Professional Documents

Culture Documents

ALUP Largo Allegro 31-110 Sales Leaflet EN 6999640304

Uploaded by

Bosznay ZoltánOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ALUP Largo Allegro 31-110 Sales Leaflet EN 6999640304

Uploaded by

Bosznay ZoltánCopyright:

Available Formats

Largo & Allegro

Air Compressors

L ARGO & ALLEGRO 31-110

ALUP’s heritage

Founded in Germany in 1923, the company derives its

name of the automotive products that were manufactured

in the Köngen’ mechanical workshop where ALUP came

into existence: Auto-LUft-Pumpen. Only two years later,

the first range of piston compressors was being developed,

whilst in 1980 rotary screw compressors were added to the

product offer.

Over time, experience grew and innovation prospered,

leading to today’s high quality product portfolio. As such,

the name ALUP Kompressoren has become synonymous

with innovative technology blended with a strong sense

of tradition.

Today, ALUP Kompressoren is still operating out of its home

town Köngen, where everything started in 1923.

Driven by technology

Designed by experience

Discover what happens when a passion for

technology is fused with hands-on industrial

experience. Designs evolve towards more

practical installation and maintenance, giving you

the freedom to focus on your job. Product ranges

include the exact machine you need, with the

right options for your performance needs. Return

on investment is ensured, while your carbon

footprint shrinks. And, because we stay close to

our customers, we’re one step ahead when your

needs change.

2 LARGO & ALLEGRO 31-110

The power of the Largo & Allegro range

Largo & Allegro 31-110 screw compressors provide high-quality compressed air for a wide range

of industrial applications. The result of continuous investment in product development, Largo &

Allegro 31-110 compressors are built around three innovative features which make them stand out.

Superior efficiency

• In-house design compression elements.

• Direct drive transmission.

• High-efficiency radial cooling fan.

• IE3 / NEMA Premium Efficiency motor.

• Integrated air dryer

Intelligent control •

• Airlogic full colour 4.3 inch HD Touch display.

• Intelligent unload cycle control.

• Precise pressure control.

• Warning indicators.

• Graphical indication service plan.

• Built-in online monitoring.

Ultimate reliability and serviceability

• Proven designs

• Reputed brands

• Modular design.

• Extensive service support.

• Designed for harsh conditions and ambient

temperatures up to 46°C.

www.alup.com

LARGO & ALLEGRO 31-110 3

10 reasons to choose Alup

Check out these innovative features and see how they provide you with high efficiency,

ease of maintenance, low noise levels and outstanding cooling.

1. Element and drive train

• Gearbox technology ensuring outstanding

efficiency and continued reliability.

• Innovative design resulting in a smaller footprint.

2. High efficiency motors

• IE3 / NEMA Premium efficiency motor (standard on fixed 5

speed machines, optional on variable speed ones).

• IP55, insulation Class. 6 8

7

3. Radial fan

• Low power consumption &

reduced noise levels.

• Optimal cooling flow.

• Increased lifetime of oil,

consumables and compressor.

4. Standard enclosed intake filter

• Low noise levels thanks to design and position of filter.

• Improved FAD due to air intake positioning.

• High quality filtration to maximize oil quality and

protect your compression element.

5. Intelligent controller

• The full-colour Airlogic controller offers a user-friendly interface to access

all the compressor parameters, service notifications and events.

• The various control modes and intelligent algorithms allow

the compressor to automatically adapt to demand changes.

• Built-in online monitoring allows the user to follow up on the

compressor everywhere he goes.

4 LARGO & ALLEGRO 31-110

6. Solid inlet baffle

• Small installation footprint: the unit can be placed against a wall.

• Fitted with insulation foam to reduce noise.

• Optimized air flow for improved cooling.

• Added protection for the cooling fan.

7. In-house designed

oil separator vessel

• Integrated minimum

pressure valve (MPV)

eliminates risk of leakage.

• Long lifetime thanks to

cast iron parts.

• Designed for optimal

oil separation.

8. In-house designed inverter

• Integrated Imperium inverter for

Allegro 55-110

• Robust industrial design with IP5X

protection rating

• Compact, smart and user-friendly,

9 controlled by Air Control 5.1

• Installed in a separate cubicle to ensure

optimal cooling and easy maintenance

9. Separate coolers

3 • Separate oil and air cooler for high-

quality cooling and long lifetime of

4 the coolers.

• Gliding rails for easy and safe removal.

• Easy access for cleaning.

1 2

10. Improved motor cooling

• Separate cooling flow.

• Suitable for harsh conditions

and temperatures up to 46°C.

LARGO & ALLEGRO 31-110 5

Optimize your energy consumption

Did you know that energy costs represent about 70% of the total operating cost of your compressor

over a 5-year period? That’s why reducing the energy consumption of our compressed air installation

should be a major focus.

Variable speed technology

For the right application, variable speed technology, such as on the Allegro variable frequency drive compressor,

can cut the energy bill of your compressor by up to 35%. The Allegro reduces energy consumption in the

following ways:

• The variable frequency drive compressor matches air supply with demand therefore reducing energy

consumption when the demand is lower. If the demand is stable then the Airlogic² controller

guarantees a fixed set pressure.

• No unload cycles above 20% load.

• No peak current due to soft start.

77% energy 12% investment

Energy Consumption

Air demand

Energy consumption

consumption Air

Demand

3% installation

8% service

Energy Consumption

35% energy savings Air

Demand Air Dema

Variable

driven co

Load Unl

Savings

Air

Airdemand

Demand

Variablefrequency

Variable frequency

driven

drivencosts

costs

Loadunload

Load Unload costs

costs

Savings

Savings

How much energy could you save in your

existing compressor installation?

Contact us for an energy audit. We will measure the air demand

and energy consumption of your existing installation and generate

a detailed report at the end. Based on your specific situation we

can simulate and show how much your energy costs would reduce

with your new compressor.

6 LARGO & ALLEGRO 31-110

Energy recovery

75% of the heat

recoverable via 100% Total electrical When air is compressed, heat is formed. The excess

energy recovery energy consumption

heat can be captured with an energy recovery option

and channeled to other applications allowing you

to save energy and cut costs. The energy recovery

option integrates a heat exchanger on the oil circuit,

which heats up the continuously pressurized water

flow. The system is regulated automatically, and in

case of limited water cooling capacity, the standard

cooling system of the compressor will operate and

backup the energy recovery device.

Airlogic² T touchscreen controller

The new Airlogic² T controller is truly state-of-the-

art, maximizing user-friendliness, efficiency and

reliability. With a large 4,3” full-colour touchscreen

display and 30+ languages, smooth control is at your

fingertips. The integrated connectivity with remote

monitoring possibilities enables full insight into your

compressed air network and helps you to optimize

and save energy.

Control and monitoring features:

• Warning indications.

• Graphical indication service plan.

• Integrated ECO6i available as option to central control up to 6 compressors limiting the energy consumption

and equalizing running hours across your whole system.

• Online visualization of running conditions.

Icons

Connectivity is the future. The LARGO & ALLEGRO 31-110

comes fully prepared and enables you to benefit from

all the advantages of ICONS:

• Remote monitoring that helps you optimize your

compressed air system and save energy.

• On-time maintenance which optimizes costs and

ensures a longer machine life.

• Potential problems are recognized before they can

pose a threat to the continuity of your production.

LARGO & ALLEGRO 31-110 7

Central controller technology

For installations with multiple compressors, a costly cascade system with a wide pressure band

used to be the only way to operate. Additionally, the running hours of the compressors were not

synchronized making strategic servicing difficult. Install the ECOntrol6 or the integrated compressor

control (with a license) and get simple, central control to reduce system pressure and energy

consumption in installations of up to 4 or 6 compressors.

Control features

• Single pressure measurement point.

• Minimized pressure band.

• Stable system pressure.

• Equalization of running hours.

• Multiple IVR speed control.

• Clear and visual graphical display.

• Online monitoring and controlling possible.

Enhanced air quality

Many people do not realize that the operating environment can have a major impact on the air quality

at the compressor outlet. Even in a dedicated compressor house the inlet air can contain particulate or

moisture which can have a negative impact on the production.

Largo & Allegro 30-75 compressors are available with an integrated dryer option, which offers significant

advantages compared to a stand-alone dryer:

• Condensation removal at source minimizing pipework corrosion.

• Reduced footprint, up to 1/3rd of a stand-alone dryer.

• Intelligent dryer control, controlled by the Air Control 5.1.

• Higher operating temperatures compared to stand-alone.

• Single service visit, reducing maintenance costs.

• No installation cost.

8 LARGO & ALLEGRO 31-110

Options to optimize your operations

Every installation is different, therefore we offer you a

wide range of options to enable you to personalize your

Largo & Allegro 31-110 compressor to your needs.

Air quality

• Internal water separator - reduces up to 90%

of the condensate in the compressed air. (standard

on Largo 31-37-45)

• Automatic drain - ensures no air loss during

condensate removal (only in combination

with internal water separator).

• Tropical thermostatic valve - for use in humid

and hot conditions.

• High-efficiency air intake pre-filtration panel -

avoids dust entering the compression element,

protecting internal components and extending

the compressor lifetime.

Energy saving

• Energy recovery pack - recovers up to 75% of the

energy formed during the compressor process heat,

which can be used to heat up water for boilers,

showers etc.

Safety

• Wrong rotation direction control - protects the

compressor from possible damage when the power

supplied by the energy provider is unreliable.

• Water shut-off valve outside the canopy -

for water- cooled machines.

• The oil pre-heater - guarantees a certain oil

temperature in the oil vessel to avoid condensation.

Control and monitoring

• ECO 4/6i - integrated multiple compressor control

for 4/6 compressors.

• Remote monitoring - for additional convenience.

Available for Largo 31-37-45:

Extended lifetime oil & filters

• “Plus” option including 4000 hours oil combined with an air and oil filter with the same lifetime.

• “Extended” option including 8000 hours oil with a long lifetime oil filter. This will guarantee optimal

performance at all times.

LARGO & ALLEGRO 31-110 9

Technical data

Fixed Max. Reference Cooling Weight Compressed

Free Air Delivery Noise

speed working working Motor power air air output

@ reference conditions* level** std plus

version pressure pressure volume diameter

Model bar bar m³/h l/s cfm kW hp dB(A) m³/h kg kg "

LARGO 31 7.5 7 357 99 210 30 40 66 6660

8.5 8 324 90 190 30 40 66 6660

626 796 1"1/2

10 9.5 297 83 175 30 40 66 6660

13 12.5 255 71 150 30 40 66 6660

LARGO 37 7.5 7 419 116 247 37 50 67 6660

8.5 8 390 108 229 37 50 67 6660

683 853 1"1/2

10 9.5 367 102 216 37 50 67 6660

13 12.5 319 89 188 37 50 67 6660

LARGO 45 7.5 7 492 137 290 45 60 68 6660

8.5 8 465 129 273 45 60 68 6660

692 900 1"1/2

10 9.5 428 119 252 45 60 68 6660

13 12.5 375 104 221 45 60 68 6660

LARGO 55 7.5 7 601 167 354 55 75 70 9000

8.5 8 572 159 337 55 75 70 9000

1130 1403 2"

10 9.5 540 150 318 55 75 69 9000

13 12.5 447 124 263 55 75 69 9000

LARGO 75 7.5 7 774 215 456 75 100 71 12600

8.5 8 756 210 445 75 100 71 12600

1317 1590 2"

10 9.5 677 188 399 75 100 70 12600

13 12.5 582 162 343 75 100 70 12600

LARGO 76 7.5 7 882 245 519 75 100 69 12600

8.5 8 821 228 483 75 100 69 12600

1570 NA 2"

10 9.5 742 206 437 75 100 68 12600

13 12.5 629 175 370 75 100 68 12600

LARGO 90 7.5 7 986 274 581 90 125 70 14760

8.5 8 972 270 572 90 125 70 14760

1600 NA 2"

10 9.5 868 241 551 90 125 69 14760

13 12.5 721 200 425 90 125 69 14760

LARGO 110 7.5 7 1238 344 729 110 150 74 14760

8.5 8 1181 328 695 110 150 74 14760

1800 NA 2"

10 9.5 1073 298 632 110 150 73 14760

13 12.5 907 252 534 110 150 73 14760

* Unit performance measured according to ISO 1217, Annex C, latest edition.

** Noise level measured according to ISO 2151 with optional baffle.

All technical data for air-cooled machines without integrated dryer.

For technical data of water-cooled machines or machines with integrated dryer, please contact your local salesforce.

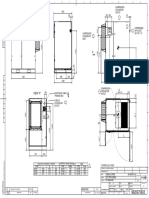

Dimensions Largo

Length Length Width Height

std plus

Model mm mm mm mm

LARGO 31

H LARGO 37 1555 2055 890 1790

LARGO 45

LARGO 55

1923 2773 1060 1630

LARGO 75

LARGO 76

2125 NA 1060 1630

LARGO 90

LARGO 110 2333 NA 1060 1630

W L

10 LARGO & ALLEGRO 31-110

Technical data

Inverter Min. free

Working

driven air delivery Max. free air delivery

pressure

version (7 bar) *

7 7 7 7 7 7 9.5 9.5 9.5 10 10 10 12.5 12.5 12.5 13 13 13

Model bar

m³/h l/s cfm m³/h l/s cfm m³/h l/s cfm m³/h l/s cfm m³/h l/s cfm m³/h l/s cfm

ALLEGRO 31 4-10 95 27 56 335 93 197 289 80 170 281 78 165 n.a. n.a. n.a. n.a. n.a. n.a.

4-13 83 23 49 291 81 171 289 80 170 289 80 170 236 66 139 229 64 135

ALLEGRO 37 4-10 118 33 69 414 115 244 364 101 214 353 98 208 n.a. n.a. n.a. n.a. n.a. n.a.

4-13 103 29 60 360 100 212 364 101 214 363 101 214 284 79 167 276 77 162

ALLEGRO 76 4-10 251 70 148 874 243 516 752 209 443 730 203 430 n.a. n.a. n.a. n.a. n.a. n.a.

4-13 211 59 124 742 206 437 752 209 443 751 209 442 629 175 370 610 169 359

ALLEGRO 90 4-10 282 78 166 990 275 583 846 235 498 821 228 483 n.a. n.a. n.a. n.a. n.a. n.a.

4-13 243 67 143 851 237 501 846 235 498 845 235 497 721 200 425 700 194 412

ALLEGRO 110 4-10 199 55 117 1145 318 674 1020 283 601 990 275 583 n.a. n.a. n.a. n.a. n.a. n.a.

4-13 167 46 98 960 267 565 954 265 562 952 264 561 883 245 520 857 238 504

* Unit performance measured according to ISO 1217, Annex C, latest edition.

** Noise level measured according to ISO 2151 with optional baffle.

All technical data for air-cooled machines without integrated dryer. For technical data of water-cooled machines or machines with

integrated dryer, please contact your local salesforce.

Noise Cooling Compressed

Motor level air Weight air output

power ** volume diameter

std plus

Model kW hp dB(A) m³/h "

kg kg

ALLEGRO 31 30 40 67 5400

840 1025 1"1/2

30 40 66 5400

ALLEGRO 37 37 50 68 5760

920 1105 1"1/2

37 50 67 5760

ALLEGRO 76 75 100 70 12600

1640 NA 2"

75 100 69 12600

ALLEGRO 90 90 125 71 14760

1670 NA 2"

90 125 70 14760

ALLEGRO 110 110 150 74 14760

1900 NA 2"

110 150 73 14760

Dimensions Allegro

Length Length Width Height

std plus

Model mm mm mm mm

ALLEGRO 31

1684 2333 1060 1630

H ALLEGRO 37

ALLEGRO 76

2125 NA 1060 1630

ALLEGRO 90

ALLEGRO 110 2333 NA 1060 1630

W L

LARGO & ALLEGRO 31-110 11

DRIVEN BY TECHNOLOGY DESIGNED BY EXPERIENCE

C O N TA C T Y O U R L O C A L

A L U P KO M P R E S S O R E N

R E P R E S E N TAT I V E

Care.

Care is what service is all about: professional service by

knowledgeable people, using high-quality original parts.

Trust.

Trust is earned by delivering on our promises of reliable,

uninterrupted performance and long equipment lifetime.

Efficiency.

Equipment efficiency is ensured by regular

maintenance. Efficiency of the service organization is

how Original Parts and Service make the difference.

6999640304

www.alup.com

You might also like

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Largo & Allegro: Air CompressorsDocument12 pagesLargo & Allegro: Air Compressorsdan 117No ratings yet

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo ratings yet

- ALUP Largo Allegro 31-110 Leaflet EnglishDocument12 pagesALUP Largo Allegro 31-110 Leaflet EnglishAndy KershawNo ratings yet

- alup_largo_allegro_31-110_leaflet_en_6999640302Document12 pagesalup_largo_allegro_31-110_leaflet_en_6999640302AkilaJosephNo ratings yet

- WorthingtonCreyssensac Rollair 40-150E Leaflet en 6999010301-LRDocument12 pagesWorthingtonCreyssensac Rollair 40-150E Leaflet en 6999010301-LRpragnesh prajapati100% (1)

- Worthington Rollair 40-150Document12 pagesWorthington Rollair 40-150kuraimundNo ratings yet

- WCO Rollair 180-420 - V - Leaflet - EN - 6999010371Document8 pagesWCO Rollair 180-420 - V - Leaflet - EN - 6999010371pragnesh prajapatiNo ratings yet

- Evoluto 45 75 Leaflet API EN 6999640450Document12 pagesEvoluto 45 75 Leaflet API EN 6999640450dan 117No ratings yet

- ALUP Largo Allegro 23-36 Leaflet en 6999640361Document12 pagesALUP Largo Allegro 23-36 Leaflet en 6999640361Infinity Pneumatic0% (1)

- ALUP Sonetto 8-20 English Catalogue LR 6999640254Document8 pagesALUP Sonetto 8-20 English Catalogue LR 6999640254Infinity PneumaticNo ratings yet

- SCK Rotary Screw Compressors Range OverviewDocument8 pagesSCK Rotary Screw Compressors Range OverviewTheBartek999No ratings yet

- Be SG Frick Compressor-2019Document12 pagesBe SG Frick Compressor-2019Christopher Kenneth ChoaNo ratings yet

- Alup SCK 20-40 Leaflet ENG 6999640461 LRDocument8 pagesAlup SCK 20-40 Leaflet ENG 6999640461 LRJak JoniNo ratings yet

- EG Series Screw Air Compressors: Life Source of IndustriesDocument12 pagesEG Series Screw Air Compressors: Life Source of IndustriesNarayan DhakalNo ratings yet

- Refrigeration dryers optimized titleDocument8 pagesRefrigeration dryers optimized titleBosznay ZoltánNo ratings yet

- Rollair Rotary Screw Compressors GuideDocument12 pagesRollair Rotary Screw Compressors Guidepragnesh prajapatiNo ratings yet

- Efficient and Reliable Air Compressors for All Your NeedsDocument8 pagesEfficient and Reliable Air Compressors for All Your Needspragnesh prajapatiNo ratings yet

- EG Series Screw Air Compressors: Life Source of IndustriesDocument12 pagesEG Series Screw Air Compressors: Life Source of IndustriesManish VermaNo ratings yet

- EG Series Screw Air Compressors Life source of industriesDocument12 pagesEG Series Screw Air Compressors Life source of industriesMAZENNo ratings yet

- Oil Free Centrifugal CompressorDocument24 pagesOil Free Centrifugal CompressorAnonymous zMWvcT0% (1)

- DRE - English enDocument8 pagesDRE - English envijaykmjNo ratings yet

- ZH355-900 Plus ZH630-1600 Plus ZH1000-3150 EN Antwerp 2935063413Document24 pagesZH355-900 Plus ZH630-1600 Plus ZH1000-3150 EN Antwerp 2935063413karun agrawalNo ratings yet

- Reliability & Efficiency Without Compromise: L30 - L45 L30 - L45 L30RS - L45RSDocument8 pagesReliability & Efficiency Without Compromise: L30 - L45 L30 - L45 L30RS - L45RSRon Don jrNo ratings yet

- Compair l160 l290 SpecDocument12 pagesCompair l160 l290 SpecpfundhNo ratings yet

- Goulds 3393 ReaderDocument12 pagesGoulds 3393 ReaderJuan Luis RodrguezNo ratings yet

- OASC TDDocument8 pagesOASC TDFati ZoraNo ratings yet

- L Series L55 75Document8 pagesL Series L55 75sugengrahayune71No ratings yet

- Worthington-Creyssensac Rollair 500-200!10!20e enDocument12 pagesWorthington-Creyssensac Rollair 500-200!10!20e enpragnesh prajapatiNo ratings yet

- Refrigeration DryersDocument8 pagesRefrigeration DryersRANA AIR SERVICESNo ratings yet

- GA30-90_antwerp_leaflet_EN_2935089249Document9 pagesGA30-90_antwerp_leaflet_EN_2935089249Tharwat Mohamed MahmoudNo ratings yet

- AGRE IndustrialPistons Leaflet en LRDocument20 pagesAGRE IndustrialPistons Leaflet en LRmogwai71No ratings yet

- WorthingtonCreyssensac Rollair 16-31 (V) Leaflet en 6999010440Document12 pagesWorthingtonCreyssensac Rollair 16-31 (V) Leaflet en 6999010440Rafa GonçalvesNo ratings yet

- ELGi Global 11kW To 75kWDocument12 pagesELGi Global 11kW To 75kWRianNo ratings yet

- Bomba de Vacio CopcoDocument12 pagesBomba de Vacio CopcoCARMACUNo ratings yet

- The Xas Box Range: Everything You Need... It'S Time To Think Inside The Box!Document5 pagesThe Xas Box Range: Everything You Need... It'S Time To Think Inside The Box!FOXX AHMNo ratings yet

- Elgi Electric Power Screw Type Air CompressorDocument12 pagesElgi Electric Power Screw Type Air Compressorvishal_87503963No ratings yet

- SCK Air Compressors Power Efficient ReliableDocument8 pagesSCK Air Compressors Power Efficient ReliableAndres RPNo ratings yet

- ZH Plus ZH 355-900 ZH 630-1600 Leaflet en LR InekoDocument20 pagesZH Plus ZH 355-900 ZH 630-1600 Leaflet en LR InekoAlbert Paco GoytiaNo ratings yet

- 2.1 EQ Series - Global CatalogueDocument8 pages2.1 EQ Series - Global CatalogueimkhanhnguyenNo ratings yet

- 3 Gardner Denver Compressor Bulletin 13-9-209 - 2nd - 9-03Document2 pages3 Gardner Denver Compressor Bulletin 13-9-209 - 2nd - 9-03Sebastian SalazarNo ratings yet

- Leaflet Vent Eng RGBDocument2 pagesLeaflet Vent Eng RGBEmrah MertyürekNo ratings yet

- CompAir Yağlı Vidalı Kompresörler L160-L290Document12 pagesCompAir Yağlı Vidalı Kompresörler L160-L290maxigas120No ratings yet

- Xas 47 Spec1 PDFDocument4 pagesXas 47 Spec1 PDFacarisimovicNo ratings yet

- Atlas Copco LE LF LTBrochureDocument12 pagesAtlas Copco LE LF LTBrochurecaptain GuillemotNo ratings yet

- Le LT LF Atlas CopcoDocument12 pagesLe LT LF Atlas CopcoAgustinus KNo ratings yet

- Airtower Series: Industrial Quality For Your ShopDocument4 pagesAirtower Series: Industrial Quality For Your ShopvankarpNo ratings yet

- Reliability & Efficiency Without Compromise: Rotary Screw CompressorsDocument8 pagesReliability & Efficiency Without Compromise: Rotary Screw CompressorsabdurohmanNo ratings yet

- Linha L e LSRDocument8 pagesLinha L e LSRaplicacao.evolucaoNo ratings yet

- Aero Indoor and Weathertight Outdoor Air Handlers: Product DataDocument172 pagesAero Indoor and Weathertight Outdoor Air Handlers: Product DataANGEL MURILLONo ratings yet

- Eco JetDocument15 pagesEco JetJustin CoyNo ratings yet

- D Series Pure AirDocument12 pagesD Series Pure Airdeniss walgatNo ratings yet

- Scroll Compressors: SF 1-6 (1.5-5.5 kW/2-7.5 HP) / SF 2-22 (2.2-22 kW/3-30 HP)Document12 pagesScroll Compressors: SF 1-6 (1.5-5.5 kW/2-7.5 HP) / SF 2-22 (2.2-22 kW/3-30 HP)FRANCOISNo ratings yet

- ALMIG Belt BrochureDocument8 pagesALMIG Belt BrochurejiangshencaoNo ratings yet

- Brochure - ZEZA - 2-6 - LR - Ineko PDFDocument16 pagesBrochure - ZEZA - 2-6 - LR - Ineko PDFpowermanagerNo ratings yet

- Oil-Injected Rotary Screw Compressors: G 2-7 G 7L-15 G 15L-22Document8 pagesOil-Injected Rotary Screw Compressors: G 2-7 G 7L-15 G 15L-22ken patrickNo ratings yet

- CompresoresDocument7 pagesCompresoresAlexander AgostiniNo ratings yet

- 100% Oil-Free - Guaranteed: D75 - D315 D110RS - D315RSDocument12 pages100% Oil-Free - Guaranteed: D75 - D315 D110RS - D315RSshahram ghomiNo ratings yet

- Edge Slayer Series ShredderDocument16 pagesEdge Slayer Series ShredderKshitiz MittalNo ratings yet

- Champion Scroll Brochure GB WorkDocument8 pagesChampion Scroll Brochure GB WorkAndy KershawNo ratings yet

- ECOntrol6 Touch Wiring Diagram 1830014288-01Document11 pagesECOntrol6 Touch Wiring Diagram 1830014288-01Bosznay ZoltánNo ratings yet

- SDS Rotair ENDocument10 pagesSDS Rotair ENBosznay ZoltánNo ratings yet

- Oil Drain IntervalsDocument7 pagesOil Drain IntervalsBosznay ZoltánNo ratings yet

- Parts List: Oil-Injected CompressorsDocument366 pagesParts List: Oil-Injected CompressorsBosznay ZoltánNo ratings yet

- ALLEGRO37 400/50 AC IE3 compressor specificationsDocument2 pagesALLEGRO37 400/50 AC IE3 compressor specificationsBosznay ZoltánNo ratings yet

- Refrigeration dryers optimized titleDocument8 pagesRefrigeration dryers optimized titleBosznay ZoltánNo ratings yet

- ALUP E-Dryer ADQ216-462Document2 pagesALUP E-Dryer ADQ216-462Bosznay ZoltánNo ratings yet

- Alup Allegro 31-45 Largo 31-45 AC 30-45Kw Metric Dimension Drawing EN 9820670603Document1 pageAlup Allegro 31-45 Largo 31-45 AC 30-45Kw Metric Dimension Drawing EN 9820670603Bosznay ZoltánNo ratings yet

- Measurements & Electronic Instruments Laboratory Experiment ManualDocument2 pagesMeasurements & Electronic Instruments Laboratory Experiment Manualfirst lastNo ratings yet

- PV776-20 003739Document0 pagesPV776-20 003739Registr Registr100% (1)

- Tomato PhytographyDocument30 pagesTomato PhytographyMafe CabilesNo ratings yet

- CPU-XL VariSpark IOM 12-13Document97 pagesCPU-XL VariSpark IOM 12-13SaasiNo ratings yet

- Saptarshi PDFDocument15 pagesSaptarshi PDFViriato SouzaNo ratings yet

- Clutch Cylinder With PWM Valves and Sensor PDFDocument2 pagesClutch Cylinder With PWM Valves and Sensor PDFSherzad Chem100% (5)

- Northwestern Visayan Colleges: Subject SyllabusDocument4 pagesNorthwestern Visayan Colleges: Subject SyllabusMa. Gladys Mae PanadoNo ratings yet

- Grade 10 Physical Science VectorDocument13 pagesGrade 10 Physical Science VectorGLADMAN PASIPANODYANo ratings yet

- Reservoir Engineering-1 Unit 1Document21 pagesReservoir Engineering-1 Unit 1PE9001 AarthiNo ratings yet

- InVesalius ManualDocument130 pagesInVesalius ManualcengizyurdalNo ratings yet

- Scooptram ST 1520 PDFDocument3 pagesScooptram ST 1520 PDFmarcos abalNo ratings yet

- Tahir Iqbal CVDocument4 pagesTahir Iqbal CVAnonymous bCFC8fjLVNo ratings yet

- Appian Developer Skills Self-AssessmentDocument6 pagesAppian Developer Skills Self-AssessmentSrikanthchowdary Maguluri100% (1)

- Manual de Servicio 66DX35G1IDocument8 pagesManual de Servicio 66DX35G1IcesarNo ratings yet

- Hydraulics Module 1Document9 pagesHydraulics Module 1Jaymark S. GicaleNo ratings yet

- 3rd-grading-physics-2022-summative-quizDocument2 pages3rd-grading-physics-2022-summative-quizOdessa SantosNo ratings yet

- Drawworks and Rig Sizing PDFDocument8 pagesDrawworks and Rig Sizing PDFAmine Mimo100% (1)

- Sailor Rt2048Document94 pagesSailor Rt2048Belha Lozano SanchezNo ratings yet

- PM-ANALYZE SystemdescriptionDocument31 pagesPM-ANALYZE Systemdescriptionpham linhNo ratings yet

- Lampiran SPSSDocument18 pagesLampiran SPSSnovitaNo ratings yet

- ALEJDocument6 pagesALEJAlejandro OdinNo ratings yet

- Track Eye Movement to Control Mouse CursorDocument11 pagesTrack Eye Movement to Control Mouse CursorStoriesofsuperheroesNo ratings yet

- Caustic Soda 1Document21 pagesCaustic Soda 1arpit garg100% (1)

- CS211 Discrete Structures - Final Exam Fall-19 - SolutionDocument11 pagesCS211 Discrete Structures - Final Exam Fall-19 - SolutionK213156 Syed Abdul RehmanNo ratings yet

- Niels Bohr Proposed The Bohr Model of The Atom in 1915. ... The Bohr Model Is ADocument3 pagesNiels Bohr Proposed The Bohr Model of The Atom in 1915. ... The Bohr Model Is AKatherineNo ratings yet

- LAN-1 Lan Cable TesterDocument2 pagesLAN-1 Lan Cable TesterDan DanNo ratings yet

- Hb2637l-Evk-301 DPT HSDocument10 pagesHb2637l-Evk-301 DPT HSAlec NanetteNo ratings yet

- WR011i002p00208 Cohon&MarksDocument13 pagesWR011i002p00208 Cohon&MarksPaulo BuenoNo ratings yet

- Site Visit Form RF Antenna AdjustmentDocument8 pagesSite Visit Form RF Antenna AdjustmentazfahaidarNo ratings yet

- Casio AT 1 Service ManualDocument28 pagesCasio AT 1 Service ManualMario Gabriel MoralliNo ratings yet