Professional Documents

Culture Documents

Acoustic Emission Inspection of Fibre Reinforced Composite Structures Oct 2013

Uploaded by

ffOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Acoustic Emission Inspection of Fibre Reinforced Composite Structures Oct 2013

Uploaded by

ffCopyright:

Available Formats

Prevent Failures of Fiber Reinforced Plastic

Structures Using Diagnostic Acoustic Emission

Technology

Integrity Diagnostics provides inspection and monitoring services of fiber reinforced

plastic structures and pressure equipment during operation using Diagnostic Acoustic

Emission (DAE) technology. DAE allows detection of delamination growth, matrix

cracking, and fiber breakage under real operational stress conditions. During operation,

operational issues causing flaw initiation and development are often identified. DAE

detects internal and surface breaking flaws with no limitation while effectively locating

flaws along the piping or vessels. Periodic or continuous monitoring of revealed flaws

alerts when repair or replacement is required.

Proven experience of Integrity Diagnostics

Monitoring of FRP acid line

includes inspection and monitoring of wide

range of fiber reinforced plastic structures in

different countries, particularly:

• FRP piping (water, acid and other)

• FRP pressure vessels

• FRP storage tanks

• Aerospace composite overlap pressure

vessels with metal liners

• FRP structures

DAE Unique Advantages – Increased Safety

with Excellent Money Saving

100% examination of structure

No need to evacuate product or clean

Reliable detection of flaws, leaks, and

evaluation of flaw propagation rate

Differentiating between developing and non-developing flaws

Quantitative long-term monitoring of flaws

Prioritization of structures for maintenance and repair

Acoustic Emission monitoring of FRP piping

What is Acoustic Emission?

Acoustic emission is a phenomenon of sound and ultrasound (stress) wave radiation in

materials that undergo deformation or fracture processes.

Crack, delamination growth, fiber breakage Epoxy matrix cracking AE signal

in stressed composite materials results in a fast

release of potential energy in form of stress

waves with frequencies typically between 50

kHz and 1 MHz. These waves propagate along

the structure for distances of several feet and

are detected by piezoelectric sensors. Special

analysis of detected AE waves is then

performed to locate acoustic emission flaw

sources, identify flaw type, evaluate rate of

flaw propagation and it sensitivity to

load/stress/operational changes.

Multi-channel AE System AE sensors during monitoring of Reverse-Osmosis

FRP pressure vessel

Acoustic Emission Standardization

Acoustic Emission is one of the standard non-destructive test methods with several dozen

standards, procedures, and test methods issued by various international organizations

such as ASTM, ASME and others. Here are some standards, codes and documents related

to use of Acoustic Emission technology:

ASME

1. ASME STP-PT-021 – Non Destructive Testing and Evaluation Methods for Composite Hydrogen

Tanks.

2. ASME STP-PT-023 – Guidelines for In-service Inspection of Composite Pressure Vessels.

3. ASME Standard: Section X, Fiber-Reinforced Plastic Pressure Vessels.

4. ASME Standard: Section V, Article 11, Subsection A, Section V, Boiler and Pressure Vessel

Code, Acoustic Emission Examination of Fiber-Reinforced Plastic Vessels.

5. ASME Standard: Section V, Article 13, Boiler & Pressure Vessel Code, Continuous Acoustic

Emission Monitoring.

ASTM

1. ASTM E 1067 Standard Practice for Acoustic Emission Examination of Fiberglass Reinforced

Plastic Resin (FRP) Tanks/Vessels.

2. ASTM E 1118 Standard Practice for Acoustic Emission Examination of Reinforced Thermosetting

Resin Pipe (RTRP).

3. ASTM E 2191 Standard Practice for Examination of Gas-Filled Filament-Wound Composite

Pressure Vessels Using Acoustic Emission

4. ASTM E 1888 / E 1888M Standard Practice for Acoustic Emission Examination of Pressurized

Containers Made of Fiberglass Reinforced Plastic with Balsa Wood Cores.

5. ASTM E 2478 Standard Practice for Determining Damage-Based Design Stress for Fiberglass

Reinforced Plastic (FRP) Materials Using Acoustic Emission.

6. ASTM E 2076 Standard Test Method for Examination of Fiberglass Reinforced Plastic Fan Blades

Using Acoustic Emission.

7. ASTM E 2661 / E 2661M-10 Standard Practice for Acoustic Emission Examination of Plate-like

and Flat Panel Composite Structures Used in Aerospace Applications.

8. ASTM WK29034 (in preparation) New Practice for Examination of the Composite Overwrap in

Filament Wound Pressure Vessels Used in Aerospace Applications by Nondestructive Testing.

9. ASTM E 1211 Standard Practice for Leak Detection and Location Using Surface-Mounted

Acoustic Emission Sensors.

10. ASTM E 569 Standard Practice for Acoustic Emission Monitoring Of Structures during

Controlled Stimulation.

11. ASTM E 1316 Terminology for Nondestructive Examinations.

12. ASTM E 2374 Guide for Acoustic Emission System Performance Verification.

You might also like

- Understanding Acoustic Emission TestingDocument400 pagesUnderstanding Acoustic Emission TestingSivaraman VisvanathanNo ratings yet

- Accostic Emmsion TestDocument8 pagesAccostic Emmsion TestShyam KapateNo ratings yet

- Acoustic Emission Inspection of Petroleum Tanks and Piping May 2016Document7 pagesAcoustic Emission Inspection of Petroleum Tanks and Piping May 2016Eng MBNo ratings yet

- AE Standards 1309Document10 pagesAE Standards 1309vrapciudorianNo ratings yet

- Astm e 1736Document5 pagesAstm e 1736EdwinMauricioMacabeoNo ratings yet

- Acoustic EmissionDocument10 pagesAcoustic Emissionzamaniu1No ratings yet

- 12tha PCNDT 2006 AnáliseDanosEmGeralUsoEmissõesAcústicas Martin&DimopoulosDocument11 pages12tha PCNDT 2006 AnáliseDanosEmGeralUsoEmissõesAcústicas Martin&DimopoulosClovis GonzattiNo ratings yet

- 1 s2.0 S0142941804000030 MainDocument5 pages1 s2.0 S0142941804000030 MainAbdallah AbdalFatah Mohamed MohamedNo ratings yet

- Astm E2863 17Document4 pagesAstm E2863 17Mohamed AboelkhierNo ratings yet

- ASTM E 90 09 StandardsDocument15 pagesASTM E 90 09 StandardsNagwan Qassem100% (2)

- Acoustic EmissionsDocument12 pagesAcoustic Emissionsharsha02.vardhanNo ratings yet

- SW2008.Critical Comparison of Ultrasonic Pile Testing StandardsDocument5 pagesSW2008.Critical Comparison of Ultrasonic Pile Testing StandardsMansourLassouedNo ratings yet

- Astm E154 PDFDocument7 pagesAstm E154 PDFIshtiaq Hussain100% (1)

- F1875 1479757-1Document6 pagesF1875 1479757-1Thaweekarn ChangthongNo ratings yet

- Astm D1527Document8 pagesAstm D1527Hernando Andrés Ramírez GilNo ratings yet

- F2686-14 Standard Specification For Glass Fiber Reinforced Thermoplastic PipeDocument8 pagesF2686-14 Standard Specification For Glass Fiber Reinforced Thermoplastic Pipemasoud132No ratings yet

- Análisis de CasoDocument6 pagesAnálisis de CasoSol AngelNo ratings yet

- D 1527 - 99 Rde1mjctukveDocument11 pagesD 1527 - 99 Rde1mjctukveHumberto GutierrezNo ratings yet

- Nondestructive Testing Standards PDFDocument9 pagesNondestructive Testing Standards PDFvelu50% (2)

- E213.1210479-1 Ultrasonido en Tuberias de MetalDocument11 pagesE213.1210479-1 Ultrasonido en Tuberias de Metaljonathan marin navarroNo ratings yet

- ASTM-E84-21a Drafting The Hanges of RevisionDocument12 pagesASTM-E84-21a Drafting The Hanges of Revisionfalmubarak RnoNo ratings yet

- ASTM Acceptance CriteriaDocument10 pagesASTM Acceptance Criteriabeshnu garanaikNo ratings yet

- Suggested Modifications To ASTM E477Document14 pagesSuggested Modifications To ASTM E477Jerry LillyNo ratings yet

- F 1624 - 99 Rje2mjqtukveDocument8 pagesF 1624 - 99 Rje2mjqtukveJuanNo ratings yet

- Acoustic Emission Data Analysis To EvaluDocument13 pagesAcoustic Emission Data Analysis To EvaluHridya LalNo ratings yet

- Use of Acoustic Emission To Detect Localised Corrosion Philosophy of Industrial Use, Illustrated With Real ExamplesDocument6 pagesUse of Acoustic Emission To Detect Localised Corrosion Philosophy of Industrial Use, Illustrated With Real ExamplesGonzalo TelleríaNo ratings yet

- F 2263 - 03 RjiynjmDocument7 pagesF 2263 - 03 RjiynjmLuis Emilio BosioNo ratings yet

- Architectural Testing, Inc. (An Intertek Company) : This Is To Attest ThatDocument20 pagesArchitectural Testing, Inc. (An Intertek Company) : This Is To Attest ThatEdward CNo ratings yet

- Acoustic EmissionDocument6 pagesAcoustic EmissionAziz MohamedNo ratings yet

- Astm D 470Document25 pagesAstm D 470Dvmc Zona Tacuba100% (3)

- Nondestructive Testing Standards - Standards Products - Standards & Publications - Products & ServicesDocument10 pagesNondestructive Testing Standards - Standards Products - Standards & Publications - Products & ServicesSuleman JahangirNo ratings yet

- ASTM D470. Crosslinked Insulations and Jackets For Wire and Cable1Document25 pagesASTM D470. Crosslinked Insulations and Jackets For Wire and Cable1sanrris4503090% (1)

- Camx 2015 Vaidya UabDocument11 pagesCamx 2015 Vaidya UabJuNeng NigLtdNo ratings yet

- ASTM D3754 Tuberia de Fibra de VIdirio para Sistemas Industriales y A PresiónDocument14 pagesASTM D3754 Tuberia de Fibra de VIdirio para Sistemas Industriales y A PresiónalexagoNo ratings yet

- Selection of Standards On Environmental Acoustics: Standard Guide ForDocument11 pagesSelection of Standards On Environmental Acoustics: Standard Guide ForAhmad Zubair RasulyNo ratings yet

- Astm E84 21Document12 pagesAstm E84 21Mariana Rodriguez IbarraNo ratings yet

- Laboratory Corrosion Testing PDFDocument7 pagesLaboratory Corrosion Testing PDFeid elsayedNo ratings yet

- F 1828 - 97 - Rje4mjgDocument6 pagesF 1828 - 97 - Rje4mjgAdrian GonzalezNo ratings yet

- Application Notes: Phase Shift Test For Bond IntegrityDocument3 pagesApplication Notes: Phase Shift Test For Bond IntegrityPDDELUCANo ratings yet

- Astm EDocument9 pagesAstm EAnonymous KA4rLc9XBwNo ratings yet

- Acoustic Emission Testing - 231130 - 142719Document3 pagesAcoustic Emission Testing - 231130 - 142719ST VANDECKANo ratings yet

- 2.forensic Structural InvestigationDocument17 pages2.forensic Structural InvestigationRevanth Local MokkapatiNo ratings yet

- Durability Testing For 100 Year Lifetime For Buried Non Pressure Plastic PipesDocument11 pagesDurability Testing For 100 Year Lifetime For Buried Non Pressure Plastic Pipesgail-doneganNo ratings yet

- Astm e 1067 96 Standard Practice For Acoustic Emission ExamiDocument17 pagesAstm e 1067 96 Standard Practice For Acoustic Emission ExamiGabriel GarciaNo ratings yet

- Astm D2996 17Document4 pagesAstm D2996 17Zakaria MOKARAMNo ratings yet

- Laboratory Simulation of Corrosion Damage in Reinforced ConcreteDocument9 pagesLaboratory Simulation of Corrosion Damage in Reinforced Concretejorge mario martinez gameroNo ratings yet

- Comparison of Asme Specifications and European StandardsDocument20 pagesComparison of Asme Specifications and European StandardsAlper Emrah Sakalsız100% (2)

- Developments in Equipment and Standards For Testing Porosity in CoatingsDocument11 pagesDevelopments in Equipment and Standards For Testing Porosity in Coatingsmfazl33No ratings yet

- ASTM F876 - 13 PexDocument11 pagesASTM F876 - 13 PexMuhammad Gullraiz ChohanNo ratings yet

- Guide To Insulation Product Specifications: ASTM Guides, Practices and Test MethodsDocument24 pagesGuide To Insulation Product Specifications: ASTM Guides, Practices and Test MethodszaheermechNo ratings yet

- Ea230 - Astm E2357 - E331Document11 pagesEa230 - Astm E2357 - E331Deco DluxeNo ratings yet

- MP 20 PDFDocument14 pagesMP 20 PDFAshraf TomizehNo ratings yet

- Astm F477Document4 pagesAstm F477Hernando Andrés Ramírez Gil100% (1)

- Acousto-Ultrasonic Assessment of Filament-Wound Pressure VesselsDocument6 pagesAcousto-Ultrasonic Assessment of Filament-Wound Pressure VesselsJ MrNo ratings yet

- E 2231 - 02 - RtiymzeDocument8 pagesE 2231 - 02 - Rtiymzemercab15No ratings yet

- D 2282 - 99 - Rdiyoditukve PDFDocument8 pagesD 2282 - 99 - Rdiyoditukve PDFAndre CasteloNo ratings yet

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesFrom EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNo ratings yet

- Non-destructive Testing and Evaluation of Civil Engineering StructuresFrom EverandNon-destructive Testing and Evaluation of Civil Engineering StructuresJean-Paul BalayssacNo ratings yet

- Chapter 2 NewDocument50 pagesChapter 2 NewKishore BhatNo ratings yet

- Aiipl Brochure 1221Document12 pagesAiipl Brochure 1221SidhuRamNo ratings yet

- Career ObjectiveDocument2 pagesCareer ObjectiveSandeep RedhuNo ratings yet

- Redundant and Voting SystemDocument10 pagesRedundant and Voting SystemGnanaseharan ArunachalamNo ratings yet

- CV AshutoshDocument2 pagesCV AshutoshAshutoshNo ratings yet

- Resume PremDocument4 pagesResume PrempremNo ratings yet

- CH 14Document25 pagesCH 14nipasNo ratings yet

- Mass ConcreteDocument4 pagesMass ConcreteTufan Kırık0% (1)

- Slab-On-Grade Reinforcing DesignDocument9 pagesSlab-On-Grade Reinforcing DesignAdam GreenlawNo ratings yet

- Steam Tracing 101Document2 pagesSteam Tracing 101fawmer61100% (1)

- CS Holding Down Bolt Design To Eurocode 2Document4 pagesCS Holding Down Bolt Design To Eurocode 2Vance KangNo ratings yet

- R 19 B.tech ChemicalDocument189 pagesR 19 B.tech ChemicalBeril NavinNo ratings yet

- The Ultimate Electrical Engineering Book List With Emphasis On ElectromagneticsDocument15 pagesThe Ultimate Electrical Engineering Book List With Emphasis On ElectromagneticsAsdf FdsaNo ratings yet

- Final Year Building Project PresentationDocument48 pagesFinal Year Building Project PresentationSudeen ShresthaNo ratings yet

- Effect of Project-Based Learning On Development of Students' Creative ThinkingDocument19 pagesEffect of Project-Based Learning On Development of Students' Creative ThinkingelenaNo ratings yet

- Mostafa IsmaelDocument1 pageMostafa Ismaelmostafa ismaelNo ratings yet

- Introduction To Korea Building Code (Draft)Document5 pagesIntroduction To Korea Building Code (Draft)rezaNo ratings yet

- CV. Muhammad Bin SurpadiDocument6 pagesCV. Muhammad Bin SurpadiShaiful Annuar50% (2)

- BPV Certification Form Checklist AccreditationDocument13 pagesBPV Certification Form Checklist AccreditationAnonymous XBq5J84No ratings yet

- Lecture 10 (Process Optimization Introduction)Document15 pagesLecture 10 (Process Optimization Introduction)Hoàng KhôiNo ratings yet

- Industry 4.0Document26 pagesIndustry 4.0Zaenal Arifin100% (1)

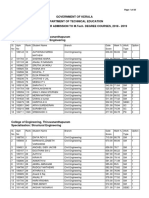

- Kerala MTech SeatDocument63 pagesKerala MTech Seattirursachin0% (1)

- CHAPTER 1 - Introduction To EIEDocument34 pagesCHAPTER 1 - Introduction To EIEBright KnightNo ratings yet

- Necessity For Ethics in Social EngineeringDocument14 pagesNecessity For Ethics in Social EngineeringMatt BaileyNo ratings yet

- 3rd SemDocument29 pages3rd SemSimanchal PrustyNo ratings yet

- Microsoft Word - SIGMA 2018 - 6!6!2017Document2 pagesMicrosoft Word - SIGMA 2018 - 6!6!2017er_aman11No ratings yet

- HK LPG PracticesDocument97 pagesHK LPG Practicesringo limNo ratings yet

- Linear Analysis of Guyed MastDocument6 pagesLinear Analysis of Guyed MastPankaj_Taneja_9684No ratings yet

- Power and Distribution Transformers Sizing Calculations 2Document10 pagesPower and Distribution Transformers Sizing Calculations 2hashimelecNo ratings yet

- WL 5200 (PLC)Document2 pagesWL 5200 (PLC)smbcardsNo ratings yet