Professional Documents

Culture Documents

Ecn Opgw PDF

Uploaded by

Razvan DonciuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ecn Opgw PDF

Uploaded by

Razvan DonciuCopyright:

Available Formats

Fig.

Composite fiber - optic TENSILE STRENGHT ELECTRIC RESISTANCE

overhead ground wires OPGW 150 25

140 20

OHM / Km

Kg /mm2

130 15

120 10

110 5

100 0

n last years there has been a significant increase Simultaneous protection to the power lines and communication

in interest of the Power utilities for the application requirements handled by these cables are the basic reasons for

of the composite fiber-optic ground wires in the new trans- this interest.

mission lines or retrofit. The typical characteristics of these conductors are:

THICKNESS OF COATING

- Number of fibers contained between 4 and 16.

WEIGHT

- The optical bundle is placed inside an extruded aluminium 180

tube which provides mechanical protection and prevents 160 70

moisture or water penetration. 140

120 60

- The aluminium tube also provides a high conductivity to

mm

Kg / Km

dissipate lightning or uneven short-circuits. 100 50

80

- The aluminium tube sizes will depend on number of fibers 60 40

and diameter of the optical bundle. 40 30

- Subsequently, one or several layers of Araweld® wires are 20

stranded over the aluminium tube giving to this composite 0 20

an external appearance similar to the conventional earthwires

for transmission lines.

- Araweld® wires are the product of preference based on their

combined mechanical, electrical and corrosion resistance.

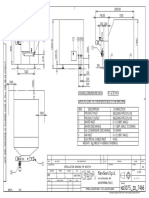

Figure 3 shows the construction of this composite with the Corrosion resistance

different components.

The corrosion resistance of the aluminium in any atmosphere is The used of Araweld® wires instead of galvanized steel prevents

Typical constructions with some of their technical characteristics

well known, and different systems like the climat test, based on this galvanic corrosion, because of the contact Aluminium/Alu-

are shown on the table of next page. Other alternative construction

the combination of wires and bolts, have been used to determine minium.

can be proposed to meet specific requirements of each particular

the corrosion resistance of pure aluminium or combined with Even existing small depositions of salty particles over the wire,

project.

other metals. Araweld® provides a longer operating life because of its thick

One of the main problem in conductors, and specially the ACSR, aluminium covering.

is the galvanic corrosion between aluminium and steel.

In a salty solution, the difference of potential of the zinc with

respect to aluminium is -300mV., and the steel +150 mV. It means

that the contact Al/Zn is anodic and zinc will tend to disappear,

while contact Al/St is cathodic and aluminium will suffer the

corrosion.

Araweld® Wires

Designación Diámetro Nominal Peso Resistencia Sección

0,15

mm Kg/Km W / Km a 20°C mm2

Figure 3 Depth of attack

0,10 4 Awg. 5,19 139,3 4,009 21,15

5 Awg. 4,62 110,5 5,056 16,77

Aluminium 99,5 6 Awg. 4,12 87,62 6,375 13,30

7 Awg. 3,67 69,48 8,038 10,55

8 Awg. 3,26 55,11 10,13 8,368

0,05

Layer or Layers Optical bundle 9 Awg. 2,91 43,71 12,78 6,632

of Araweld® wire 10 Awg. 2,59 34,66 16,12 5,261

Aluminium tube 11 Awg. 2,30 27,49 20,32 4,172

12 Awg. 2,05 21,80 25,63 3,309

5 10 Modulus of Elasticity: Strand 16,200 Kg / mm2; solid wire 16,500 Kg / mm2.

Coeficient of linear expansion: 0.000013

Time of exposure / years Tensile strength: In accordance to the applicable specification.

Aluminium clad steel

Optical fiber grond wires

Code word Cross section Stranding and wire diam. Diám. ext/int. tube. Overall diam.

mm2 mm2 mm2 Nºx mm mm mm

Aluminium tube AW AA Total AW

Also, in order to verify the right adherence of aluminium and 57/24 24,4 57,30 81,70 13x2,37 7,90/5,60 12,64

steel to guarantee the minimum aluminium thickness by 10% 66/32 32,4 66,20 98,60 15x2,37 9,50/7,00 14,24

of the wire radius after drawing, along with the measurements 74/32 36,9 36,90 32,4 106,20 7x2,59(AW)+7x2,59(AA) 9,50/7,00 14,68

75/33 33,5 50,00 25,0 108,50 10x2,53(AW)+5x2,53(AA) 10,1/7,70 15,15

of the mechanical and electrical characteristics, each Araweld®

75/34 33,5 75,10 108,60 15x2,53 10,1/7,70 15,15

rod is subjet to the following tests: 83/32 32,4 83,00 115,40 13x2,85 9,50/7,00 15,20

- Twist test 83/34 33,5 83,42 44,2 116,98 14x2,75 10,1/7,70 15,60

88/47 47,5 44,20 135,90 7x2,84(AW)+7x2,84(AA) 10,4/6,90 16,00

- Reverse bending test to breaking

106/63 62,8 106,00 168,80 15x3,00 12,0/8,00 18,00

Characteristics Optical fiber grond wires

Code word Unit weight Rated strength Electric. resist. at 20ºC Shortcircuit capacity

of the ARAWELD® wires kg/km

Total

kN ohm/km I2t

- Araweld® wires provide 33% the conductivity of an aluminium 57/24 470,00 75,50 0,6540 34,0

wire of the same size and 1,91 times the conductance of steel. 66/32 573,00 86,80 0,5219 50,7

he electrical characteristics of the aluminium and 74/32 457,00 62,49 0,3712 100,0

- The tensile strength is over 140 Kg / sqmm.

75/33 535,00 76,10 0,3956 90,0

its performance against corrosion, along with - Because of their thick cladding of aluminium the weight is 75/34 637,76 101,10 0,4855 80,0

high mechanical resistance of the steel make the ARAWELD®. 15% lower than a steel wire of the same size. 83/32 676,00 103,60 0,4740 88,0

83/34 690,80 111,94 0,4637 91,0

ARAWELD® Process 88/47

106/63

580,00

891,00

31,80

131,00

0,2827

0,2866

187,0

188,0

ECN Cable Group by means of an advanced process achieves a PProperties of Araweld® overhead ground wire compared with

metallurgical and inseparable bond between the aluminium and galvanized steel and aluminized steel (Fig. 1) Technical characteristics composite fiber-optic overhead ground wires (OPGW)

the steel, guaranteed by the quality control on the cladding line. Designation Type Composition Overall diam. Cross sectional area N. of opt. fibers Weight Máx. eléc. resist. R. ten.strength Mod.elast. Coef. of linear I2.t

Comparative graphics for a 3.26 mm. wire in the different

Such a control is based on: No./Ø No./Ø Ø

mm mm2 mm2 mm2

materials: mm2 (mm)

AW

(mm)

Alloy

(mm)

Tube Al AW Alloy Tube Al

Total Kg/Km Ω/km Kg Kg/mm2 ºC-1 kA2.S

- Cleaning of the steel

A Galvanized steel A class, according to ASTM B - 498 83/32 1 13/2,85 - 9,50/7,00 15,20 82,9 - 32,4 115,3 6./8./12. 677 0,4739 10.560 13.350 14,25 x 10-6 > 86,7

- Cleaning of the aluminium

B Galvanized steel B class, according to ASTM B - 498 106/63 2 15/3,00 - 12,00/8,00 18,00 106,0 - 62,8 168,8 6./12. 891 0,2866 13.350 12.400 14,80 x 10-6 >188,0

- Operating temperature 66/32 3 15/2,37 - 9,50/7,00 14,24 66,2 - 32,4 98,6 4./6. 555 0,5219 9.050 13.600 14,50 x 10-6 > 50,7

C Galvanized steel C class, according to ASTM B - 498 32+64/35 4 4/3,20 8/3,20 9,60/6,90 16,00 32,1 64,3 35,0 131,4 8. 525 0,2808 6.500 8.600 14,30 x 10-6 >137,8

- Bonding atmosphere

AW Araweld® according to ASTM B - 502

AZ Aluminized according to ASTM B - 341

Fiber optic characteristics

Typ Overall diam. Outer diameter Type of construction Attenuation Wave length Max. attenuation Max. spectral dispersion Cut-off wave length General Specification

μm

μm nm dB/Km ps/nm Km

Loose Primary coating

Single Mode 125 9,5 1 250 Core 1.300/1.550 0,50/0,30 1.300 nm< 3,5 1.100/1.280 CCITT G-652

1.550 nm< 18,0

You might also like

- J4 PDFDocument1 pageJ4 PDFRvin Jay Cabontocan MarianoNo ratings yet

- Volvo Penta Inboard Diesel: 125-147-162 KW (170-200-220 HP) Crankshaft Power Acc. To ISO 8665Document2 pagesVolvo Penta Inboard Diesel: 125-147-162 KW (170-200-220 HP) Crankshaft Power Acc. To ISO 8665Alberto100% (1)

- Tobee TL Slurry Pump Technical SpecifcationsDocument1 pageTobee TL Slurry Pump Technical SpecifcationstobeepumpNo ratings yet

- Loop Detector: CustomerDocument1 pageLoop Detector: Customerzia ansariNo ratings yet

- Dolce Gabanna-Layout3 (ELECTRICAL)Document1 pageDolce Gabanna-Layout3 (ELECTRICAL)Nelson M. Malicdem Jr.No ratings yet

- Elevation A Elevation D Elevation C Elevation B: A A A 2 2 ADocument1 pageElevation A Elevation D Elevation C Elevation B: A A A 2 2 AJem CapistranoNo ratings yet

- Vs30 Correlations UC DavisDocument8 pagesVs30 Correlations UC Davisbasum matNo ratings yet

- Gfps System Specification PVC C Metric en PDFDocument24 pagesGfps System Specification PVC C Metric en PDFMohammed sabatinNo ratings yet

- Goalpara Outdoor Foundation-24-ModelDocument1 pageGoalpara Outdoor Foundation-24-Modelvishnusinghal2007No ratings yet

- OP 800SD 800SD-2 OP530-V01 D FinalDocument2 pagesOP 800SD 800SD-2 OP530-V01 D FinalPasindu PriyankaraNo ratings yet

- FT11 - FT12 V-Line Glass Thermometer (LR)Document1 pageFT11 - FT12 V-Line Glass Thermometer (LR)hazimNo ratings yet

- Memco International: Notes: - All Material To Be Used Is of Grade ASTM A36 or EquivalentDocument1 pageMemco International: Notes: - All Material To Be Used Is of Grade ASTM A36 or EquivalentMohammad FathiNo ratings yet

- Cembre Tools 203,205Document2 pagesCembre Tools 203,205Amol PATILNo ratings yet

- The Ultimate Inert Coating. Also Known As Sulfinert and SiltekDocument2 pagesThe Ultimate Inert Coating. Also Known As Sulfinert and SiltekSadot GutierrezNo ratings yet

- PPVC - Column To Column - Connection DetailDocument3 pagesPPVC - Column To Column - Connection DetailJustin TanNo ratings yet

- Cross Section of Bridge Scale: 1/50)Document1 pageCross Section of Bridge Scale: 1/50)Anh NgôNo ratings yet

- Loop Ube02-00002engDocument1 pageLoop Ube02-00002engjulio89bsNo ratings yet

- Electrical Specification:: Midband Gold Plating) Structure Material: Rotating Speed Max / Norm: 30rpm /10rpmDocument1 pageElectrical Specification:: Midband Gold Plating) Structure Material: Rotating Speed Max / Norm: 30rpm /10rpmLong NguyenNo ratings yet

- ERA Mono PERC 325W 60cDocument1 pageERA Mono PERC 325W 60cAngel M Granados EscalonaNo ratings yet

- 5L Vacuum CurveDocument1 page5L Vacuum Curveasistente.peninsulaNo ratings yet

- Ick Work - Partition Layout (First Floor)Document1 pageIck Work - Partition Layout (First Floor)Shubham PokhriyalNo ratings yet

- Designing Silicon Carbide (Sic) Based DC Fast Charging System: Key Challenges, Design Considerations, and Building ValidationDocument31 pagesDesigning Silicon Carbide (Sic) Based DC Fast Charging System: Key Challenges, Design Considerations, and Building Validationtakaca40No ratings yet

- Bubble Cap Distillation ColumnDocument1 pageBubble Cap Distillation ColumnVinh Lê KhảiNo ratings yet

- FinalDocument1 pageFinalVinh Lê KhảiNo ratings yet

- Bxa-185060-4 - FPDocument1 pageBxa-185060-4 - FPpandavision76No ratings yet

- Sec. of Lintel L1 On C-C (Typical) : General NotesDocument1 pageSec. of Lintel L1 On C-C (Typical) : General NotesA.K.M Shafiq MondolNo ratings yet

- Skylight DetailDocument1 pageSkylight Detailharicv019No ratings yet

- Elevation (E-1) Elevation (E-2) Elevation (E-3) : Roof Plan PlanDocument1 pageElevation (E-1) Elevation (E-2) Elevation (E-3) : Roof Plan PlanRavi Kishore GadariNo ratings yet

- Cross Section 5Document1 pageCross Section 5pravin awalkondeNo ratings yet

- (Colored) Refrigerant 134a P-H Diagram (SI Units) PDFDocument1 page(Colored) Refrigerant 134a P-H Diagram (SI Units) PDFMc Jason LaureteNo ratings yet

- (Colored) Refrigerant 134a P-H Diagram (SI Units)Document1 page(Colored) Refrigerant 134a P-H Diagram (SI Units)Mc Jason LaureteNo ratings yet

- Anern 580W Half-Cell N-Type Bifacial Module With Dual Glass Mono Solar Panels DatasheetDocument2 pagesAnern 580W Half-Cell N-Type Bifacial Module With Dual Glass Mono Solar Panels DatasheetRohit SahNo ratings yet

- KS SPRDocument5 pagesKS SPRChandra AndrikaNo ratings yet

- Mechanical Specifications: Non Ulls in The H-Pla NeDocument1 pageMechanical Specifications: Non Ulls in The H-Pla NeFernando Cuestas RamirezNo ratings yet

- TANK ModelDocument1 pageTANK ModelEmily MuthigaNo ratings yet

- Consider Pitot Tube Pumps For Low-Flow, High-Head ApplicationsDocument3 pagesConsider Pitot Tube Pumps For Low-Flow, High-Head ApplicationsFawmNo ratings yet

- Ax001 PDFDocument1 pageAx001 PDFAl Fakhamah LiftsNo ratings yet

- Searchlight Sonar: ModelDocument4 pagesSearchlight Sonar: Modelsyarifahdwi92No ratings yet

- Pompa Icar EcofilDocument2 pagesPompa Icar EcofilTito SaranaNo ratings yet

- ELD Meatshop Sheet P1 PLANS PDFDocument1 pageELD Meatshop Sheet P1 PLANS PDFJysar ReubalNo ratings yet

- DAH Mono Low Current DHT-M72X10LC-520 - 560W High Efficiency PV ModuleDocument2 pagesDAH Mono Low Current DHT-M72X10LC-520 - 560W High Efficiency PV ModuleEdson SucupiraNo ratings yet

- DAH Mono Low Current DHT-M72X10LC-520 - 560W High Efficiency PV ModuleDocument2 pagesDAH Mono Low Current DHT-M72X10LC-520 - 560W High Efficiency PV ModuleEdson SucupiraNo ratings yet

- Pavillion DesignDocument1 pagePavillion DesignNusry MohamedNo ratings yet

- RWB-80014-120 - 3°Document1 pageRWB-80014-120 - 3°shaker76No ratings yet

- Amphenol Cobre Bxa-18506312cfDocument1 pageAmphenol Cobre Bxa-18506312cfJimmytjr JaimesNo ratings yet

- CUTLASSDocument7 pagesCUTLASSPedro GonzalezNo ratings yet

- Plano NS3075 - ID - 7466Document1 pagePlano NS3075 - ID - 7466Christian CastilleroNo ratings yet

- Bulk HP: Achieve MoreDocument4 pagesBulk HP: Achieve MoreTangguh JayaNo ratings yet

- LC-LC-LF-SP SeriesDocument4 pagesLC-LC-LF-SP SeriesABC - Angela GomezNo ratings yet

- FT Square SQ 053Document1 pageFT Square SQ 053IreneNo ratings yet

- Lower Ground Upper Ground: CR LanaiDocument1 pageLower Ground Upper Ground: CR LanaiBethoven KhoNo ratings yet

- Série 17. RE51465 - 2021-04Document10 pagesSérie 17. RE51465 - 2021-04Gold PartsNo ratings yet

- Jinko N Type 54HL4 B ENDocument2 pagesJinko N Type 54HL4 B ENPauNo ratings yet

- Graf CNG CompressorDocument40 pagesGraf CNG CompressorcaginmulukNo ratings yet

- LF CL Brochure 2019Document4 pagesLF CL Brochure 2019indra putraNo ratings yet

- Jinko Tds 400-420 Tiger Neo 54hl4-b enDocument2 pagesJinko Tds 400-420 Tiger Neo 54hl4-b enEnock ChinakaNo ratings yet

- Dah 460 PDFDocument2 pagesDah 460 PDFDenis SilvaNo ratings yet

- CCW R 214W 14 Head Multihead WeigherDocument2 pagesCCW R 214W 14 Head Multihead WeigherBarun MukherjeeNo ratings yet

- Product Information SWEDAC Damping CassettesDocument8 pagesProduct Information SWEDAC Damping CassettesJay JayNo ratings yet

- BS 2494-90 (Elastomeric Seal For Joints in Pipes)Document16 pagesBS 2494-90 (Elastomeric Seal For Joints in Pipes)Razvan DonciuNo ratings yet

- Single Core Oil Filled Cable 60-36-kvDocument2 pagesSingle Core Oil Filled Cable 60-36-kvRazvan DonciuNo ratings yet

- Catalogue Cables AAAC (Almelec) - ECN Company PDFDocument6 pagesCatalogue Cables AAAC (Almelec) - ECN Company PDFRazvan DonciuNo ratings yet

- ECV - Contractual Considerations Under FIDIC Contracts When A Force Majuere Event OccursDocument6 pagesECV - Contractual Considerations Under FIDIC Contracts When A Force Majuere Event OccursRazvan DonciuNo ratings yet

- AMACOM Books - The AMA Handbook of Project Management by Paul C. DinsmoreDocument471 pagesAMACOM Books - The AMA Handbook of Project Management by Paul C. DinsmoreRazvan DonciuNo ratings yet