner diameters within tolerance, cutting grooves and steps to specified depths, engraving identification and drilling side holes using a macro program, inserting helicoils and checking them with a torque wrench, lapping and cleaning the part, and final packaging after quality control.

Copyright:

© All Rights Reserved

Available Formats

Download as TXT, PDF, TXT or read online from Scribd

You are on page 1of 1

S929482-REV3

OP1 - PARTING

BIG ROD WITH HOLLOW

CLAMP WITH FIXTURE (ID CLAMPING)

FACE OD & ID LEAVE 8MM STOCK

THICKNESS LEAVE 1.5/2MM

OP2 FACING

CONTROL FLATNESS FOR TAPING OP2

OP2 - OD ID FIN & GROOVING

GUIDE PART OD (GUIDING WILL LOOSE BCUZ OF DISTORTION)

FINISHING OD & ID

GROOVING DEEPER TO MAXIMUM TOLERANCE

THICKNESS FACE APPORX 0.2

OP3- TURNING STEP

GUIDE ID

TURNING STEP FIN DEEPER 0.1

THICKNESS LEAVE 0.15

OP4 - MILLING TAP & DRILL

OP5 - MILLING OPEN SLOT & 30 ANGLE CHAMFER

OP6- ENGRAVING & SIDE HOLE

GUIDE WITH FIXTURE (DOVELPIN) OUTSIDE MACHINE FOR MARKING

MACHINE GUIDE WITH DOVEL PIN ( ENGRAVE SIDE & HOLE SIDE)

USING MACRO PROGRAM FOR ENGRAVE

OP7 - INSERT HELICOIL & CHECKING

CHECKING DONE UNDER (CCTV)

-HELICOIL CHECKING

-TORQUE WRENCH CHECKING

OP8 - FACING GROOVE SIDE (-0.05)

OP9 - FACING STEP SIDE (-0.1)

OP10 - LAPPING AFTER QC CHECKING

OP11 - DEBURRING

OP12 - CLEANING

LIQUIDNOT - CITRANOT - DISTILLED WATER - IPA

(CITRANOT AND DISTILLED WATER CAN SKIP IF NO LAPPING)

OP13 - PACKAGING (AFTER QC FINAL CHECK)

You might also like

- Solid-Body Guitar PlanDocument1 pageSolid-Body Guitar PlanLucioMerlo100% (4)

- Harrison Raven Abridged ManualDocument52 pagesHarrison Raven Abridged Manualhansonian100% (1)

- Ap Racing Ibiza Cupra cp6607-30cd - Sheet1Document1 pageAp Racing Ibiza Cupra cp6607-30cd - Sheet1Gabriele BertaggiaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- AmvexCatalog SOTDocument28 pagesAmvexCatalog SOTSergio Adolfo Flores CabezasNo ratings yet

- IAI 05 RC General CJ0203-2A P371-416 GripperDocument46 pagesIAI 05 RC General CJ0203-2A P371-416 GripperElectromateNo ratings yet

- Process Parameter (Autosaved) DEE1Document6 pagesProcess Parameter (Autosaved) DEE1DeepakNo ratings yet

- DefDocument4 pagesDefPeter100% (3)

- Spinning Training ReprotDocument62 pagesSpinning Training ReprotPranav Sharma100% (2)

- Omr Na Hn12ka02Document4 pagesOmr Na Hn12ka02seaqu3stNo ratings yet

- Dyadic Systems 2011 CatalogDocument16 pagesDyadic Systems 2011 CatalogServo2GoNo ratings yet

- Final WordDocument27 pagesFinal WordShaswata BoseNo ratings yet

- Final Symbol List Testing LineDocument4 pagesFinal Symbol List Testing LineSHUBHAM KUMARNo ratings yet

- Inverter Abb - Acs800Document7 pagesInverter Abb - Acs800dorinplNo ratings yet

- Bill of Material of 1500cfmDocument6 pagesBill of Material of 1500cfmSudipta DeyNo ratings yet

- DAEWOO DTCDocument8 pagesDAEWOO DTCMinh HangNo ratings yet

- Listino 1 - Imesa English 2008Document5 pagesListino 1 - Imesa English 2008machine_toolsNo ratings yet

- Ordering Information: Text Text DIP Switch (Rotary Type) - A6R/A6RV DIP Switch (Rotary Type) - A6C/A6CVDocument4 pagesOrdering Information: Text Text DIP Switch (Rotary Type) - A6R/A6RV DIP Switch (Rotary Type) - A6C/A6CVNiklasNo ratings yet

- Emtex Machinery Pvt. LTDDocument2 pagesEmtex Machinery Pvt. LTDPrasanna kumar subudhiNo ratings yet

- Manual Grua INST-19441-0999Document52 pagesManual Grua INST-19441-0999oadriano06No ratings yet

- FabricationDocument50 pagesFabricationashishghadiya75% (16)

- OGM BrochureDocument10 pagesOGM BrochureMoustaffaNo ratings yet

- Operaciones Herramientas - Llavero USADocument3 pagesOperaciones Herramientas - Llavero USAAylin EscobarNo ratings yet

- Lohia Corps Limited ReportDocument23 pagesLohia Corps Limited ReportAnkit Patel100% (1)

- Service Manual: SpecificationDocument88 pagesService Manual: SpecificationAipok SolamenteNo ratings yet

- Service Equipment and Supplies: 219-5890 FILM GPDocument9 pagesService Equipment and Supplies: 219-5890 FILM GPjohnnyNo ratings yet

- 118 QTN - CMT - Mauritius - RSPM With Individual Drive - 200817Document10 pages118 QTN - CMT - Mauritius - RSPM With Individual Drive - 200817Hardik A ShahNo ratings yet

- Op 27Document20 pagesOp 27Udaya Kumar KarnamNo ratings yet

- Spmidtp60-Setup ProceduresDocument4 pagesSpmidtp60-Setup ProceduresZarana BhattNo ratings yet

- Dyadic Systems 2011 CatalogDocument16 pagesDyadic Systems 2011 CatalogElectromateNo ratings yet

- Certificate: Shri Leeladhar Pal, JR - Officer Plate Mill (Elect.), Bhilai Steel Plant, BhilaiDocument51 pagesCertificate: Shri Leeladhar Pal, JR - Officer Plate Mill (Elect.), Bhilai Steel Plant, BhilaiAditya SinghNo ratings yet

- Altronic Cpu-95 Ignition System Application List Medium Engines, 2-18 Cylinders FORM CPU-95 AL 1-02Document11 pagesAltronic Cpu-95 Ignition System Application List Medium Engines, 2-18 Cylinders FORM CPU-95 AL 1-02dg_cd7340No ratings yet

- Oem Gardner Denver Pz-11Document8 pagesOem Gardner Denver Pz-11caballero_tigre100% (1)

- Versions: OMR Hydraulic MotorDocument30 pagesVersions: OMR Hydraulic MotortorrematicNo ratings yet

- DM WaterDocument61 pagesDM WaterAmitraja DasNo ratings yet

- Elektro KomponenDocument150 pagesElektro KomponenRiky HidayatNo ratings yet

- AGE Catalogue FebDocument56 pagesAGE Catalogue FebsitewebsaNo ratings yet

- Samson Sound SystemDocument30 pagesSamson Sound Systemtadesse_woudnehNo ratings yet

- Samsung ML 1650exploded View & Part List PDFDocument11 pagesSamsung ML 1650exploded View & Part List PDFcataroxiNo ratings yet

- Ak20 e CatalogDocument4 pagesAk20 e CatalogsaravanaplusNo ratings yet

- Mc-909 Service NotesDocument49 pagesMc-909 Service NotesGenilson Dias GomesNo ratings yet

- SN74LS173NDocument7 pagesSN74LS173NMozz WildeNo ratings yet

- 124 Code BookDocument21 pages124 Code BookYuriPasenkoNo ratings yet

- Libro de Codigod de PermcoDocument21 pagesLibro de Codigod de Permcotecnicomineria14060No ratings yet

- 1444800103346Document3 pages1444800103346Anonymous KWnm6SLnn1No ratings yet

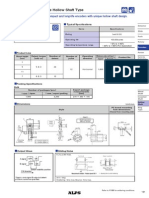

- 18mm Size Insulated Shaft Type: Absolute Type Achieving High Water Resistance and Heavy TorqueDocument4 pages18mm Size Insulated Shaft Type: Absolute Type Achieving High Water Resistance and Heavy TorqueshyhuNo ratings yet

- Spinning With Technical Acess: by Eshan Bansal Department of Textile Engineering Gzs Ptu Campus BathindaDocument32 pagesSpinning With Technical Acess: by Eshan Bansal Department of Textile Engineering Gzs Ptu Campus BathindaMehzabeen ShahidyNo ratings yet

- CHM-18XX Service Manual RevA 2Document30 pagesCHM-18XX Service Manual RevA 2stereojos86No ratings yet

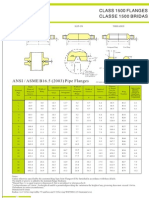

- Flanges 2Document15 pagesFlanges 2chicotonyxdNo ratings yet

- 699 Pressure Sensor PDFDocument5 pages699 Pressure Sensor PDFEnriqueQNo ratings yet

- 10mm Size Hollow Shaft Type: A Series of Compact and Long-Life Encoders With Unique Hollow Shaft DesignDocument3 pages10mm Size Hollow Shaft Type: A Series of Compact and Long-Life Encoders With Unique Hollow Shaft DesignshyhuNo ratings yet

- Cupling Gear 02Document22 pagesCupling Gear 02Ilse Achanty Barradas100% (1)

- LPKF ProtoMat S103Document2 pagesLPKF ProtoMat S103jhonny639No ratings yet

- Dial Gauge DigitalDocument21 pagesDial Gauge DigitalSheikh ZakirNo ratings yet

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet