0% found this document useful (0 votes)

1K views11 pagesBlock Shear PDF

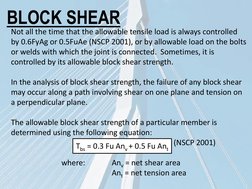

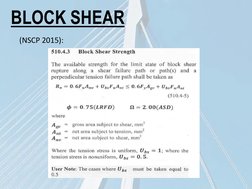

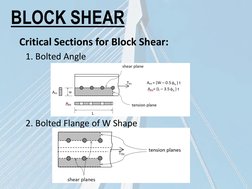

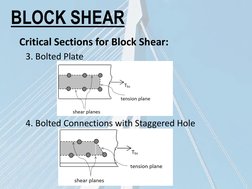

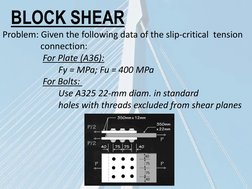

This document provides an overview of a lecture on principles of steel design. It discusses bolted connections for tension members, designing tension members, and calculating block shear strength. The key topics covered are the types of failure for bolted connections, computing edge distance and minimum spacing, and designing tension members. It also examines critical sections for block shear, including bolted angles, bolted shapes, bolted plates, and staggered bolted connections. An example problem is provided on calculating block shear strength for a slip-critical tension connection.

Uploaded by

Alvin DeliroCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

1K views11 pagesBlock Shear PDF

This document provides an overview of a lecture on principles of steel design. It discusses bolted connections for tension members, designing tension members, and calculating block shear strength. The key topics covered are the types of failure for bolted connections, computing edge distance and minimum spacing, and designing tension members. It also examines critical sections for block shear, including bolted angles, bolted shapes, bolted plates, and staggered bolted connections. An example problem is provided on calculating block shear strength for a slip-critical tension connection.

Uploaded by

Alvin DeliroCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd