Professional Documents

Culture Documents

SIMOPS SMG 06-007-2016 (Final)

Uploaded by

Ayman AlradiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SIMOPS SMG 06-007-2016 (Final)

Uploaded by

Ayman AlradiCopyright:

Available Formats

Saudi Aramco

Safety Management Guide

SIMULTANEOUS OPERATIONS

(SIMOPS)

Guide Number 06-007-2016

Table of Contents

1. Purpose .................................................................................................................. 1

2. Scope ........................................................................................................... ……...1

3. Definitions...................................................................................................... ……..1

4. Introduction..................................................................................................... …....2

5. Responsibilities............................................................................................... …....3

6. Procedure ............................................................................................................... 5

7. Competency Requirements .................................................................................. 10

Supplements

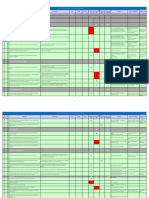

Supplement 1: Simultaneous Operations Flowchart ...................................................... 12

Supplement 2: Example SIMOPS Hazards and Conditions Register ............................. 13

Supplement 3: Example SIMOPS Matrix (Partial).......................................................... 14

Supplement 4: Example SIMOPS Conditions / Mitigations (Partial) ............................... 15

Supplement 5: 2nd Example SIMOPS Matrix (Partial) .................................................... 16

Supplement 6: 2nd Example SIMOPS Conditions / Mitigations ....................................... 17

Prepared by the Loss Prevention Department

August 1, 2016

© Copyright 2016 Saudi Aramco. All Rights Reserved.

Simultaneous Operations Guide Issue Date: August 1, 2016

Simultaneous Operations

1. PURPOSE

The purpose of this Safety Management Guide (SMG) is to provide a methodical process

that will assist Saudi Aramco proponent organizations in determining whether or not

Simultaneous Operations (SIMOPS) plans are required, help the proponent develop

appropriate plans and also help with managing the work by applying effective risk

management techniques. SIMOPS agreements and plans are used to protect all involved

personnel, company assets and the environment.

2. SCOPE

This Safety Management Guide applies to all Saudi Aramco (SA) facilities (onshore and

offshore), project sites and support facilities where simultaneous activities may occur.

Some examples where SIMOPS may take place include construction within an existing

facility, during commissioning activities, upgrades, start up, expansion projects, major

plant shut downs, turnarounds, drilling, workover, pipeline work, laydown yards,

workshops, seismic, subsea and well intervention, etc.

3. DEFINITIONS

For the purpose of this document, the following terms and definitions apply:

3.1 GOSP: Gas-Oil Separation Plant.

3.2 Hazard Identification: A systematic process used to identify hazards within a

particular task or group of tasks (i.e. HAZID, HAZOP). It is considered the first

step in the hazard analysis process and is dependent on the level of knowledge and

experience of the individuals involved.

3.3 Lower Flammable Limit (LFL): The minimum concentration of a fuel vapor in

air mixture, below this concentration level the mixture is too lean to burn; therefore,

ignition will not occur. If a vapor/air mixture is above the LFL, a fire or explosion

is likely in the presence of an ignition source.

3.3 Procedure: The specified steps that are performed to accomplish a task.

3.4 Qualitative Risk Assessment: A method of hazard analysis that uses descriptive

scales or ranking schemes (e.g., high/medium/low) to define the magnitude of

potential consequences and the probability that those consequences may occur.

Qualitative analysis is generally used for an initial screening to identify risks that

require more detailed analyses. It can also be used where the level of risk does not

justify or where numerical data is insufficient for a quantitative analysis. (SMG 02-

002-2010 Qualitative Risk Assessment)

Guide Number 06-007-2016 Page 1 of 17

Simultaneous Operations Guide Issue Date: August 1, 2016

3.5 Readiness Review: This review is held involving key representatives from

relevant parties and Subject Matter Experts to assure Saudi Aramco managers that

all SIMOPS hazards have been identified and appropriately mitigated prior to

beginning work.

3.6 Rupture Exposure Radius (RER): For toxic effects, the rupture exposure radius

refers to the horizontal distance from a leak source to specified levels of hydrogen

sulfide (H2S) concentration in parts per million (ppm). Concentration thresholds to

be considered are 30 ppm and 100 ppm. For a flammable gas hazard, with no toxic

gases in its composition, the RER refers to the horizontal distance from a leak

source to ½ the Lower Flammable Limit (LFL).

3.7 SIMOPS Coordinator: The single point of contact for all SIMOPS activities to

be conducted. This position is not required for all SIMOPS projects but is advisable

for major project work with a high number of SIMOPS activities or high risk

activities such as but not limited to: total plant shutdown or up-grade, onshore well

work, offshore well work, hook up and commissioning of major projects with other

nearby activities such as laying pipelines or flowlines and drilling/workover with

two or more rigs on the same drill site/well pad. See section 5.6 of this document

for more details.

3.8 Simultaneous Operations (SIMOPS): The activities of two or more work groups

working near each other where the actions of one work group may affect the safety

of the adjacent work group personnel, company assets or an adjacent operating

facility.

3.9 SIMOPS Matrix: This document encompasses all activities to be executed by the

various organizations, work groups and contractors. It provides recommendations

for the elimination and mitigation of workplace hazards and control measures

required to undertake simultaneous work.

3.10 SIMOPS Plan: This plan clarifies the roles and responsibilities of the parties

involved in the work. It establishes or identifies which operations take priority over

others and who has the overall decision-making authority. It also establishes

emergency response protocols, the overall Work Permit process, daily

communication requirements, highlights the hazards along with the appropriate

elimination, mitigations and / or control measures to be used.

4. INTRODUCTION

As outlined in the Saudi Aramco Safety Management System, safe and reliable operations

are Saudi Aramco’s primary operational objectives. This guide assists organizations in

identifying potential simultaneous activities and the elements needed to establish a specific

SIMOPS Plan. Effective planning will decrease the level of risk associated with SIMOPS

by:

Limiting the number of simultaneous activities and simultaneous work where

there is a high risk of an incident or where schedules can be changed to

Guide Number 06-007-2016 Page 2 of 17

Simultaneous Operations Guide Issue Date: August 1, 2016

eliminate the need for SIMOPS

Identifying preventive measures to be implemented prior to starting SIMOPS

activities.

Implementing open and effective communication rules among SIMOPS

organizations.

Safe SIMOPS requires that all activities are identified, effectively assessed, properly

planned, communicated, authorized and executed by following the SIMOPS Plan.

Following this SMG will help ensure a structured method for developing the plan while

coordinating the work and managing the risks. Proper SIMOPS planning will assist

proponent organization’s management in complying with the company’s Loss Prevention

Policy to evaluate, identify and eliminate or manage hazards prior to beginning any

operation or activity which requires SIMOPS.

5. RESPONSIBILITIES

The following describes the typical assignment of responsibilities to individuals

(organizational positions) for implementing a proponent’s Simultaneous Operations Plan.

5.1 Saudi Aramco Asset Management:

5.1.1 Establish a process to perform SIMOPS in accordance with the

requirements of this guide.

5.1.2 Provide appropriate and adequate resources for SIMOPS development.

5.1.3 Appoint a specific person responsible for SIMOPS Approval.

5.1.4 Assign and/or approve SIMOPS Coordinator that possesses the adequate

skills and experience (as described in Section 7 of this guide) to ensure

proper execution of the overall project.

5.1.5 Clearly define who the SIMOPS Coordinator reports to and the boundaries

and areas under his responsibility.

5.1.6 Identify a person or committee with adequate skills and experience (as

described in section 7 of this guide) responsible for developing the SIMOPS

plan and associated documents.

5.1.7 Ensure that hazard/risk studies are conducted with all affected parties and

acceptable risk control measures are established.

5.1.8 Establish a process to effectively communicate important information (i.e.

conflicts, changes, emergencies) with all parties (employees and

contractors) involved in SIMOPS activities.

5.1.9 Ensure the leadership and all personnel in supervisory positions of all

parties are fully trained and understand the application of the SIMOPS plan.

5.1.10 Ensure audits are conducted to determine effectiveness and completeness

of implementation of the SIMOPS plan. Audits should be conducted

immediately after SIMOPS begins and then quarterly.

5.1.11 Approve the plan only after a readiness review is carried out before the high

risk SIMOPS activities start. These activities can be found on the risk

assessment.

5.1.12 Ensure a safe handover of facilities to the proponent once SIMOPS are

complete.

Guide Number 06-007-2016 Page 3 of 17

Simultaneous Operations Guide Issue Date: August 1, 2016

5.2 Saudi Aramco Supervisors (e.g. Foremen/Supervisors/Liasonman):

5.2.1 Assist and support management in all matters pertaining to SIMOPS

activities.

5.2.2 Ensure that the implementation and requirements of the SIMOPS Plan are

being adhered to by all personnel.

5.2.3 Coordinate with management and all contractors on all matters concerning

SIMOPS (i.e. Attends all meetings, participates and reviews hazard

identification, risk assessment results and confirms that the risk reduction

and control measures are suitable).

5.2.4 Conduct inspections and tours regularly to maintain compliance with

SIMOPS requirements and inform management of any issue that has the

potential to compromise SIMOPS.

5.2.5 Document a complete and safe handover of the facilities or activities once

SIMOPS are complete.

5.3 Project Management Team (PMT):

5.3.1 Communicate with all parties to recognize and evaluate and resolve

potential SIMOPS conflicts.

5.3.2 Ensure strict compliance with the agreed upon coordination schedule /

sequence of work and the safe management of simultaneous activities.

5.3.3 Conduct and participate in SIMOPS risk assessments, inspections and

monitoring.

5.3.4 Ensure that the SIMOPS precautions and activities can be achieved within

the current schedule.

5.3.5 For expansion projects, ensure SIMOPS are part of the deliverables.

5.4 Saudi Aramco Loss Prevention Department (LPD):

5.4.1 Provide consultation on developing and reviewing the SIMOPS Plan as

requested by proponent organizations.

5.4.2 Participate in SIMOPS risk assessment, analysis and mitigation

development as requested.

5.4.3 Assist with acquiring dispersion model calculations when required

5.4.4 Assist with the Qualitative Risk Analysis as requested.

5.5 Contractor Management and Supervision:

5.5.1 Participate in SIMOPS risk assessment, analysis, elimination and mitigation

development as requested.

5.5.2 Communicate all the actual and potential hazards including proposed

mitigation measures to the proponent.

Guide Number 06-007-2016 Page 4 of 17

Simultaneous Operations Guide Issue Date: August 1, 2016

5.5.3 Provide clear and effective communication and instruction to employees

and sub-contractors such as readiness review meetings and safety talks

concerning:

The SIMOPS Plan

Emergency response plans and procedures

5.5.4 Maintain direct control over the work and compliance with the SIMOPS

plan.

5.6 SIMOPS Coordinator:

The SIMOPS Coordinator is the single point of contact for all work to be executed.

He ensures that the simultaneous activities / work is allowed and all requirements

stipulated in the SIMOPS Matrix are met prior to the execution of the work. He will

work with all organizations and work groups to resolve conflicts and facilitate the

ongoing work to ensure the optimization of the schedule to ensure the best possible

chance of meeting deadlines and target dates.

The SIMOPS Coordinator should:

5.6.1 Provide regular updates to the management concerning the progress of the

project and any unforeseen or unplanned delays or events. The schedule of

updates should be determined by the project manager.

5.6.2 Coordinate and communicate with other areas, projects, contractors and

sub-contractors to evaluate and help resolve potential SIMOPS conflicts.

5.6.3 Participate in reviews of the implementation of the SIMOPS Plan and check

that agreed upon controls are in place.

5.6.4 Coordinate and communicate all agreed upon changes to the SIMOPS

matrix with all affected parties prior to starting work.

5.6.5 Serve as the single point of contact for all permits to be issued for SIMOPS

work to ensure that the work can commence safely.

6. PROCEDURE

The following steps describe the basic process of developing SIMOPS plans:

6.1 Identify the need for SIMOPS and assembling the team.

6.1.1 Once the need for SIMOPS has been identified (see definition), a meeting

should be held to discuss possible schedule changes to eliminate the need

for SIMOPS.

6.1.2 If SIMOPS cannot be avoided then all affected parties should develop

detailed job plans and time lines so that an effective risk assessment can

take place.

6.1.3 Identify all the organizations that will be present conducting activities on

site or will be directly involved in the operations.

Guide Number 06-007-2016 Page 5 of 17

Simultaneous Operations Guide Issue Date: August 1, 2016

6.1.4 Identify all organizations that (although may not be present on-site at the

time of the work) may be affected by any unplanned event during the

operations.

6.1.5 Identify organizations that own equipment or hardware on-site and that are

authorized to shut-in / Lock-Out the energy sources.

6.1.6 Assemble the team to develop the SIMOPS Plan by nominating

representatives from each organization identified in the previous steps.

6.1.7 Each organization will identify the activities to be conducted onsite within

the timeframe of proposed SIMOPS activities and identify the required

schedule for such activities.

6.2 Once the team is assembled, the following activities take place:

6.2.1 A SIMOPS Coordinator may need to be appointed to ensure that the

planning schedule will address SIMOPS activities and consider the activity

duration, manpower, equipment, restricted areas, proximity conflicts (e.g.

offshore vessels) and work permits for each affected area and organization.

6.2.1 Identify each organization’s activities to be conducted onsite.

6.2.2 Identify the required schedule for such activities.

6.2.3 Create a field schedule (e.g. Gantt chart) to illustrate the principal activities

of all parties.

6.2.4 Conduct a SIMOPS workshop to assess each organization’s activities. The

risk register in attachment 3 can be used to document hazards while

conducting SIMOPS.

6.2.5 Use as many combinations as required to assess potential effects from one

organization to another. Some examples include: Drilling vs. Producing,

Construction vs. Field Services, Maintenance vs. T&I activities, etc.

Combinations may involve external and internal operational overlaps.

6.2.6 Use the corporate Risk Management matrix to provide a risk rank to each

organization’s activity.

6.2.7 Identify which organization has the highest risk level (i.e. the most

dangerous output if an uncontrollable event happens).

6.2.8 The organization with the highest risk level, will be on the Y-Axis of the

SIMOPS Matrix.

6.2.9 The other organizations will be on the X-Axis.

6.2.10 The team will choose if independent SIMOPS Matrices are needed or one

complex matrix including all organizations can be developed.

6.2.11 Determine conditions required for each combination of activities among the

organizations identified by the team as absolutely necessary to allow

SIMOPS.

6.2.12 Throughout the life of the project at specified intervals determined by the

team, periodic reviews of the schedule should be made to identify additional

SIMOPS situations (i.e. revisions/changes to the schedule).

NOTE: For these specific guidelines as required by SAES-B-062 section 6.1.1.e,

any Saudi Aramco activity conducted within the 100 ppm H2S RER

Guide Number 06-007-2016 Page 6 of 17

Simultaneous Operations Guide Issue Date: August 1, 2016

during drilling/workover operations while penetrating hydrocarbon

zones is considered SIMOPS. For other activities that are not subject

to SAES-B-062, SIMOPS zones or SIMOPS boundaries must be

defined based primarily from SA standards, RERs, ½ LFLs. If there is

no standard available, a common agreement within SIMOPS

development team must be reached to determine the SIMOPS

boundary.

6.3 If SIMOPS involves equipment or hardware with live processes, the following

additional steps are recommended:

6.3.1 Explore the possibility and impact of shutting-in or shutting down the

process or equipment during the entire operation or partially during critical

activities.

6.3.2 If the equipment and/or processes cannot be shut-in or shut-down during the

operations, request a dispersion model analysis from LPD for credible

release scenarios.

6.3.3 Based on dispersion model results, define contingency plans for Shelter-In-

Place and/or escape routes.

6.3.4 Consider the possibility of conducting a Quantitative Risk Assessment

(QRA) for major projects to assist management in the decision making

process.

6.3.5 Rank all possible contingency plans giving the highest rank to the safest

plan.

6.3.6 Provide a cost-effective evaluation of contingency plans.

6.3.7 All procedures must be in compliance with GI 6.012.

6.4 A formal SIMOPS Plan shall be written to ensure the SIMOPS is conducted

properly.

6.4.1 Sections that should be included in the SIMOPS Plan:

a) Project / Work Activity Overview

b) Project Drawings

c) Operational Schedules

d) Project Contact List

e) Project SIMOPS Matrix

f) Roles and responsibilities of key personnel

g) SIMOPS procedures

h) Emergency response procedures

i) Communication protocol

j) Work permit system

k) Stop work criteria

l) Stop work authorization

m) Management of Change Process (MOC)

Guide Number 06-007-2016 Page 7 of 17

Simultaneous Operations Guide Issue Date: August 1, 2016

n) The establishment of reporting lines for the SIMOPS work. This is

critical to the success of the project and provides the frame work for

managing the interface among multiple companies involved.

6.4.2 Items that should be resolved when developing the SIMOPS Plan:

a) Confirm the dates/schedules, scope and SIMOPS coordination

requirements.

b) Review and list all existing operating activities and risk register.

c) Identify the high level view of the areas impacted by the work, consider

the organizations affected, constraints and the boundaries of a work

area(s) and define the various activities that may occur.

d) Agreement of an integrated approach to risk management and

awareness of SIMOPS issues.

e) Stop work criteria.

f) Stop work authority.

g) Type and frequency of all meetings e.g. PMT, SIMOPS Coordination.

h) Confirm understanding of SIMOPS Plan and methodology.

i) Responsibilities.

j) Communication protocols.

k) Authorization of work.

l) Compliance Monitoring (field reports, work permit, JSAs, inspections,

reviews, audits).

m) Confirm timeline of activities (when, where).

n) Confirm all parties’ commitment to all SIMOPS related rules,

processes and the principles of control.

o) Identify the named individual i.e. SIMOPS coordinator / focal point

who will develop and manage a detailed SIMOPS Plan and will liaise

with the affected organizations.

p) Agreement and arrangements for Risk Management: Identify formal

hazard and assessment requirements.

q) Work Permit program – which one to use and who will sign and

counter sign.

r) Identify any critical concerns for line and management review.

s) Identify Restricted Areas and how safety requirements will be met.

t) Consider requirements for interface documents / Bridging Documents

/ Handover Process.

u) A Site Visit should be arranged to help prepare for Risk Management

actions.

v) Identify applicable standards, GIs and important references.

w) Develop a bridging document of the involved companies to establish a

unified HSE plan for the project. Normally the strictest document is

followed. For example, if one plan requires a worker to be 100% tied

off above 4 feet and another requires 100% tie off above 6 feet, we

would use 4 feet as the threshold for tie off for all personnel. This

would be clearly indicated in the bridging document.

Guide Number 06-007-2016 Page 8 of 17

Simultaneous Operations Guide Issue Date: August 1, 2016

x) A SIMOPS Matrix should be developed to assist personnel with

decision making while conducting SIMOPS. SIMOPS Matrices have

been used for several projects within Saudi Aramco. A brief example

of one can be found in Supplements 3-6.

NOTE: Any deviation from the approved SIMOPS plan and/or Matrix is

required to go through a formal Management of Change process to

ensure all affected parties are formally notified of the change in the

plan. Refer to LP SMG 05-001-2006 Management of Change.

6.5 Contingency / Emergency response planning.

6.5.1 Contingency / emergency response planning for SIMOPS activities is

critical. The existing ability and arrangements of the facility’s emergency

response organization to cope with more than a single incident may be

compromised by the increased activity. Integrated emergency response

plans may be required for major activities such as drilling and laying

flowlines, offshore construction activities in the 30 ppm rupture exposure

radius (RER) of a drilling or workover rig, major plant or GOSP work or

any other activity that may affect emergency response activities.

Considerations for these integrated emergency response plans may

include:

a) Identify the Incident Commander for the integrated ERP.

b) Assembly Areas (onshore) / Muster points (offshore).

c) Emergency escape of personnel on vessels.

d) Communication process for coordination among SIMOPs affected

parties.

e) Medical resources.

f) Firefighting resources.

g) Security arrangements.

h) Pre-incident planning (credible scenarios).

i) Additional emergency exercise (drills) will be required to identify

areas for improvement.

j) Additional fixed LEL gas detection (and H2S on known sour fields).

k) Restricting manning during SIMOPS to essential personnel.

l) Evacuation routes: Modifying or providing an alternative means of

escape.

m) Extra fire-water monitors e.g. from the rig to ensure coverage of the

well manifold area. This will require a review of the rig fire-water

system to ensure that the system is suitable for any extra demand.

n) Additional portable fire monitors or a deluge system.

o) Ensure there is sufficient firewater capacity.

p) Additional portable fire extinguishers.

q) Additional portable gas detectors.

Guide Number 06-007-2016 Page 9 of 17

Simultaneous Operations Guide Issue Date: August 1, 2016

r) All emergency response plans should be written in line with Saudi

Aramco SMG 08-001-2008 (Emergency Preparedness).

6.6 Obtain signature approval from all affected Managers for SIMOPS.

6.7 Conduct a Kick-off Meeting prior to starting operations with all organizations

participating and affected by the SIMOPS and make a final review of the

SIMOPS Plan to validate or resolve any pending issues such as:

6.7.1 Confirm the dates/schedules, scope and SIMOPS requirements.

6.7.2 Review the operating activities and risk register.

6.7.3 Stop work criteria.

6.7.4 Stop work authority.

6.7.5 Type and frequency of all meetings (e.g. Operations, Producing, PMT,

SIMOPS Coordination, etc.).

6.7.6 Confirm understanding of SIMOPS Plan and methodology from all stake

holders.

6.7.7 Responsibilities.

6.7.8 The establishment of reporting lines for the SIMOPS work is critical to the

success of the project and provides the frame work for managing the

interface among multiple companies involved. Interface meetings and

communication meetings will be a priority to maintain these reporting lines.

6.7.9 Compliance Monitoring (field reports, work permit, JSAs, inspections,

reviews, audits).

6.7.10 Confirm that all pre-set controls are in place.

6.7.11 Identify the named individual SIMOPS coordinator / focal point

6.7.12 Work Permit program – or Authorization of work. (i.e. who will sign and

counter sign permits)

6.7.13 Identify any critical concerns for line and management review.

6.7.14 Identify Restricted Areas and how safety regulations are to be met.

6.7.15 Bridging Documents and Handover Process.

6.7.16 Arrange Site Visit and prepare for Risk Management actions.

6.7.17 Identify applicable standards, GIs and important references.

6.8 Conduct the SIMOPS work. The SIMOPS Coordinator should make notes of issues

and concerns that arise during the execution of the work to compile the lessons

learned for future work.

6.9 After the work is complete, a close out meeting should be held to finalize, document

and communicate the lessons learned.

Guide Number 06-007-2016 Page 10 of 17

Simultaneous Operations Guide Issue Date: August 1, 2016

7.0 COMPETENCY REQUIREMENTS

7.1 The hazard assessment group must be a group of Subject Matter Experts (SME),

experienced and knowledgeable of the operations related with his organization.

7.2 The SIMOPS Coordinator must be a person with experience at least in the operation

providing the major risk during the SIMOPS.

Guide Number 06-007-2016 Page 11 of 17

Simultaneous Operations Guide Issue Date: August 1, 2016

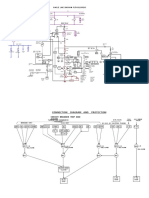

Supplement 1

SIMOPS Flow Chart

Guide Number 06-007-2016 Page 12 of 17

Simultaneous Operations Guide Issue Date: August 1, 2016

Supplement 2

Example SIMOPS Hazards & Conditions Register

Left Column: List of Activities and operations from the organization that potentially will expose other

groups to hazards

Top Row: Organization / Activities being potentially affected by the operations listed on left

Column if carried out simultaneously

Column 1: Identified Hazards (it is recommended to use HAZOP terminology)

Column 2: Consequences from identified hazards for credible scenarios on top row organization’s

personnel, activities, processes and assets

Column 3: Current Safeguards in place from the organization in left column against the identified

hazards

Column 4: Do current operating conditions allow SIMOPS between these two organizations (Yes /

NO)

Column 5: If answer in column 3 is NO, describe which conditions, if implemented, would allow

SIMOPS between these two organizations. (This columns will be the base for the

development of the conditions matrix later)

Column 6: Recommendations to achieve or implement the conditions described in column 5

Column 7: Party or parties responsible to complete the actions described in column 6

Guide Number 06-007-2016 Page 13 of 17

Simultaneous Operations Guide Issue Date: August 1, 2016

Supplement 3

Example SIMOPS Matrix (Partial)

Left Column: List of Activities and operations from the organization that potentially will expose

other groups to hazards

Top Row: Organization / Activities being potentially affected by the operations listed on left

Column if carried out simultaneously

Internal Cells: For each combination of two activities from top row and left column, provide the

restriction or condition code (from the Condition matrix in Supplement 4) the allows

these two activities to be carried out simultaneously or be classified as “N/A” (Not

Acceptable” if the activities cannot overlap at any time

Guide Number 06-007-2016 Page 14 of 17

Simultaneous Operations Guide Issue Date: August 1, 2016

Supplement 4

Example SIMOPS Matrix Conditions / Mitigations (Partial)

Guide Number 06-007-2016 Page 15 of 17

Simultaneous Operations Guide Issue Date: August 1, 2016

Supplement 5

2nd Example SIMOPS Matrix (Partial)

Guide Number 06-007-2016 Page 16 of 17

Simultaneous Operations Guide Issue Date: August 1, 2016

Supplement 6

2nd Example SIMOPS Example Matrix Conditions / Mitigations

Guide Number 06-007-2016 Page 17 of 17

You might also like

- Simultaneous Operations (SIMOPS) HSE Procedure for Pars Oil & Gas CompanyDocument24 pagesSimultaneous Operations (SIMOPS) HSE Procedure for Pars Oil & Gas CompanyOsman KozuNo ratings yet

- Work Permit System: Saudi Arabian Oil Company (Saudi Aramco)Document7 pagesWork Permit System: Saudi Arabian Oil Company (Saudi Aramco)Danilo de JurasNo ratings yet

- Hip - Qatif Aramco - FinalDocument10 pagesHip - Qatif Aramco - FinalDarius DsouzaNo ratings yet

- General Instruction Manual: Saudi Arabian Oil Company (Saudi Aramco)Document5 pagesGeneral Instruction Manual: Saudi Arabian Oil Company (Saudi Aramco)bryanNo ratings yet

- 0006 - 005 RevDocument14 pages0006 - 005 RevDanilo de JurasNo ratings yet

- General Instruction Manual: Organization Consulting DepartmentDocument12 pagesGeneral Instruction Manual: Organization Consulting DepartmentChaudhary Wasim MurtazaNo ratings yet

- 1021.000 Street and Road Closure Excavations Reinstatement and Traffic ControlsDocument37 pages1021.000 Street and Road Closure Excavations Reinstatement and Traffic ControlsZubair Ahmed Khaskheli0% (1)

- CSM by AramcoDocument3 pagesCSM by AramcoSharifullahNo ratings yet

- Saep 50Document33 pagesSaep 50Demac SaudNo ratings yet

- Hazard Identification Plan for Tanajib Gas Plant ProjectDocument247 pagesHazard Identification Plan for Tanajib Gas Plant ProjectAbdul WasayNo ratings yet

- Gi-0006 006Document7 pagesGi-0006 006malika_00No ratings yet

- PSSR Checksheet - Offshore Asset - DraftDocument6 pagesPSSR Checksheet - Offshore Asset - Draftjai kumar100% (1)

- Content:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualDocument10 pagesContent:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualMohd IshtiaqNo ratings yet

- General Instruction Manual: Saudi Arabian Oil Company (Saudi Aramco)Document10 pagesGeneral Instruction Manual: Saudi Arabian Oil Company (Saudi Aramco)mozammilNo ratings yet

- Saudi Aramco General Instruction Manual IndexDocument12 pagesSaudi Aramco General Instruction Manual IndexRiaz ahmed100% (2)

- MIP17 - HSE - PP - 004 Short Serviece Employee Program PKG 17 REV 1Document10 pagesMIP17 - HSE - PP - 004 Short Serviece Employee Program PKG 17 REV 1AmeerHamzaWarraichNo ratings yet

- Jsa - Hot TappingDocument15 pagesJsa - Hot TappingAmadeo Sabanal0% (1)

- Gi-2 104Document10 pagesGi-2 104ck19654840No ratings yet

- 0002 104Document11 pages0002 104Buddharaju KiranNo ratings yet

- TSP PR-HSE-SAF-139 Rev 0 04/08/01 Simultaneous Operations: Total Fina ElfDocument18 pagesTSP PR-HSE-SAF-139 Rev 0 04/08/01 Simultaneous Operations: Total Fina Elfiwansalma100% (5)

- General Instruction Manual: Saudi Arabian Oil Company (Saudi Aramco)Document25 pagesGeneral Instruction Manual: Saudi Arabian Oil Company (Saudi Aramco)parijat pramanikNo ratings yet

- Aamco 1624293493Document80 pagesAamco 1624293493GUSTAVO MANUEL ESPINOSA RUTTERNo ratings yet

- MSHEM-Specific Awareness: Growing A Saudi Global Mining GiantDocument27 pagesMSHEM-Specific Awareness: Growing A Saudi Global Mining GiantShadifNo ratings yet

- EN-099-PL-1810 - Rev B - Fire Protection PlanDocument41 pagesEN-099-PL-1810 - Rev B - Fire Protection PlanSkinhead TvNo ratings yet

- Form-11 Third Party Monthly & End of Contract EHSS ReportDocument9 pagesForm-11 Third Party Monthly & End of Contract EHSS ReportMohammad GouseNo ratings yet

- Gi-2 700Document3 pagesGi-2 700ck19654840No ratings yet

- OISD External Safety Audit Checklist for Onshore Drilling RigsDocument30 pagesOISD External Safety Audit Checklist for Onshore Drilling RigsSiddhartha ChakradharNo ratings yet

- Aramco - Risk Assessment PDFDocument14 pagesAramco - Risk Assessment PDFali bahmaniNo ratings yet

- 14) Hazard Identification Plan (HIP) For UGOSP-9 29-01-2020Document31 pages14) Hazard Identification Plan (HIP) For UGOSP-9 29-01-2020HaleemUrRashidBangash100% (1)

- Confined Space Entry Safety - Never Enter Without Gas TestingDocument1 pageConfined Space Entry Safety - Never Enter Without Gas Testingramod100% (1)

- Safety Presentation - AramcoDocument11 pagesSafety Presentation - AramcoMang Doros EsquilloNo ratings yet

- 0002 710 Mechanical Completion Performance Acceptance of Facilities PDFDocument33 pages0002 710 Mechanical Completion Performance Acceptance of Facilities PDFjusstv1No ratings yet

- Cse ProcedureDocument24 pagesCse ProcedureMuhammad Usman100% (1)

- General Instruction Manual: ContentDocument13 pagesGeneral Instruction Manual: Contentck19654840No ratings yet

- T00-A-Dd-842201-001 - Rev DDocument17 pagesT00-A-Dd-842201-001 - Rev DNaveedNo ratings yet

- 000-ZA-E-009712 - 00 HSE Requirement For Subcontractor and Vendors Annexe 1 PDFDocument66 pages000-ZA-E-009712 - 00 HSE Requirement For Subcontractor and Vendors Annexe 1 PDFzizu1234No ratings yet

- 5.007 SAFETY RECOGNITION AND INCENTIVE PROGRAMS (SRIPs)Document5 pages5.007 SAFETY RECOGNITION AND INCENTIVE PROGRAMS (SRIPs)Ahmed TrabelsiNo ratings yet

- 20) Hazard Identification Plan (HIP) For UGOSP-11 29-01-2020Document27 pages20) Hazard Identification Plan (HIP) For UGOSP-11 29-01-2020HaleemUrRashidBangash100% (2)

- Gi-0008 001Document8 pagesGi-0008 001Tasasdaq khan100% (1)

- PR 1172 Rev 9.9Document141 pagesPR 1172 Rev 9.9joenediath934580% (5)

- Content:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualDocument5 pagesContent:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualMd Azizul MawlaNo ratings yet

- Sinopec MIP PKG 16 & 17 Lifting & Rigging Campaign - August 2022Document22 pagesSinopec MIP PKG 16 & 17 Lifting & Rigging Campaign - August 2022AmeerHamzaWarraichNo ratings yet

- HIP For AramcoDocument6 pagesHIP For Aramcoahsanhasan84No ratings yet

- SAES-B-062 Editorial Revision-16 March 2023Document22 pagesSAES-B-062 Editorial Revision-16 March 2023Faheem Khan100% (1)

- Breaking Containment Checklist EssentialsDocument4 pagesBreaking Containment Checklist Essentialsromedic36No ratings yet

- Content:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualDocument4 pagesContent:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction Manualjhoni100% (1)

- General Instruction Manual: ScopeDocument14 pagesGeneral Instruction Manual: ScopeJithuRajNo ratings yet

- Gi-0006 003Document8 pagesGi-0006 003khrayzie bhoneNo ratings yet

- Saudi Aramco LPD review of contractor CSARDocument2 pagesSaudi Aramco LPD review of contractor CSARShahid BhattiNo ratings yet

- Saes B 064Document14 pagesSaes B 064Engr HafeezullahNo ratings yet

- Hse CotracorDocument64 pagesHse Cotracorsafety.engNo ratings yet

- 000-A-JD-801400-231 - Rev B SOW - Part-4Document8 pages000-A-JD-801400-231 - Rev B SOW - Part-4Senthil KumarNo ratings yet

- Docslide - Us Critical Lift Plan Gi 70281Document64 pagesDocslide - Us Critical Lift Plan Gi 70281Mohamed rasheedNo ratings yet

- Simultaneous Operations (SIMOPS) TERM OF REFERANCE (TORDocument25 pagesSimultaneous Operations (SIMOPS) TERM OF REFERANCE (TORkokykarkar80% (5)

- Aug 2022, ARRAZI's SHEM-09 OMS-317 Management of ChangeDocument21 pagesAug 2022, ARRAZI's SHEM-09 OMS-317 Management of ChangeBilal SarhanNo ratings yet

- SMG 06-003 Job Safety Analysis (JSA)Document12 pagesSMG 06-003 Job Safety Analysis (JSA)md shadab anwarNo ratings yet

- Risk and Control Self Assessment IRMDocument27 pagesRisk and Control Self Assessment IRMidrisngr100% (3)

- Saer 5437Document92 pagesSaer 5437Tarek Mustafa100% (1)

- RCM-optimized maintenanceDocument13 pagesRCM-optimized maintenancegvc1No ratings yet

- Saudi Aramco HAZOP Guidelines LOSS PREVE PDFDocument92 pagesSaudi Aramco HAZOP Guidelines LOSS PREVE PDFPandhu100% (1)

- Yutra 3Document31 pagesYutra 3ကိုနေဝင်းNo ratings yet

- Corn Tastes Better On The Honor System - Robin Wall KimmererDocument53 pagesCorn Tastes Better On The Honor System - Robin Wall Kimmerertristram59100% (1)

- Area and Circumference of CircleDocument17 pagesArea and Circumference of CircleJared VallesNo ratings yet

- Shantappa B K FinalDocument32 pagesShantappa B K Finalasmita patilNo ratings yet

- TextDocument17 pagesTextnaser zoabiNo ratings yet

- Concepts of ProbabilityDocument32 pagesConcepts of ProbabilityRushina SinghiNo ratings yet

- My Heart Sings Praises - Line UpDocument4 pagesMy Heart Sings Praises - Line UpAnthony JimenezNo ratings yet

- Grove RT422 22T PDFDocument4 pagesGrove RT422 22T PDFJulio QuilarqueNo ratings yet

- LESSON 1 Random-VariablesDocument29 pagesLESSON 1 Random-Variablesnica jane madrigalNo ratings yet

- Immuno HistochemistryDocument26 pagesImmuno HistochemistrySAMMYNo ratings yet

- Replacing ATA5567/T5557/ TK5551 With ATA5577 Application NoteDocument5 pagesReplacing ATA5567/T5557/ TK5551 With ATA5577 Application NoteM0n3No ratings yet

- DetergentsDocument12 pagesDetergentsBujju BujjukuttyNo ratings yet

- PublicLifeUrbanJustice Gehl 2016-1Document119 pagesPublicLifeUrbanJustice Gehl 2016-1bronsteijnNo ratings yet

- Signal Sampling, Quantization, Binary Encoding: Oleh Albert SagalaDocument46 pagesSignal Sampling, Quantization, Binary Encoding: Oleh Albert SagalaRamos D HutabalianNo ratings yet

- Question 1Document72 pagesQuestion 1dominateqNo ratings yet

- Lecture 9: Exploration and Exploitation: David SilverDocument47 pagesLecture 9: Exploration and Exploitation: David Silver司向辉No ratings yet

- Mswin 9Document388 pagesMswin 9KZNo ratings yet

- Rear Axle ShaftsDocument4 pagesRear Axle ShaftsMaria AparecidaNo ratings yet

- Synthesis of Novel Benzimidazole Clubbed Pyrazole Heterocycles Derivatives As Potentially AntibacterialDocument7 pagesSynthesis of Novel Benzimidazole Clubbed Pyrazole Heterocycles Derivatives As Potentially AntibacterialAgung RahmadaniNo ratings yet

- Olympian G60F1 G75F1 Spec SheetDocument6 pagesOlympian G60F1 G75F1 Spec Sheetkman548No ratings yet

- WEG Guia de Instalacao pws5610 Quick Guide English PDFDocument1 pageWEG Guia de Instalacao pws5610 Quick Guide English PDFÁgó AttilaNo ratings yet

- Microflow Air Sampler User ManualDocument31 pagesMicroflow Air Sampler User Manualira rahmaNo ratings yet

- Island of The Blue Dolphins: Before You Read The ChaptersDocument12 pagesIsland of The Blue Dolphins: Before You Read The ChaptersCostea CibanuNo ratings yet

- Technical Specification For Sorghum GrainsDocument6 pagesTechnical Specification For Sorghum GrainsMohd SaifulNo ratings yet

- Industrial Coupling and HoseDocument57 pagesIndustrial Coupling and HoseCesar CoronelNo ratings yet

- Level 2 Repair: 7-1. Components On The Rear CaseDocument8 pagesLevel 2 Repair: 7-1. Components On The Rear CaseNguyễn Duy LinhNo ratings yet

- Process Flow ChartDocument4 pagesProcess Flow Chartchacko chiramalNo ratings yet

- 1.trijang Rinpoche Bio CompleteDocument265 pages1.trijang Rinpoche Bio CompleteDhamma_Storehouse100% (1)

- Diagram PLTA SLJDocument4 pagesDiagram PLTA SLJMEi Cuiet Luph-LuPhNo ratings yet

- VOLLEYBALL HISTORY AND RULESDocument12 pagesVOLLEYBALL HISTORY AND RULESJennybelle MolinaNo ratings yet