Professional Documents

Culture Documents

Pruebas y Ajustes

Pruebas y Ajustes

Uploaded by

Intercambio de Manuales0 ratings0% found this document useful (0 votes)

20 views41 pagesOriginal Title

pruebas y ajustes

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views41 pagesPruebas y Ajustes

Pruebas y Ajustes

Uploaded by

Intercambio de ManualesCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 41

Testing And Adjusting

c Test Equipment

400176 Electrical System Analyzer

(1) 408177 Test Lead Set included. (2) 409178 inductive Clamp

Irevuced

‘The 409176 Electrical System Analyzer is designed for

se on all gasoline engine Lift Trucks. The analyzer:

measures engine RPM, dwell, volts, ohms and amps;

‘checks diodes and continuity. For more information

see the instructions included with the analyzer.

c47040P1

'5P584 Timing Light

Troubleshooting

‘Adhere to the following warnings when performing any

tests oF adjustments while the engine is running

Work carefully around an engine that is running.

Engine parts that are hot, or parts that are moving,

‘can cause personal injury.

Exhaust fumes contain carbon monoxide (CO)

which can cause personal injury or death. Start and

operate the engine in a well ventilated area only. In

an enclosed area, vent the exhaust to the outside.

Troubleshooting can be difficult, On the pages thet

follow is a list of possible problems. To make a repair to

‘a problem, make reference to the probable cause

This lst of problems, causes and corrections will only

give an indication of where a possible problem can be

{and what repairs are needed. Normally, mare or other

repair work is needed beyond the recommendations in

the list, Remember that a problem is not normally

caused only by one part, but by the relation of one part

with the other parts. This list cannot give all possible

problems and probable causes. The serviceman must

find the problem and its source, then make the

necessary repairs.

There is a troubleshooting problem list for the gasoline

{uel system and a Ist for the quid petroleum fuel

system,

For problems with the gasoline portion of a Duel Fuel

System, see Troubleshooting Problem List: Gasoline

Fuel System. For problems with the LP portion of a

Dual Fuel System, see Troubleshooting Problem List:

LP Fuel Systern.

Troubleshooting Problem List: Gasoline

Fuel System

1. Engine crankshaft will not turn when the ignition

Switch is turned to the start position,

2. Engine will not start

3. Engine mistires or runs rough.

2.0 Liter (XN1P) Gasoline Engine

Testing And Adjusting

4, Engine idle not constant.

5. Stall at iow engine speed (1pm).

6. Sudden changes in engine speed (rpm),

7. Not enough power.

8 Too much vibration,

9. Loud combustion noise

10.

1".

12.

13,

14.

15.

16.

w.

18.

19,

20.

21.

22.

23.

24,

25.

2.

28.

29.

30.

at.

32.

Loud noise from valve compartment.

Oil in cooling system.

Mechanical noise in engine.

Fuel consumption too high.

Loud noise from valves or valve ctive components

Little movernent of valves and too much valve

clearance.

Valve spring lock is fre.

Ol at the exaust

Lite oF no valve clearance

Engine has early wear.

Coolant in tubrication oft

Too much black or gray smoke.

Too much white of blue smoke

Engine has low ol pressure.

Engine uses too ruch lubrication oit

Engine coolant is too hot

- Short spark plug life.

Early combustion

Starting motor does not turn or turns too slow.

Armature turns, but pinion does not engage

flywheel ring gear.

\With starting motor on, pinion engages ring gear,

but engine does not crank

Starting motor continues to run after ignition switch

has been released.

Pinion does not disengage atter engine starts to

run,

83. Alternator does not charge.

34. Alternator charge rate is low or not regular.

35. Alternator charges too much.

36. Alternator is noisy

Troubleshooting Problems: Gasoline

Fuel System

Problem 1: Engine crankshaft will not turn when

the ignition switch is turned to the start position.

Probable Cause:

1. Battery has low output

Make reference to Problem 34.

2. Circuit breaker open:

Push in the re-set button

3. Wiring, ignition switch or directional control switch

has defect

(Check all the wiring and connections. Make an

electrical test of the components parts for defects,

4. Starting motor solenoid has a defect:

Make reference to Problem 29.

. Starting motor has a defect:

Make reference to Problem 28.

6. Inside problem prevents engine crankshaft from

turning:

Ifthe crankshaft cannot be turned after

isconnecting the driven equipment, remove the

spark plugs and check for fuid in the cylinders

while turning the crankshaft. ffuid in the cylinders

is not the problem, the engine must be

disassembled to check for other inside problems,

‘Some of these inside problems are bearing

‘seizure, piston seizure, wrong pistons installed in

the engine

Problem 2: Engine will not start.

Probable Cause:

41. Slow cranking speed

Make reference to Problem 28.

2. No fuel to cylinders

‘Check gas supply.

‘Check carburetor throtte, and linkage between the

carburetor and the governor.

2.0 Liter (KN1P) Gasoline Engine

Testing And Adjusting

‘3. Weak or no spark to combustion chamibers:

(Check the wiring for cracks and the connections

for opens.

Check distributor cap for cracks and sensors for

defects.

Make sure the battery has good voltage.

‘Check the spark plugs and the ignition module for

correct operation,

See the test procedure for the respective Ignition

‘System in Testing And Adjusting,

A. Dirty air fiter:

Check air intake filter for a dirty fiter. See

Operation and Maintenance Manual.

5. Dirty fuel filter:

Install a new fuel filter element.

6. Dirty or broken fue! lines:

Clean or install new fuel lines as necessary.

7, Bad fuel pump:

Install 2 new fust pump.

8. Bad quality fuel

Remove the fuel from the fuel tank. Install a new

{uel filter element, Put a good grade of clean fuel

in the fuel tank,

‘8. Wrong ignition timing:

Set engine timing, See Ignition Timing Check and

‘Adjustment in Testing And Aqjusting,

10. Loose wiring connection in the starting system:

(Check and repair all wiring connections,

Problem 3: Engine misfires or runs rough.

Probable Cause:

1. Weak spark to combustion chambers:

‘See Problem 2 for correction.

2. Spark plug wires, in firing order sequence, are next

to each other.

Place wires so they are not parallel with each other

and are not next to each other in the fring

sequence.

38. Carburetor adjustment not correct:

Make adjustment as necessary. See Fuel System

in Testing And Adjusting,

4. Crosssfring (ignition voltage discharge) in distributor

cap:

Clean spark plug tip and check gap.

‘Check fuel mixture for being too lean under a load

condition

Clean inside and outside of aistrioutor cap

(Check and replace spark pug wires it necessary

5. Fuel pressure is low

Make sure there is fuel in the fuel tank

Look for leaks or bad bends in the fuel nes.

Look for atin the fue! system.

Check fue fw.

Check for plugged tue! fit

8, Engine timing isnot core:

Set engine timing. See ignition Timing Check And

Aquustment in Testing And Adusting

7. Ignition system problem:

See Ignition System in Testing And Adjusting.

8. Valve clearance is not correct

Make adjustment to valve clearance,

9. Intake or Exhaust valve leaks:

Do a oylinder leakage test. See Cylinder Leakage

Test in Testing And Adjusting,

Make a replacement or correction of the valves,

10. Head gasket leaks

Make a replacement of the gasket and other

‘components as needed,

11. Bent or broken push rod:

Make a replacement of the push rod

12. Hot engine temperatures:

(Check the water pump operation. See Cooling

System in Testing Ang Adjusting,

2.0 Liter (XN1P) Gasoline Engine

Testing And Adjusting

Problem 4: Engine idle not constant.

Probable Cause:

1. Air leaks to and around carburetor:

Tighten all screws.

Make sure the gaskets have a good seal

‘Check the lines and connections for ar leakage.

2. Carburetor idle speed adjustment is not correct:

Make an adjustment to carburetor ide speed. See

Low Idle Speed Adjustment in Testing And

Adjusting

3. Carburetor die mixture adjustment needs

adjustment:

Make an adjustment to the idle mixture setting,

See Idle Mixture Adjustment in Testing And

Adjusting

4, Intake air restriction in the air intake system

Check air intake filter for a dirty fiter. See

Operation and Maintenance Manual.

5. Operation of carburetor components is not correct:

Inspect the carburetor operation, replace the

components that are worn andjor damaged

6. Fuel pressure is low:

Make sure there is fuel in the fuel tank

Look for leaks or bad bends in the fue ine.

Look fo arin the fuel system.

Check fue! flow.

Problem 5: Stall at low engine speed (rpm).

Probable Cause:

4. Fuel pressure is low

Make sure there is fuel in the fuel tank.

Look for leaks or bad bends in the fuel ines

Look for air in the fuel system.

(Check fuel flow and check for a plugged fuel fer.

2. Ile tpm too low:

‘Make adjustment to get the correct iow ile speed.

See Low Idle Speed Adjustment in Testing And

Adjusting,

8. Carburetor adjustments not correct:

Make adjustments as necessary.

4. Carburetor and accelerator linkage adjustment is not

correct

Adjust the linkage, see Accelerator Control Linkage

‘Agjustment in Testing And Adjusting.

Problem 6: Sudden changes in engine speed

(rpm).

Probable Cause:

1. Failure of velocity governor:

Install new parts for those that have defects or are

damaged,

2. Damaged accelerator or carburetor linkage:

Repair or replace damaged components and

adjust the linkage. See Accelerator Control Linkage

‘Adjustment in Testing And Adjusting,

Problem 7: Not enough power.

Probable Cause:

1. Failure of velocity governor:

Install new parts for those that have defects or are

damages,

2. Bad quality fue!

Remove the fuel from the fue! tank, Install a new

‘uel fiter element, Put a good grade of clean fuel

in the fuel tank.

3. Weak spark to combustion chambers:

(Check the wiring for cracks and the connections

for opens.

(Check distributor cap for cracks and sensors for

defects.

Make sure the battery has good voltage

Check the spark plugs and the ignition module for

ccorect operation.

See the test procedure for the respective ignition

System in Testing And Adjusting,

4, Adjustment of carburetor not correct

Make adjustment to carburetor.

5. Wrong ignition timing:

Make adjustment to ignition timing, See Ignition

Timing Check And Adjustment in Testing And

Adjusting,

2.0 Liter (XN1P) Gasoline Engine 46

Testing And Adjusting

Engine is too hot

Make reference to Problem 25.

7, Leaks in air inlet system

Check for leakage at gaskets for inlet manifold and

carburetor

Look for restrictions in the air cleaner or air inlet

hoses.

8. Wrong vaive clearance:

Make adjustment to the valve clearance. See Valve

Clearance Adjustment in Testing And Adjusting:

9. Restriction in exhaust system:

(Check for bad mutter and exhaust pipes.

10. Fuel pressure is low:

Make sure there is fuel in the fuel tank

Look for leaks, or bad bends inthe ful lines

Look for ain the fuel system,

Check fue! flow and/or a plugged fuel filter.

Problem 8: Too much vibration.

Probable Cause:

1. Loose bolts or nuts that hold pulleys onto

‘crankshaft:

Tighten bol(s). See Crankshatt in Specifications,

2. Pulley has a defect:

Install a new pulley.

3. Fan blade not in balance:

Loosen or remove fan belts and operate engine for

a short time at the rpm that the vibration was

present. If vibration is not stil present, make a

replacement of the fan assembly.

4, Engine supports are loose, worn, or have a defect

Tighten all mounting bolts. Install new components,

if necessary.

5. Engine misfires or runs rough:

Make reference to Problem 3,

Problem 9: Loud combustion noise (detonation).

Probable Cause:

1. Bad quality fuel

Remove the fuel from the fue! tank, Install a new

{uel filter element. Put a good grade of clean fue!

in the fuel tank.

2. Wrong ignition timing:

Make adjustment to ignition timing. See ignition

Timing Check And Adjustment in Testing And

Adjusting,

Problem 10: Loud noise from valve compartment.

Probable Cause:

1. Damage to valve spring(s) or locks:

Install new parts where necessary.

2. Too much valve clearance:

Make adjustment to valve clearance. See Valve

Clearance Adjustment in Testing And Adjusting,

3. Not enough lubrication:

‘Check lubrication in valve compartment. There

‘must be a constant flow of oil at engine high rpm,

but only a small flow of oil at low rpm. Oil

passages must be clean, especially those that

‘send oil to and from the eylinder head

Problem 11: Oil in cooling system.

Probable Cause:

Detect in head gasket

Install a new head gasket.

2. Oil cooler leak

Repair or replace the radiator oil cooler

Problem 12: Mechanical noise

engine.

Probable Cause:

1. Failure of connecting rod and/or main bearings:

Inspect the bearings and the bearing surface on

the crankshaft. Install new parts when necessary.

2. Damage to timing chain and sprockets:

Install new parts where necessary.

3. Damage to crankshaft

Make replacement of the crankshaft

2.0 Liter (XN1P) Gasoline Engine

47

Testing And Adjusting

4. Loose or broken pin in piston

Make replacement of parts as necessary.

Problem 13: Fuel consumption too high.

2. End of valve stem worn:

if there is too much wear, install new valves. Make

adjustment of valve clearance according to Valve

Clearance Adjustment in Testing And Adjusting,

3. Tappets (valve lifters) worn

Probable Cause:

1. Fuel system leaks:

Large changes in fuel consumption may be the

result. Make replacement of parts as necessary.

4

2. Bad spark plugs:

Clean or make replacement as necessary.

3. Wrong ignition timing:

Make an adjustment to ignition timing. See Ignition

Timing Check And Adjustment in Testing And

Adjusting,

4. Worn piston rings:

Install new parts as necessary,

Problem 14: Loud noise from valves or valve drive

components.

Probable Cause: 5

1. Damage to valve springs:

Make replacement of parts with damage.

2. Damage to camshaft

Make replacement of parts with damage. Clean

engine thorough.

3. Damage to tappet (valve lifter)

Clean engine thoroughly.

Make a replacement of the camshaft and tappets

(valve lifters).

Look for valves that do not move freely.

Make an adjustment to valve clearance. See Valve

Clearance Adjustment in Testing And Adjusting,

4, Damage to valves: 7.

Make replacement of parts with damage,

Problem 15: Little movement of valves and too

‘much valve clearance.

Probable Cause:

1. Too much valve clearance:

Make adjustment according to Valve Clearance

‘Adjustment in Testing And Adjusting.

If there is too much wear, install new tappets

(valve lifters). Make adjustment of valve clearance

according to Valve Clearance Adjustment in

Testing And Adjusting,

Damage to tappets (valve liters):

Install new tappets (valve Iiters)

Check camshatt for wear. See Camshaft Lobe

Measurement in Testing And Adjusting

Check for free movement of valves or bent valve

stem

Clean engine thoroughy.

Make adjustment of valve clearance according to

Valve Clearance Adjustment in Testing And

Adjusting,

Worn lobes on camshaft

(Check valve clearance.

(Check for free movement of valves or bent valve

stems.

Check for tappet (valve lifter) wear.

Install a new camshaft

Make adjustment of valve clearance according to

Valve Clearance Adjustment in Testing And

Adjusting,

Worn push rods:

If there is too much wear, install new push rods.

Make adjustment of valve clearance according to

Valve Clearance Adjustment in Testing And

Adjusting

Rocker arm worn at face that makes contact with

valve stem:

If there is too much wear, install new rocker arms.

Make adjustment of valve clearance according to

Valve Clearance Adjustment in Testing And

Adjusting,

Not enough lubrication:

‘Check lubrication in valve compartment. There

must be a constant flow of ol at engine high rpm,

‘but oniy a small flow of oil at low rpm. Oil

passages must be clean, especially those that

‘send oil to and from the cylinder head,

2.0 Liter (XN1P) Gasoline Engine 48

Testing And Adjusting

Probable Cause:

4. Damage to locks:

Locks with damage can cause the valve to be

loose. Install new parts as necessary,

2, Damage to valve spring}

install new valve spring(s)

Problem 17: Oil at the exhaust.

Probable Cau:

1. Worn exhaust valve seats:

Install new exhaust valve seats,

2. Damaged or worn exhaust valve seals:

Inspect and install new parts as needed

3. Too much ail in the valve compartment:

Look at both ends of the rocker arm shaft. Be sure

that there is a plug in each end,

}- Worn piston rings:

Inspect and install new piston rings. See Cylinder

Leakage Test in Testing And Adjusting,

Problem 18: Little or no valve clearance.

Probable Cause:

1. Worn valve seat or face of valve:

Reconditioning of valves and valve seats is

needed. Make adjustment of valve clearance

according to Valve Clearance Adjustment in

Testing And Adjusting,

Problem 19: Engine has early wear.

Probable Cause:

1. Dirt in lubrication oi

Remove dit lubrication oi

Install a new filter element,

Put clean olin the engine.

2. Air inlet leaks:

Inspect all gaskets and connections. Make repairs

if leaks are present,

Problem 20: Coolant in lubrication oil.

Probable Cause:

1. Failure of cylinder head gasket

Install a new cylinder head gasket. Tighten the

bolts that hold the cylinder head, according to

Specifications,

2. Crack or detect in cylinder head:

Install a new cylinder head,

3. Crack or detect in cylinder biock:

Install @ new cylinder block,

4. Crack or defect in cylinder liner seal:

Install new cylinder liner seals,

Problem 21: Too much black or gray smoke.

Probable Cause:

1. Timing advance does not operate correctly

See Ignition Timing Check And Adjustment in

Testing And Adjusting. Make a replacement of the

advance timing components, if necessary.

2. Not enough air for combustion

Check air cleaner for restrictions

(Check air inlet hose and air horn for restriction.

3. Low quality of fuel

Remove the fuel from fuel tani

Install a new ful fiter element

Put a good grade of clean fuel inthe ful tank

4. Wrong ignition timing:

Make adjustment to timing. See Ignition Timing

Check And Adjustment in Testing Ang Adjusting,

5. Valve adjustment not correct

Make adjustment according to Valve Clearance

‘Agjusiment in Testing And Adjusting,

Carburetor has wrong adjustments:

Make adjustments to carburetor. See Fuel System

in Testing Ang Adjusting

7, Exhaust system restriction

Make visual inspection of exhaust system

(Check the back pressure inthe exhaust system,

‘$20 Arr Inlet And Exhaust System in Testing And

‘Adjusting,

2.0 Liter (XN1P) Gasoline Engine 49

Testing And Adjusting

Problem 22: Too much white or blue smoke.

Probable Cau:

41. Too much lubricating oil in engine:

Remove extra oil. See Operation and Maintenance

Manual

2. Engine misfires or runs rough:

‘Make reference to Problem 3.

3. Wrong ignition timing:

Make adjustment to timing. See Ignition Timing

‘Check And Adjustment in Testing And Adjusting.

4, Timing advance does not operate correctly

See Ignition Timing Check And Adjustment in

Testing And Adjusting. Replace the advance

timing components, if necessary.

5. Coolant in combustion system:

Check for cracked head

6. Worn piston rings:

Install new piston rings.

7. Carburetor has wrong adjustments:

Meke adjustment to carburetor. See Fusl System in

Testing And Adjusting.

8. Plugged positive crankcase ventilation valve:

Install a new PCV valve for crankcase ventilation,

Problem 23: Engine has low oil pressure.

Probable Cause:

1. Defect in oil pressure light or gauge’

Install new light, gauge, or instrument panel

2. Not enough oil in system:

‘Add cil to the crankcase. See Operation and

Maintenance Manual

3. Dirty oi!

Remove dirty oil from engine.

Install new oil filter element

Put clean oil in engine.

Check the oil fiter assembly for defects. Install

new parts if necessary,

4. Broken shaft for oll pump drive:

Install new parts as necessary.

Dirty sereen on oi pump suction bell

Clean screen.

Remove dirty ol from engine

Put clean ol in engine.

6. Relief valve for oll pump does not operate correctly:

lean valve and housing, Install new parts as

necessary.

7. Oil pump has a defect

Make repair or replacement of oil pump it

necessary,

8. Too much clearance between crankshaft and

‘crankshaft bearings:

Install new crankshatt or crankshaft bearings if

necessary,

8. Too much clearance between camehaft and

camshaft bearings:

Install new camshaft or camshaft bearings if

necessary.

Problem 24: Engine uses too much lubrication oil

Probable Cause:

4 Too much lubrication oll in engine:

Remove extra oil. See Operation and Maintenance

Manual

2. Oil leaks:

Find all oll leaks. Make repairs as needed.

3. Oil temperature is too high:

‘Make reference to Problem 25.

4. Worn piston rings:

Install new pars if necessary.

'5. Too much oll in valve compartment

Make reference to Problem 17.

2.0 Liter (XN1P) Gasoline Engine

Testing And Adjusting

Problem 25: Engine coolant is too hot.

Probable Cause:

1. Dirty radiator (plugged cores):

To prevent personal injury, never use

that is more than 205 kPa (30 psi).

Remove the dirt with an air hose in the direction

‘opposite fan airflow.

2. Loose or missing fan shrouds:

‘Shrouds are very important for cooling of the lit

truck engine. Make sure the fan is centered in the

shroud and is tightly fastened,

3. Loose or worn fan belts and worn pulleys:

Replace any worn belts or pulleys. See Belt

‘Adjustment in Testing And Adjusting,

4. Loose or defective radiator cap or low water level in

radiator:

Tighten or test the radiator cap. See Cooling

System in Testing And Adjusting,

Fill the raciator with coolant to the correct level

‘Check hoses and connections for high pressure

leaks.

Replace the parts that have wear,

5. Thermostat has a defect

Check and replace thermostat it defective. See

Cooling System in Testing And Adjusting,

‘6. Combustion gases in coolant:

Find out where gases get into cooling system,

Make replacement or repairs as needed.

7,

Water pump has a defect

Make replacement or repairs as needed,

8. Too much load on the lift truck:

Decrease the oad,

Wrong ignition timing,

Make adjustment to the timing. See Ignition Timing

Check And Adjustment in Testing And Adjusting,

10. Transmission not operating correctly that causes

an increase in the coolant temperature:

Make correction to the transmission. See

respective Power Train service module,

11. Water temperature light or gauge has a defect

Install a new light, gauge or instrument panel.

Problem 26: Short spark plug lif

Probable Cause:

1. Wire on wrong spark plug

Make reterence to Ignition Sequence (Firing Order)

in Specttications,

2. Spark plug gap too wide

Make adjustment to the gap for the spark plug,

See Spark Plug in Specifications,

3. Wrong spark plugs in engine:

Install the correct spark plugs.

Problem 27: Early combustion.

Probable Causé

1. Wrong ignition timing:

Make adjustment to timing, See Ignition Timing

Check And Adjustment in Testing And Adjusting,

2. Fuel octane rating (too low}

Use a good grade of clean fue!

3. BTU content of fuel too low

Use the correct grade of fuel.

4. High cooling system temperature:

Make repairs as necessary. See Cooling System in

Testing And Adjusting

5. Carburetor adjustment not correct

Make adjustments as necessary. See Fue! System

in Testing And Adjusting,

6. Too much load on engine:

Make a reduction to load on engine,

7. Deposits in combustion chamber:

Remove deposits from combustion chamber.

Problem 28: Starting motor does not turn or turns

100 slow.

Probable Cause:

1. Battery is discharged:

Charge battery

2.0 Liter (XN1P) Gasoline Engine 51

7.

Battery is detective:

Replace battery.

Battery cable terminals loose, corroded or poor

(ground connection:

Tighten cable terminals, clean them and battery

posts if corroded and apply antacid grease.

. Starting motor terminals or brushes have short

Circuit to ground:

Remove short circuit.

3. Brushes do not seat against commutator correctly.

‘They stick in their holders, are worn, broken, cily or

dirty

(Check brushes, clean or replace them. Clean

brush holders if necessary.

Ignition switch or solenoid damaged (burned or

loose parts)

Replace ignition switch or solenoid.

Excessive voltage drop in cables, damaged cables,

loose cable connections, or terminal connections

corroded:

Check starting motor cables and their

connections.

NOTE: For more information on the starting motor,

‘see the Nigpondenso Reduction Starting Motors.

service module, Form No. SENA3B28,

Problem 29: Armature turns, but pinion does not

‘engage flywheel ring gear.

Probable Cause:

1

4

5

Pinion drive/overrunning clutch is detective:

Replace pinion drive/overrunning clutch.

Damaged flywheel ring gear:

Replace flywheel ring gear.

Damaged or broken shitt lever:

Replace shit lever,

Damaged or broken solenoid:

Replace solenoid

Damaged or broken armature, idler or clutch gear

Replace armature or idler gear or overtunning

clutch as needed

NOTE: For more information on the starting motor,

‘see the Nippondenso Reduction Starting Motors.

service module, Form No, SENR3828

Problem 30: With starting motor on, pinion

engages ring gear, but engine does not crank.

Probable Cause:

1. Low battery:

Charge battery.

2. Not enough brush pressure on commutator:

(Check brush spring tension. Check brushes and

clean or replace them.

3. Excessive voltage drop in cables:

(Check cables and ther connections,

4, Clutch section of pinion drive/overrunning clutch

sls

Replace pinion drive/overrunning clutch.

NOTE: For more information on the starting motor,

‘see the Nippondenso Reduction Starting Motors

service madula, Form No. SENRG828,

Problem 31: Starting motor continues to run after,

ignition switch has been released.

Probable Cause:

1. Detective ignition switch or solenoid

Replace ignition switch or solenoid.

Problem 32: Pinion does not disengage after

‘engine starts to run.

Probable Cause:

4. Solenoid return spring weak or broken:

Replace solenoid return spring,

2. Shift lever is binding or broken:

Find cause of binding. Replace the shift lever if

broken.

3. Detective ignition switch

Feplace ignition switch

NOTE: For more information on the starting motor,

‘see the Nippondenso Reduction Starting Motors

service module, Form No. SENR3828,

Problem 33: Alternator does not charge.

Probable Cause:

1. Loose drive belt for alternator:

‘Adjust the alternator drive belt. See Belt

Adjustment in Testing And Adjusting

2.0 Liter (XN1P) Gasoline Engine

52

2. Loose alternator drive pulley:

Check the pulley for wear. If itis worn, installa

‘new pulley. Tighten the pulley nut to the correct

torque shown in Specifications,

38. Charging or ground return circuit or battery

‘connections are defective:

Inspect all cables and connections. Clean and

tighten all connections, Replace defective parts.

4. Rotor field winding or reguator is defective:

Replace the rotor or regulator.

NOTE: For more information on the alternator, see the

respective Alternator service module,

Problem 34: Alternator charge rate is low or not

regular

Probable Cause:

1. Loose orive belt for alternator:

‘Adjust the alternator drive belt. See Belt

‘Adjustment in Testing And Adjusting,

2, Loose alternator drive pulley

Check the pulley for wear. fit is worn, install a

ew pulley. Tighten the pulley nut to the correct

torque shown in Specifications,

8. Charging or ground return circuit or battery

connections defective

Inspect all cables and connections. Clean and

tighten all connections. Replace defective parts,

4, Reguiator is detective:

Replace the regulator.

5. Rectitier is detective:

Replace the rectifier.

6. Brushes are worn or dirty:

Replace the brushes.

NOTE: For more information on the alternator, see the

respective Alternator service module.

Problem 35: Alternator charges too much.

Probable Causs

1. Alternator or regulator has loose connections:

Tighten all connections to alternator or regulator

2, Reguiator is detective:

Replace the regulator.

NOTE: For more information on the alternator, see the

respective Alternator service module.

Problem 36: Alternator is noisy.

Probable Cause:

1. Drive belt for alternator is worn or defective:

Install a new drive belt forthe alternator.

2. Loose alternator drive pulley:

Check the pulley for wear. If itis worn, install a

‘new pulley. Tighten the pulley nut to the correct

toraue shown in Specifications

3. Drive belt and drive pulley for alternator are not in

alignment:

Make an adjustment to put the drive belt and drive

pulley in correct alignment.

4. Alternator bearings are worn

Replace the bearings in the alternator.

NOTE: For more information on the alternator, see the

respective Alternator eerviee module

Troubleshooting Problem List: Liquid

Petroleum Fuel System

1. Engine will not start,

2. Engine runs, but loses power.

3. No fuel from converter to carburetor.

4. Converter leaks fuel into carburetor with too much

Primary pressure.

5. Converter jeaks fuel into carburetor with normal

primary pressure

6. Converter is freezing during normal operation.

7. Fuelock is freezing during engine operation

8. No fuel ow to converter

NOTE: Other problems that have a relation withthe

engine can be found in the Gasoline Fuel System

troubleshooting,

Troubleshooting Problems: Liqui

Petroleum Fuel System

Problem 1: En

Probable Cause:

1e will not start.

1, Battery has low output:

‘Check condition of battery, Charge battery or

make replacement as necessary

2.0 Liter (XN1P) Gasoline Engine

Testing And Adjusting

2. Dirty fuel filter:

Clean or replace the fue! filter.

3. Starting motor solenoid has a defect:

Make reference to Problem 29 in Gasoline Fue!

System troubleshooting.

4. Starting motor has a defect:

Make reference to Problem 28 in Gasoline Fuel

‘System troubleshooting

5, No fuel in LP tank:

(Check fuel tank supply.

6. Weak or no spark to combustion chambers:

For correction, see Problem 2 in Gasoline Fuel

System troubleshooting,

7. Wrong ignition timing:

Make adjustment to timing. See Ignition Timing

Check And Adjustment in Testing And Adjusting,

8. Carburetor component parts have wear or have

foreign deposit:

Make a replacement of the parts if necessary, or

clean the part with brush and kerosene

9. Over flow valve in tank closed (can happen soon

after filing a tank which was low on fue)

Close fuel tank valve and open again slowly

10. Fuel ine between tank and fiterlock or fuelock has

damage (pinched)

Replace fue! line

11. Operation of the fiteriock, fuslock or vacuum

switch not correct:

Make repair or replacement if necessary.

12. Operation of the converter not correct

Make repair or replacement if necessary.

13. Quick disconnect coupling, at fuel tank, not fully

engaged:

Check the coupling

14, Fuel tank valve not open:

Open the valve.

15. Worn or damaged exhaust vaives:

Replace the exhaust vaive. Make a

the cause for the damaged valves.

Problem 2: Engine runs, but loses power.

Probable Cause:

4. Engine backfires:

‘Check ignition timing. Check for leaks in the head

{gasket. See Ignition Timing Check And Adjustment

in Testing And Agjusting,

2. Fuel system has a restriction:

Check the system. Clean the system if necessary.

8. Too much heat in the intake air:

Make sure intake air is being puled in trom outside

the engine compartment,

44. Fuel system is in contact with too much heat that

‘causes vaporization (vapor in the fuel systern):

‘Check the lift truck for components that are too

close to the fuel system. Remove the problem that

‘causes the heat

5, Dirty fue! filter:

Clean or replace filter if necessary.

6. Fuel system has some freezing:

Cooiant level too low and check for a restriction in

the cooling system.

7. Engine is too hot

Make reference to Problem 25 in Gasoline Fuel

System troubleshooting.

8. Fuel air mixture too lean’

Make adjustment to carburetor. See Idle Mixture

Adjustment in Testing And Adjusting.

9. Distodged plastic washer at converter:

Ifthe elbow of the balance line at the converter

has been serviced recently, the plastic washer can

islodge when the elbow is screwed too far into

the converter. If this has occurred, shorten the

thread length of the elbow and reassemble with

the plastic washer in the correct location.

Problem 3: No fuel from converter to carburetor.

Probable Cause:

41. Dirty fue! fiter:

Clean or replace the filter i necessary.

2, Failure of converter

Repair converter.

3. No carburetor vacuum to the converter and no

‘manifold vacuum to the vacuum switch:

(Check for vacuum leak belween the carburetor

and converter or the manifold and vacuum switch.

2.0 Liter (XN1P) Gasoline Engine 54

Testing And Adjusting

4, Carburetor adjustment not correct:

Make adjustment to carburetor. See Fuel System in

Testing And Adjusting

5. Fuel flow restriction in the fuel line:

Check for bad bend, partial closed (ginched) fue!

lines.

Problem 4: Converter leaks fuel into carburetor

with too much primary pressure.

Probable Cause:

41, Failure of converter:

Repair converter.

Problem

normal primary pressure.

Probable Cause:

1. Failure of converter:

Repair converter

2. Primer stays activated!

Check the primer spring.

Problem 6: Converter is freezing during normal

operation,

Probable Cause:

1. Low coolant level:

Fill raciator. I there is leakage, repair.

2. Coolant lines have restriction:

Repair or replace water hoses, lines or fitings if

too small for adequate water flow,

3. Air in converter:

Remove air from the coolant outlet hose.

4, Water pump has a defect or drive belt loose:

Check drive belt; repair or replace water pump.

5. Thermostat has a defect or is removed:

Install a new thermostat. See Cooling System

Tests in Testing And Adjusting

6. Restriction in water passage of converter:

Clean out rust or deposits. Install Caterpillar

Cooling System Conditioner in the cooling system,

7. Not enough antifreeze in coolant

Add antifreeze as needed,

&. Internal fue! leak:

‘Make inspection, replace the component that leaks

if necessary

Problem 7: Fuelock is freezing during engine

operation.

Probable Cause:

1. Fuslock valve outlet opening has a restriction:

Clean or make replacement of the parts as

necessary.

Problem 8: No fuel flow to converter

Probable Cause:

1. Carburetor vacuum low to converter:

(Check for restriction in vacuum hose,

‘Check for manifold vacuum to vacuum switch and

vacuum switch operation,

Check fue! selector valve position (dual fuel oniy).

Check all wiring and connections.

2. Fuclock valve closed (stuck):

Replace the fuelock valve

3. LP fuel tank valve closed

(Open LP fuel tank vaive slowly.

Ignition System

‘Adhere to the following warnings when performing any

tests or adjustments while the engine is running:

Work carefully around an engine that is running.

Engine parts that are hot, or parts that are moving,

can cause personal injury.

7 Ey

Exhaust fumes contain carbon monoxide (CO)

which can cause personal injury or death. Start and

operate the engine in a well ventilated area only. In

‘an enclosed area, vent the exhaust to the outside.

2.0 Liter (XN1P) Gasoline Engine 55

Testing And Adjusting

Ignition Component Checks

‘The procedures that follow are given as a guide. Use

these procedures to find possible solutions for ignition

problems,

Distributor Rotor Inspection

(@)Poter.

2. Inspect rotor (6) for breaks, cracks and dirt. Check

the rotor blade and spring condition. Be sure the

rotor fits correctly on the distributor shaft

3. Check 1 be suse distributer (4) ¢ clamped tightly in

the block to prevent tining changes. Check the

hose from the vacuum advance diaphragm to the

carburetor fora good fit and no holes or cracks.

Check the wiring between distributor (8) and

ignition module (1)

Ignition System Components

"ignition module. (2) Battery (8) Spark pug wires.

(4) Distributor

Inspection OF Distibuter Cap

(6) Dstaibutor cap,

‘Spark Plug Wires Inspection

(@ Spark plug wires. (7) Cover. (8) nsuater tube

1. Inspect distributor cap (5). Look for breaks, cracks

or Girt inside and on the outside. Clean the

ilwibuies can eee ara oir 4, Inspect spark plug wires (3) for breaks, cracks or

bburn marks. Use the 4C9176 Electrical System

Analyzer, or its equivalent to check the spark plug

wires for continuity. Make sure cover (7) on each

tend of the spark plug wire fits tightly and is in good

condition. Be sure insulator tube (8) is present and

is not burnt, cracked or broken. Cneck the spark

plug wires for a good electrical connection and.

distributor cap (6) and extension (9),

2.0 Liter (XN1P) Gasoline Engine 56 Testing And Adjusting

Spark Plug inspection

(@) Extension. (10) Spark plug

5. Be sure the area around spark plug (10) is clean,

Remove extension (9) and spark plug (10)

Extension (8) should be tight on the top of spark

plug (10). Inspect the spark plug insulator for cracks

or Girt, Be sure the electrode end of the spark plug

's not burnt and is free of carbon deposits

6. Check the spark plug gap. The correct gap for a

gasoline engine or a ual fue! engine is 0.6 mm

(026 in). The correct spark plug gap for an LP

engine is .4 to 0.5 mm (.016 to .020 in),

7. Install the spark plug and extension, Tighten the

‘spark plug to @ torque of 22.5 to 25 Nem (16.5 to 18

lo ft.

Ignition System Test

a

GETS Cereal Sten Analyzer

Ifthe engine will nat start, do the procedure in Ignition

Component Checks fist. If no defect was found, do

the test that follows to find the faulty component.

To make the electronic ignition test correctly, be sure

that the battery has a full charge. Do the steps in the

sequence that follow:

1. Make a battery voltage check with the use of the

4C9176 Electrical System Analyzer.

4. Put the analyzer (+) probe on the (+) battery

terminal and the (-) probe on the (-) battery terminal

b. The indication should be 12 to 13 volts. If the

battery is low, charge it

When the ignition system is checked for sparks,

hold the ignition wires with special insulated pliers.

Electrical shocks can be the result if the ignition

wires are held with bare hands.

‘Spark Check

2. Remove the coil wire from the distributor cap. Hold

the wite with special insulated pliers so that the end

Of the wire is approximately 12.5 mm (50 in) away

{rom the module coll tower. Turn the engine wit

starting motor.

a. If no spark is present, go to Step 3.

b. It 2 spark is present, check the distributor cap,

rotor, and spark plugs for defects,

2.0 Liter (XN1P) Gasoline Engine

7

Testing And Adjusting

—e—oo—— 5. PICKUP ASSEMBLY SHORT CIRCUIT CHECK -

Distributor pickup connector (3) remains

disconnected from the ignition module. Put the (-)

analyzer probe on a good ground. Put the (+) probe

(on either contact in distributor pickup connector (3)

Put the analyzer on the 20M (20 000 000 ohms)

range.

caT041PL 3

)

‘a, There should be no continuity.

». If there is continuity, replace the pickup assembly in

the distributor

Ignition Timing Check And Adjustment

[___________ Tools Needed

AOSITE Electrical System Analyzer 7

‘P6564 Timing Light 1

Eh

:

x

Use the procedure that follows to chack and adjust

ignition timing,

Igniton Module

{Ch Venice harness connector. (2) lion module connecter,

{@) Distrnutor pickup connect.

9. IGNITION MODULE POWER CHECK - Disconnect

vehicle harness connector (1) from ignition module

‘connector (2). Put the analyzer (+) probe on the

contact in vehicle harness connector (1). Put the (-)

probe on a good ground. Turn the ignition switch

ON.

1, The indication should be 12 to 13 volts. f so, go to

step 4 Ignivon Vacuum Advance Components

{A )Disteoutor. (2) Vacuum advance tbe, (9) Vacuum advance

b. Ifthe indication is not 12 to 13 volts, check the a

ignition system wiring for an open circu.

1. Remove vacuum advance tube (2) from vacuum

4. PICKUP ASSEMBLY RESISTANCE CHECK ~ advance diaphragm (3) Puta plug in tube (2).

Disconnect distributor pickup connector (3) from the

ignition module. Put the anaiyzer probes on the

Contacts in distributor pickup connector (3), Put the

analyzer on the 2K (2.000 ohms) range.

fa. The indication should be 960 + 190 ohms. If so, go

to Step 5.

». If the indication is not 950 + 190 ohms, replace the

pickup assembly inthe distributor,

2.0 Liter (XN1P) Gasoline Engine 58 Testing And Adjusting

‘Cover Location

(4) Cover pate

2. Remove cover plate (4) from the flywheel housing,

8. Connect the 409176 Electrical System Analyzer to

‘ead engine pm. See Engine RPM Check in Testing

And Adjusting,

4. Connect the red (+) wire of the SP6584 Timing Light

to the battery positive (+) terminal. Connect the

timing light black () wire to the battery negative (-)

terminal. Connect the timing light pickup to the

spark plug wire for No. 1 cylinder. The No. 1

cylinder is toward the flywheel end of the engine.

5. Start the engine. Run the engine at low idle speed,

6. Check the timing as follows

“Timing Mark Location (T250-TC400: V250-VC400 Models)

(51Fiywheel timing mark (groove). (6) Fywhee! housing timing

‘mark (groove).

NOTE: Timing marks (5) and (6)have been painted vite to make

them ease to see

. On T25D-TC40D; V25D-VC400 Models, point the

timing light at flywheel housing timing mark (grcove)

(©). Fiywhee! timing mark (groove) (5) must be in

algnment with flywheel housing timing mark (6)

‘when the timing light “Hashes

Timing Mark Location

140D-TOS0D; v400-VCBOD: T4DE & TSOE; VAVE & VSOE Models

(5) Timing marks, (6) Flyhee housing timing poner

NOTE: The timing marks ang pointer have been painted white to

make them easier to see.

'b. On T400-TC60; V40D-VC60D; T40E & TSOE: V40E

& VSOE Models, point the timing light at flywheel

housing pointer (6) and timing marks (6). Look at

the timing mark as it comes in alignment with

Pointer (6). The eighth mark after the O° mark is 8°

before top center (BTC). The fifteenth mark after the

0° mark is 15° before top center (BTC),

© 7. The correct ignition timing is:

Gasoline and dual fuel

LP tue!

sarc

18°BTC

The ignition timing is set when the correct timing mark

(6) isin alignment with timing mark (6) when the timing

light flashes,

Distrioutor Clamp Batt Location

(1) Distributor. (7) Distributor clamp batt

8. IT the ignition timing is not correct, loosen distributor

‘clamp bolt (7). Turn distributor (1) counterclockwise

{small amount to advance the ignition timing or

Clockwise to retard the ignition timing, Repeat Step

6. When the ignition timing is correct, tighten clamp

bolt (7).

2.0 Liter (XN1P) Gasoline Engine

59 Testing And Adjusting

Fuel System

‘Adhere to the following warnings when performing any

tests or adjustments while the engine is running:

Work carefully around an engine that is running.

Engine parts that are hot, or parts that are moving,

can cause personal injury.

Exhaust fumes contain carbon monoxide (CO)

which can cause personal injury or death. Start and

‘operate the engine in a well ventilated area only. In

an enclosed area, vent the exhaust to the outside.

Most of the following adjustments are common to the

gasoline, liquid petroleum and dual fuel systems. Any

differences are plainly marked in the adjustment tte.

2.0 Liter (XN1P) Gasoline Engine

60

Testing And Adjusting

Accelerator Control Linkage Adjustment

‘Tasp-TC40D;

/25D-VC40D Models,

sore

‘Accelerator Control Linkage (T25D-TC40D; v2S0-VC40D Models)

{) Accelerator pedal lever, 2) Acceerator pedal (3) Linkage rod (4) Accelerator pedal stop bot (5) Stop. (6) Rod. (7) Lever assembly, 0) 65.0

£5.0mm (256 79in) (¥) 8021 0mm(.12 = 04 i,

should be 65 + 5.0 mm (2.56 + .20 in). If not

correct, adjust linkage rod (3) to obtain the correct

distance (X),

3. Push down on accelerator pedal (2) until the

‘carburetor lever is against the high idle stop.

‘Acosirator Control Linkage Measurement

Use the procedure that follows to adjust the accelerator

Control linkage.

1. With the engine OFF and carburetor lever in the

high idle position, adjust rod (6) until lever assembly

(7) clears stop (5) by dimension (Y) 3.0 = 1.0 mm.

(12.04 in),

‘Accelerator Pedal Stop Bolt

(1) Accelerator pedal lever. (¢) Accelerator pedal stop bot.

2. With the carburetor lever in the low idle position,

measure distance (X) from the bottom of the 4. Adjust accelerator pedal stop bolt (4) until it just

accelerator pedal to the floor plate. Distance (X) Contacts lever (1),

2.0 Liter (XN1P) Gasoline Engine 1

Testing And Adjusting

‘T40D-TC6OD; V40D-VC6OD; TADE & TSOE; VA0E &

“VS0E Models

arsr0P1

Acoeerator Control Linkage

‘T40D-TC600; V400-VCEDD; T40E & TSOE: VAOE & VEOE Models

(1) Accelerator pecal lever, (2) Linkage od. (2) Accelerator pedal stop batt. (4) Clewis (6) Stop (6) Lover assemby. (7) Carburetor rod.

‘Acoeerator Stop Bolt

(7) Accelerator pedal lever. (9) Accelerator pedal stop bolt

Use the procedure that follows to adjust the accelerator

linkage.

1. With the engine OFF, disconnect clevis (4) from

accelerator pedal (1)

2. Agjust stop bolt (3) so that when the accelerator

pedal is depressed for ful throttle, bolt (3) stops

lever (1) just before it hits the floor plate. Tighten the

locknut.

3, Put the pedal against stop bott (3). Put rod (2) in the

full throttle position,

44. Acjust clevis (4) on rod (2) unti it can be connected

to pedal lever (1). Then turn cievis (4) on to rod (2)

‘one complete turn, to ingure full throttle. Tighten the

locknut.

'5. Connect the clevis to the pedal lever.

NOTE: If lever assembly (6) hits stop (5) curing full

throttle, lengthen rod (2) and repeat Steps 35,

6. Release the accelerator pedal and make sure the

carburetor returns to the low ide stop. If not, adjust

{00 (7) a8 needed and repeat Steps 26

Low Idle Speed Adjustment

Tools Needed

4C0176 Elston Systom Analyzer i

‘The low ile speed is agjusted at the velocity governor

on all fuel systems.

NOTE: Make sure al air intake components (air filter)

are in place and working propery.

2.0 Liter (XN1P) Gasoline Engine

Testing And Adjusting

1, Connect the 409176 Electrical System Analyzer to

measure engine rpm. See Engine RPM Check.

2. Start the engine and run until normal operating

temperature is reached. Read the 409176 Analyzer

to determine the idle speed.

The correct low idle speed is 850 ++ 50 rpm.

3. Check and adjust the hydraulic relief pressure. See

the Vehicle Systems module of the respective lft

truck service manual

NOTE: The hydraulic relief valve pressure must be

set properly in order to correctly adjust the velocity

governor,

Low lle Speed Adjustment (Gas/LP Carburetor Shown)

() Low ide speed setscew.

3. Ifthe low idle speed is not correct, make an

adjustment to low idle speed setscrew (1). Turn the

‘Screw clockwise to increase, or counterclockwise to

decrease the low idle speed

High Idle Speed Adjustment (Velocity

Governor Adjustments)

Tests Needed +

409176 _ Electrical System Analyzer 1

NOTE: Spring retainer sleeve (3) has two positions to

allow for wearing of spring (4). f more spring tension is

necessary, move spring (4) to the second position

within sleeve (3)

The high idle speed is adjusted at the velocity governor

on all fuel systems. The velocity governr is calibrated

at the factory and sealed. It controls the high idle

speed of the engine. The corract high idle Speed is:

TeSD-TC40D; V250-VC400

Models 2400+ 1001pm

T40D-TC800, V40D-VC60D; T40E & TSOE: V40E &

SOE Models 2500 100 rpm

Do the high idle speed (velocity governor) adjustment

as follows:

1. Check the accelerator linkage for binging or

improper adjustment

2. Connect the 4C9176 Electrical System Analyzer to

read engine rpm. See Engine RPM Check.

ersasres 5 2 3

Velocity Governor Components

(0) Velocity governor adjustment cover. (2) Spring tensioner

Adjusting screw. (9) Spring retaining sleeve. (4) Velosty governor

‘spring (5) Throttle pate

\Velocty Governor Lecaton

(1) Velocity governor aajustment cover.

Velocity Governor Adjustment

(2)Soring tensioner acusting screw. (3) Spring retaining sleeve.

2.0 Liter (XN1P) Gasoline Engine

Testing And Adjusting

NOTE: Both the engine and the hydraulic system must

be at normal operating temperature before making any

checks or adjustments,

4. Remove the velocity governor adjustment cover (1)

NOTE: Spring retaining sleeve (3) adjusts the spring

rate, The sleeve is made of aluminum (silver.colored),

Spring tensioner adjusting screw (2) agjusts the spring

tension. The screw is made of brass (gold-colored),

5. Turn spring retaining sieeve (3) counterclockwise

Until only one coil of the spring is visible past the

outside edge of the sleeve,

6. Turn spring tensioner adjusting screw (2) clockwise

Until there is a small gap between the brass screw

and the aluminum sieeve.

7. Turn spring tensioner adjusting screw (2)

counterclockwise unti it just makes contact with

spring retaining sleeve (3)

&. Start the engine and push the accelerator pedal

down against the stop. The engine will run at high

idle and may surge

8. Siowly turn spring retaining sleeve (3) clockwise:

Until the engine just stops surging

NOTE: As spring retaining sleeve (3) is turned, the

engine will begin to surge. itis important to stop

turning spring retaining sleeve (3) just atthe point the

engine stops surging. The point where the engine

stops surging willbe approximately 1800 rom.

10. Hold spring retaining sleeve (3) soit does not turn

while spring tensioner agjusting screw (2) is being

tured, Tur spring tensioner adjusting screw (2)

counterclockwise Unt the engine is atthe correct

high ile setting

‘The correct high idle speed is:

T25D-TC40D; V25D-VC40D

Models 2400+ 100 cpm

‘T40D-TOBOD: V40D-VC800; TAOE & TSOE: V40E &

\VS0E Models 2500+ 100 spn

11. Move a hydraulic lever to the full back position and

hold it for ten seconds. This will operate the

hydraulic relief valve for ten seconds. The engine

should be at 2200 rpm,

NOTE: When the hydraulic lever is first moved to the

full back position, the engine rpm may drop 2s low as.

1850 rpm then slowly increase back to the full load

setting,

42. Install governor adjustment cover (1) and repeat

Step 11

18. Readjust if necessary. Replace gaskets that are

damaged

Idle Mixture Adjustment - Gasoline

Ine Mixture Aaustment

("Low ide speed Setsecow. (2) oe mixture adjustment screw.

NOTE: Make sure all ar intake components (ar filter)

are in place and working propery.

4. Connect the 409176 Electrical System Analyzer to

read engine rpm, See Engine RPM Check.

2. Check to be sure the ignition timing is set correcty.

See ignition Timing Check And Adjustment

3. Run the engine until normal operating temperature is

reached,

4, Adjust low idle speed setscrew (1) to obtain a low

Idle speed of 850 + $0 rpm.

5. Turn ile mixture adjustment screw (2) clockwise or

counterclockwise to obtain the maximum rpm.

6. Readjust low idle speed setscrew (1) to obtain a low

idle speed of 850 + 50 rpm.

Idle Mixture Adjustment - LP

Two different LP fuel systerns are used: earlier and

current, The converter that is used, distinguishes the

eartier from the current system, The converter on the

eariier sysiem has the idle mixture adjustment screw

within the body of the converter. The converter on the

current system has no idle mixture adjustment screw, a

separate valve is used for idle mixture adjustment.

2.0 Liter (XN1P) Gasoline Engine

Testing And Adjusting

Earlier LP Fuel System

Carburetor

(1) Low ide spees setscrew.

Idle Mature Adlustment

(@)idle mixture adustment sorew. (3) Converter.

6. Readjust low idle speed setscrew (1) to obtain a low

idle speed of 850 = 50 rpm,

Current LP Fuel System With Gas/LP Carburetor

ccanezee1

Tools Nesded ]

“408176 Electrical System Analyzer 7

The idle mixture adjustment screw is part of the

converter,

NOTE: Make sure all air intake components (ar filter)

are in place and working properly.

1. Connect the 409176 Electrical System Analyzer to

read engine pm, See Engine RPM Check

2. Check to be sure the ignition timing is set correctly

See Ignition Timing Check And Adjustment.

‘3. Run the engine unti normal operating temperature is

reached,

4. Agjust low idle speed setscrew (1) to obtain a low

idle speed of 850 + 50 rpm.

5. Tum idle mixture adjustment screw (2) clockwise or

counterclockwise to obtain the maximum smooth

‘pm, then turn screw (2) in unti the engine speed

drops to 60 rpm less than the maximum,

2.0 Liter (XN1P) Gasoline Engine

Iie Mbure Adjustment

(1) Priming button. (2) Gas/LP carburetr. (3) ee mixture

adjustment valve,

a

‘cooeaaes

ole Mixture Adjustment Vatve

(@)lce mixture adjustment vaive,

Testing And Adjusting

Tools Needed

Ca17S _ Eectical System Analyzer ol

Veouurn

A separate valve is used for idle mixture agjustment.

The complete air intake system must be installed.

41. Connect the 409176 Electrical System Analyzer to

read engine rpm. See Engine RPM Check.

2. Connect @ vacuum gauge to the intake manifol,

8. Close idle mixture adjustment valve (3). Open the

valve one turn off its seat,

4, Press priming button (1) on the converter and hold

for three seconds. This purges the air from the fuel

lines.

5. Start the engine,

NOTE: If the engine does not start, open idle

mixture adjustment valve (3) in increments of an

‘additional 1/4 turn until engine stars.

6. Run the engine unti it reaches normal operating

temperature

7. Agjust low ile speed to 850 + 50 rpm.

8. Run the engine at low idle. Adjust idle mixture

adjustment valve (3) to obtain the highest possible

inlet manifold vacuum,

The approximate highest vacuum is 457 to S08

mm (18 to 20 in) of mercury.

9. Tur idle mixture adjustment valve (3) to reduce

‘vacuum by 25 mm (1.0 in) of mercury.

10. Reagjust low idle speed to 850 + 50 rpm,

2.0 Liter (XN1P) Gasoline Engine

Current LP Fuel System With LP Carburetor

SECTION AA

ccaves2P1

Idle Mixture Acjustment Screw

(1) ole mixture acjustment screw.

f Tools Needed

CSTE Elecrcal System Analyzer 1

1. Connect the 409176 Electrical System Analyzer to

read engine rpm, See Engine RPM Check.

2. Check to be sure the ignition timing is set correctly

See ignition Timing Check And Adjustment.

3. Run the engine until normal operating temperature is

reached

Check to be sure the low idle speed is set correctly

See Low Idle Speed Adjustment

5. Tur idle mixture adjustment screw (1) clockwise or

counterclockwise to obtain the maximum smooth

rpm.

6. Check the low idle speed again, See Low idle

Speed Agiusiment

Testing And Adjusting

SECTION AA

ccaoeaar2

Powor Mixture Adjustment kn0D

(1) Power mixture aclustment kno

‘The power mixture adjustment applies only to current

machines with an LP carburetor. The method of

adjustment depends upon the test equipment that is

avaliable. The power mixture can be adjusted using a

CO meter, vacuum gauge or electrical system analyzer.

The CO meter method is the preferred method for

reduced emissions. The vacuum gauge method is the

‘next most accurate method if CO measuring

equipment is not available. The engine speed method

is the easiest but least accurate method

Engine Speed Method

‘Tools Needed

405176 Electrical System Analyzer 7

1. Connect the 409176 Electrical System Analyzer to

read engine RPM, See Engine RPM Cheok

2. Check to be sure the ignition timing is set correctly.

See ignition Timing Check And Adjustment.

'3. Fun the engine untii normal operating temperature is

reached,

4. Turn power mixture knob (1) midway between lean

(Wand rich (F),

5. Accelerate the engine to high idle RPM, Put a load

‘on engine by holding the tit cylinder against rele,

6. Turn power mixture knob (1) toward lean (L) until

engine RPM drops,

7. Turn power mixture knob (1) toward rich (R) until the

RPM recovers.

8. The correct mixture will be that setting just before

the engine RPM drops.

CO Meter Method

‘Tools Needed

cower 7

(oF Exhaust Analyzer Testing Equipment

‘The power mixture adjustment must be done with the

engine in a load condition. A CO meter or exhaust

analyzer testing equipment must be used to measure

te CO content in the exhaust fumes. To adjust the

ower mixture, turn knob (1) either toward the "L” (ean)

"(rch fue flow mixture for a 1.0 10 1.5 percent

0 indication on the test equipment. Start the

adjustment with knob (1) in the maximum °° (rien)

position

if the engine power fals off with a leaner mixture than

3.5 percent CO, itis an indication of poor fue!

distribution in the air flow to the intake manifold.

NOTE: A lift truck, that does not operate with a heavy

load all the time, can operate efficiently with a leaner

Power mixture setting (less than 1.0 to 1.5 percent

CO). This is because the truck will not be in operation

Constantly in a load condition for a long period of time,

During heavy load and high speed conditions the it

truck requires a richer power mixture setting (1.0 t0 1.5

percent CO).

Vacuum Gauge Method

_ Tools Needed

Vacuum Gage 7

1. Connect the vacuum gauge to the intake manifold.

Start and run the engine until normal operating

temperature is reached

2.0 Liter (XN1P) Gasoline Engine

67

Testing And Adjusting

2. Run the engine at high idle. Turn power mixture

adjustment knob (1) to the maximum R* (rich)

position,

3, Puta load on the engine by operating the hydraulic

system,

4, Monitor the vacuum gauge reading. Turn power

mixture adjustment knob (1) toward the °L’ (ean)

position, until the vacuum starts to drop. The correct

‘mixture is the point at which the vacuum starts to

drop.

Converter Pressure Test

To check the LP converter for leakage, do the

procedure that follows:

1. Puta plug in the fuel outlet opening

2. Put compressed air in the fuel iniet opening, up to a

‘maximum of 725 kPa (120 pei)

3, Wait ten minutes and then check the converter for

air leaks. Listen for air to come out around gaskets,

or seals,

4, If there are no air leaks, the converter is good.

5. If air does come out, the converter will have to be:

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Copia de TA2 Spanish - Track-Type TractorDocument13 pagesCopia de TA2 Spanish - Track-Type TractorIntercambio de Manuales100% (1)

- Easyplus eDocument1 pageEasyplus eIntercambio de ManualesNo ratings yet

- 6847 PDFDocument27 pages6847 PDFIntercambio de ManualesNo ratings yet

- ACV - Changeover - Procedur - Rev - 1Document1 pageACV - Changeover - Procedur - Rev - 1Intercambio de ManualesNo ratings yet

- 50053_1228revDDocument3 pages50053_1228revDIntercambio de ManualesNo ratings yet

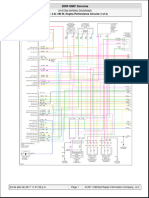

- 2000 GMC Sonoma 2000 GMC SonomaDocument9 pages2000 GMC Sonoma 2000 GMC SonomaIntercambio de ManualesNo ratings yet

- Desarmado y ArmadoDocument100 pagesDesarmado y ArmadoIntercambio de ManualesNo ratings yet

- 601 International Ave. Washington, Missouri 63090 (636) 239-2772 (636) 239-5652 (FAX)Document21 pages601 International Ave. Washington, Missouri 63090 (636) 239-2772 (636) 239-5652 (FAX)Intercambio de ManualesNo ratings yet

- Herramientas SKFDocument6 pagesHerramientas SKFIntercambio de ManualesNo ratings yet

- WR6000 - WR8000: Pantallas JUDIT en LaptopDocument46 pagesWR6000 - WR8000: Pantallas JUDIT en LaptopIntercambio de ManualesNo ratings yet

- WALKIDocument73 pagesWALKIIntercambio de ManualesNo ratings yet

- EspesificacionesDocument21 pagesEspesificacionesIntercambio de ManualesNo ratings yet

- Pruebas y AjustesDocument69 pagesPruebas y AjustesIntercambio de ManualesNo ratings yet

- Sistema y OperacionDocument5 pagesSistema y OperacionIntercambio de ManualesNo ratings yet

- Reman Nissan H20 EngineDocument3 pagesReman Nissan H20 EngineIntercambio de ManualesNo ratings yet

- Parts Manual: CascadeDocument17 pagesParts Manual: CascadeIntercambio de ManualesNo ratings yet

- Case 580D Operator ManualDocument187 pagesCase 580D Operator ManualIntercambio de Manuales100% (2)

- Perkins Engines: Narrow Front CoverDocument4 pagesPerkins Engines: Narrow Front CoverIntercambio de ManualesNo ratings yet

- Installation Instructions: CascadeDocument2 pagesInstallation Instructions: CascadeIntercambio de ManualesNo ratings yet

- 7588 7591 7592 A Do Not Use For Ind. Eng. Do Not Use For Ind. Eng. Ntes DE LA Entrega Visita 1 Visita 2Document1 page7588 7591 7592 A Do Not Use For Ind. Eng. Do Not Use For Ind. Eng. Ntes DE LA Entrega Visita 1 Visita 2Intercambio de ManualesNo ratings yet

- TA1 Spanish - Skid Steer Loader & Multi-Terrain LoaderDocument7 pagesTA1 Spanish - Skid Steer Loader & Multi-Terrain LoaderIntercambio de ManualesNo ratings yet

- Engine Delivery Service Record: Delivered byDocument1 pageEngine Delivery Service Record: Delivered byIntercambio de ManualesNo ratings yet

- NSHS0594 03Document34 pagesNSHS0594 03Intercambio de ManualesNo ratings yet