Professional Documents

Culture Documents

NACE Requirements For Super Duplex Welds

Uploaded by

Juan Rodriguez0 ratings0% found this document useful (0 votes)

4 views1 pageOriginal Title

NACE requirements for super duplex welds

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views1 pageNACE Requirements For Super Duplex Welds

Uploaded by

Juan RodriguezCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

From: Peter Kinney <peter.kinney@acutetechserv.

com>

Sent: Tuesday, December 09, 2014 1:22 PM

To: Juan.Rodriguez1

Cc: Mike Lemker

Subject: NACE requirements for super duplex welds

Juan,

Here are the requirements from NACE MR0175

A.7.3 Welding of duplex stainless steels of this materials group

The requirements for the cracking-resistance properties of welds shall apply; see 6.2.2.

The hardness of the HAZ after welding shall not exceed the maximum hardness allowed for the base metal,

and the hardness of the weld metal shall not exceed the maximum hardness limit of the respective alloy used

for the welding consumable.

A cross-section of the weld metal, HAZ and base metal shall be examined as part of the welding procedure

qualification. The microstructure shall be suitably etched and examined at ⋅400 magnification and shall have

grain boundaries with no continuous precipitates. Intermetallic phases, nitrides and carbides shall not exceed

1.0 % in total. The sigma phase shall not exceed 0.5 %. The ferrite content in the weld metal root and

unreheated weld cap shall be determined in accordance with ASTM E562 and shall be in the range of 30 % to

70 % volume fraction.

Thanks,

Peter

You might also like

- Paper 5qa 002 Sa2Document12 pagesPaper 5qa 002 Sa2Siva Kumar100% (1)

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesFrom EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNo ratings yet

- Duplex & Super Duplex InformationDocument7 pagesDuplex & Super Duplex InformationrajeshNo ratings yet

- The Essentials of Material Science and Technology for EngineersFrom EverandThe Essentials of Material Science and Technology for EngineersRating: 5 out of 5 stars5/5 (1)

- Weld AbilityDocument34 pagesWeld AbilityMuzaffarNo ratings yet

- RM01 SawDocument15 pagesRM01 SawAnonymous cgcKzFtXNo ratings yet

- CON-03!03!22 Temper Bead Welding ProcedureDocument6 pagesCON-03!03!22 Temper Bead Welding ProceduresusanwebNo ratings yet

- Microstructure and Mechanical Properties of Laser Beam Welds of 15CDV6 SteelDocument4 pagesMicrostructure and Mechanical Properties of Laser Beam Welds of 15CDV6 SteelKarthik RaoNo ratings yet

- "Downsizing" in The World of Resistance WeldingDocument15 pages"Downsizing" in The World of Resistance WeldingRudi DaNo ratings yet

- Properties and Welding Procedure For Grade 91 Alloy Steel: Siddharth Pant and Swati BhardwajDocument6 pagesProperties and Welding Procedure For Grade 91 Alloy Steel: Siddharth Pant and Swati BhardwajArvind ShuklaNo ratings yet

- Hemps 11.100 A1Document33 pagesHemps 11.100 A1हेमंत कुमार मीणाNo ratings yet

- Laser Assisted Arc Welding: Shop TalkDocument8 pagesLaser Assisted Arc Welding: Shop TalkWilly UioNo ratings yet

- The Efffect of Post-Weld Heat Treatment On Properties of Low-Alloyed Crmonb Steel After Submerged WeldingDocument8 pagesThe Efffect of Post-Weld Heat Treatment On Properties of Low-Alloyed Crmonb Steel After Submerged WeldingMenad SalahNo ratings yet

- Effect of Multi-Pass SMAW Welding On The Surface HDocument7 pagesEffect of Multi-Pass SMAW Welding On The Surface HYousab CreatorNo ratings yet

- Effect of Laser Welding Process Parameters On Mechanical P Roperties of Stainless Steel-316Document11 pagesEffect of Laser Welding Process Parameters On Mechanical P Roperties of Stainless Steel-316kamal touilebNo ratings yet

- WELDABILITY of SteelDocument41 pagesWELDABILITY of Steel0502ravi75% (4)

- Unit Ii Resistance Welding ProcessesDocument49 pagesUnit Ii Resistance Welding ProcessesparthibankNo ratings yet

- The Effect of Groove Welding On Mechanical PropertDocument8 pagesThe Effect of Groove Welding On Mechanical PropertMuhammad Zuhairy jabarNo ratings yet

- Dissimilar Steel WeldingDocument9 pagesDissimilar Steel Weldingbh hbNo ratings yet

- 3SS NW00 00007 PDFDocument10 pages3SS NW00 00007 PDFKarthikNo ratings yet

- N9509-Welding Techniques For Tailored BlanksDocument7 pagesN9509-Welding Techniques For Tailored BlanksAgustine SetiawanNo ratings yet

- Microstructural Parameter Controlling Weld Metal Cold CrackingDocument4 pagesMicrostructural Parameter Controlling Weld Metal Cold CrackingSadhasivam VeluNo ratings yet

- Optimization of Welding Parameters of Submerged Arc Welding Process: A ReviewDocument6 pagesOptimization of Welding Parameters of Submerged Arc Welding Process: A ReviewsettaNo ratings yet

- 718 To 316 WeldingDocument9 pages718 To 316 WeldingRagerishcire Kanaalaq100% (1)

- Welding Research Paper OutlineDocument4 pagesWelding Research Paper Outlinecapz4pp5100% (1)

- ProjectionWelding JiangDocument23 pagesProjectionWelding JiangVimal KumarNo ratings yet

- Defect Analysis of Electric Arc Welding Seams With Coated Electrode by Non-Destructive Testing of Different ThicknessesDocument10 pagesDefect Analysis of Electric Arc Welding Seams With Coated Electrode by Non-Destructive Testing of Different ThicknessesChaka BertheNo ratings yet

- M CR 101r1Document24 pagesM CR 101r1Earl HarbertNo ratings yet

- The E Ect of Process Parameters On Penetration in Gas Metal Arc Welding ProcessesDocument8 pagesThe E Ect of Process Parameters On Penetration in Gas Metal Arc Welding ProcessesSreevardhan BGNo ratings yet

- Structural Changes in 12-2.25% CR Weldments - An Experimental and Theoretical ApproachDocument8 pagesStructural Changes in 12-2.25% CR Weldments - An Experimental and Theoretical ApproachAli AhmadNo ratings yet

- Technical Confirmation List Pipe & PlatesDocument2 pagesTechnical Confirmation List Pipe & Platessiva8000No ratings yet

- Proy Sold ResDocument3 pagesProy Sold Resvitor17050137No ratings yet

- Duplex and Superduplex Stainless Steels May Be Welded To Carbon Steels From TW1Document1 pageDuplex and Superduplex Stainless Steels May Be Welded To Carbon Steels From TW1valli rajuNo ratings yet

- Mil C 26074eDocument11 pagesMil C 26074edharlanuctcomNo ratings yet

- Effect of Developed Flux and Process Parameters On Hardness of Weld in SawDocument6 pagesEffect of Developed Flux and Process Parameters On Hardness of Weld in SawJames PhillipsNo ratings yet

- Creep Behavior of 2.25Cr-1Mo Steel Shield Metal Arc WeldmentDocument10 pagesCreep Behavior of 2.25Cr-1Mo Steel Shield Metal Arc WeldmentTrushar ParmarNo ratings yet

- Shielded Metal Arc WeldingDocument45 pagesShielded Metal Arc WeldingBharichalo007No ratings yet

- Metallurgy For Downhole Oilfield Equipment PDFDocument1 pageMetallurgy For Downhole Oilfield Equipment PDFYousuf MemonNo ratings yet

- Experiment 1Document16 pagesExperiment 1samayNo ratings yet

- Project 2020 PDFDocument29 pagesProject 2020 PDFDaya ShankarNo ratings yet

- A 1 Gen MC SP 0001Document8 pagesA 1 Gen MC SP 0001api-19762124100% (1)

- Nd-Yag Laser Beam and Gta Welding of Ti-6Al-4V Alloy: Abdel-Monem El-Batahgy, Tarasankar DebroyDocument8 pagesNd-Yag Laser Beam and Gta Welding of Ti-6Al-4V Alloy: Abdel-Monem El-Batahgy, Tarasankar DebroyerpublicationNo ratings yet

- 3 Edwin NT JongDocument15 pages3 Edwin NT JongfelixNo ratings yet

- A Literature Review On CO Laser WeldingDocument7 pagesA Literature Review On CO Laser Weldingkamal touilebNo ratings yet

- Mar2014/zip/10462990 TD Technical SpecificationDocument6 pagesMar2014/zip/10462990 TD Technical SpecificationNaresh Ch MahapatraNo ratings yet

- Weldability of Thermo-Mechanically Rolled Steels Used in Oil and Gas Offshore StructuresDocument8 pagesWeldability of Thermo-Mechanically Rolled Steels Used in Oil and Gas Offshore Structuresபரணி ராஜாளிNo ratings yet

- Welding Metallurgy 2Document37 pagesWelding Metallurgy 2Asad Bin Ala QatariNo ratings yet

- Welding of Nickel-Based Alloy 617 Using Modified Dip Arc ProcessesDocument12 pagesWelding of Nickel-Based Alloy 617 Using Modified Dip Arc ProcessesAnonymous KzJcjGCJbNo ratings yet

- Cswip QusDocument4 pagesCswip QusRob WillestoneNo ratings yet

- Welding of Nickel-Based Alloy 617 Using Modified Dip Arc ProcessesDocument12 pagesWelding of Nickel-Based Alloy 617 Using Modified Dip Arc ProcessesAnonymous KzJcjGCJbNo ratings yet

- Effectof Welding Processeson Microstructure MechanicalDocument12 pagesEffectof Welding Processeson Microstructure MechanicalDr. Rachid djoudjouNo ratings yet

- Difference Between Cold Welding and Pseudo SolderingDocument12 pagesDifference Between Cold Welding and Pseudo SolderingjackNo ratings yet

- 9% Nickel Steel WeldingDocument11 pages9% Nickel Steel WeldingSridharan ChandranNo ratings yet

- Design of A Spot Weld Machine For WorkshopsDocument5 pagesDesign of A Spot Weld Machine For WorkshopsOscar Choque PardoNo ratings yet

- Ceramics International: Rasool Saeedi, Reza Shoja Razavi, Saeed Reza Bakhshi, Mohammad Erfanmanesh, Ahmad Ahmadi BaniDocument14 pagesCeramics International: Rasool Saeedi, Reza Shoja Razavi, Saeed Reza Bakhshi, Mohammad Erfanmanesh, Ahmad Ahmadi BaniLaryNo ratings yet

- Line Pipe Specification&Corrosion Protection CoatingDocument27 pagesLine Pipe Specification&Corrosion Protection CoatingEngr Arfan Ali DhamrahoNo ratings yet

- Sciencedirect: Preliminary Studies On Mecahnical and Metallurgical Behaviour of Friction Stir Welded Butt JointsDocument7 pagesSciencedirect: Preliminary Studies On Mecahnical and Metallurgical Behaviour of Friction Stir Welded Butt JointsV.v. TaguisNo ratings yet

- Astm A 036 2005Document4 pagesAstm A 036 2005gorgonoidemarcoNo ratings yet

- SAE Steel Grades - ReferenceDocument12 pagesSAE Steel Grades - ReferenceJuan RodriguezNo ratings yet

- Iso 5817 - 2014 NDTDocument34 pagesIso 5817 - 2014 NDTJuan RodriguezNo ratings yet

- NSWE Company ProfileDocument9 pagesNSWE Company ProfileJuan RodriguezNo ratings yet

- NST Corporate Presentation April 2016Document38 pagesNST Corporate Presentation April 2016Juan RodriguezNo ratings yet

- Jetline Capabilities CatalogueDocument4 pagesJetline Capabilities CatalogueJuan RodriguezNo ratings yet

- Macro Etch-Micro EtchDocument1 pageMacro Etch-Micro EtchJuan RodriguezNo ratings yet

- Shipbuilding KOBELCO Kobe Steel,. LTDDocument10 pagesShipbuilding KOBELCO Kobe Steel,. LTDJuan RodriguezNo ratings yet

- Cross Sectional Area of WeldsDocument4 pagesCross Sectional Area of WeldsJuan RodriguezNo ratings yet

- Exotic Metal Base Metal & Filler GuideDocument1 pageExotic Metal Base Metal & Filler GuideJuan RodriguezNo ratings yet

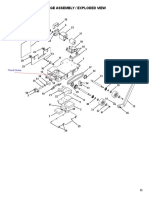

- Kbug-3010 Carriage Assembly / Exploded View: Thumb ScrewDocument2 pagesKbug-3010 Carriage Assembly / Exploded View: Thumb ScrewJuan RodriguezNo ratings yet

- Instructions AND Parts Manual: STW-2000 Programmable Stiffener WelderDocument32 pagesInstructions AND Parts Manual: STW-2000 Programmable Stiffener WelderJuan RodriguezNo ratings yet

- AWS Estimating PreheatDocument1 pageAWS Estimating PreheatJuan RodriguezNo ratings yet

- Tip-TIG CladdingDocument5 pagesTip-TIG CladdingJuan RodriguezNo ratings yet

- A2-Multitrac A2TFDocument2 pagesA2-Multitrac A2TFJuan RodriguezNo ratings yet

- AWS D1.1-2010 Preheat GuidlinesDocument5 pagesAWS D1.1-2010 Preheat GuidlinesJuan RodriguezNo ratings yet

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontFrom EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontRating: 4.5 out of 5 stars4.5/5 (18)

- Waste: One Woman’s Fight Against America’s Dirty SecretFrom EverandWaste: One Woman’s Fight Against America’s Dirty SecretRating: 5 out of 5 stars5/5 (1)

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (52)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionFrom EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionRating: 3 out of 5 stars3/5 (1)

- Slow Violence and the Environmentalism of the PoorFrom EverandSlow Violence and the Environmentalism of the PoorRating: 4 out of 5 stars4/5 (5)

- Principles of direct and superior responsibility in international humanitarian lawFrom EverandPrinciples of direct and superior responsibility in international humanitarian lawNo ratings yet

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaFrom EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaRating: 4 out of 5 stars4/5 (1)

- Reduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksFrom EverandReduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksNo ratings yet

- The Rights of Nature: A Legal Revolution That Could Save the WorldFrom EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldRating: 5 out of 5 stars5/5 (1)

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionFrom Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionNo ratings yet

- Busted!: Drug War Survival Skills and True Dope DFrom EverandBusted!: Drug War Survival Skills and True Dope DRating: 3.5 out of 5 stars3.5/5 (7)

- The People's Agents and the Battle to Protect the American Public: Special Interests, Government, and Threats to Health, Safety, and the EnvironmentFrom EverandThe People's Agents and the Battle to Protect the American Public: Special Interests, Government, and Threats to Health, Safety, and the EnvironmentNo ratings yet

- Environmental Education in Practice: Concepts and ApplicationsFrom EverandEnvironmental Education in Practice: Concepts and ApplicationsNo ratings yet

- All About The Ozone Layer : Effects on Human, Animal and Plant Health - Environment Books | Children's Environment BooksFrom EverandAll About The Ozone Layer : Effects on Human, Animal and Plant Health - Environment Books | Children's Environment BooksNo ratings yet

- Climate Action Challenge: A Proven Plan for Launching Your Eco-Initiative in 90 DaysFrom EverandClimate Action Challenge: A Proven Plan for Launching Your Eco-Initiative in 90 DaysNo ratings yet

- Down to the Wire: Confronting Climate CollapseFrom EverandDown to the Wire: Confronting Climate CollapseRating: 4.5 out of 5 stars4.5/5 (8)