Professional Documents

Culture Documents

CIEGO DE 2 X 150 RF-6346 - Dingxiang - (M) PDF

Uploaded by

Fernando A CardozoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CIEGO DE 2 X 150 RF-6346 - Dingxiang - (M) PDF

Uploaded by

Fernando A CardozoCopyright:

Available Formats

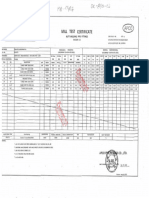

DINGXIANG BEICHENG FLANGE CO.

,LTD

Approved according to ISO9001:2000 No.01 100 059504 by Nord Tuv and PEO 97/23/EC,Ad2000-W0/TRD100 by Rheinland Tuv

ANALYSIS CERTIFICATE 3.1 EN 10204

Certificate No.20091108

CUSTOMER: ORDER NO:3985.54

DESCRIPTION OF MERCHANDIZE: FORGED FLANGES Date:2009-11-08

SPECIFICATION: ANSI B16.5 MATERIAL: ASTM A105

DESIGNATION OF ARTICLE . Pieces Heat No. DESIGNATION OF ARTICLE Pieces Heat No.

. -

I

2" 150# BLRF 100 6346 1O" 150# BLRF 20 6346

. -

.

3" 150# BLRF 150 6346 12" 150# BLRF 20 6346

.

4" 150# BLRF 174 6346 14" 150# BLRF 10 6346

- 6 11 150# BLRF

- -

80 6346 16" 150# BLRF 20 6346

8" 150# BLRF . 50 6347 18" 150# BLRF 15 6347

- CHEMICAL COMPOSITION

%C %Si %Mn %P %S %Ni %Al %Cu %Cr %Nb %Mo %V CEV

Heat No

0.08-0.20 0.4Max 0.5-1.3 0.025Max 0.015Max 0.30Max 0.3Max 0.3Max 0.1Max 0.08Max 0.02Max 0.41Max

6346 0.17 0.22 0.87 0.011 0.01 0.28 0.016 0.02 0.01 0.01 0.01 0.34

6347 0.19 0.25 0.89 0.012 0.01 0.28 0.016 0.02 0.01 0.01 0.01 0.34

�EV=C+Mn/6+(V+Mo+Cr)/5+(Ni+Cu)/15

º º

i/lelting process:Y(NORMALIZED 890 C-930 C},COOL IN STILL AIR) . - -

MECHANICAL TESTS -

Position Reduction Tensile Strength Yield Strength Charpy-impact Test ISO-V Hard-

Heat No of of Area Mpa Mpa(220Min) Elongation specimen ness

Specimen (25Min)% (410-530)N/mm 2 2

(N/mm )Rp0.2% (23Min)% J(20ºC) HB

6346 Tanqential - 3,q\ \.,\'} 509 335 34 31 34 34 143

't3i J

\ '' -

-

6347 Tanqenti�J � \ •-\�\� 507 339 35 32 34 35 144

:harpy impapt fest·ISO 'Vl'(daj/cm2) at +20 ºC mini 27, average mini 27

.

\ '

lSR��Q\-1� \,1\.

\ v•

'r§\,�pfa)id dimensional inspection with out complaint We hereby certify that flanges are conform to the standard contracted

You might also like

- Gas Line Sizing - Api 14E Input Description Unit: General DataDocument13 pagesGas Line Sizing - Api 14E Input Description Unit: General DataSamuel Onyewuenyi100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- BS 3059-2Document11 pagesBS 3059-2abhiNo ratings yet

- Inspection ReportDocument8 pagesInspection ReportchikannosNo ratings yet

- Inspection Certificate: Customer: CommodityDocument1 pageInspection Certificate: Customer: CommodityGisella Mariel Rubilar100% (1)

- S690Document2 pagesS690corsini999No ratings yet

- Mill Test Certificate Certificate Conform To: EN 10204/3.1Document1 pageMill Test Certificate Certificate Conform To: EN 10204/3.1GLORIA MONSALVE SALAZARNo ratings yet

- Page 1 of 6: Test Certificate No. 0000052877Document6 pagesPage 1 of 6: Test Certificate No. 0000052877panduranganraghurama78% (9)

- M 001 22Document1 pageM 001 22LUISNo ratings yet

- MTC Forged Fitting ElbowDocument1 pageMTC Forged Fitting Elbowfreeman11072000No ratings yet

- AcerinoxDocument1 pageAcerinoxOmkar PrindavankarNo ratings yet

- Item 13. Codo SCH-80 A234 - 783Document1 pageItem 13. Codo SCH-80 A234 - 783ELMER CHILON MINCHANNo ratings yet

- VTB-600-2 A105n W1834221,235,230.QR PDFDocument1 pageVTB-600-2 A105n W1834221,235,230.QR PDFJoe KylaNo ratings yet

- Quantity and Quality Certificate (EN 10204/3.1) : PAGE:1/7Document1 pageQuantity and Quality Certificate (EN 10204/3.1) : PAGE:1/7Nilton Santillan OrtegaNo ratings yet

- 1.VFB-150-2 Tr.316 90601-077 QRDocument1 page1.VFB-150-2 Tr.316 90601-077 QRSurya ManaluNo ratings yet

- SL MI1. Pipe Ixdl S Rries: Ta C e Na 600103. TN. tNO A - Phone +-91 379083276 6379083371Document1 pageSL MI1. Pipe Ixdl S Rries: Ta C e Na 600103. TN. tNO A - Phone +-91 379083276 6379083371Isaac SamuelNo ratings yet

- B56. 6775-4 - Brida WNDocument1 pageB56. 6775-4 - Brida WNdanielsalcedomringenierosNo ratings yet

- Certificado EsparragosDocument8 pagesCertificado EsparragosJesus CondoriNo ratings yet

- 1.14.1 MTC-11372 - Tube - 1 TUBINGDocument1 page1.14.1 MTC-11372 - Tube - 1 TUBINGgroupj.sr.servicesNo ratings yet

- Fr20-016.007-1-Bridas de 10-SlipDocument1 pageFr20-016.007-1-Bridas de 10-SlipEduardo Dudlei Jimenez CarbajalNo ratings yet

- "Orange Line": AC Contactors, AC OperatedDocument2 pages"Orange Line": AC Contactors, AC OperatedfelipeffcNo ratings yet

- Certificados Luda La Obra JJDocument6 pagesCertificados Luda La Obra JJLA OBRA JJ c.a.No ratings yet

- FRA20-034-3 - Filttro YDocument1 pageFRA20-034-3 - Filttro YHuber Pucuhuayla RojasNo ratings yet

- Ribo TC 324 (00000003)Document1 pageRibo TC 324 (00000003)Vinay YadavNo ratings yet

- Engineering Calculations: Ampacity CriteriaDocument2 pagesEngineering Calculations: Ampacity Criteriarettore84No ratings yet

- TubacexDocument1 pageTubacexMANUFACTURER OF FORGED FLANGES AND PIPE FITTINGSNo ratings yet

- Karachi Port Trust Construction of Connectivity Bridge Between East & West Wharf at Karachi Port Bill of QuantitiesDocument2 pagesKarachi Port Trust Construction of Connectivity Bridge Between East & West Wharf at Karachi Port Bill of QuantitiesIrfan AyubNo ratings yet

- Certif. Varilla B7-TornirapDocument1 pageCertif. Varilla B7-TornirapFabian LopezNo ratings yet

- SOW 09380SB2T SpecSheetDocument2 pagesSOW 09380SB2T SpecSheetAi NayNo ratings yet

- TEE ST 2PULG - GNCDocument1 pageTEE ST 2PULG - GNCjuan aguilarNo ratings yet

- Dosing Pump DocumentsDocument7 pagesDosing Pump Documentsbmanojkumar16No ratings yet

- Chemical Analysis and Mechancial Test Certificate: Yield Strength Tensile Strength ElongationDocument1 pageChemical Analysis and Mechancial Test Certificate: Yield Strength Tensile Strength ElongationDigna Bettin CuelloNo ratings yet

- Dokumen - Tips SR en 10088 1 2005 Oteluri Inoxidabile Partea 1 Lista Otelurilor InoxidabilepdfDocument2 pagesDokumen - Tips SR en 10088 1 2005 Oteluri Inoxidabile Partea 1 Lista Otelurilor InoxidabilepdfraduonoNo ratings yet

- Name NO: Company LimitedDocument26 pagesName NO: Company LimitedAK TRIPATHINo ratings yet

- Universal 1-2 Clase 6000 Tipo 316Document2 pagesUniversal 1-2 Clase 6000 Tipo 316comercial 3100% (1)

- Colada 5306Document1 pageColada 5306Lizz EstradaNo ratings yet

- WAGP-1-PAR-9A-M-SAS-99-0011 Hydrocarbons 1500 ANSI E1Document4 pagesWAGP-1-PAR-9A-M-SAS-99-0011 Hydrocarbons 1500 ANSI E1tope odumboniNo ratings yet

- E7014 Data Sheet: ISO 9001:2015 REGISTEREDDocument3 pagesE7014 Data Sheet: ISO 9001:2015 REGISTEREDThomas MacDonaldNo ratings yet

- Img 0001Document1 pageImg 0001Harish RanaNo ratings yet

- Reducciones CopaDocument2 pagesReducciones CopaYazeth MartinezNo ratings yet

- Section 10 Useful Information: Steel GuideDocument1 pageSection 10 Useful Information: Steel GuideEasun - MR TechnicalNo ratings yet

- Catalogo Importpegaus WimgerDocument46 pagesCatalogo Importpegaus WimgerSantiago Santi MuñozNo ratings yet

- Certificado de Calida Brida Cuello GasDocument1 pageCertificado de Calida Brida Cuello GasJKarlos Barrientos ÑufloNo ratings yet

- Certificado Brida 3Document1 pageCertificado Brida 3juan aguilarNo ratings yet

- Cross Reference of STANDARDS For Equivalent Grades of Steel: 1. Bearing Quality Steel: BS DIN IS EN Sae/AisiDocument4 pagesCross Reference of STANDARDS For Equivalent Grades of Steel: 1. Bearing Quality Steel: BS DIN IS EN Sae/AisiManjunath MNo ratings yet

- AR029022.001 (Filtro - ITEM 616A) (1) CCDocument1 pageAR029022.001 (Filtro - ITEM 616A) (1) CCJohan PintoNo ratings yet

- AR029022.001 (Filtro - ITEM 616A) HHDocument1 pageAR029022.001 (Filtro - ITEM 616A) HHJohan PintoNo ratings yet

- 7963 Brida Ac WN 6 X 150 SCH STD SWDocument2 pages7963 Brida Ac WN 6 X 150 SCH STD SWAlejandro L MagnusNo ratings yet

- BSM90C-3150AF: Product Information PacketDocument10 pagesBSM90C-3150AF: Product Information PacketRoberto CNo ratings yet

- 2017MEA46 50Hz Copeland CR Compressor Cross Reference - FlyerDocument2 pages2017MEA46 50Hz Copeland CR Compressor Cross Reference - FlyershadNo ratings yet

- Hot-Dip Galvanized Steel Strip: Range of Supply April 2019Document8 pagesHot-Dip Galvanized Steel Strip: Range of Supply April 2019Meme VillacortaNo ratings yet

- MS Sheets MTCDocument6 pagesMS Sheets MTCAmit Kumar OjhaNo ratings yet

- E6013 Data Sheet: ISO 9001:2015 REGISTEREDDocument3 pagesE6013 Data Sheet: ISO 9001:2015 REGISTEREDThomas MacDonaldNo ratings yet

- Inspection ReportDocument8 pagesInspection Reporttuan mai vanNo ratings yet

- Dossier Merla - ODB 4604279Document33 pagesDossier Merla - ODB 4604279Indira briceñoNo ratings yet

- CCF 000163Document1 pageCCF 000163Erik Jhonattan Jara YpanaqueNo ratings yet

- PQR No: Tme 000 Pass/Layer NO. Process Consumable Current (Amps) Voltage (Volts) Aws Class SIZE (MM)Document1 pagePQR No: Tme 000 Pass/Layer NO. Process Consumable Current (Amps) Voltage (Volts) Aws Class SIZE (MM)Sudhir KotkarNo ratings yet

- 16MO3 Data Sheet PDFDocument1 page16MO3 Data Sheet PDFMohamedNo ratings yet

- Pass/Layer NO. Process Consumable Current (Amps) Voltage (Volts) Aws Class SIZE (MM)Document1 pagePass/Layer NO. Process Consumable Current (Amps) Voltage (Volts) Aws Class SIZE (MM)Sudhir KotkarNo ratings yet