0% found this document useful (1 vote)

2K views28 pagesBlock Shear

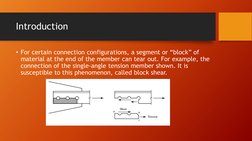

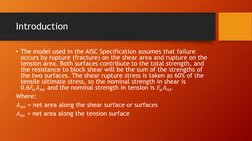

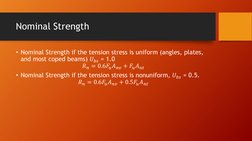

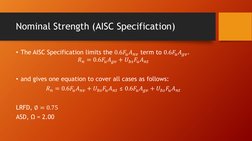

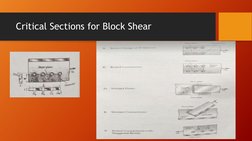

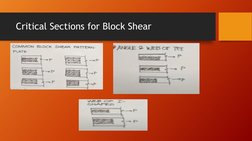

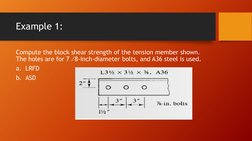

Block shear is a failure mode where a segment or "block" of material tears out of a connection. It can occur at the ends of tension members or in gusset plates connected by bolts. The AISC specification models block shear failure as rupture on the shear surface and tension rupture on the tension surface. It calculates the nominal block shear strength as the sum of the shear and tension capacities. Several examples calculate the block shear capacity of angles, plates, channels and wide flange sections according to this model.

Uploaded by

Melchizedek EllCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (1 vote)

2K views28 pagesBlock Shear

Block shear is a failure mode where a segment or "block" of material tears out of a connection. It can occur at the ends of tension members or in gusset plates connected by bolts. The AISC specification models block shear failure as rupture on the shear surface and tension rupture on the tension surface. It calculates the nominal block shear strength as the sum of the shear and tension capacities. Several examples calculate the block shear capacity of angles, plates, channels and wide flange sections according to this model.

Uploaded by

Melchizedek EllCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd