Professional Documents

Culture Documents

Brida WN Ac S40 150 A105 RF 6 MTF

Brida WN Ac S40 150 A105 RF 6 MTF

Uploaded by

Fercomil S.A.SOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Brida WN Ac S40 150 A105 RF 6 MTF

Brida WN Ac S40 150 A105 RF 6 MTF

Uploaded by

Fercomil S.A.SCopyright:

Available Formats

A01

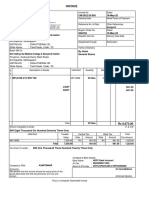

COMPANY WITH METALFAR PRODOTTI INDUSTRIALI SPA COMPANY WITH

MANAGEMENT SYSTEM 23861 CESANA BRIANZA (LC) - ITALY MANAGEMENT SYSTEM

CERTIFIED BY DNV GL VIA G. PARINI, 28 CERTIFIED BY DNV GL

= ISO 9001 = PHONE + 39 031 655441 - FAX +39 031 655149 = ISO 9001 =

= ISO 14001 = certificate@metalfaritaly.com = ISO 14001 =

A02

INSPECTION CERTIFICATE EN 10204:2004 / 3.1 Nr A03 2020-C_MFF-02872 Data / Dated 02.10.2020 Z02

A06 A07

GRANADA S.A. Ordine / PO PO-270

CARRERA 40 No. 10-15 - TEL. (571) 7954080 Item 035

111411 BOGOTA` CO DDT / Delivery note 2020-3E301-0002700

Packing List 2020-3E401-0002721

A08

Fattura / Invoice 2020-3E401-0002721

Ns. rif. / Our ref. 2020-3E201-0002146-0035

B07 B07 B08 B01 - (B09 - B11)

Cod. colata Nr. colata Quantità Descrizione

Heat Code Heat Nr Quantity Description

20/45618 97,00 W/N 150 RF 6" STD A105N

B02

Mat. in acc. a / Mat. in acc. to ASTM A105M - 18 ,ASME SA105M-19 ASME CODE SECT. II, PART A, ED. 2019

NACE MR-0175/2015 ISO 15156-2 :2015

NACE MR-0103/2015 ISO 17945 :2015

Q.A.S.IN ACCORD.WITH PRESS.EQUIPM.DIRECT.2014/68/EU(PED) ANNEX I,PARAGRAPH 4.3

CERT.4687-2014-CE-ITA-DNV GL

B02

Ann. mat. / Mat. remarks FULLY KILLED STEEL AND FINE GRAIN PRACTICED

(C71 - C92)

Elementi / Elements C Si Mn S P Cr Ni Mo Ti Cu V Nb N

LADLE ANALYSIS 0,180 0,210 1,030 0,008 0,011 0,120 0,070 0,010 0,020 0,130 0,001 0,001 0,010

PRODUCT ANALYSIS 0,183 0,224 1,046 0,005 0,007 0,129 0,055 0,014 0,017 0,112 0,003 0,002 0,007

Al B Ca CE LF CE SF F1 F2 PREN

LADLE ANALYSIS 0,030 0,0002 0,001 0,391 0,352 0,331 0,130 --

PRODUCT ANALYSIS 0,034 0,0000 0,001 0,398 0,357 0,313 0,143 --

CE LF=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15 CE SF=C+(Mn/6) F1=Cu+Ni+Cr+Mo+V F2=Cr+Mo

Provetta Forma C10 C03

°C Snervamento>0,2% C11 Snervamento>1,0% C11 Rottura C12

Allungamento C13

Contrazione C15

Test specimen Shape Yield Strength>0,2% Yield Strength>1,0% Tensile Elongation Reduction of area

Sez/Sect mm2 Gauge L.mm 1=O - 2= MPa MPa MPa % %

126,60 50,80 1 20 344,0 -- 529,0 37,0 64,0

DUREZZA / HARDNESSC22 RESILIENZA / IMPACT TEST

HBW Tipo/Type C40 Provetta / Test Specimen °C C03 1-Joule C42 2-Joule C42

3-Joule C42

Media/Average C43

156,0 ; 153,0 KV 10x10 mm 20 184 146 158 162,7

C70

Tratt. Term. / Heat treatment NORMALIZED AT 920 °C - COOLED IN STILL AIR GAS FURNACE

B14

Dim in acc. a / Dim. acc. to ASME/ANSI B16.5 -2017 ; ASME/ANSI B36.10M -2018 ; ASME/ANSI B16.25 -2017

Finitura / Roughness ASME/ANSI B46.1 -2019

RF FINISHING 125-250 µin AARH

Marcatura in acc. B06 Origine EUROPEAN UNION

ANSI/MSS SP-25-2018 Vis. & Dim. SATISFACTORY

Marking in acc. to Origin of Steel

Note / Notes 100% MANUFACTURED IN ITALY

MATERIAL IN ACCORDANCE WITH ORDER AND SPECIFICATION

A05 Z03 A04

UFFICIO CONTROLLO QUALITA' ENTE UFFICIALE DI COLLAUDO MARCHIO PRODUZIONE

QUALITY CONTROL DEPARTMENT INSPECTION AUTHORITY MANUFACTURER'S SYMBOL

S. Frigerio

Page 41 - 69

You might also like

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Contract Law Case SummariesDocument95 pagesContract Law Case SummariesNdovoi KikoNo ratings yet

- Lab - 1st - Semester 2017-18 Class IX ICTDocument10 pagesLab - 1st - Semester 2017-18 Class IX ICTrahimuddinNo ratings yet

- Consumer Adoption of Mobile Payment Services During COVID-19 - Extending Meta-UTAUT With Perceived Severity and Self-EfficacyDocument32 pagesConsumer Adoption of Mobile Payment Services During COVID-19 - Extending Meta-UTAUT With Perceived Severity and Self-EfficacyFaizan KhanNo ratings yet

- Research Article: A Comparative Analysis of The Top Ott Platforms in India Liya RajeshDocument18 pagesResearch Article: A Comparative Analysis of The Top Ott Platforms in India Liya RajeshPrathamesh DivekarNo ratings yet

- CSF 20Document9 pagesCSF 20Rafan KenNo ratings yet

- Lesson 1 - Introduction To Project ManagementDocument30 pagesLesson 1 - Introduction To Project ManagementJunaid RaiNo ratings yet

- BBCF4073 202201F1168 20220429054802Document10 pagesBBCF4073 202201F1168 20220429054802Tron TrxNo ratings yet

- LATIHAN4 CFM Imam SartonoDocument10 pagesLATIHAN4 CFM Imam Sartonoims.mercubuanaNo ratings yet

- According To Kanthaswamy BalasubramaniamDocument8 pagesAccording To Kanthaswamy BalasubramaniamAditya BatraNo ratings yet

- Designing A Survey QuestionnaireDocument4 pagesDesigning A Survey QuestionnaireRiala Teresa GalangNo ratings yet

- Checklist:: The 10 Leading Indicators That Predict Employee Safety EngagementDocument9 pagesChecklist:: The 10 Leading Indicators That Predict Employee Safety EngagementAsimNo ratings yet

- Creditors DebitorsDocument14 pagesCreditors DebitorsArpita DhalNo ratings yet

- Umeme FY2021 ResultsDocument2 pagesUmeme FY2021 ResultsTrial MeisterNo ratings yet

- Activity 2 FormationDocument4 pagesActivity 2 FormationCris TineNo ratings yet

- Impact of Rera On Real State in EldicoDocument94 pagesImpact of Rera On Real State in EldicosalmanNo ratings yet

- Final Annual Report For The Year2021 22Document304 pagesFinal Annual Report For The Year2021 22tech bhattjiNo ratings yet

- P B F S: Acked Ed Ume CrubbersDocument4 pagesP B F S: Acked Ed Ume CrubbersmadhuNo ratings yet

- Haba Kinderschule Contract 26 July 2022Document7 pagesHaba Kinderschule Contract 26 July 2022이제원No ratings yet

- Us Client User Guide KPMG ClaraDocument42 pagesUs Client User Guide KPMG Clarahitesh vallechaNo ratings yet

- Mba 109: Strategic Management Strategic Management Case FormatDocument2 pagesMba 109: Strategic Management Strategic Management Case FormatAndrea MercadoNo ratings yet

- DuPont Analysi - Playing The Numbers GameDocument5 pagesDuPont Analysi - Playing The Numbers GameJonathan David CHNo ratings yet

- Exam Financial ManagementDocument10 pagesExam Financial ManagementShrief MohiNo ratings yet

- HRM Chap. 7 International HRMDocument17 pagesHRM Chap. 7 International HRMyonasNo ratings yet

- The Growing Business of FoodTechDocument86 pagesThe Growing Business of FoodTechtamlqNo ratings yet

- Ipr - I PDFDocument38 pagesIpr - I PDFVenu Gopal gowdaNo ratings yet

- 2nd Part Bus485 ReportDocument13 pages2nd Part Bus485 ReportAffan AhmedNo ratings yet

- Accounting VoucherDocument1 pageAccounting Vouchersuplex suryaNo ratings yet

- Financial Accounting:: Lecturer:Agil AzizovDocument28 pagesFinancial Accounting:: Lecturer:Agil AzizovKəmalə AslanzadəNo ratings yet

- Business Requirement SpecificationDocument6 pagesBusiness Requirement SpecificationANIL SINGHNo ratings yet

- Transforming The Automotive Retail - Drivers For Customers' OmnichannelDocument15 pagesTransforming The Automotive Retail - Drivers For Customers' OmnichannelmakehaysshNo ratings yet