Professional Documents

Culture Documents

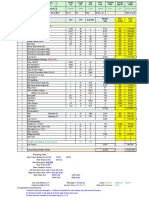

Dimensions and Specs of BFA Retarder Proofer Models

Uploaded by

Patrick O'neillOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dimensions and Specs of BFA Retarder Proofer Models

Uploaded by

Patrick O'neillCopyright:

Available Formats

52

30

1880

2210

H

108

P

L Po (porte ouverte)

Dimensions of the BFA models

Example : BFA 1 compartment, 1 door, 1 temperature

BFA standard model (Grid and linen canvas are not supplied)

1 Compartment - 1 Door - 1 Temperature

Dough

Tray size Reference Control Compressor unit L P Po H Weight Power capacity

(mm) (mm) (mm) (mm) (mm) (kg) (kW) (max.)

(kg)

400 x 600 W9005294 ** Opticom Standard assembled 560 1065 1343 2286 130 0.9 29

400 x 600 W9005267 Opticom Standard assembled 560 1065 1343 2286 130 0.9 29

400 x 800 W9005268 Opticom Standard assembled 620 1265 1603 2286 176 0.9 35

460 x 800 W9005269 Opticom Standard assembled 620 1265 1603 2286 176 0.9 43

600 x 800 W9005270 Opticom Standard assembled 760 1265 1743 2328 232 1.3 60

BFA standard model (Grid and linen canvas are not supplied)

1 Compartment - 2 Doors - 1 Temperature

Dough

Tray size Reference Control Compressor unit L P Po H Weight Power capacity

(mm) (mm) (mm) (mm) (mm) (kg) (kW) (max.)

(kg)

BFA

700 x 800 W9005271 Opticom Standard assembled 965 1265 1549 2328 260 1.3 63

765 x 800 W9005272 Opticom Standard assembled 965 1265 1549 2328 260 1.3 69

815 x 800 W9005274 Opticom Standard assembled 965 1265 1549 2328 260 1.3 77

915 x 800 W9005275 Opticom Standard assembled 1275 1265 1704 2328 274 1.9 99

1015 x 800 W9005276 Opticom Standard assembled 1275 1265 1704 2328 274 1.9 99

1115 x 800 W9005277 Opticom Standard assembled 1275 1265 1704 2328 274 1.9 120

Retarder-proofer

BFA standard model (Grid and linen canvas are not supplied)

2 Compartments - 2 Doors - 2 Temperatures

Dough

Tray size Reference Control Compressor unit L P Po H Weight Power capacity BFA retarder proofers have been designed to

(mm) (mm) (mm) (mm) (mm) (kg) (kW) (max.)

(kg) optimise the slow expansion of all types of

400 x 600 W9005278 Opticom Standard assembled 560 1065 1343 2286 170 1.9 24 product.

600 x 800 W9005279 Opticom Standard assembled 760 1265 1743 2328 270 1.9 51

Bongard reserves the features of its models at any time without prior notice.

Due to its exclusive temperature management

BONGARD — Global design — January 2009 — FROI002

system, Bongard’s BFA guarantees consistent

heating at the core of the dough and prevents any

thermal shocks and condensation.

Available in various sizes and mounted on castors

to make transportation easier, it will easily fit into

BP 17 Holtzheim — F-67843 Tanneries Cedex - France

Tel : +33 3 88 78 00 23 - Fax : +33 3 88 76 19 18 your bakery, even if you have limited space.

www.bongard.fr - bongard@bongard.fr

Machine according to the standards

The standard BFA model is

delivered pre-assembled, ready

to be connected, with :

• an Opticom control box

• an assembled freezing

compressor (for an ambient

temperature below 30°C)

• a single-phase, 230 V + earth,

50 Hz power supply

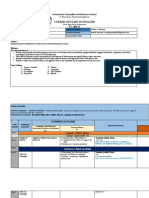

Details of the fan and the ventilation plate Examples of retarder proofers

You won’t be able to resist its Total accessibility to technical

beauty and functionality ! components

A totally modern look A high position for the evaporator The temperature is regulated to an accuracy of one

You will be charmed by the BFA’s modern and functional The evaporator is placed on the top panel of the BFA. In degree with a stabilisation time at each degree (actual

characteristics. addition to promoting flow, this position offers the slow increment).

possibility of delivering the BFA in a dismantled state.

A tilted control panel The platform, ready for use, merely needs to be Heating is done naturally and in a consistent manner,

The inclination of the control panel matches that of the assembled with the panels. directly to the core of the dough, preventing any thermal

hoods, to ensure better readability. shock and reducing condensation. Your products remain

soft and smooth with a beautiful appearance.

Stainless steel internal components If the PLC is not in operation for a period of 45 min

The ventilation, cladding and shielding metal plates, the (duration given as an example) after the end of the

discharge tank and the fastenings are made of stainless fermentation cycle, the “Dormillon” function allows for a

steel 304 in order to eliminate all possibility of equipment restart of the cooling process, and Opticom automatically

oxidation and to simplify maintenance. controls the end-of-cycle day.

Ventilation is used for automatic defrosting during the

Clip-on magnetic gaskets blocking phase.

Easily removable, clip-on magnetic gaskets are used for the

door closure. The door opens easily; it is not necessary to Fans, resistors and nozzles

adjust the hinge. The finishing and aesthetics are pleasant, Signification des touches

All these technical elements are installed on the front of

cleaning is easy! the cabinet (photo ). The “Joker” button is used to manually modify the

parameters of a cycle, even while in progress,

Ergonomic handles This allows for quicker and easier maintenance. using the +/- buttons.

The handles have been specially designed to ensure easy

gripping and to reduce effort when opening the door. La maintenance des éléments techniques en devient

plus rapide et plus facile. With the 2 buttons P01 and P02, you can

No-offset hinges directly access your 2 preferred programs.

The hinges mounted on the BFA have no offset, which

allows the door to be opened at a 90° angle. The doors are

very easy to operate and the handles do not impede their

travel.

Opticom, simple and efficient

The manual mode allows the BFA to be used in

You can also attach the BFA to a wall or to other baking position, slow increment or positive cold,

equipment. With its 30 pre-programmable cycles, the Opticom control

without time limit.

is extremely user-friendly, intuitive and extremely

A very practical leg assembly reliable, and allows for the automatic control of the BFA.

The BFA is installed on casters to simplify its When opening the doors to insert the dough for

transportation. The 2 front legs are used to stabilise the The program saved in the memory controls pre-cooling, cooling, the “unloading procedure” key stops the

BFA on the ground, level with its environment. blocking and rises in temperature. The evolution of the fans to prevent any heat loss or an excessively

cycle can be monitored on the screen. rapid rise in temperature.

You might also like

- CT3 - Floating Floor Loading Calculation - R0 - 020320Document4 pagesCT3 - Floating Floor Loading Calculation - R0 - 020320MyureshwaranNo ratings yet

- Pipe Rack A Dan CDocument4 pagesPipe Rack A Dan Cdikkipermana2901No ratings yet

- BOQ Steel Structure BOPDocument33 pagesBOQ Steel Structure BOPmeydicitra90No ratings yet

- At12 304Document1 pageAt12 304KAREN ROMANNo ratings yet

- At12 304 PDFDocument1 pageAt12 304 PDFGmo HdezNo ratings yet

- Austlift Part-4.MaterialHandlingDocument18 pagesAustlift Part-4.MaterialHandlingNeil WayneNo ratings yet

- SDL J (Pedestal)Document4 pagesSDL J (Pedestal)SURAJ SINHANo ratings yet

- TMPRO CASABE 1318 Ecopetrol Packer SuperiorDocument10 pagesTMPRO CASABE 1318 Ecopetrol Packer SuperiorDiego CastilloNo ratings yet

- 1200 Series DatasheetDocument12 pages1200 Series DatasheetbandaemetNo ratings yet

- EPC eDocument21 pagesEPC emario lazoNo ratings yet

- Precision Balances - Compact Design with Advanced FunctionsDocument4 pagesPrecision Balances - Compact Design with Advanced FunctionsjoaquinespalterNo ratings yet

- Brochure SEU-20201010Document5 pagesBrochure SEU-20201010Sendy PratamaNo ratings yet

- C29-JE-Y (ST) Y BD PDFDocument1 pageC29-JE-Y (ST) Y BD PDFNarendra Reddy BhumaNo ratings yet

- JE-Y (ST) Y: BD Si Industry-Electronic Cable According To DIN VDE 0815Document1 pageJE-Y (ST) Y: BD Si Industry-Electronic Cable According To DIN VDE 0815Narendra Reddy BhumaNo ratings yet

- Industry-Electronic Cable SpecsDocument1 pageIndustry-Electronic Cable SpecsNarendra Reddy BhumaNo ratings yet

- NANTE Cranes Components - Crane Components - Crane RailDocument2 pagesNANTE Cranes Components - Crane Components - Crane RailPham Thanh PhongNo ratings yet

- HS-901D Technical Data SheetDocument4 pagesHS-901D Technical Data SheetAji SetiawanNo ratings yet

- BA EOB 35K10 enDocument28 pagesBA EOB 35K10 enengage247salesNo ratings yet

- Besd Led - XR Series-1Document16 pagesBesd Led - XR Series-1ghafoorieskandarnejadNo ratings yet

- Concrete Corbel Design SummaryDocument14 pagesConcrete Corbel Design Summarynavneet3bawaNo ratings yet

- Frimec Packaged Units Catalogue-2022Document8 pagesFrimec Packaged Units Catalogue-2022walid.saab2No ratings yet

- Price List - 2018: Grip SheetsDocument4 pagesPrice List - 2018: Grip SheetsIrada Marketing ServicesNo ratings yet

- Grade 100 Alloy ChainDocument1 pageGrade 100 Alloy ChainPanthNo ratings yet

- Annex - B - BOQ - Detailed - Estimate Smart Street LightDocument8 pagesAnnex - B - BOQ - Detailed - Estimate Smart Street LightArun Kumar ShakarNo ratings yet

- Circular/elliptical polarization panel for triangular mastsDocument1 pageCircular/elliptical polarization panel for triangular mastsMarcos Duván Pineda AlhucemaNo ratings yet

- AIRWAVE King Series - Kitchen ESPDocument12 pagesAIRWAVE King Series - Kitchen ESPMason LeeNo ratings yet

- KWSM-09R410aCF to KWSM-24R410aCF specsDocument1 pageKWSM-09R410aCF to KWSM-24R410aCF specshernan trinoNo ratings yet

- HS-900B Technical Data SheetDocument3 pagesHS-900B Technical Data SheetAji SetiawanNo ratings yet

- HS-900A Technical Data SheetDocument3 pagesHS-900A Technical Data SheetAji SetiawanNo ratings yet

- ARRI - SkyPanel S360-C - Data Sheet - EN - Sep2018Document2 pagesARRI - SkyPanel S360-C - Data Sheet - EN - Sep2018asdfNo ratings yet

- Brosur Perkins Silent P220D5Document4 pagesBrosur Perkins Silent P220D5MUGIYANTANo ratings yet

- Ice Cube Machine Self-Contained Types and ModelsDocument12 pagesIce Cube Machine Self-Contained Types and ModelsKiyanto PurnomoNo ratings yet

- UE Piso Duto Dai KINDocument40 pagesUE Piso Duto Dai KINNelson Antonio De Souza MendesNo ratings yet

- ADU450900 V 06Document2 pagesADU450900 V 06RobertNo ratings yet

- XL 2600Document2 pagesXL 2600javier perezNo ratings yet

- Cabinet Thermal Solutions: Web: EmailDocument8 pagesCabinet Thermal Solutions: Web: EmailXiaofeng XuNo ratings yet

- Ahu 1 2FDocument1 pageAhu 1 2FAhmed AliNo ratings yet

- Antenna SpecificationsDocument2 pagesAntenna SpecificationsRobertNo ratings yet

- HMAG Data Sheet v1 3 DynaserDocument4 pagesHMAG Data Sheet v1 3 DynaserMiguel CabezasNo ratings yet

- Fan&Coil - Información TécnicaDocument2 pagesFan&Coil - Información TécnicaCarlos GonzálezNo ratings yet

- Antenna SpecificationsDocument2 pagesAntenna SpecificationsRobertNo ratings yet

- NonPre Hex 8.8 Nonpreloaded88hex S275 BS5950 UK 15 - 06 - 2021Document5 pagesNonPre Hex 8.8 Nonpreloaded88hex S275 BS5950 UK 15 - 06 - 2021yasser elnessaryNo ratings yet

- MitsubishiDocument8 pagesMitsubishiRaheem_ka67% (3)

- At13 303 PDFDocument1 pageAt13 303 PDFKAREN ROMANNo ratings yet

- At13 303Document1 pageAt13 303KAREN ROMANNo ratings yet

- Aalborg OL Modular Boiler Plant Capacities and DimensionsDocument2 pagesAalborg OL Modular Boiler Plant Capacities and Dimensionsthlim19078656No ratings yet

- EDAU391723v2 FXMQ-PV1ADocument52 pagesEDAU391723v2 FXMQ-PV1AignatiusglenNo ratings yet

- Bolt Capacities: Non-Preloaded Ordinary BoltsDocument1 pageBolt Capacities: Non-Preloaded Ordinary BoltsSelvasathaNo ratings yet

- Brosur BM7010 Brake TesterDocument2 pagesBrosur BM7010 Brake TesterAndhy AksaNo ratings yet

- Ias Lootah Contracting Gardencity 132/11 KV Substation ProjectDocument26 pagesIas Lootah Contracting Gardencity 132/11 KV Substation ProjectJoe Ps100% (1)

- Annexture 1Document9 pagesAnnexture 1BalajiYachawadNo ratings yet

- BA 001 R0A (Without Mezzanine)Document1 pageBA 001 R0A (Without Mezzanine)Muhammad Hassan TariqNo ratings yet

- Fan&Coil 40erq BDocument1 pageFan&Coil 40erq BAlejandro DuranNo ratings yet

- 40erq183b-E 40erq243b-E 40erq363b-E 40erq483b-E 40erq603b-EDocument1 page40erq183b-E 40erq243b-E 40erq363b-E 40erq483b-E 40erq603b-EAlejandro DuranNo ratings yet

- Daikin FXM-LVE - IMDocument32 pagesDaikin FXM-LVE - IMmr dangNo ratings yet

- GB011 Underground HV Cable and Accessories 22kV CablesDocument14 pagesGB011 Underground HV Cable and Accessories 22kV CablesMauricio SaulNo ratings yet

- J-Y (ST) y LG Rev004Document2 pagesJ-Y (ST) y LG Rev004Ruslan ValiakhmetovNo ratings yet

- Carrier Unit DataDocument1 pageCarrier Unit DatamohamedNo ratings yet

- Logicool 5100XDocument3 pagesLogicool 5100Xsreekanth6959646No ratings yet

- Insight IAS Prelims 2020 Test 13 S PDFDocument66 pagesInsight IAS Prelims 2020 Test 13 S PDFApooNo ratings yet

- Wooldridge ExampleDocument4 pagesWooldridge Examplejomarta01No ratings yet

- Sendai Framework For DRRDocument19 pagesSendai Framework For DRRAryaaaNo ratings yet

- The Construction of Self-Made Freaks: Interviews with the Vampire WomanDocument68 pagesThe Construction of Self-Made Freaks: Interviews with the Vampire WomanAdriano LeoneNo ratings yet

- Managing Supply Chain Risks R1Document48 pagesManaging Supply Chain Risks R1DebashishDolonNo ratings yet

- Entrainment Instability Quasi PeriodicitDocument17 pagesEntrainment Instability Quasi PeriodicitDe Nicolas JaidarNo ratings yet

- PCS-974A-G X Instruction Manual en Domestic General X R1.10Document194 pagesPCS-974A-G X Instruction Manual en Domestic General X R1.10Hikari DewiNo ratings yet

- Geographic AtmosphereDocument2 pagesGeographic AtmosphereLexter FalloNo ratings yet

- ĐỀ ÔN TỐT NGHIỆP THPT SỐ 2Document4 pagesĐỀ ÔN TỐT NGHIỆP THPT SỐ 2Lê Minh NguyệtNo ratings yet

- Collaborative Inter Agency Coordination SkillsDocument10 pagesCollaborative Inter Agency Coordination SkillsMark AngihanNo ratings yet

- Raising Awareness of Solid Waste Management PracticesDocument143 pagesRaising Awareness of Solid Waste Management PracticesPrimo Ernesto CanoyNo ratings yet

- Planning and Optimal Control Policy Gradient MethodsDocument34 pagesPlanning and Optimal Control Policy Gradient MethodscosmicduckNo ratings yet

- Does The Graduate Record Examination Predict Meaningful Success in The Graduate Training of Psychologists?Document12 pagesDoes The Graduate Record Examination Predict Meaningful Success in The Graduate Training of Psychologists?carainNo ratings yet

- International Application InstructionsDocument4 pagesInternational Application InstructionsTahiNo ratings yet

- ABB TZIDC CatalogueDocument32 pagesABB TZIDC CataloguesizmaruNo ratings yet

- Pipeline and Piping RepairDocument18 pagesPipeline and Piping RepairkhoerulNo ratings yet

- Course-Outline-For-Stud2020 (1) - English 9 THIRD QUARTERDocument3 pagesCourse-Outline-For-Stud2020 (1) - English 9 THIRD QUARTERTyrone Dave BalitaNo ratings yet

- HIN4801 MODULE OVERVIEWDocument6 pagesHIN4801 MODULE OVERVIEWZukiswa PetseNo ratings yet

- Iso Roof-Guard 1066 enDocument2 pagesIso Roof-Guard 1066 enMahmut AlmalahNo ratings yet

- Dirac (Bra-Ket) Notation/ FormalismDocument5 pagesDirac (Bra-Ket) Notation/ FormalismIjaz TalibNo ratings yet

- Cambridge Primary Reading Student's Book 6Document13 pagesCambridge Primary Reading Student's Book 6Mari Gold0% (1)

- Lab 02-Center of The Galaxy LabDocument7 pagesLab 02-Center of The Galaxy LabBNo ratings yet

- STATISTIC AND PROBABILITY 1ST QUARTER EXAM - SourceDocument72 pagesSTATISTIC AND PROBABILITY 1ST QUARTER EXAM - SourceAmanda Dinah RamilNo ratings yet

- 8.me331f20 Static Force Analysis ExamplesDocument7 pages8.me331f20 Static Force Analysis ExamplesTaylan KaraçelikNo ratings yet

- Aries Vs Gemini, VirgoDocument2 pagesAries Vs Gemini, VirgoIsabella BalcosNo ratings yet

- Understanding Faults and EarthquakesDocument8 pagesUnderstanding Faults and EarthquakesJerome CastilloNo ratings yet

- Perform Duties Following Workplace InstructionsDocument2 pagesPerform Duties Following Workplace InstructionsDan Rey Miras MiñaNo ratings yet

- Magnetic Particle Test Record Truck Crane Articulating Boom (Gb-La03)Document2 pagesMagnetic Particle Test Record Truck Crane Articulating Boom (Gb-La03)Hario PramuditoNo ratings yet

- Explains The Indicators For FitnessDocument7 pagesExplains The Indicators For FitnessCHITO PENJIE ODUYANo ratings yet

- Kelas Xii - May I Help You - Chapter 1Document2 pagesKelas Xii - May I Help You - Chapter 1Syifa Fauziah50% (2)