Professional Documents

Culture Documents

02 Conveyor-Operation Manual

Uploaded by

Hernan Romero QuirozOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

02 Conveyor-Operation Manual

Uploaded by

Hernan Romero QuirozCopyright:

Available Formats

Operation Manual

Filled Bottle Conveyor

GUANGZHOU TECH-LONG PACKAGING

MACHINERY CO., LTD

广州达意隆包装机械股份有限公司

Guangzhou Tech-Long Packaging Machinery Co., Ltd.

电话(Tel):+86 20-62956888 传真(Fax):+86 20-82266913

网址(Website):www.tech-long.com 邮政编码(PC):510530

地址:中国·广州萝岗区云埔一路 23 号

st

ADD:No. 23, 1 Yunpu Road, Luogang District, Guangzhou

Contents

A. Preface........................................................................................................................................ 1

B. Safety Rules................................................................................................................................ 3

B.1 General Rules..................................................................................................................... 3

B.2 Safety Mark and Instruction...............................................................................................5

B.3 Personnel Contacting with Machine.................................................................................. 8

B.4 Safety Rules during Operation......................................................................................... 10

B.5 Safety Check.................................................................................................................... 11

C. After Service............................................................................................................................. 13

C.1 Problem Solution..............................................................................................................13

C.2 Purchase of Spare Parts....................................................................................................14

Part One General Information....................................................................................................... 15

1.1 Brief Introduction............................................................................................................. 15

1.2 Full Bottle Conveyer.........................................................................................................16

1.3 Technical Data.................................................................................................................. 16

Part Two Pack, Transport & Installation........................................................................................17

2.1 Pack...................................................................................................................................17

2.2 Transport........................................................................................................................... 17

2.3 Installation........................................................................................................................ 17

2.3.1 Housing...................................................................................................................17

2.3.2 Plastic Guide........................................................................................................... 17

2.3.3 Chain Plate..............................................................................................................18

2.3.4 Guardrail................................................................................................................. 18

2.3.5 Drip Tray.................................................................................................................18

Part Three Operation......................................................................................................................19

3.1 Check before Operation.................................................................................................... 19

3.2 Startup...............................................................................................................................20

3.3 Processing Flow................................................................................................................21

3.3.1 Safety...................................................................................................................... 21

3.3.2 Downtime............................................................................................................... 21

3.3.3 Problem during Production.....................................................................................22

3.4 End of Production............................................................................................................. 22

Part Four Maintenance...................................................................................................................23

4.1 Mechanical Maintenance.................................................................................................. 23

4.1.1 Adaptation Period................................................................................................... 23

4.1.2 Working Days......................................................................................................... 23

4.1.3 Regular Interval...................................................................................................... 23

4.2 Electrical Maintenance..................................................................................................... 24

Part Five Analyses and Solution of Problems................................................................................26

5.1 Common Problems........................................................................................................... 26

5.2 Analyses and Solution.......................................................................................................27

Filled Bottle Conveyor I

广州达意隆包装机械股份有限公司

Guangzhou Tech-Long Packaging Machinery Co., Ltd.

电话(Tel):+86 20-62956888 传真(Fax):+86 20-82266913

网址(Website):www.tech-long.com 邮政编码(PC):510530

地址:中国·广州萝岗区云埔一路 23 号

st

ADD:No. 23, 1 Yunpu Road, Luogang District, Guangzhou

A. Preface

Advise:

If you want to make full use of this full bottle conveyer and take charge of all

its advantages, please read this manual as careful as you can before conducting any

work on it. If it can give any suggestion of your operation, maintenance on this

machine, this manual has reached its goal.

Read the SAFETY RULES as careful as you can before operation on this

machine.

Responsibility Declaration:

Our company is not responsible of any problem, damage or accidences

resulting from ignorance of instruction in this manual. Similarly, our company does

not take charge of problem from modification, re-construction, or installation

without our permission.

Specially point out:

Our company does not take any duty to damage from the following reasons:

z Natural Calamity;

z Mal-operation;

z Lack of maintenance;

z Electric short-circuit.

Operate the machine only within the framework of its permissible

application; use permissible operation and material; and observe the

permissible operation limits.

If there is any parts need changing, only use a new one. Change each part

within its lifespan to make full use of the machine as well as avoid

problem from happening. We will not take any responsibility because of

usage of components from other companies.

Filled Bottle Conveyor 1

广州达意隆包装机械股份有限公司

Guangzhou Tech-Long Packaging Machinery Co., Ltd.

电话(Tel):+86 20-62956888 传真(Fax):+86 20-82266913

网址(Website):www.tech-long.com 邮政编码(PC):510530

地址:中国·广州萝岗区云埔一路 23 号

st

ADD:No. 23, 1 Yunpu Road, Luogang District, Guangzhou

Instruction (specification, basic data, schematic drawings, etc.) applied in

this manual is only for reference. The practical machine may be different

in accordance with requirements of a specific customer.

Tech-Long is keeping on improving their techniques as well as machines.

Thus, we reserve the right to make change of our product under

modification or commercial reasons without further notice.

The information provided in this manual must not be duplicated, misused

or passed to a third party without our permission.

Filled Bottle Conveyor 2

广州达意隆包装机械股份有限公司

Guangzhou Tech-Long Packaging Machinery Co., Ltd.

电话(Tel):+86 20-62956888 传真(Fax):+86 20-82266913

网址(Website):www.tech-long.com 邮政编码(PC):510530

地址:中国·广州萝岗区云埔一路 23 号

st

ADD:No. 23, 1 Yunpu Road, Luogang District, Guangzhou

B. Safety Rules

B.1 General Rules

Keep in mind: Safety is the First!

People in workshop must wear necessary protection devices.

Production supervisor of this filling monobloc must have a deep

knowledge of safety in production. What’s more, he must train his men with

the following knowledge:

z Safety protection as well as self-protection in problem;

z Special operation requirements of this machine;

z Position of control devices;

z Position of emergency stop button.

Specially Notice:

Instruction about emergency stop button: press it under an emergency,

the machine will stop.

z No matter when you press the emergency stop button down, the machine

will stop at once. At it will automatically lock in this state.

z If the emergency button is pressed down, the machine will automatically

lock at stoppage state.

z Inspection device on the machine will display that the emergency button

has been pressed down.

Before release the pressed emergency button:

z Check out the reason why the emergency button is pressed down, and then

check out whether the reason (e.g., problem, etc) has been resolved.

z If there are more than one people working on the machine, inform every

one before re-start to assure that there will be no damage to any people or

the machine.

Filled Bottle Conveyor 3

广州达意隆包装机械股份有限公司

Guangzhou Tech-Long Packaging Machinery Co., Ltd.

电话(Tel):+86 20-62956888 传真(Fax):+86 20-82266913

网址(Website):www.tech-long.com 邮政编码(PC):510530

地址:中国·广州萝岗区云埔一路 23 号

st

ADD:No. 23, 1 Yunpu Road, Luogang District, Guangzhou

Notice:

Post the safety rules of this manual in a suitable position. Our company is

not responsible for problem from misuse of this machine during operation.

Operation on this machine, such as assemble and disassemble,

transportation, as well as installation should be carried out by professional

personnel.

z Supply power to this machine as required;

z Routinely check cable with different load.

Specially point out:

Cut off power that supplies to this machine when it stops to avoid mal-

operation.

Filled Bottle Conveyor 4

广州达意隆包装机械股份有限公司

Guangzhou Tech-Long Packaging Machinery Co., Ltd.

电话(Tel):+86 20-62956888 传真(Fax):+86 20-82266913

网址(Website):www.tech-long.com 邮政编码(PC):510530

地址:中国·广州萝岗区云埔一路 23 号

st

ADD:No. 23, 1 Yunpu Road, Luogang District, Guangzhou

B.2 Safety Mark and Instruction

We will post relative marks to positions where may cause damage to the

operator or maintainer. The user of this machine can find them on the machine.

The specific content of marks may be different for various requirements

of customers. If there is nay difference between mark shown below and

the practical one on your machine, the one on the machine is the standard.

Warning

HAZARDOUS

VOLTAGE!

Contact may cause

Look out for

A electric shock or

electric shock!

burn.

This unit is to be

serviced by trained

personnel only.

Warning

MIND CABLES!

B Mind cables! You may damage the

cables here.

Be careful!

Caution

MACHINE

INJURY!

Rotary part. Be Injury may happen

C careful for due to mechanical

damage! motion when

approaching.

Don’t touch when

machine is running.

Caution

D Danger! DANGER!

Be careful!

Filled Bottle Conveyor 5

广州达意隆包装机械股份有限公司

Guangzhou Tech-Long Packaging Machinery Co., Ltd.

电话(Tel):+86 20-62956888 传真(Fax):+86 20-82266913

网址(Website):www.tech-long.com 邮政编码(PC):510530

地址:中国·广州萝岗区云埔一路 23 号

st

ADD:No. 23, 1 Yunpu Road, Luogang District, Guangzhou

Caution

SLIPPERY!

Slipperiness may

happen when

E Slippery!

standing on

machine.

Refer to instruction

manual for safety.

Danger

NO TOUCHING!

Hands may be

injured due to high

F No touch!

temperature or sharp

edges.

Do not touch! Or use

special tools.

Caution

Lubricate

G Lubricate

Periodically!

periodically!

Caution

Rinse

H To rinse

Periodically!

periodically!

Caution

Sanitize

I Sanitize

Periodically!

periodically!

Caution

J Drain Off! Drain off the water

before start-up!

Filled Bottle Conveyor 6

广州达意隆包装机械股份有限公司

Guangzhou Tech-Long Packaging Machinery Co., Ltd.

电话(Tel):+86 20-62956888 传真(Fax):+86 20-82266913

网址(Website):www.tech-long.com 邮政编码(PC):510530

地址:中国·广州萝岗区云埔一路 23 号

st

ADD:No. 23, 1 Yunpu Road, Luogang District, Guangzhou

Caution

High

K Be careful!

Temperature!

High temperature!

Caution

High

Warning! High

L Temperature!

temperature! High

High Voltage!

voltage!

Filled Bottle Conveyor 7

广州达意隆包装机械股份有限公司

Guangzhou Tech-Long Packaging Machinery Co., Ltd.

电话(Tel):+86 20-62956888 传真(Fax):+86 20-82266913

网址(Website):www.tech-long.com 邮政编码(PC):510530

地址:中国·广州萝岗区云埔一路 23 号

st

ADD:No. 23, 1 Yunpu Road, Luogang District, Guangzhou

B.3 Personnel Contacting with Machine

z People who are not operator or maintainer should not approach the

machine.

z All the people who contact with the filling machine should be trained with

knowledge about sanitation and food safety routinely.

z People who conduct operation and maintenance to this machine must be

authorized with a license. What’s more, she or he should be familiar with

work to do.

z People who conduct operation and maintenance to this machine should

not cough or sneeze to it, especially those who are in respiratory disease

and/or infection disease infected by saliva. (We recommend that these

people should not take part in production to assure product quality.)

z Do not get into the machine during rest time, unless absolutely in need.

z People who conduct operation and maintenance should know that, during

work in workshop:

¾ It is not allowed to smoke;

¾ It is not allowed to eat foods;

¾ It is not allowed to store foods;

¾ It is not allowed to nap when on duty;

¾ People under influence of alcohol is not allowed to enter the workshop;

¾ You’d better not put wastebin in the workshop; if you have to, clear

waste in it at any time.

¾ Under precondition that can satisfy air conditioning requirements,

you’d better avoid over aeration. Close all doors and windows to

prevent dust or other contamination from entering the workshop.

¾ Do not approach the rotary components of the machine with head,

hand, feet or other part of your body to avoid injury.

¾ Personnel shall practice good sanitation and health habits. Do not enter

the workshop with dirty clothes.

¾ Do not wear clothes that may be caught by rotary components of the

machine, such as scarf, bracelet, watch, and so on.

¾ Wear necessary protection:

Filled Bottle Conveyor 8

广州达意隆包装机械股份有限公司

Guangzhou Tech-Long Packaging Machinery Co., Ltd.

电话(Tel):+86 20-62956888 传真(Fax):+86 20-82266913

网址(Website):www.tech-long.com 邮政编码(PC):510530

地址:中国·广州萝岗区云埔一路 23 号

st

ADD:No. 23, 1 Yunpu Road, Luogang District, Guangzhou

9 Ear protection cover;

9 Safety glasses;

9 Safety gloves;

9 Helm, including hat and cover if necessary, such as people with

long hair;

9 Protective apparel, including jacket, apron, and other auxiliary

clothes if necessary;

9 Protective footware, including rubber boots, galosh, gumshoe,

antiskid shoes, and so on if necessary.

Protections can prevent damage from:

9 Detergent or disinfectant that spray out;

9 Fragments of burst container (e.g., bottles, etc.).

Protections can also assure product quality by preventing contact between

human body and product. It can also prevent contamination (e.g., dust, etc.)

from entering.

Filled Bottle Conveyor 9

广州达意隆包装机械股份有限公司

Guangzhou Tech-Long Packaging Machinery Co., Ltd.

电话(Tel):+86 20-62956888 传真(Fax):+86 20-82266913

网址(Website):www.tech-long.com 邮政编码(PC):510530

地址:中国·广州萝岗区云埔一路 23 号

st

ADD:No. 23, 1 Yunpu Road, Luogang District, Guangzhou

B.4 Safety Rules during Operation

z Before operation, check whether there is any obvious defect of safety

devices;

z Check whether the emergency stop button functions normally;

z Check whether there is any foreign body (e.g., tools, cleaning cloth, etc.)

inside the filling monobloc;

z Check whether there is nay abnormal sound; if so, stop the machine at

once and find out the reason.

z Check all the protections;

z Caps inside cap sorter should be dry (without water).

z Warning: Operation on the machine should be conducted by a

qualified operator.

z Do not disturb a running machine.

z Keep a certain distance from the rotary components.

Danger Warning:

z Close the main switch and press down the emergency stop button when

regulating devices.

z Do not approach the machine with tools or other things during running.

z Do not run the machine, if the indicating light shows that there is defect.

z Check and maintenance should be done by special mechanical and

electrical engineers.

z Do not move any protection of the machine, unless it is specially

authorized.

z Do not clean electric units with water or other liquid.

z During cleaning process, relative operator must wear suitable gown as

well as glasses and gloves to avoid burn by chemical detergent.

z Only conduct repair work to pneumatic units after releasing pressure

system or pressure in the unit.

z Operation on electric units should be conducted after power supply is cut

off. What’s more, the machine should be well grounded.

z Avoid accidental power supply when the machine stops.

Filled Bottle Conveyor 10

广州达意隆包装机械股份有限公司

Guangzhou Tech-Long Packaging Machinery Co., Ltd.

电话(Tel):+86 20-62956888 传真(Fax):+86 20-82266913

网址(Website):www.tech-long.com 邮政编码(PC):510530

地址:中国·广州萝岗区云埔一路 23 号

st

ADD:No. 23, 1 Yunpu Road, Luogang District, Guangzhou

B.5 Safety Check

After repair work and before startup of filler, supervisor of the workshop

should conduct completely check to all systems.

z Check before Operation

¾ Check all the safety devices;

¾ Check lubrication situation of each part (e.g., motors, gearboxes,

bearings, etc.); add lubricant to them if necessary.

¾ Check whether there is any fastener loose;

¾ Switch power supply on and run the three-phased motor to check its

running direction as well as that of each rotary component.

z Daily Check

Check the following items during operation:

¾ Whether the motor runs as expected;

¾ Whether programs run as expected;

¾ Whether installation environment satisfy design requirements;

¾ Whether cooling system is normal;

¾ Whether there is any abnormal sound or vibration;

¾ Whether there is any abnormal overheat or discolor;

¾ During operation, check input/output voltage with multi-meter to

assure that the machine runs normally.

z Routine Check

¾ Whether the air filter need cleaning;

¾ Because of vibration and temperature change, fastener like bolts and

nuts may loose. Thus, check them routinely and fasten them if

necessary;

¾ Check situation of conductor and insulation resistance;

¾ Check and change of cooling blower, capacitor and relay.

Notice: only conduct the check items above when the machine completely

stops.

Filled Bottle Conveyor 11

广州达意隆包装机械股份有限公司

Guangzhou Tech-Long Packaging Machinery Co., Ltd.

电话(Tel):+86 20-62956888 传真(Fax):+86 20-82266913

网址(Website):www.tech-long.com 邮政编码(PC):510530

地址:中国·广州萝岗区云埔一路 23 号

st

ADD:No. 23, 1 Yunpu Road, Luogang District, Guangzhou

z Six (6)-Month Check

¾ Check all the safety devices.

z One (1)-Year Check

¾ Check all the safety systems and components by special mechanical

and electrical engineers. Post relative check label on the machine after

this.

z Ten (10)-Year Check

¾ After ten years service, our company will conduct a completely check

to this filling monobloc.

Filled Bottle Conveyor 12

广州达意隆包装机械股份有限公司

Guangzhou Tech-Long Packaging Machinery Co., Ltd.

电话(Tel):+86 20-62956888 传真(Fax):+86 20-82266913

网址(Website):www.tech-long.com 邮政编码(PC):510530

地址:中国·广州萝岗区云埔一路 23 号

st

ADD:No. 23, 1 Yunpu Road, Luogang District, Guangzhou

C. After Service

C.1 Problem Solution

We provide maintenance to our machines during their lifespan. If the machine

need repair, please send the following information to us:

z Description of problem;

z How do you judge it;

z Your solution to the problem;

z Other relative information.

Please send those information to:

Address: 23, 1st Yunpu Road, Yunpu Industrial District, Guangzhou,

Guangdong Province, PRC.

Name of Our Company: Guangzhou Tech-Long Packaging Machinery Co.,

LTD

PC: 510530

Telephone: +86 20 8226-6688 (Telephone Exchange);

+86 20 8226-6999 (After Service Hot Line)

Fax: +86 020-82266911

E-mail: service@tech-long.com

When you send those information to us, you should also tell us its serial

number, delivery date and performance which can be found on the nameplate:

Tech-Long Packaging Co., LTD

Model:

Installed Power: Speed (BPH):

Consumption of Compressed Air:

Volume:

Serial No.: Ex-work Date:

Fig. 1 Nameplate

Note: for different customers, the nameplate maybe various. Take the

practical nameplate (those on the machine) as standard.

Filled Bottle Conveyor 13

广州达意隆包装机械股份有限公司

Guangzhou Tech-Long Packaging Machinery Co., Ltd.

电话(Tel):+86 20-62956888 传真(Fax):+86 20-82266913

网址(Website):www.tech-long.com 邮政编码(PC):510530

地址:中国·广州萝岗区云埔一路 23 号

st

ADD:No. 23, 1 Yunpu Road, Luogang District, Guangzhou

C.2 Purchase of Spare Parts

There are many consumable components on the machine. We will provide our

customer one or some sets of relative spare parts. What’s more, we will deliver one

copy of detailed spare parts manual to you. If you are in need of purchasing parts,

you can let us know by:

1) Fill the purchase order shown below;

2) Inform us the description and size & model of the part;

3) If you cannot go through the two ways mentioned above (e.g., you have

lost the spare parts manual; the part is not listed in the manual you have;

etc), you can send a photo of that component to us, and we will check

with our R & D department to solve this.

Purchase Order

Customer Description

Model of Equipment

Way for Delivery

Item No. Drawing No. Description Qty. Note

Filled Bottle Conveyor 14

广州达意隆包装机械股份有限公司

Guangzhou Tech-Long Packaging Machinery Co., Ltd.

电话(Tel):+86 20-62956888 传真(Fax):+86 20-82266913

网址(Website):www.tech-long.com 邮政编码(PC):510530

地址:中国·广州萝岗区云埔一路 23 号

st

ADD:No. 23, 1 Yunpu Road, Luogang District, Guangzhou

Part One General Information

1.1 Brief Introduction

Full bottle conveyer of TECH-LONG are composed of several sections.

According to application and plant layout, it can convey different kinds of

containers, such as, glass bottle, PET bottle, can, and so on. Working processes

(e.g., container conveying, distribution, lane change, etc) are controlled by electric

system automatically. The manual control mode can separately control devices on

full bottle conveying system (e.g., bottle stopper, bottle ejector, etc).

Fig. 2 Schematic Diagram of Full Bottle Conveyer

Filled Bottle Conveyor 15

广州达意隆包装机械股份有限公司

Guangzhou Tech-Long Packaging Machinery Co., Ltd.

电话(Tel):+86 20-62956888 传真(Fax):+86 20-82266913

网址(Website):www.tech-long.com 邮政编码(PC):510530

地址:中国·广州萝岗区云埔一路 23 号

st

ADD:No. 23, 1 Yunpu Road, Luogang District, Guangzhou

1.2 Full Bottle Conveyer

Designation Full Bottle Conveyer

Please consult “List of Content Equipments” in

Structure

parts manual

Application Scope For container indicated in contract only!

Manufacturer TECHLONG PACKAGING LTD.

Position:

Nameplate z Control cabinet;

z Housing of conveyers;

Please consult contract:

Model z Nameplate;

z “List of Content Equipments” in parts manual;

1.3 Technical Data

Dimension

Length Depends on plant layout

Width 105mm to 2570mm

Height Depends on plant layout

Weight

Depends on quantity of lanes and length of

Net Weight

conveyer

Permissible Production Environment

Permissible Temperature +5°C ~ +50°C

Permissible Pressure 6bar

Noise Level 75 ~ 85dBA

Model & Size;

Please consult:

Efficiency;

● Parts manual;

Structure;

z Plant layout;

Dimension

Please consult:

Electrical Information ● Nameplate on control cabinet;

● Electric documents;

Filled Bottle Conveyor 16

广州达意隆包装机械股份有限公司

Guangzhou Tech-Long Packaging Machinery Co., Ltd.

电话(Tel):+86 20-62956888 传真(Fax):+86 20-82266913

网址(Website):www.tech-long.com 邮政编码(PC):510530

地址:中国·广州萝岗区云埔一路 23 号

st

ADD:No. 23, 1 Yunpu Road, Luogang District, Guangzhou

Part Two Pack, Transport & Installation

In order to keep the full bottle conveyer runs normally, please install the

conveyer by professional personnel!

It is recommended to have service engineers from Tech-Long for this work.

2.1 Pack

Pack the conveyer in wooden container; connect it with bottom of the

container; parts in small volume, such as chain plate, supporting foot, and spare

parts, should be packed separately and fixed inside the container; wrap each parts

with transparent plastic film.

2.2 Transport

Do NOT incline or turn over the container during transport; take the bottom

of container as hoisting point, and the inclination should not be larger than 10°.

2.3 Installation

2.3.1 Housing

The full bottle conveyer is composed of several sections which includes

different quantity of standard housing. Before installation, read plant layout as

carefully as possible at first, and position each housing as indicated in the layout.

Keep the housing level and straight, and the connection part smooth. The deviation

should not overpass 0.3mm. Make sure height of each housing follows

requirements in layout. Fasten screw.

2.3.2 Plastic Guide

Usually, the guide is made of HMWPE. During installation, keep the guide in

line. If possible, use one strip only. In consideration of influence from heat, only

one end of the guide is fixed up by one (or two) screw, while the other end id

Filled Bottle Conveyor 17

广州达意隆包装机械股份有限公司

Guangzhou Tech-Long Packaging Machinery Co., Ltd.

电话(Tel):+86 20-62956888 传真(Fax):+86 20-82266913

网址(Website):www.tech-long.com 邮政编码(PC):510530

地址:中国·广州萝岗区云埔一路 23 号

st

ADD:No. 23, 1 Yunpu Road, Luogang District, Guangzhou

flexible.

2.3.3 Chain Plate

Position chain in different models on floor at first, and then connect them one

by one. After that, install the chain plate onto housing. This can avoid chain plate

from twisting and ease connection work. Special attention should be paid that

installation of chains has specific direction: direction of arrow on back must be the

same with running direction. If there is bypass sections, (in standard design) the

conveyer speeds up from multilane to single lane. Or, the conveyer slows down

from single lane to multilane.

2.3.4 Guardrail

Guardrail is used to guide containers on the conveyer and prevent them from

falling down or dropping. During installation, keep the guardrail straight, and keep

the connection part smooth. Usually, connection part is located at clamp on

guardrail.

2.3.5 Drip Tray

There is central outlet between adjacent drip trays. Therefore, properly incline

the drip tray to the outlet. The waste water will flow into the outlet, and then drains

out to ditch or for recycle. After installation, the drip tray can also function to

prevent water from contacting return side of chain plate.

Filled Bottle Conveyor 18

广州达意隆包装机械股份有限公司

Guangzhou Tech-Long Packaging Machinery Co., Ltd.

电话(Tel):+86 20-62956888 传真(Fax):+86 20-82266913

网址(Website):www.tech-long.com 邮政编码(PC):510530

地址:中国·广州萝岗区云埔一路 23 号

st

ADD:No. 23, 1 Yunpu Road, Luogang District, Guangzhou

Part Three Operation

3.1 Check before Operation

Before startup, make sure that the conveying system is ready to run.

If the conveying system is improperly positioned or not ready, it will cause:

z Problem during production;

z Damage to components on conveyer;

z Injury to operators;

Therefore, before startup, check the following items:

z Whether relative parameter (e.g., height, width, etc) has been set up

according to containers to be treated;

z Whether mark (e.g., identification number, colorful point, etc) on

driving parts is set up according to requirements of this system;

z Make sure that all driving parts are installed as required;

z Make sure that all regulation work have been done as required;

z Whether the conveying system is ready to run;

z Whether there is damage on surface of safety device, photoelectric tube

and reflector;

z Whether all guards have been installed as required;

z Whether all maintenance work have been done as required, and

lubrication follows;

z Whether there are odds and ends (e.g., tools, dirty cloth, etc) left on the

conveyer;

z Before production, clear all problems.

Filled Bottle Conveyor 19

广州达意隆包装机械股份有限公司

Guangzhou Tech-Long Packaging Machinery Co., Ltd.

电话(Tel):+86 20-62956888 传真(Fax):+86 20-82266913

网址(Website):www.tech-long.com 邮政编码(PC):510530

地址:中国·广州萝岗区云埔一路 23 号

st

ADD:No. 23, 1 Yunpu Road, Luogang District, Guangzhou

3.2 Startup

z Make sure that equipments at upstream and downstream are all started;

z Open main valve of compressed air;

Check running pressure on manometer.

z Switch on power supply, and:

¾ Check whether power supply is on;

¾ Open lock on e-stop/maintenance switch;

¾ Press down e-stop/maintenance switch;

¾ Change broken lamps (work of electrician) to indicate problems and

running status;

¾ Press down “RESET” button;

¾ Check problem indicator;

z Switch on conveying system, and:

¾ Press down “Conveying System On” button;

¾ Check whether safety devices work normally;

z Stop the system when:

¾ E-stop button is pressed down;

¾ E-stop/Maintenance switch is pressed down;

¾ Safety door is opened;

z If there is any problem,

¾ Solve it before startup;

¾ Please consult information in “Problem Analyses and Solution”

section;

Filled Bottle Conveyor 20

广州达意隆包装机械股份有限公司

Guangzhou Tech-Long Packaging Machinery Co., Ltd.

电话(Tel):+86 20-62956888 传真(Fax):+86 20-82266913

网址(Website):www.tech-long.com 邮政编码(PC):510530

地址:中国·广州萝岗区云埔一路 23 号

st

ADD:No. 23, 1 Yunpu Road, Luogang District, Guangzhou

3.3 Processing Flow

3.3.1 Safety

z Do NOT interfere in processing of conveyer with hand or other tools

(e.g., stick, etc), or injury may be caused;

z Do NOT interfere in relative movement between containers and

conveying belt/chain plate;

z Do NOT stay at driving point of shaft;

z Do NOT interfere in rotary parts on bottom;

z Do NOT stay at outer diameter line of curve chain;

z Do NOT touch pneumatic components (e.g., stopper, turnover device,

ejector, pneumatic guide rail, etc);

z Danger area of conveying system is protected by guarding (e.g., cover,

guard net, etc). Nevertheless, potential damage/injury cannot be solved

completely. Therefore, only when conveying system is stopped and

locked (i.e., it cannot be started by accidence), the operator can

interfere processing flow.

z Monitor conveying process regularly;

z Take off containers on ejection conveyer by hand according to stream

of containers;

Note: Prevent injury from broken container or odds and ends (e.g., glass, cap,

etc). Similarly, prevent injury from blocked container or container jam.

3.3.2 Downtime

z When there is any problem on production line, the control system will

stop the conveyer;

(Speed control depends on that of upstream and downstream equipments.)

z The conveying system is standby;

(If container supply is normal, the conveyer will start automatically.)

z Rest time;

In order to prevent accidental startup,

¾ Stop the conveyer during rest time;

Filled Bottle Conveyor 21

广州达意隆包装机械股份有限公司

Guangzhou Tech-Long Packaging Machinery Co., Ltd.

电话(Tel):+86 20-62956888 传真(Fax):+86 20-82266913

网址(Website):www.tech-long.com 邮政编码(PC):510530

地址:中国·广州萝岗区云埔一路 23 号

st

ADD:No. 23, 1 Yunpu Road, Luogang District, Guangzhou

¾ Press down e-stop button for safety;

3.3.3 Problem during Production

z If there is any problem, the conveyer should stop automatically;

z If the conveyer has not stopped even when there is obvious problem,

stop it and solve the problem;

z Order of problem searching:

¾ Find out where is the problem and reason for that;

¾ Use the following way: control panel, information on HMI, test

device to find out problem;

¾ If in need, ask professional personnel for help;

¾ Analyze;

¾ Solve the problem;

3.4 End of Production

z Take off containers on conveyer;

z Cut off energy supply to power system;

z Stop control system and lock up;

z Press down e-stop/maintenance switch;

z Lock up (take with the key);

z Close main valve of compressed air;

Filled Bottle Conveyor 22

广州达意隆包装机械股份有限公司

Guangzhou Tech-Long Packaging Machinery Co., Ltd.

电话(Tel):+86 20-62956888 传真(Fax):+86 20-82266913

网址(Website):www.tech-long.com 邮政编码(PC):510530

地址:中国·广州萝岗区云埔一路 23 号

st

ADD:No. 23, 1 Yunpu Road, Luogang District, Guangzhou

Part Four Maintenance

4.1 Mechanical Maintenance

4.1.1 Adaptation Period

Usually, the adaptation period is only two or three days. During this period,

maintain the conveyer as follows:

z Check flexibility of chain plate, especially when the conveyer runs

under heavy load and high speed. If the conveyer is too long,

disassemble one or some chain.

z Clean the conveyer to remove dust and potential particles, which can

reduce damage.

4.1.2 Working Days

z Lubricate the conveyer at the beginning of each shift;

z If there is any chain cannot be lubricated, add water and lubricant in

time; if the lubrication nozzle is blocked, clear it;

z If there is any fastener loose, fasten it;

z Clear odds and ends on chain plate or drip tray.

4.1.3 Regular Interval

z Completely clean the conveyer, and disassemble drip trays for cleaning;

z Check whether there is any part deformed, if so, regulate it;

z Check tension of chain plate, and keep it at 3 ~ 5bar with about 30mm

suspending;

z Add lubrication oil to bearings and parts needed lubricating;

z Check oil level in gearbox, and change the oil if necessary;

z Disassemble all lubrication nozzles to clean;

z Check abrasion situation of chain plate, guardrail, driving wheels, idle

wheels as well as sprockets; change with new one if necessary;

Filled Bottle Conveyor 23

广州达意隆包装机械股份有限公司

Guangzhou Tech-Long Packaging Machinery Co., Ltd.

电话(Tel):+86 20-62956888 传真(Fax):+86 20-82266913

网址(Website):www.tech-long.com 邮政编码(PC):510530

地址:中国·广州萝岗区云埔一路 23 号

st

ADD:No. 23, 1 Yunpu Road, Luogang District, Guangzhou

4.2 Electrical Maintenance

The situation of pneumatic components (e.g. cylinder, solenoid valve, airway

plate, and speed control valve) and their reliability can be checked by manual

adjustments.

PLC and the frequency inverter are the main electrical parts. The check and

maintenance conducted to the input/output signal of other switches, such as

whether there is any breach of them; whether the circuit breaks, whether the output

components (e.g., relay, indicative lamp, the coil of solenoid, etc.) function well,

can carry out according to the PLC input/output signal indicative lamp.

PLC and frequency inverter are stationary device with semiconductor

components as the center. Routinely check should be conducted to preclude the

impact from the utility environment (temperature, humidity, dust, vibration, etc), as

well as aging of parts.

A. Notice for Check and Maintenance

a) The operator should check whether the power supply is on or off to

preclude mal-operation;

b) The voltage in the capacitor is still high after the frequency inverter has just

been cut off. Thus, only when the load indicative lamp on the printed panel

is off as well as the voltage between P and N (the two terminals of the

major loop of the frequency inverter) is lower than DC 30V, can the check

be conducted.

B. Check Items

PLC and the general used frequency inverter have power indicator and

problem indicator during the running, which should be informed at first. What’s

more, the operator should also get familiar with the setup of the electron thermal

relay and speed up/down time listed in the parameters of the frequency inverter, as

well as write down these data.

Filled Bottle Conveyor 24

广州达意隆包装机械股份有限公司

Guangzhou Tech-Long Packaging Machinery Co., Ltd.

电话(Tel):+86 20-62956888 传真(Fax):+86 20-82266913

网址(Website):www.tech-long.com 邮政编码(PC):510530

地址:中国·广州萝岗区云埔一路 23 号

st

ADD:No. 23, 1 Yunpu Road, Luogang District, Guangzhou

C. Routine Inspection

Check the following item when the machine is running:

a) Whether the motor runs as expected; whether the procedure runs normally;

b) Whether the installation environment is normal;

c) Whether the cooling system runs normally;

d) Whether there is unusual vibration or noise;

e) Whether there is unusual heat or discolor;

Generally, the measure of the input/output voltage during manipulation is

conducted with multi-meter.

D. Periodic Inspection

Inspection of some places can only be conducted when the machine completely

stops. Check these places and those need periodic inspection.

a) Whether the cooling system runs normally; clean the air filter;

b) The fasteners such as the screw, bolts will turn loose under the impact of

vibration and/or change of temperature. Thus, it is necessary to check the

fastening situation frequently. Fasten them if necessary.

c) Conductor and insulation resistance;

d) Inspection and replacement of fan, capacitor, and relay.

Note: conduct items mentioned above when the conveyer is completely stopped

(i.e., it cannot be started by accidence).

Filled Bottle Conveyor 25

广州达意隆包装机械股份有限公司

Guangzhou Tech-Long Packaging Machinery Co., Ltd.

电话(Tel):+86 20-62956888 传真(Fax):+86 20-82266913

网址(Website):www.tech-long.com 邮政编码(PC):510530

地址:中国·广州萝岗区云埔一路 23 号

st

ADD:No. 23, 1 Yunpu Road, Luogang District, Guangzhou

Part Five Analyses and Solution of Problems

5.1 Common Problems

1) “Common Problem” indicator lamp keeps lighting up;

2) “RESET” button keeps lighting up;

3) Emergency stop;

4) Driving devices are overloaded;

5) The chain plate is broken apart;

6) Chain plate and plastic parts are abraded abnormally;

Filled Bottle Conveyor 26

广州达意隆包装机械股份有限公司

Guangzhou Tech-Long Packaging Machinery Co., Ltd.

电话(Tel):+86 20-62956888 传真(Fax):+86 20-82266913

网址(Website):www.tech-long.com 邮政编码(PC):510530

地址:中国·广州萝岗区云埔一路 23 号

st

ADD:No. 23, 1 Yunpu Road, Luogang District, Guangzhou

5.2 Analyses and Solution

Problem Analyses Solution

“Common

z Check relative driving

Problem”

z Some safety device of motor is device and solve the problem;

indicator lamp

tripped; z Press “RESET” button

keeps lighting

on control cabinet;

up.

z Press down “RESET” button

z Check relative driving

“RESET” when problem is solved;

device and solve the problem;

button keeps z Problem is solved, but

z Press “RESET” button

lighting up. “RESET” button has not been

on control cabinet;

pressed for confirmation.

z Check the conveyer and

problem area;

z Make sure that the

Emergency z There is problem and the e-stop

problem is solved and there is

stop button is pressed sown;

no people staying within

problem area, and then loosen

e-stop button;

z Run under permissible

condition;

z Check relative driving

Driving z Runs overloaded (e.g., block); device and solve the problem;

devices (e.g., z There is oil leaking from gearbox; z Check and change oil

motor) are z Runs in high/low frequency for a tight; top it up;

overloaded. long time; z Frequency deviation

should not be large; if

necessary, regulate the speed

ratio;

Filled Bottle Conveyor 27

广州达意隆包装机械股份有限公司

Guangzhou Tech-Long Packaging Machinery Co., Ltd.

电话(Tel):+86 20-62956888 传真(Fax):+86 20-82266913

网址(Website):www.tech-long.com 邮政编码(PC):510530

地址:中国·广州萝岗区云埔一路 23 号

st

ADD:No. 23, 1 Yunpu Road, Luogang District, Guangzhou

Problem Analyses Solution

z Power supply stops suddenly,

z Clear containers on

and the conveyer start fully loaded;

conveyer and repair; after

z There is foreign things between

that, start the motor again;

housing and chain plate (e.g., bolt,

The chain plate z Clear foreign things and

spacer, etc), which causes destructive

is broken apart. regulate clearance between

strain;

chain plate and housing;

z Fixing pin of chain plate is

z Change broken parts and

deviated, which causes chain plate

fix the pin up;

and housing to break apart;

z There is angle deviation during z Adjust the housing;

Chain plate and connection of housing; z Clean the chain plate and

plastic parts are z There is foreign things (e.g., remove foreign things;

abraded particles) blocking; z Clear burr on housing;

abnormally. z There is sharp burr on housing; z Run the conveyer under

z The conveyer runs overloaded; permissible condition;

Filled Bottle Conveyor 28

You might also like

- Wiring Diagram J08EDocument376 pagesWiring Diagram J08EKaereesena Hikayana100% (7)

- International HX Wiring DiagramsDocument482 pagesInternational HX Wiring DiagramsNathan CrestaniNo ratings yet

- Mitsubishi 4g92 Engine Manual PDFDocument2 pagesMitsubishi 4g92 Engine Manual PDFMohammed Hanafi60% (5)

- Wrap Around Packer DetailsDocument24 pagesWrap Around Packer DetailsUmair Younus100% (1)

- ScannerDocument76 pagesScannerMAYESTONNo ratings yet

- OPERATION MANUAL-Necking MachineDocument12 pagesOPERATION MANUAL-Necking Machinecarlogeretto2No ratings yet

- Amateur Radio Direction FindingDocument8 pagesAmateur Radio Direction Findingsorin birouNo ratings yet

- Service Manual: Split TypeDocument112 pagesService Manual: Split TypeVăn NamNo ratings yet

- M318D - M322D PDFDocument14 pagesM318D - M322D PDFwesley candido0% (1)

- XLCT Series: Operational and Spare Parts ManualDocument36 pagesXLCT Series: Operational and Spare Parts ManualArthamigas EngineeringNo ratings yet

- Electrical System - Wiring DiagramsDocument321 pagesElectrical System - Wiring DiagramsKevin Vega BarandicaNo ratings yet

- SM 1Document207 pagesSM 1Jan Svein Hammer100% (1)

- Toyota Hilux 2018 Overall EWD Vehicle Interior Air Conditioner (RHD Manual)Document2 pagesToyota Hilux 2018 Overall EWD Vehicle Interior Air Conditioner (RHD Manual)gabrielzinho43No ratings yet

- Codecard: Service ?Document23 pagesCodecard: Service ?victor hugo100% (1)

- IMD Equipment Guide PDFDocument159 pagesIMD Equipment Guide PDFSalem GarrabNo ratings yet

- Promat Exhibitors ListDocument145 pagesPromat Exhibitors ListSaksham TharejaNo ratings yet

- 140701Document16 pages140701MarceloPolicastroNo ratings yet

- Programming Manual - TPSys - 2.4Document458 pagesProgramming Manual - TPSys - 2.4Денис ФроловNo ratings yet

- Manual de Instrucciones Karceher HD 5 12 C - BTA-5309339-000-01Document40 pagesManual de Instrucciones Karceher HD 5 12 C - BTA-5309339-000-01Christian TrujilloNo ratings yet

- Service Manual: WashingDocument49 pagesService Manual: WashingМастер ремонтаNo ratings yet

- 3606&3608 Mar PRJ Guide - LEBM0600Document124 pages3606&3608 Mar PRJ Guide - LEBM0600della alNo ratings yet

- Bi0068130001 - Manual de PartesDocument677 pagesBi0068130001 - Manual de PartesMiguel angel Guerra Briceño100% (1)

- User Manual: SBO 24/24 - #13115Document436 pagesUser Manual: SBO 24/24 - #13115okuk denisNo ratings yet

- 601-10-14-V3.7.38 (Ware Handling)Document81 pages601-10-14-V3.7.38 (Ware Handling)Yogesh BadheNo ratings yet

- Conveyor Systems Maintenance Manual XS, XL, XM, XH, XK, XBDocument43 pagesConveyor Systems Maintenance Manual XS, XL, XM, XH, XK, XBTamal Tanu RoyNo ratings yet

- Steel Products and Structural Shapes - OptDocument12 pagesSteel Products and Structural Shapes - OptmurdicksNo ratings yet

- EPI-3522 GRAND - Abian BlisreringDocument12 pagesEPI-3522 GRAND - Abian Blisreringmohammad pirayesh100% (1)

- Complete Water and Syrup Filling Line 3000bph at 1000ml: To: Matic Gdańsk 11.04.2023 Offer No: 074 - 04 - 2023 - MKDocument49 pagesComplete Water and Syrup Filling Line 3000bph at 1000ml: To: Matic Gdańsk 11.04.2023 Offer No: 074 - 04 - 2023 - MKAlija IbrisevicNo ratings yet

- GPL-5545C Manual - NewDocument30 pagesGPL-5545C Manual - NewRocio GimenezNo ratings yet

- NM402 Norden Tube FillingDocument8 pagesNM402 Norden Tube FillingSaka International LtdNo ratings yet

- Multimac DDocument40 pagesMultimac Dloko221No ratings yet

- Meech Web Cleaning Overview Brochure 2015Document24 pagesMeech Web Cleaning Overview Brochure 2015danceNo ratings yet

- Project Report On Electric VehiclesDocument51 pagesProject Report On Electric VehiclesNaveen PrabhuNo ratings yet

- Car Insurance Go Digit SkodaDocument3 pagesCar Insurance Go Digit SkodaAbhiroop AwasthiNo ratings yet

- MRF Tyres: Presented byDocument33 pagesMRF Tyres: Presented byRajneesh Sharma50% (4)

- User Manual: Tia Technology India Pvt. LTDDocument83 pagesUser Manual: Tia Technology India Pvt. LTDRobin PNo ratings yet

- 2ML70Document4 pages2ML70Dezső Lőcsei50% (2)

- Company Profile PT. Kinar Prospek TeknologiDocument16 pagesCompany Profile PT. Kinar Prospek TeknologiOcky Hendrawan LimansagitaNo ratings yet

- TC3 - Op - Man - Rev B 2011-04-15allDocument91 pagesTC3 - Op - Man - Rev B 2011-04-15alljosue nievesNo ratings yet

- PEC - FP .19.01sDocument156 pagesPEC - FP .19.01sCristian MartinsNo ratings yet

- HS SLSMAN 01 Rev.W - Pasteurizer 520 115V Operation ManualDocument33 pagesHS SLSMAN 01 Rev.W - Pasteurizer 520 115V Operation ManualErick LoganNo ratings yet

- GIAD0019ED03ESDocument205 pagesGIAD0019ED03ESDekker LuukNo ratings yet

- CS 5200 Operating ManualDocument15 pagesCS 5200 Operating ManualJoan LamedaNo ratings yet

- HDSD may cắt hàn màng nhiệtDocument20 pagesHDSD may cắt hàn màng nhiệtsetavietnamNo ratings yet

- FINAL 120 BPM CSD Filling Line NewDocument14 pagesFINAL 120 BPM CSD Filling Line NewOMKAR JADHAVNo ratings yet

- INDOSA Technology: The World's No. 1 in Can MachineryDocument25 pagesINDOSA Technology: The World's No. 1 in Can Machinery高金辉No ratings yet

- Operator's Manual: Automatic Round Product Labeling SystemDocument69 pagesOperator's Manual: Automatic Round Product Labeling SystemERICK HIOVANIS AVILA LARANo ratings yet

- Pama - Product Pasteurization, Heating and Cooling Systems PDFDocument9 pagesPama - Product Pasteurization, Heating and Cooling Systems PDFCar MiguelNo ratings yet

- Machine Manual - TPSys - 2.4Document276 pagesMachine Manual - TPSys - 2.4Денис ФроловNo ratings yet

- Operator Manual H12Document104 pagesOperator Manual H12KestutisNo ratings yet

- Operating Manual Multi-Cooler SimpsonDocument367 pagesOperating Manual Multi-Cooler SimpsonAgurtzane Ibabe Barruetabeña100% (1)

- 2002 ExplorerDocument336 pages2002 ExplorerSteve AbonyiNo ratings yet

- Kzo 816 824 01Document16 pagesKzo 816 824 01fahnoeNo ratings yet

- Grant Ultra Sonic Water Baths Xub Series ManualDocument156 pagesGrant Ultra Sonic Water Baths Xub Series ManualIs IskandarNo ratings yet

- Wilson Hardness Conversion Chart - ShortDocument1 pageWilson Hardness Conversion Chart - ShortwellbeingempireNo ratings yet

- PSS 3.2 - 520 - 5,5kW - DrawingDocument1 pagePSS 3.2 - 520 - 5,5kW - DrawingCentrifugal SeparatorNo ratings yet

- PennDOT EmailsDocument328 pagesPennDOT EmailsmegankshannonNo ratings yet

- Hitachi Printer: Technical Manual Ink Jet Printer For Industrial MarkingDocument164 pagesHitachi Printer: Technical Manual Ink Jet Printer For Industrial MarkingRodrigoNo ratings yet

- MED 4006-SW SupplementaryAdd 040713Document18 pagesMED 4006-SW SupplementaryAdd 040713Ovidiu ChirvaseNo ratings yet

- Om 01102046 Ic448ffs GBDocument70 pagesOm 01102046 Ic448ffs GBmohamed algharbi0% (1)

- Operation Manual: Plastic Processing MachineDocument98 pagesOperation Manual: Plastic Processing Machinehbj52506100% (1)

- Basic Handling Guide of Small Satellite Hardware For Non Government Organizations v3 Read OnlyDocument35 pagesBasic Handling Guide of Small Satellite Hardware For Non Government Organizations v3 Read OnlyNickElderfieldNo ratings yet

- Deh-80prs Deh-80prsDocument98 pagesDeh-80prs Deh-80prsTai HuatNo ratings yet

- Delta ASDA B2 User Manual PDFDocument337 pagesDelta ASDA B2 User Manual PDFSỹ HưởngNo ratings yet

- Washing Machine: Service ManualDocument56 pagesWashing Machine: Service ManualRubén DaríoNo ratings yet

- Nara Bassinet Maintenance ManualDocument46 pagesNara Bassinet Maintenance ManualAnonymous KiraNo ratings yet

- Vegetable-Vending-Carts Cart CorporationDocument7 pagesVegetable-Vending-Carts Cart Corporationmanavseva credit100% (1)

- Blasting Basics - Empire AbrasiveDocument5 pagesBlasting Basics - Empire AbrasiveYoutube For EducationNo ratings yet

- Innovis 10 ManualDocument104 pagesInnovis 10 ManualSariel Castaño DíazNo ratings yet

- Acme Screw Data PDFDocument4 pagesAcme Screw Data PDFAnggit PrakasaNo ratings yet

- ch18Document20 pagesch18Mahmmod Al-QawasmehNo ratings yet

- DECS-250: Digital Excitation Control SystemDocument374 pagesDECS-250: Digital Excitation Control SystemLOI HONo ratings yet

- Motor Master 20000 SeriesDocument56 pagesMotor Master 20000 SeriesArnulfo Lavares100% (1)

- MSD Prevention Toolbox PartC English in Depth Risk Assessment FinalDocument49 pagesMSD Prevention Toolbox PartC English in Depth Risk Assessment FinalLuiz Rubens Souza CantelliNo ratings yet

- Sinajet Digital Cutter Manual-EnDocument40 pagesSinajet Digital Cutter Manual-EnMaulana YusufNo ratings yet

- Virtual Reality, Artificial Intelligence and Specialized Logistics in HealthcareFrom EverandVirtual Reality, Artificial Intelligence and Specialized Logistics in HealthcareNo ratings yet

- Refacing Valves and Valve StemsDocument4 pagesRefacing Valves and Valve StemsHaftay100% (1)

- Wildcat 2014 BrochureDocument24 pagesWildcat 2014 BrochurebadrayyanNo ratings yet

- 2020Document738 pages2020Almina SalihNo ratings yet

- Smart Cameras As Embedded Systems REPORTDocument40 pagesSmart Cameras As Embedded Systems REPORTJaya SwaroopNo ratings yet

- General Motors Parts Plant For Silverado EV and Sierra EVDocument121 pagesGeneral Motors Parts Plant For Silverado EV and Sierra EVMaria MeranoNo ratings yet

- Operating A Moped or ScooterDocument75 pagesOperating A Moped or ScooterJohnNo ratings yet

- Technical Specifications: 2021 FORD F-150Document12 pagesTechnical Specifications: 2021 FORD F-150Attchu HunNo ratings yet

- Troubleshooting para Mixer PDFDocument16 pagesTroubleshooting para Mixer PDFMauricio Ariel H. OrellanaNo ratings yet

- BCM 2 JEEP Cherokee 2015Document1 pageBCM 2 JEEP Cherokee 2015Iván Israel Mora PonceNo ratings yet

- Moving Freight Over The Road: Lecture ObjectivesDocument7 pagesMoving Freight Over The Road: Lecture ObjectivesAlfath GhaniNo ratings yet

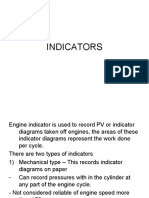

- 03 Indicator DiagramDocument37 pages03 Indicator DiagramnareshNo ratings yet

- Al-Si Centrifugalni Lijev LMMDocument8 pagesAl-Si Centrifugalni Lijev LMMMarija MusaNo ratings yet

- Daikin FCU CatalogueDocument35 pagesDaikin FCU CatalogueAniket GajendragadkarNo ratings yet