Professional Documents

Culture Documents

Unit 4a Vehicle Body Engg Cars

Uploaded by

Shemsudin AhmedteibOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Unit 4a Vehicle Body Engg Cars

Uploaded by

Shemsudin AhmedteibCopyright:

Available Formats

Automotive Aerodynamics & Body Engineering

Vehicle Body Engineering

Car Body Construction

R P Kakde

Govt College Of Engineering & Research Awasari

AABE by R P Kakde GCOEARA Awasari Khurd

Unit II Car Body Construction

After studying this chapter, we should be able to:

- Explain the current design of motor vehicles

Summarize the various types of frames commonly used on modern cars, trucks,

vans, and SUVs

Compare and contrast modern

GCOEARA body-over-frame

Awasari Khurd and unibody construction

technology

Locate the major parts of a perimeter frame ‘

Locate the major parts of a unibody frame ‘i) Compare a conventional full frame

with modern hydroformed frames Identify the major structural components,

sections, and assemblies of a motor vehicle

Explain how simulated and actual crash tests are used to evaluate the structural

integrity of a motor vehicle

Describe the lay person’s names for body shapes used on passenger vehicles

Answer ASE-style review questions relating to vehicle construction

AABE by R P Kakde GCOEARA Avasari Khurd

Unit II Car Body Construction

Identification & Functions of Body Pressings

• In a separate body and chassis construction :

• - Chassis resists bending & twisting loads

• - Body provides only functional needs

• Separate body & chassis type of construction is being

superseded by the integral or mono-construction system

• In integral construction the frame members become an

integral part of the body

AABE by R P Kakde GCOEARA Avasari Khurd

Identification

Unit II & Functions ofCar

Body Pressings

Body Construction

• Car Body Assemblies

AABE by R P Kakde GCOEARA Avasari Khurd

Unit IV Car Body Construction

Identification & Functions of Body Pressings

• Car Underbody Assemblies

AABE by R P Kakde GCOEARA Avasari Khurd

Unit IV Car Body Construction

Identification & Functions of Body Pressings

• Box sectioning of the body sills, door pillars and roof

reinforcements form a framed structure in which stresses

are distributed to all parts of the body

• In reinforced body shell buckling is prevented by use of

curved plates with multiple radii ( or crown ). A flat plate

offer little resistance to buckling.

• For stress carrying parts of body shell greater rigidity can

be achieved by using ‘ top of hat ‘ section or channel &

angles built into the assembly

• This is also convenient for construction of streamlined

shapes for minimum aerodynamic resistance's

AABE by R P Kakde GCOEARA Avasari Khurd

Unit IV Car Body Construction

Identification & Functions of Body Pressings

• Mass production of car bodies in steel consists of manufacturing of sub-

assemblies like floor-pan, two sides, roof cross-member, etc. assembled

together and spot-welded to form a complete body shell

• For construction of a typical Car Body Shell various sub-assemblies generally

required are described in order to understand a sequence of its construction .

AABE by R P Kakde GCOEARA Avasari Khurd

Unit IV Car Body Construction

Sub- Assemblies & Construction of Body Shell

• Underbody assembly

• Body side assembly

• Shroud and dash panel assembly

• Roof & back window aperture panels

• The Center pillar ( B- C post )

• Rear Bulk-head and parcel shelf

• Front end work

• Front wings

• Door panel assembly

AABE by R P Kakde GCOEARA Avasari Khurd

Unit IV Car Body Construction

AABE by R P Kakde GCOEARA Avasari Khurd

Unit IV Car Body Construction

Sub- Assemblies & Construction of Body Shell

• Bonnet panel assembly

• Boot lid assembly

• Under body assembly

• - This positions the engine, transmission, wheel-

arches, seats, etc.

• - Body sills provide longitudinal edge reinforcements

• - The floor pan strengthened by; box members at right

angles to the transmission tunnel; all cross members

AABE by R P Kakde GCOEARA Avasari Khurd

Unit IV Car Body Construction

Sub- Assemblies & Construction of Body Shell

• Under body assembly

• at the rear,front of the front seats, front of the rear seats, etc. joined together provide lateral reinforcements

• - The transmission tunnel, which acts like an inverted channel section provide central strength built into the

floor

• - The remaining area of flat metal is ribbed or dished below the seats and in the foot wells to add stiffness to

the sub-assembly

AABE by R P Kakde GCOEARA Avasari Khurd

Unit IV Car Body Construction

• Body side assembly

• - The side frames reinforcing the floor pan,

body sills also transmit loads between them

Sub- • - The center pillars are welded in between the

body sill and the roof / cant rails.

Assemblies • - These are usually assembled as a box section

& using a ‘top-hat’ section and flat plate, with the

Construction flanges forming attachments for the door,

weather seals, etc.

of Body Shell • - The front hinge pillars extend forward to join

with the dash panel, front bulkhead cross

member. This provides strength by ‘boxing’ the

front end.

AABE by R P Kakde GCOEARA Avasari Khurd

Unit IV Car Body Construction

AABE by R P Kakde GCOEARA Avasari Khurd

Unit IV Car Body Construction

Sub- Assemblies & Construction of Body Shell

• Shroud & Dash panel assembly

• - These assemblies are complex structures connecting the

two body sides across the car

• - The complete assembly is also called the firewall because it

is the partition between the passenger and engine

compartment, and carries part of the forces set up by the

front suspension, weight of the power unit.

• - The heating / cooling systems & its distribution chamber,

instrument panel & its necessary controls, wiring, tubing,

etc., the steering column are all attached to the front bulk

head of the body and is

AABE by R P Kakde GCOEARA Avasari Khurd

Unit IV Car Body Construction

Sub- Assemblies & Construction of Body Shell

• Shroud & Dash panel assembly

• usually formed by assembling together several smaller panels ( dash & shroud ) which are

joined by welds to form an integral unit.

• - The instrument panel connected to the cowl panel provides mountings for instruments.

• - In some cases the wind screen opening is connected to the cowl panel. In this case the

windscreen pillars, the narrow sloping construction at either side of the windscreen opening

are part of the cowl. Upper edge of the cowl panel forms the front edge of the roof panel

• Shroud & Dash panel assembly

• - On many passenger cars the front door hinge pillar is also an integral part of the cowl

• Roof & back window aperture panels

• - Roof panel is one of the largest of all major body panels and it is one of the simplest in

construction.

• - Usually it is all-steel, one piece construction.

• - On some cars it ends at the windscreen on front side & rear window on the rear side.

It may extend down

•

AABE by R P Kakde GCOEARA Avasari Khurd

Unit IV Car Body Construction

AABE by R P Kakde GCOEARA Avasari Khurd

Unit IV Car Body Construction

Sub- Assemblies & Construction of Body Shell

• Roof & back window aperture panels

• wards around windscreen on front side and on rear side the rear window opening is

in the lower rear roof and forming the top panel around the rear boot opening

• - The roof and its reinforcing members form lid of the box structure.

• - The stiffness is built by the curvature given to it, the reinforcement consisting of

small metal strips placed crosswise to the roof at intervals along the inside surface.

These also provide tacking strips for securing

• the heal lining & inside trims in place . In some cases the roof panel is also ribbed or

dished longitudinally.

• The Center Pillar ( B - C post )

• - It acts as central roof and side support between the front and rear of the car body

side structure.

• - Its construction must be exceptionally strong as it is the shut ( lock ) pillar and the

hinge pillar for the doors.

• - The center pillar is irregular in shape since it must conform to outside contours of

the door as well as

AABE by R P Kakde GCOEARA Avasari Khurd

Unit IV Car Body Construction

Sub- Assemblies & Construction of Body Shell

• Roof & back window aperture panels

AABE by R P Kakde GCOEARA Avasari Khurd

Unit IV Car Body Construction

Sub- Assemblies & Construction of Body Shell

• The Center Pillar ( B - C post )

• accommodate door lock, striker plate, hinges,etc.

depending on the body style.

AABE by R P Kakde GCOEARA Avasari Khurd

Unit IV Car Body Construction

Sub- Assemblies & Construction of Body Shell

• Rear Bulk - Head and Parcel Shelf

• - This provides transverse stiffness and is welded between the body side frames and rear seat frame. In

construction they are often pierced and flanged to increase rigidity.

• - The rear panel is curved to form part of the external shape of the body with its upper edge providing support

to the boot lid seal.

AABE by R P Kakde GCOEARA Avasari Khurd

Unit IV Car Body Construction

Sub- Assemblies & Construction of Body Shell

• Front End Work

• -The front end carries the engine and front suspension, steering gear and radiator.

• - The suspension system may affect detail design of the panels but the loads must be transmitted to the

wings and/or wheel arches and on into the body panels

• - The front cross- member assembly braces the front of the car and carries the radiator, headlamps, etc.

The side assemblies and front wheelhouse panel assembly form a housing for the wheel, a mating edge

for the bonnet and a strong box section for attachment to the side frames and front bulkhead.

AABE by R P Kakde GCOEARA Avasari Khurd

Unit IV Car Body Construction

Sub- Assemblies & Construction of Body Shell

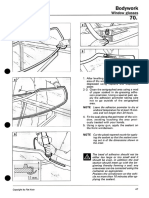

• Front Wings

• - The front wings are each attached to the inner construction of the car body by

means of a flange along the length of the wing, which is turned inwards from the

outside surface and through which securing bolts can pass.

• - To add strength and to prevent vibration the wing brackets are sometimes fitted.

• - The unsupported edges are swaged and turned inwards to give strength& cracks

developing in the edges of the wings due to vibrations. This provides a smooth

finished appearance to the edges of the wings.

• - Apart from covering the suspension & wheel the wings prevent water and mud,

etc. being thrown up onto the body by the wheels.

• Door Panel Assembly

• - The door is composed of two main panels; outer and inner panel, constructed

to act as a frame for the door.

• - The outer panel flanges over the inner panel around the edges to form a single

unit.

AABE by R P Kakde GCOEARA Avasari Khurd

Unit IV Car Body Construction

Sub- Assemblies & Construction of Body Shell

• Door Panel Assembly

• - The window channel may be welded or bolted to inner door panel to provide support & direction to

the window glass.

• - The inner panel has holes or apertures drilled, punched or formed for attachment of door trims.

• - The thickness of the door is due to the depth of the inner panel which accommodate door

catch,window mechanism,etc.

• - The inner panel forms the lock pillar and the hinge pillar sections of the door.

AABE by R P Kakde GCOEARA Avasari Khurd

Unit IV Car Body Construction

Sub- Assemblies &

Construction of Body Shell

• Door Panel Assembly

• - Small reinforcement angles are

• usually used between the outer

• and inner panels where lock is

• inserted through the door and the

• hinges are attached.

• - The outer panel is provided with

• an opening through which

outside

• door handle protrudes.

AABE by R P Kakde GCOEARA Avasari Khurd

Unit IV Car Body Construction

Sub- Assemblies &

Construction of Body Shell

• Bonnet Assembly

• - The bonnet is the panel covering

• the engine compartment.

• - Most one-piece bonnets are

• hinged at the rear so that the front

• end swings up when opened. The

• catches are at front and in most

• cases controlled from inside the

car.

AABE by R P Kakde GCOEARA Avasari Khurd

Unit IV Car Body Construction

Sub- Assemblies & Construction of Body Shell

• Bonnet Panel Assembly

• - One-piece bonnets are quite large and, to make opening

easier, the hinges are usually counter - balanced by means of

tension or torsion springs.

• - Smaller bonnets are held in place by a stay

• - The bonnet consists of the outer panel and inner

reinforcement constructed in the ‘H’ or cruciform pattern. The

reinforcement is basically a top-hat section to give rigidity to

the component.

• - The main strength of the bonnet lies in the fact that the inner

construction acts like a frame and the outer panel is formed

round its edges, acting as flanges

AABE by R P Kakde GCOEARA Avasari Khurd

Unit IV Car Body Construction

Sub- Assemblies & Construction of Body Shell

• Boot Lid Assembly

• - The boot lid is composed of an inner and an outer

panel spot-welded together along their flanged edges to

form a single unit .

• - Both type of hinges ; external & concealed are used.

• - A catch is provided at the bottom rear of the boot lid

and controlled by an external handle. In some models

handles are not provided. The hinges are spring loaded

so that lid rises automatically by the hinge mechanism

for opening & holding it in place.

AABE by R P Kakde GCOEARA Avasari Khurd

Unit IV Car Body Construction

Body Build, Paint and Sealing

• Body build

• - A car body is made up of six major units ;

Floor, Two sides, Front end, Rear end, Roof

• - These major units themselves made up

from numerous smaller pressings reach

main body-build conveyors as sub-

assemblies

• - Special jigs carry the body floor assembly,

pairs of side frames, front & rear sections

mate up with the trucks so that all the units

are clamped securely together while the

welding is done. The roof is the last major

section to go on.

AABE by R P Kakde GCOEARA Avasari Khurd

Unit IV Car Body Construction

Body Build, Paint and Sealing

• Body build

• - Various forms of welding are used in building up a car

body shell like spot- welding, seam welding, etc.

• - After welding, every joint is sealed with special

compounds to make it a watertight car body.

• - After the body shells have assembled their doors,

bonnet panels, boot lids, etc. they are prepared for the

paint shop.

• - Panel surfaces are inspected and blemishes in the

sheet metal are removed with portable sanding

machines

AABE by R P Kakde GCOEARA Avasari Khurd

Unit IV Car Body Construction

Body Build, Paint and Sealing

• Painting

• - The painting of a car body means protection of

sheet metal, inside and out, underneath as well as on

top besides giving them a coat of bright shiny colour.

• - The first stage is a multi-part rust-proofing

treatment by complete immersion of the body shell

in a huge bath of anti-rust alkyd primer.

• - This is followed by surface priming. The entire

under body,wheel arches, insides of the body sills,etc.

are treated with multi-coats of epoxy primer followed

by baking in huge high- temperature ovens.

AABE by R P Kakde GCOEARA Avasari Khurd

Unit IV Car Body Construction

Body Build, Paint and Sealing

• Painting

• - The under body areas are coated with thick layers of bituminous or

polymer compounds for anti-corrosion protection. This also helps

reduce road noise.

• - In final stage the complete body is given a base coat of acrylic paint

with special adhesion qualities. This is followed by multi-coats of the

finish colour paint which is basked in hot oven to create a hard, deep-

gloss finish.

• - In between these operations rubbing, washing, cleaning, etc are

carried out .

AABE by R P Kakde GCOEARA Avasari Khurd

Unit IV Car Body Construction

Body Build, Paint and Sealing

• Sealing

• - The entire car body is vulnerable to the entry of water,

fumes, and dust.

• - The various locations on the vehicle body that require

some form of seal are ;

• 1. Areas where a permanently flexible seal is required,

e.g. windscreen, rear screen

• 2. External panel seams.

• 3. Areas where a seal is required to withstand stone

pecking, e.g. wheel arches, floor pan

• 4. Protected areas where a bulk sealer is required

AABE by R P Kakde GCOEARA Avasari Khurd

Unit IV Car Body Construction

Body Build, Paint and Sealing

• Sealing

• - It is essential for the various sealing materials ( caulking cmpound, multi-

purpose adhesive, metal joint sealer, windshield sealer, double-sided

adhesive tape, PVC foil, etc. ) to be applied to clean dry surface if they are

to adhere and form an effective seal.

• Fixtures and fittings

• - From paint shop the car body pass into the trim shop for ‘furnishing’

where various items like carpets, seats, door handles, window glass,

chrome moldings, electric wiring, steering wheel,fascia panels,instrument

AABE by R P Kakde GCOEARA Avasari Khurd

Unit IV Car Body Construction

Body Build, Paint and Sealing

• Fixtures and fittings clusters, etc. are fitted

• - Midway through this long furnishing the body pass through a

long water tunnel where it is drenched by powerful jets of water.

This water contains a fluorescent dye and any drop of water that

may have found its way into the body can be detected.

• - Before the bodies leave the trim-shop some minor mechanical

units are added and transferred to the ‘body drop’.

AABE by R P Kakde GCOEARA Avasari Khurd

Automotive Aerodynamics & Body Engineering

Unit IV

Body Terminology, Visibility & Space

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body Engineering Terminology

Body Engineering Terminology

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body Engineering Terminology

Tailfin

• The tailfin era of

automobile styling

encompassed the 1950s

and 1960s, peaking

between 1957 and 1960. It

was a style that spread

worldwide, as car

designers picked up styling

trends from the US

automobile industry where

it was the golden epoch of

American auto design

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Center console

Body Engineering Terminology

The center console in an

automobile refers to the control-

bearing surfaces in the center of

the front of the vehicle interior.

The term is applied to the area

beginning in the dashboard and

continuing beneath it, and often

merging with the transmission

tunnel which runs between the

front driver's and passenger's

seats of many vehicles

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body Engineering Terminology

Fascia

Fascia often refers to the decorative panels of a car's dashboard or the entire

dashboard assembly

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body Engineering Terminology

Fender skirts

Fender skirts,

known in Australia

and the United

Kingdom as spats,

are pieces of

bodywork on the

fender that cover

the upper portions

of the rear tires of

an automobile

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body Engineering Terminology

Glove compartment

A glove compartment

or glovebox or glovie is

a compartment built

into the dashboard,

located over the front-

seat passenger's

footwell in an

automobile often used

for miscellaneous

storage

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body Engineering Terminology

Greenhouse

The greenhouse (or

glasshouse) of a car

comprises the windshield

rear and side windows,

the pillars separating them

(designated A-pillar, B-

pillar and so on, starting

from the car's front), and

the car's roof

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body Engineering Terminology

Hood scoop

A bonnet/hood scoop, sometimes called bonnet airdam /air dam, or

colloquially speed hole, is an upraised component on the hood of an

automobile that either allows a flow of air to directly enter the engine

compartment, or appears to do so

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body Engineering Terminology

Nerf bar

A nerf bar is a tubular device fitted to the side of a racecar, typically single-seat

race cars that compete on asphalt or dirt oval tracks. A "nerf" is a small,

sometimes intentional, collision between two cars in which one driver bumps

the other to facilitate a successful pass. The nerf bar protects the sides of the

vehicles and also keeps their tires from becoming entangled

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body Engineering Terminology

Power bulge

A power bulge is a raised part (a bulge) of the hood of a car. The reason for a

power bulge is to fit for instance a large engine or air filters that otherwise

would not fit. Sometimes a power bulge is used to be able to fit a larger engine

into a car that originally was not designed for it or it may be a design choice to

be able to get a lower profile. As a power bulge is associated with performance

cars it may also be used as a design element to give the impression of a fast car

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body Engineering Terminology

Quarter panel

A quarter panel is the body panel

(exterior surface) of an automobile

between a rear door (or only door

on each side for two-door models

and the trunk (boot) and typically

wraps around the wheel well. The

similar front section between the

door and the hood (bonnet) , is

called a fender but is sometimes

incorrectly also referred to as a

quarter panel. Quarter panels are

typically made of sheet metal, but

are sometimes made of fiberglass

or fiber-reinforced plastic

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body Engineering Terminology

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body Engineering Terminology

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body Engineering Terminology

Body Body Sill : The panel (metal plate) directly

Engineering

below the bottom of doors supporting the floor

Terminology

and may be used to combine floor & body.

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body Engineering Terminology

- Bonnet : The metal cover over the engine

compartment

- Bulk Head : A transverse support or assembly in a

body structure.

- Boot : A compartment which takes luggage and

often the spare wheel & fuel tank

- Center Pillar : The central vertical support of a four

door saloon, sometimes referred to as B-C post

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body Engineering Terminology

Body - Cant Rail : The longitudinal framing of the roof at

Engineering the joint

Terminology

- Cant Panel : The curved section of the roof top

running between the comparatively flat top and

the rain channel

- Door Skins : Door exterior panels/outside door

panels

- Door Trim : The interior lining of a door

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body Engineering Terminology

- Drip Moulding : A roof gutter to direct water from door

openings

- Fire wall : Panel dividing engine compartment from

passenger compartment

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body Engineering Terminology

Body Engineering Terminology

• Head Lining : The material, cloth, PVS, etc.

• Heel Board : A vertical board or panel rear seat

which forms the support for the seat cushion

• Hinge Pillar : A pillar on which the door swing

open or close

• Pillar : A vertical support of a body frame

• Quarter Panel : The curved side panels extending

from the door to the rear end of the body

including the wing or the curved panels which

connect the side panels, including the rear wing

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body Engineering Terminology

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body Engineering Terminology

Body Engineering Terminology

• - Quarter light : The window directly

above quarter panel

• - Scuttle Panel: The panel between

bonnet & windscreen

• Sub- frame : Members to which the

engine & front-end assembly are

attached

• - Tunnel : A raised floor panel section

for drive shaft clearance

• - Wheel arch : A break in the rear

panels to accommodate the rear

mudguards and wheels

• - BBC : Abbreviation for the distance

from the bumper to the back of cab

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body Engineering Terminology

Body Engineering Terminology

• - Sub- frame : Members to which the

engine & front-end assembly are

attached

• - Tunnel : A raised floor panel section for

drive shaft clearance

• - Wheel arch : A break in the rear panels

to accommodate the rear mudguards

and wheels

• - BBC : Abbreviation for the distance

from the bumper to the back of cab

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body Engineering Terminology

Body Engineering Terminology

• - Bearers : The cross- members that support the

body floor. They are located on either chassis

member or longitudes

• - Bulker : A general term for vehicles carrying

liquid and powder

• - Cab : The part of a vehicle enclosing the driver

• - Cant rail : The member which connects the side

panels of vans to the roof structure

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body Engineering Terminology

Body Engineering Terminology

• - Cleat : Bracket used for joining longitudinal transverse

body members

• - COE : Abbreviation for “cab over engine”

• - CV : Abbreviation for “commercial vehicle”

• - Drop side panels : Hinged panels which are fitted to

the sides of platform bodies

• - GRP : Abbreviation of glass reinforced plastic used for

vehicle roofs and vehicle cab

• - GVW : Gross Vehicle Weight is total weight of vehicle

• - Longitudes : The main longitudinal members of a body

which normally rest upon the chassis

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body Engineering Terminology

Body Engineering Terminology

• Overhang : The dimension from the center-line of the

rear axle to the rear of the body

• Pay load : The difference between gross vehicle

weight and unladen weight , that is carrying weight of

vehicle

• Rave : Often referred to as bottom rail, this is the

longitudinal section which mates with the outer

extremities of the floor & bearers and in case of vans,

connects with the side panel

• Rub rail : A longitudinal section fitted to van sides in

order to minimize damage to side sheets

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body Engineering Terminology

Requirements of Automobile Body

• A frameless type body of an Automobile must

satisfy requirements in terms of :

• Strength

• Stiffness

• Space

• Air Drag

• Protection against weather

• Resistance to Corrosion

• Protection in accident

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body Engineering Terminology

Strength : Body must withstand all types of forces to which vehicle is

subjected to ;

• - weight of the vehicle, passenger, luggage

• - inertia, braking, & side forces

• - impact loads of reasonable magnitude

Stiffness : Body may be considered as a beam supported on wheels at

each end. It must possess sufficient stiffness to prevent sagging in the

middle.

Torsional Stiffness : Body should be sufficiently rigid to resist twisting on

bad roads.

Space : Adequate space to be provided in the body for passenger and

luggage.

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body Engineering Terminology

Air drag : Resistance of air during vehicle movement depends upon body

shape. The shape of the body should be such that the air drag is

minimum

Protection against weather : Body should be such that the occupants and

luggage not affected from weather.

Resistance to Corrosion : Body should be designed such that no moisture

is accumulated and material should be such that rust & corrosion does

not take place.

Protection in accident : It is an important consideration of vehicle body

design. Driver must be at maximum ease to avoid accident due to fatigue.

However, body should be designed such that the occupants are best

protected even in case of accident

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body Engineering Terminology

Visibility

• Good all round visibility

is one of the main

requirements of body

design

• Visibility depends upon

the window opening and

their relative position to

the occupants

• Figures below show eye

position of driver, angle

of visibility & space

between the pillar and

seat

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body Engineering Terminology

1x2z

Improvement in Frontal visibility

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body Engineering Terminology

Visibility

• Types of Visibility

• - If occupant is placed close to windscreen the

forward visibility is considerably improved but

comfortable entry is adversely affected as dimension

between pillar & seat is decreased requiring suitable

shaping of the door, if possible.

•- Downward visibility can be improved by

positioning the driver as high as possible in relation

to the lower edge of windscreen.

• - Rearward visibility is achieved by increase in glass

area required to maintain rear view vertical angle

with back window

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body Engineering Terminology

Space Requirements & Methods of its Improvements

• Amount of space has to be allocated to passenger needs according

to dimension & type of body

• Space for access to fuel tank, spare wheel, batteries, tools, boot, and

spare wheel placing, etc. depend upon dimension & type of body

and the inventiveness of the designer.

• Window opening should ensure good visibility without affecting

stiffness of the body shell.

• Main requirement of door opening is the comfort of entry

• In two door design passage way to back seat should be ensured

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body Engineering Terminology

Space Requirements & Methods of its Improvements

Measurement of comfortable passage way is shown in figure.

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body Engineering Terminology

Space Requirements & Methods of its Improvements

• Avoid pockets for the feet by sloping the door post & side walls as

shown.

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body Engineering Terminology

Space Requirements & Methods of its Improvements

• Considerable experience in design is needed to position the

compartments in a planned outline of the body.

• Good utilization of space is particularly significant for small vehicles

and in general makes the vehicle lighter resulting in improved

power-to-weight ratio. This reduces cost of vehicle also.

AABE by R P Kakde GCOEARA Awasari Khurd

Automotive Aerodynamics & Body Engineering

Unit IV

Design Considerations & Body Construction

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

Morphology of Vehicle Body ( Structural ) Design

• Emancipation of the Body Designer

•- A wide range of skills required for vehicle design and

manufacture

•- Development of motor vehicle may require following

group of activities;

• Technical innovation and refinement

• Construction and configuration by Designing & Styling

• Methods of production, and manufacturing systems

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

Morphology of Vehicle Body ( Structural ) Design

• Technical innovation and refinement

•- Innovative developments have often been the work of

several different engineers working in parallel but

independently

• - Many apparently new inventions are adaptations from

different technologies, e.g.,

• differential mechanism used by watchmakers, aerospace,

electronics, materials,etc.

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

Morphology of Vehicle Body ( Structural ) Design

• Construction and configuration by Designing & Styling

• Methods of production and manufacturing systems in early

times were adaptations from horse-drawn carriage

construction methods for upper body works.

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

Morphology of Vehicle Body ( Structural ) Design

• Construction and configuration by Designing & Styling

• Above a wooden chassis, sat a light wooden framework

covered with a skin of sheet metal, wood or fabric.

• As motor vehicles had to sustain loads and vibrations of

engine, transmission and of vehicle dynamics at higher speeds

( higher shock loads ) the metal chassis frame were quickly

adopted

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

Morphology of Vehicle Body ( Structural ) Design

• Construction and configuration by Designing & Styling

• A combination of steel chassis, wooden framework

and sheet metal skinning were used for most vehicle

with aluminum often used in more expensive and

higher performance vehicles

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

Morphology of Vehicle Body ( Structural ) Design

• Construction and configuration by Designing & Styling

• A few fabric and wooden bodied vehicles were still produced

as late as 1930s by specialist coach builders mainly because

the antiquated style conveyed an air of past elegance.

• Subsequently increasing use of pressed – steel skin panels in

place of flat sheets or hand beaten or wheeled panels

followed.

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

Morphology of Vehicle Body ( Structural ) Design

• Construction and configuration by Designing & Styling

• Sheets of steel were pressed in moulds to produce complex

shapes with multiple curvature and the process enabling

economic production bulbous styling forms, that became

popular, took over

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Design Considerations &

Morphology of Vehicle Body Construction

Body ( Structural ) Design

• Construction and configuration by Designing & Styling

• Multiple curvature also made panels much stiffer and the

skin could take a significant part of load.

• Some manufacturers began to dispense with wooden

frames and use metal frame or even no frame work at all,

relying on panels & formed sheet metal stiffening elements

to provide all rigidity necessary for upper body

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

Morphology of Vehicle Body ( Structural ) Design

• Construction and configuration by Designing & Styling

• Lower chassis frames initially retained but separate chassis

began to disappear, being replaced by a stiff floor ‘pan’ that

was fabricated from welded shaped sheet elements.

• By 1950s ‘unitary’ type of construction was almost universally

adopted for mass-produced cars.

• Recently, the shell construction has been refined to produce

smooth aerodynamically shape with minimum protrusions or

gaps.

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

Morphology of Vehicle Body ( Structural ) Design

• Construction and configuration by Designing & Styling

• Composite construction in fiberglass and resin was developed

soon after the war

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

Mass Production - Designing & Styling

• Two giants of vehicle manufacture following

World War I were Ford and General Motors

• Initially Ford were predominant with

standardized Model-T car & van

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

• Ford fathered mass production and design

standardization.

• GM in addition recognized another strong force

in the market place: customers personal

preference

Mass • - sectorized market & designed accordingly

Production - • - offer proliferation of body shapes & colours

Designing & • - in mid 20s GM gave birth to ‘ Stylist’

Styling • GM was outselling Ford. Serious business of

body design took its place amongst industry

professionals.

• A stylist would ‘package’ occupants and

luggage around a fairly standardized layout of

engine and drive train.

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

Design Considerations

• Task Assignment

• General layout

• Artistic utilitarian design

• Dummies & models

• Preliminary design

• Body weight, stress, geometric analysis, etc.

• Master model and mathematical models

• Scanning of master model with electronic sensors and

compilation of data

• Scanned data integration and analysis with the help of

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

Design Considerations

• computers to generate geometrically perfect

surfaces & reproduction of tapes

• Tapes are used by numerically controlled machines

(e.g. milling ) to prepare high precision dies

• These dies are used by Power Presses to produce

the Pressed Metal Panels which are welded

together to construct the structures and body of

the vehicle

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

Design Considerations

• Task assignment :

• - The task of designing of vehicle is broken down into various

components ;

• Body / Chassis / Engine / Transmission

• - Consider components need to be designed and the

components to be used as standard items, e.g, transmission

system.

• - Consider ergonomics of seating &controls, legal requirements

of body, engine, etc. field of vision, aerodynamics, etc.

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

Design Considerations

• General layout :

• - Designer in consultation with Stylist prepares

perspective drawings & sketches

• - Construct suitable models or mock-ups and initial

design drawings

• - Carryout structural analysis on body design and

compare new design with existing designs to ensure

• some advances made

• - Finalize basic dimensions, often called ‘ package of

the vehicle ‘ and include overall dimensions as per

legal requirements

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

Design General layout :

Considerations

- As per above the external dimensions, wheel-base, etc.

are decided and a general layout is prepared as shown :

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

Design Considerations

• Artistic Utilitarian Design :

• - Aesthetically pleasing body shape is set out

considering aerodynamics and other design

requirements

• - The design of a shape based on the elements of

functions and logic together with an artistic

appreciation of forms is called “ artistic utilitarian

design “. Such designs have advantage over irrational

styling and is a necessary part of good design.

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

• Dummies & Models :

• - The dimensionally complicated form of

vehicle bodies require practical checking at

all stages of design. These are carried out

by means of dummies and models

Design

Considerations • Dummies :

• - Dummies are built to ensure that the

principal dimensions are compatible. This

includes dimensions of driver’s position,

passenger’s seat, size of door & window

openings, etc.

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

• Dummies & Models :

• - A full scale dummy allows for complete

reproduction of the drawing dimensions

and thus check for comfort, visibility, ease

of exit & entry, position of steering wheels,

chassis - engine mechanisms, layout of

Design dashboard, etc.

Considerations • - Dummies are usually constructed in timber

and / or other synthetic materials which are

easy for manual working.

• - Apart from checking dimensions of the

body the position of components can be

determined using

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

Design Considerations

• Dummies & Models :

• chassis & engine either real or their dummies

• Models :

• - Inside dimensions of a vehicle body, having being

checked & finalized with dummies, form the basis for

developing models of the outside surfaces of the

body.

• - Scale models ( say 1 in 20 ) are constructed using

materials like plasticine or plaster of paris laid on a

wooden base with tools such as knives & spatulas,

etc. Some scribing devices are used as measuring

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

Design Considerations

• Models :

• the principal sections ( called outlines ) are transferred

onto the model using templates.

• - A few variants of a model with corrected basic sections

of the design are considered for finally choosing the

model for obtaining templates for larger scale models (

say 1 in 5 ) such that it represents vehicle in details as far

as possible. Such a model is called a “ reduced model “

• - the principal dimensions of the vehicle are determined

by the development of such models and

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

Design Considerations

• Models :

• and dummies, and the first outlines of the

drawings can be made without details.

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

Material Requirements and Body Parts

• Steel Sheets used for making Car Bodies :

• - Low tensile strength and high ductility for ease of forming

• - Easily assembled to form a body unit

• - Light in weight

• - Low cost

• A Typical Low-Carbon Steel Composition

• Carbon - 0.080 % Phosphorus - 0.020

%

• Silicon - 0.002 % Manganese - 0.350 %

• Sulfur - 0.020 %

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

Material Requirements and Body Parts

• The liquid steel is cast into large ingots for subsequent

hot - rolling to sheets of different thickness. Typical

sheet thickness & their use are :

• 10g 3.25mmbrackets & supports and heavy

• 12g 2.65mm internal construction

• 14g 2.03mmpanel assemblies which take

• 16g 1.63mm stresses & loads ( floor bulk head,

• 18g 1.22mm sills, sub-frames, cross-members

• and inner stress panels )

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

Material Requirements and Body Parts

• 20g 0.95mmouter panel construction ( skin

• 22g 0.71mm panels, doors, bonnet, boot,

lid,wing panels )

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

Material Requirements and Body Parts

• Comparison between Steel & Aluminum

• - The requirements of Fuel Economy &

Environment has demanded Vehicle Body weight

reductions.

• - Aluminum has been considered strong alter

native to steel in order to achieve weight reduction.

However, the magnitude of weight reduction has to

be attractive despite its higher cost.

• - Generally, Aluminum has been found better in

castings for housing, engine blocks, etc resulted in

savings in weight & costs

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

Material Requirements and Body Parts

• Comparison between Steel & Aluminum

• - The compelling demand for change in material

• properties has been the need for reduced weight

• - To meet such demand a new generation

improved

• high-strength steels has been developed that offer :

• I) sufficient ductility to meet fabrication

requirements

• ii) meets the minimum yield strength requirements

• iii) improved conductivity & weldability

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

• Comparison between Steel & Aluminum

• - Comparison of Relative Material

Material Properties of Aluminum ( Base Steel = 1

Requirements )

and Body • I) Tensile Strength 1/3

Parts • ii) ductility 1/2

• iii) density 1/3

• iv) elastic modulus 3

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

Material Requirements and Body Parts

• Comparison between Steel & Aluminum

• - Considerations for Competitiveness

• For tensile strength limited applications

replacement of steel by aluminum requires a

cross-section that is

• three times greater which makes it approximately

equal in weight for equivalent modulus of

elasticity. Overall it means three times the cost.

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

Material Requirements and Body Parts

• Comparison between Steel & Aluminum

• Factors for material selection for Car Body Pressings

• - Yield strength

• - failure strength

• - formability

• - indentation resistance

• - fabricability

• - painting systems / requirements

• - Welding

• - Heat - Treatment

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

Material Requirements and Body Parts

• Comparison between Steel & Aluminum

• Some Comments / Observations

• - Most automotive components are not loaded in pure

tension, but where simple tensile properties are the

design criteria, a steel with higher yield strength is

capable of saving about 40% of weight and may be

comparable .

• - Functional requirements vary from simple bending

or indentation resistance to complex twisting and

structural loading of components. By changing to

higher-strength steel, appreciable weight reductions

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

Material Requirements and Body Parts

• Comparison between Steel & Aluminum

• Some Comments / Observations

• can be obtained. The type of improvements

generally achieved by increasing the product

strength can be as high as 30%.

• - Welding : Aluminum parts require increased

thickness ( 1.4 times ) and larger dia. Electrodes

for welding & greater edge distances for

equivalent weld-bond strength. Disparity

increases as thickness increases. At about 2.2mm

steel

AABE by R P provides

Kakde 3 times strength advantage.

GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

Material Requirements and Body Parts

• Comparison between Steel & Aluminum

• Some Comments / Observations

• Welding :

• - In order to improve inherent lack of spot

weldability of aluminum sheets the adhesive

bonding & welding may be used to achieve

satisfactory strength. This may have additional

cost implications.

• - Oxide coating of aluminum vary significantly

and cause production of unacceptable

AABE by R P Kakde

welds.

GCOEARA Awasari Khurd

Unit IV Design Considerations &

Body Construction

Material Requirements and Body Parts

• Comparison between Steel & Aluminum

• Some Comments / Observations

• In summary, steel has many inherent

advantages over aluminum for

applications in pressings however, aluminum

has advantage in castings for housings,

engine blocks, etc.

AABE by R P Kakde GCOEARA Awasari Khurd

Automotive Aerodynamics & Body Engineering

Unit IV

Vehicle Body Engineering

Body & Safety Considerations

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body & Safety Considerations

Introduction

• Designer should ensure maximum safety of the

driver, passenger, and other road users

• Vehicle should be designed to reduce the

effects of collision and ensure minimum injury

• Stylists should avoid sharp ornaments, edges

and projected elements. Careful attention to

door handles, mirrors, hooks, control

knobs,etc. reduces injury to pedestrians and

also affects in reduction of aerodynamic drag

& noise.

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body & Safety Considerations

Safety Features Of Vehicles can be grouped as :

• Vehicle Body Structure, its Systems & Parts

• Additional Safety Features & Systems

• General & other safety recommendations

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body & Safety Considerations

Safety Features Of Vehicles :

• Vehicle Body Structure, its Systems & Parts

• Basis of body design for safety

• Safety features of Door system

• Window Glasses & Windscreen

• Bumpers

• Seat back & head restraints

• Rear view mirrors

• Ventilation

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body & Safety Considerations

Vehicle Body Structure, its Systems & Parts

• Basis of body design for safety

• - The design of vehicle body for optimum

characteristics should be based on basic energy

relationship

• - The kinetic energy of a vehicle destroyed during a

collision is absorbed by the workdone on materials

by elastic deformation

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body & Safety Considerations

Basis of body design for safety

• The kinetic energy of a vehicle destroyed

during

• a collision can be expressed as

• K.E = ( m - m ) V2 / 2

• where ;

• m = total mass of vehicle

• m = moveable mass(passenger or load)

• V = Velocity

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body & Safety Considerations

Workdone on materials by elastic deformation is

Pds = (2 / 2E) A L

where; P = force generated during collusion on

vehicle structure

S = distance traveled during the collision

E = Young’s modulus, Stress/Strain

A = cross sectional area of the structure

= local stress in the material

L = deformation in cm

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body & Safety Considerations

Vehicle Body Structure, its Systems & Parts

• Safety Features of Door System

• - Photo - electric beam door closes automatically at pre -

determined time

• - Gear shift lock prevent selection of gear until all exit

doors are closed

• - Electrically sensitive edge on exist door causes

automatic opening if obstruction is encountered

• - Pneumatic - sensitive - edges give audible and visual

warning to the driver of door obstruction

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body & Safety Considerations

Vehicle Body Structure, its Systems & Parts

• Safety Features of Door System

• - Transmission interlock prevent opening of doors whilst

vehicle is in motion

• Window Glasses

• - Shatter proof glass should be used. When hit against

any object the whole glass falls out and there will be no

sharp edged pieces

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body & Safety Considerations

Vehicle Body Structure, its Systems & Parts

• Window Glasses

• - In bullet proof glass when hit there will be no normal

angle of incident (inclination). The bullet is thrown out

as there will always be some angle of incident.

• Reliability / Safety Requirements Windscreen

• - Freedom from faults which interfere with vision

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body & Safety Considerations

Vehicle Body Structure, its Systems & Parts

• Reliability / Safety Requirements Windscreen

• - High transparency & freedom from visual distortion

• - External durability to reduce surface degradation &

scoring from wipers, ice scrapers, road grit, etc.

• - Vision not affected by normal road stone impacts

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body & Safety Considerations

Vehicle Body Structure, its Systems & Parts

• Reliability / Safety Requirements Windscreen

• - Retention of impacting occupant with low

• deceleration to avoid brain damage

• - Fragment formation should not expose the

• face & head to risk of severe laceration.

• Bumper

• - Shock absorbers behind the bumpers may be used. In

some designs semi - circular

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body & Safety Considerations

Vehicle Body Structure, its Systems & Parts

• Bumper shape is adapted. This avoids direct collision

and tilt of the vehicle.

• - Bumper design & height should be such that in case of

accident it hits passenger below the knee. In this case

the passenger will fall on to the vehicle otherwise on

road which would be more dangerous.

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body & Safety Considerations

Vehicle Body Structure, its Systems & Parts

• Seat - Back & Head Restraints

• - Seat-backs should be in an upright position to get

maximum protection from the seat belts

• - In reclined seat-back position the risk of sliding under

the seat belt increases in a severe crash.

• - The front head restraints help from whiplash and other

injures.

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body & Safety Considerations

Vehicle Body Structure, its Systems & Parts

• Seat - Back & Head Restraints

• - For most effectiveness, the Head Restraint should be

adjusted such that the top of the restraint is even with

the top of the ears as shown

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body & Safety Considerations

Vehicle Body Structure, its Systems & Parts

• Ventilation

• - Proper air vents directed towards the windscreen, side

windows,passenger compartment, front and rear

passenger foot walls should be provided.

• Rear View Mirror

• - Inside rear view mirror can be adjusted up, down or

sideways to obtain the best view. Always adjust the

mirror set to day positions

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body & Safety Considerations

Vehicle Body Structure, its Systems & Parts

• Rear View Mirror

• - Outside rear view mirror can be folded flat against

the side of the vehicle and can be inclined at an angle

to position it properly. The size or distance of a vehicle

or object seen in an outside convex mirror look smaller

and appear farther away as compared to a flat mirror.

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body & Safety Considerations

Safety Features Of Vehicles can be grouped as :

• Additional Safety Features & Systems

• ABS braking system

• Seat belts

• Air bags

• Flashers & horns

• Child safety

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body & Safety Considerations

Additional Safety Features & Systems

• ABS braking system

• - The ABS braking system prevents the wheels from

locking when braking

• - It makes the best road grip and provides safest

control during emergency braking under difficult road

conditions.

• - The driver can feel as ABS comes into play when the

brake pedal pulsates slightly and the system gets

noisier.

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body & Safety Considerations

Additional Safety Features & Systems

• ABS braking system

• - This indicates that the ABS is working and vehicle is

travelling at the limit of the road grip, and the vehicle

speed should be changed to fit the type of road surface.

• - The ABS is in addition, if failure occurs the basic

braking system continue to work.

• - The advantage of the system is to give maximum

maneuverability by preventing the

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body & Safety Considerations

Additional Safety Features & Systems

• ABS braking system

• the wheels from locking.

• - The light on the dash board warns driver to reduce

speed.

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body & Safety Considerations

Additional Safety Features & Systems

• Seat Belts

• - Need & Requirements : Inside a moving car, if car suddenly stops,

the occupant get hurled forward as the car has decelerated or

stopped due to impact but occupant keep moving at about same

speed as the car at the time of impact. So the body, particularly the

head & chest smash into whatever is in front;windscreen,dash

board, steering wheel

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body & Safety Considerations

Additional Safety Features & Systems

• Seat Belts

• Sometimes the occupant can be thrown out of the

car through windscreen or opened door. It is not

only the front seat passengers who are at risk but

also the back seat passengers.

• Seat Belts restrain occupant & holds back to the

• seat - preventing from hitting any hard structure in

the car

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body & Safety Considerations

Additional Safety Features & Systems

• Seat Belts

• - Construction : Seat belt comprise of a lap band

and shoulder band held in place by single

buckle, and bolts fastened to the car body.

• - Types : Seat belts are of two types ; non-

retracting and automatic-retraction. First type

do not adjust to wearer’s movement & not

convenient. The second type allows to

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body & Safety Considerations

Additional Safety Features & Systems

• Seat Belts

• move around freely. It has mechanism that

restrains the occupant when car hits or stops

suddenly.

• - Precautions to be observed : Seat belts are

designed to bear upon the bony structure of the

body, and should be worn low across the front of

the pelvis, chest, and shoulders. Seat belts

should be adjusted as firmly as

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body & Safety Considerations

Additional Safety Features & Systems

• Seat Belts

• possible. Belt should not be worn with straps

twisted. It is dangerous to put belt around a

child being carried on the occupant’s lap.

• Working of the Seat Belt System :

•- Lap/Shoulder Belt has a single belt that

goes over the shoulder, across chest, and across

pelvis as shown in figure.

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body & Safety Considerations

Additional Safety Features & Systems

• - In normal driving, the belt fitted

with a locking retractor allows

occupant move freely in the seat

while keeps tension on the belt.

During a collision or sudden stop the

retractor automatically locks the belt

to help

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body & Safety Considerations

restrain body.

- Before putting on the seat belt move seat as far back as possible,seat

back to be up upright and there should be no twists in the belt.

Air Bag

-Air bag is a safety device that protects the driver & the front seat

passenger during head-on collision

- Air bag is an instantly inflatable cushion stored in the center pad of

steering wheel and in the dash board on passenger side

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body & Safety Considerations

Additional Safety Features & Systems

• - In case of a collision of magnitude exceeding the

set value, the sensor activates the mechanism and

cushion inflates instantly to act as a soft protecting

• barrier

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body & Safety Considerations

Additional Safety Features & Systems

• Hertomatic Flashers and Horn (beep noise)

• operate for every one minute, if not attended

then ultimately the ignition will be automatically

switched off.

• Child Safety

• - Infants and young children should always be

properly restrained whenever they ride in a car

as shown

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body & Safety Considerations

Additional Safety Features & Systems

• Children should ride in rear seat and not in lap of

• adults. Place the child restraint in the seat with a

• lap/ shoulder belt through the restraint ( infants

• & toddler seat ). Use child proof door locks

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body & Safety Considerations

General & other safety recommendations

• There should be no loose items inside vehicle which

could be thrown around and may hurt during accident

or sudden braking / stops

• Luggage should be securely stored or tied downed

• Seats should be upright, head restrain adjusted, & seat

belts fastened

• Vehicle operation control should not be obstructed

• First-Aid kits should be available

AABE by R P Kakde GCOEARA Awasari Khurd

Unit IV Body & Safety Considerations

General & other safety recommendations

• Driver should not be under the influence of alcohol or

drugs

• Ensure all doors are properly closed

• Ensure buckling up of children and child constraint system

is properly installed

AABE by R P Kakde GCOEARA Awasari Khurd

You might also like

- Unit2 ChassisDocument31 pagesUnit2 ChassisMarthandeNo ratings yet

- Vehicle Construction TechnologyDocument47 pagesVehicle Construction TechnologyLOUI SIBBALUCANo ratings yet

- Dr. B.C. Roy Engineering CollegeDocument25 pagesDr. B.C. Roy Engineering CollegeVishal KarmakarNo ratings yet

- Unit - IDocument60 pagesUnit - IChandraSekharKondaveetiNo ratings yet

- ChassisDocument34 pagesChassisSimarjyot SinghNo ratings yet

- AerodynamicsDocument10 pagesAerodynamicsBekalu DanielNo ratings yet

- ChassisDocument50 pagesChassissigitNo ratings yet

- Automotive & BIW - 231212 - 121616Document100 pagesAutomotive & BIW - 231212 - 121616Kasturi Venkata Mohana RaoNo ratings yet

- Car Body ConstructionDocument30 pagesCar Body ConstructionPethurajNo ratings yet

- Vehicle Body EngineeringDocument247 pagesVehicle Body Engineeringshaheen604550% (2)

- 1.3 Chassis and FramesDocument17 pages1.3 Chassis and FramesSachin GautamNo ratings yet

- Vehicle Body Engg-1Document247 pagesVehicle Body Engg-1Aman HanspalNo ratings yet

- Chassis Frame and Body: Palak Desai Mechanical Engineering DepartmentDocument23 pagesChassis Frame and Body: Palak Desai Mechanical Engineering DepartmentPalak NaikNo ratings yet

- Chassis: by Naveen KDocument56 pagesChassis: by Naveen KNaveen KandasamyNo ratings yet

- Chasis DesignDocument19 pagesChasis DesignTANMAYNo ratings yet

- Biw 180626141814Document22 pagesBiw 180626141814Mahesh KarpeNo ratings yet

- Vehicle Body Engineering: Body Terminology, Visibility & SpaceDocument36 pagesVehicle Body Engineering: Body Terminology, Visibility & SpaceB. selvababuNo ratings yet

- Ehicle Evelopment Rganization: Product Engineering Vehicle Engineering StylingDocument56 pagesEhicle Evelopment Rganization: Product Engineering Vehicle Engineering StylingSundhar SavariNo ratings yet

- Types of Chassis FrameDocument11 pagesTypes of Chassis FrameBHOOMI100% (3)

- Sent Automotive Engineering - 1st PDFDocument260 pagesSent Automotive Engineering - 1st PDFsakshiNo ratings yet

- Chasis PDFDocument56 pagesChasis PDFPavan Karthik Mallela100% (1)

- Frame and ChassisDocument20 pagesFrame and ChassisnameNo ratings yet

- Structural Analysis of Ladder Chassis Frame For Jeep Using AnsysDocument7 pagesStructural Analysis of Ladder Chassis Frame For Jeep Using AnsysIJMERNo ratings yet

- Research Design Analysis of Chassis and Frame Work of e RickshawDocument40 pagesResearch Design Analysis of Chassis and Frame Work of e RickshawBlueBat GamingNo ratings yet

- Design ConstructionDocument157 pagesDesign ConstructionfarahNo ratings yet

- Vehicle Body EngineeringDocument37 pagesVehicle Body EngineeringBugulu Bangada100% (1)

- Auto - Suspension - 23Document84 pagesAuto - Suspension - 23Ishrita SaxenaNo ratings yet

- Sme PPT - U4Document158 pagesSme PPT - U4auatesakibNo ratings yet

- Denting Process VehicleDocument59 pagesDenting Process VehicleNaishadh J Desai AnD'sNo ratings yet

- Applications of ROBOTS in The Automobile IndustryDocument24 pagesApplications of ROBOTS in The Automobile Industryhey_panks100% (6)

- Module 2 Au205Document28 pagesModule 2 Au205Sreeram HNo ratings yet

- Lesson 2Document100 pagesLesson 2hafidhadam2002No ratings yet

- SuspensionDocument47 pagesSuspensiongsaratkumar50% (2)

- Construction of Integral Bus Body (MonocoqueDocument3 pagesConstruction of Integral Bus Body (MonocoqueAghil BuddyNo ratings yet

- Pp2-Lec Note 1Document10 pagesPp2-Lec Note 1Marine EngineeringNo ratings yet

- Car BodyDocument67 pagesCar Bodybhargav550850% (2)

- Rhta Vehicle Extrication PDFDocument158 pagesRhta Vehicle Extrication PDFcolteapaul100% (1)

- Chassis Design Report PDFDocument8 pagesChassis Design Report PDFPrakhar YadavNo ratings yet

- 07 Formula SAEWEBDocument38 pages07 Formula SAEWEBKushal LokeshNo ratings yet

- Kishan RupareliaDocument25 pagesKishan RupareliaAnupamNo ratings yet

- Automobile Chassis System UNIT IDocument58 pagesAutomobile Chassis System UNIT IA - STAR100% (1)

- Unit 1autoDocument46 pagesUnit 1autochezhianbabuNo ratings yet

- Collision Body Repair Manual Jeep Grand Cherokee 54-DocumentDocument370 pagesCollision Body Repair Manual Jeep Grand Cherokee 54-DocumentAhmad AlshaerNo ratings yet

- Automobile by KranthiDocument97 pagesAutomobile by KranthiVirat ChinnaNo ratings yet

- Adama Science and Technology University School of Mechanical Chemical and Materials Engineering Department of Mechanical EngineeringDocument54 pagesAdama Science and Technology University School of Mechanical Chemical and Materials Engineering Department of Mechanical EngineeringShemsudin AhmedteibNo ratings yet

- 14264A Construction Mechanic Basic Chapters 14 PDFDocument77 pages14264A Construction Mechanic Basic Chapters 14 PDFMarvin Sarmiento TalimonganNo ratings yet

- ChassisDocument21 pagesChassisIsabella BianchinNo ratings yet

- Chassis OptimizationDocument42 pagesChassis OptimizationNavyadeep SaiNo ratings yet

- BIWDocument20 pagesBIWArvind KatyayanNo ratings yet

- Automobilechassisandbody 160622030425Document95 pagesAutomobilechassisandbody 160622030425Thomas TamangNo ratings yet

- CH2 - DKN 5162 Marine Engineering Practice and Legislation - CHAPTER 2 - BEDPLATE-1Document34 pagesCH2 - DKN 5162 Marine Engineering Practice and Legislation - CHAPTER 2 - BEDPLATE-1Priya Sweetie100% (1)

- Lesson 4: Reciprocating Engine Design and ConstructionDocument66 pagesLesson 4: Reciprocating Engine Design and ConstructionMikhael CastroNo ratings yet

- Automobile IntroductionDocument67 pagesAutomobile IntroductionArvind KatyayanNo ratings yet

- Reciprocating Engine Design and ConstructionDocument66 pagesReciprocating Engine Design and ConstructionGopu PjNo ratings yet

- Collision Body Repair Manual Jeep Compass 52-DocumentDocument341 pagesCollision Body Repair Manual Jeep Compass 52-Documentdomingo59100% (1)

- The Modern Chassis: A Practical Manual of Automotive Chassis and Suspension DesignFrom EverandThe Modern Chassis: A Practical Manual of Automotive Chassis and Suspension DesignRating: 3.5 out of 5 stars3.5/5 (3)

- Honda K-Series Engine Swaps: Upgrade to More Horsepower & Advanced TechnologyFrom EverandHonda K-Series Engine Swaps: Upgrade to More Horsepower & Advanced TechnologyRating: 3 out of 5 stars3/5 (4)

- Solar Assisted Electrical Vehicles PPT by Shemsudin AhDocument37 pagesSolar Assisted Electrical Vehicles PPT by Shemsudin AhShemsudin AhmedteibNo ratings yet

- Adama Science and Technology University School of Mechanical, Chemical and Materials Engineering Department of Mechanical EngineeringDocument21 pagesAdama Science and Technology University School of Mechanical, Chemical and Materials Engineering Department of Mechanical EngineeringShemsudin AhmedteibNo ratings yet

- Group PresentationDocument21 pagesGroup PresentationShemsudin AhmedteibNo ratings yet

- Difinition of Timer CircuitDocument8 pagesDifinition of Timer CircuitShemsudin AhmedteibNo ratings yet

- Adama Science and Technology University School of Mechanical Chemical and Materials Engineering Department of Mechanical EngineeringDocument54 pagesAdama Science and Technology University School of Mechanical Chemical and Materials Engineering Department of Mechanical EngineeringShemsudin AhmedteibNo ratings yet

- Magnum Manual Mgg100m PartsDocument88 pagesMagnum Manual Mgg100m Partsbalajiboss005No ratings yet

- 501-02 Front End Body Panels Freelander 2Document14 pages501-02 Front End Body Panels Freelander 2narutoNo ratings yet

- Catalogo BujesDocument120 pagesCatalogo BujesJason BurtonNo ratings yet

- Peterbilt - Medium Duty Trucks - Owners ManualDocument280 pagesPeterbilt - Medium Duty Trucks - Owners ManualRolando DaclanNo ratings yet

- Body RepairsDocument185 pagesBody RepairsDiego Fuertes ForeroNo ratings yet

- Genesis 3.8L Section 3Document120 pagesGenesis 3.8L Section 3Nacho MowjiNo ratings yet

- Chassis & FrameDocument38 pagesChassis & Framejayant pathakNo ratings yet

- Service Manual Trucks: Hood VHDDocument46 pagesService Manual Trucks: Hood VHDsetiup holjiNo ratings yet

- Is-14226 1995Document10 pagesIs-14226 1995김동은No ratings yet

- Fiat Barchetta: BodyworkDocument23 pagesFiat Barchetta: BodyworkHallex OliveiraNo ratings yet

- Needle Valve CatalogueDocument4 pagesNeedle Valve CatalogueEnrique AssmannNo ratings yet

- LDV 200 400 Pilot Convoy Body PDFDocument103 pagesLDV 200 400 Pilot Convoy Body PDFMick BurnsNo ratings yet

- 42 BodyDocument90 pages42 Bodywanderlei669085No ratings yet

- DirectWire 2015 Honda CR-V Xha27zk298Document6 pagesDirectWire 2015 Honda CR-V Xha27zk298Pedro ToribioNo ratings yet

- BodyworkDocument43 pagesBodyworkGarcia CruzNo ratings yet

- Collision Vol 9 - KW T800Document7 pagesCollision Vol 9 - KW T800Juan RomeroNo ratings yet

- Isp West - Type1 - Body..Document5 pagesIsp West - Type1 - Body..lrcs2000No ratings yet

- Catalog Dorman HD 2015Document108 pagesCatalog Dorman HD 2015BillNo ratings yet

- Ford Figo Body Repair Manual B517 PDFDocument718 pagesFord Figo Body Repair Manual B517 PDFjgarfield420No ratings yet

- ChassisDocument5 pagesChassisSapari VelNo ratings yet

- Hood AnalysisDocument5 pagesHood Analysisymadhu319No ratings yet

- Body, Lock & Security System: SectionDocument130 pagesBody, Lock & Security System: SectionNoerNo ratings yet

- Kia Ceed 2006 - 2012 Gasoline Diesel Factory Workshop Service Repair ManualDocument2,345 pagesKia Ceed 2006 - 2012 Gasoline Diesel Factory Workshop Service Repair ManualEmilian NicuNo ratings yet

- Vehicle System: Disassembly & AssemblyDocument87 pagesVehicle System: Disassembly & AssemblyTrevor Burnett100% (1)

- Kia Rio - BDDocument85 pagesKia Rio - BDkusanagishanNo ratings yet

- Rear Bumper Reinforcement Removal/Installation: 2008 Mazda CX-9 Grand Touring 2008 Mazda CX-9 Grand TouringDocument17 pagesRear Bumper Reinforcement Removal/Installation: 2008 Mazda CX-9 Grand Touring 2008 Mazda CX-9 Grand TouringЯрослав ПіхманецьNo ratings yet

- Ford Focus 2011 Body Repair ManualDocument20 pagesFord Focus 2011 Body Repair Manualmark98% (58)

- Screenshot 2023-07-11 at 12.36.33 PMDocument3 pagesScreenshot 2023-07-11 at 12.36.33 PMNGRD MotorsNo ratings yet

- SM - 29 - Fenders, Engine Hood - BMW M3 1992-1998Document6 pagesSM - 29 - Fenders, Engine Hood - BMW M3 1992-1998Hermawan 0103No ratings yet

- PROTON Waja 4 DR Sal 1.6 (CF1) (A)Document32 pagesPROTON Waja 4 DR Sal 1.6 (CF1) (A)Mitsuton Lanspira100% (1)