Professional Documents

Culture Documents

Technical Summary of Pumps

Uploaded by

Nick JohnsonnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Summary of Pumps

Uploaded by

Nick JohnsonnCopyright:

Available Formats

Confidential. Do not share without consent.

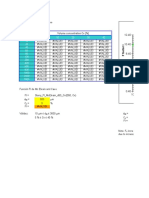

Iron Ore Fines Production Capacity at Target Capacity

1.0 Initial Operation Conditions

Magnetite density 5.20 T/m3

Marine sands density 1.70 T/m3

Seawater density 1.03 T/m3

Magne-sand density (comb) 2.05 T/m3

Raw feed density (comb) 1.33 T/m3

Raw feed rate (Heads) 4,000.00 cmh

Initial solids concentration 30% [-]

Raw feed grade, %Fe 10% [-]

Target concentrate grade, %Fe 63% [-]

Operating hours per day 16.00 hours per day

Operating days per month 26.00 days per month

Magnetic separation efficiency 90% [-]

Pumping efficiency 80% [-]

2.0 Gravimetric ratio - Fe3O4 : Fe 1.38 [-]

At raw feed %Fe grade of 10%, the %Fe3O4 is 13.82% [-]

The marine sands is 86.18% [-]

Adjusted magne-sand density 2.18 T/m3

Adjusted raw feed density 1.37 T/m3

Raw solids after separation, as volume 864.00 cmh

as weight 1,886.72 T/h

Magnetite (Fe3O4) volume 260.75 T/h

Marine sands volume 1,625.97 T/h

Concentrate volume, as Fe content 188.67 T/h

Tailings, at Fe3O4 72.07 T/h

Tailings, at marine sands 1,625.97 T/h

Primary total 1,886.72 T/h

Final concentrate volume, at 63% grade, 100% recovery 299.48 T/h

at 50% recovery rate 149.74 T/h

per day 2,395.83 T/d

per month 62,291.70 T/mo

3.0 For other feed Fe grade

Raw solids, Concentrate Fe Final concentrate,

%Fe %Fe3O4 %Sand

as weight, T/h content, T/h at 50%, T/mo

5% 6.91% 93.09% 1,677.76 83.89 27,696.35

6% 8.29% 91.71% 1,719.55 103.17 34,063.50

8% 11.06% 88.94% 1,803.14 144.25 47,625.68

10% 13.82% 86.18% 1,886.72 188.67 62,291.70

12% 16.58% 83.42% 1,970.30 236.44 78,061.56

15% 20.73% 79.27% 2,095.68 314.35 103,786.04

Technical Pump Review Pages 1/5

Summary of Pumps Available Revision 00

Confidential. Do not share without consent.

Iron Ore Fines Production Capacity at Canata Rated Pump

1.0 Initial Operation Conditions

Magnetite density 5.20 T/m3

Marine sands density 1.70 T/m3

Seawater density 1.03 T/m3

Magne-sand density (comb) 2.05 T/m3

Raw feed density (comb) 1.33 T/m3

Raw feed rate (Heads) 2,200.00 cmh

Initial solids concentration 30% [-]

Raw feed grade, %Fe 10% [-]

Target concentrate grade, %Fe 63% [-]

Operating hours per day 16.00 hours per day

Operating days per month 26.00 days per month

Magnetic separation efficiency 90% [-]

Pumping efficiency 80% [-]

2.0 Gravimetric ratio - Fe3O4 : Fe 1.38 [-]

At raw feed %Fe grade of 10%, the %Fe3O4 is 13.82% [-]

The marine sands is 86.18% [-]

Adjusted magne-sand density 2.18 T/m3

Adjusted raw feed density 1.37 T/m3

Raw solids after separation, as volume 475.20 cmh

as weight 1,037.70 T/h

Magnetite (Fe3O4) volume 143.41 T/h

Marine sands volume 894.29 T/h

Concentrate volume, as Fe content 103.77 T/h

Tailings, at Fe3O4 39.64 T/h

Tailings, at marine sands 894.29 T/h

Primary total 1,037.70 T/h

Final concentrate volume, at 63% grade, 100% recovery 164.71 T/h

at 50% recovery rate 82.36 T/h

per day 1,317.71 T/d

per month 34,260.44 T/mo

3.0 For other feed Fe grade

Raw solids, Concentrate Fe Final concentrate,

%Fe %Fe3O5 %Sand

as weight, T/h content, T/h at 50%, T/mo

5% 6.91% 93.09% 922.77 46.14 15,232.99

6% 8.29% 91.71% 945.75 56.75 18,734.93

8% 11.06% 88.94% 991.72 79.34 26,194.13

10% 13.82% 86.18% 1,037.70 103.77 34,260.44

12% 16.58% 83.42% 1,083.67 130.04 42,933.86

15% 20.73% 79.27% 1,152.62 172.89 57,082.32

Technical Pump Review Pages 2/5

Summary of Pumps Available Revision 00

Confidential. Do not share without consent.

Iron Ore Fines Production Capacity at Taian Rated Pump

1.0 Initial Operation Conditions

Magnetite density 5.20 T/m3

Marine sands density 1.70 T/m3

Seawater density 1.03 T/m3

Magne-sand density (comb) 2.05 T/m3

Raw feed density (comb) 1.33 T/m3

Raw feed rate (Heads) 1,000.00 cmh

Initial solids concentration 30% [-]

Raw feed grade, %Fe 10% [-]

Target concentrate grade, %Fe 63% [-]

Operating hours per day 16.00 hours per day

Operating days per month 26.00 days per month

Magnetic separation efficiency 90% [-]

Pumping efficiency 80% [-]

2.0 Gravimetric ratio - Fe3O4 : Fe 1.38 [-]

At raw feed %Fe grade of 10%, the %Fe3O4 is 13.82% [-]

The marine sands is 86.18% [-]

Adjusted magne-sand density 2.18 T/m3

Adjusted raw feed density 1.37 T/m3

Raw solids after separation, as volume 216.00 cmh

as weight 471.68 T/h

Magnetite (Fe3O4) volume 65.19 T/h

Marine sands volume 406.49 T/h

Concentrate volume, as Fe content 47.17 T/h

Tailings, at Fe3O4 18.02 T/h

Tailings, at marine sands 406.49 T/h

Primary total 471.68 T/h

Final concentrate volume, at 63% grade, 100% recovery 74.87 T/h

at 50% recovery rate 37.43 T/h

per day 598.96 T/d

per month 15,572.93 T/mo

3.0 For other feed Fe grade

Raw solids, Concentrate Fe Final concentrate,

%Fe %Fe3O6 %Sand

as weight, T/h content, T/h at 50%, T/mo

5% 6.91% 93.09% 419.44 20.97 6,924.09

6% 8.29% 91.71% 429.89 25.79 8,515.88

8% 11.06% 88.94% 450.78 36.06 11,906.42

10% 13.82% 86.18% 471.68 47.17 15,572.93

12% 16.58% 83.42% 492.58 59.11 19,515.39

15% 20.73% 79.27% 523.92 78.59 25,946.51

Technical Pump Review Pages 3/5

Summary of Pumps Available Revision 00

Confidential. Do not share without consent.

Iron Ore Fines Production Capacity at Dragflow Rated Pump

1.0 Initial Operation Conditions

Magnetite density 5.20 T/m3

Marine sands density 1.70 T/m3

Seawater density 1.03 T/m3

Magne-sand density (comb) 2.05 T/m3

Raw feed density (comb) 1.33 T/m3

Raw feed rate (Heads) 2,000.00 cmh

Initial solids concentration 30% [-]

Raw feed grade, %Fe 10% [-]

Target concentrate grade, %Fe 63% [-]

Operating hours per day 16.00 hours per day

Operating days per month 26.00 days per month

Magnetic separation efficiency 90% [-]

Pumping efficiency 80% [-]

2.0 Gravimetric ratio - Fe3O4 : Fe 1.38 [-]

At raw feed %Fe grade of 10%, the %Fe3O4 is 13.82% [-]

The marine sands is 86.18% [-]

Adjusted magne-sand density 2.18 T/m3

Adjusted raw feed density 1.37 T/m3

Raw solids after separation, as volume 432.00 cmh

as weight 943.37 T/h

Magnetite (Fe3O4) volume 130.38 T/h

Marine sands volume 812.99 T/h

Concentrate volume, as Fe content 94.34 T/h

Tailings, at Fe3O5 36.05 T/h

Tailings, at marine sands 812.99 T/h

Primary total 943.37 T/h

Final concentrate volume, at 63% grade, 100% recovery 149.74 T/h

at 50% recovery rate 74.87 T/h

per day 1,197.93 T/d

per month 31,146.30 T/mo

3.0 For other feed Fe grade

Raw solids, Concentrate Fe Final concentrate,

%Fe %Fe3O7 %Sand

as weight, T/h content, T/h at 50%, T/mo

5% 6.91% 93.09% 838.88 41.94 13,848.18

6% 8.29% 91.71% 859.78 51.59 17,031.75

8% 11.06% 88.94% 901.57 72.13 23,812.84

10% 13.82% 86.18% 943.36 94.34 31,145.85

12% 16.58% 83.42% 985.15 118.22 39,030.78

15% 20.73% 79.27% 1,047.84 157.18 51,893.02

Technical Pump Review Pages 4/5

Summary of Pumps Available Revision 00

Confidential. Do not share without consent.

Iron Ore Fines Production Capacity at Canata Rated Pump

1.0 Initial Operation Conditions

Magnetite density 5.20 T/m3

Marine sands density 1.70 T/m3

Seawater density 1.03 T/m3

Magne-sand density (comb) 2.05 T/m3

Raw feed density (comb) 1.33 T/m3

Raw feed rate (Heads) 2,200.00 cmh

Initial solids concentration 30% [-]

Raw feed grade, %Fe 10% [-]

Target concentrate grade, %Fe 63% [-]

Operating hours per day 16.00 hours per day

Operating days per month 26.00 days per month

Magnetic separation efficiency 90% [-]

Pumping efficiency 80% [-]

2.0 Gravimetric ratio - Fe3O4 : Fe 1.38 [-]

At raw feed %Fe grade of 10%, the %Fe3O4 is 13.82% [-]

The marine sands is 86.18% [-]

Adjusted magne-sand density 2.18 T/m3

Adjusted raw feed density 1.37 T/m3

Raw solids after separation, as volume 475.20 cmh

as weight 1,037.71 T/h

Magnetite (Fe3O4) volume 143.42 T/h

Marine sands volume 894.29 T/h

Concentrate volume, as Fe content 103.77 T/h

Tailings, at Fe3O6 39.65 T/h

Tailings, at marine sands 894.29 T/h

Primary total 1,037.71 T/h

Final concentrate volume, at 63% grade, 100% recovery 164.72 T/h

at 50% recovery rate 82.36 T/h

per day 1,317.73 T/d

per month 34,260.93 T/mo

3.0 For other feed Fe grade

Raw solids, Concentrate Fe Final concentrate,

%Fe %Fe3O8 %Sand

as weight, T/h content, T/h at 50%, T/mo

5% 6.91% 93.09% 922.77 46.14 15,232.99

6% 8.29% 91.71% 945.75 56.75 18,734.93

8% 11.06% 88.94% 991.72 79.34 26,194.13

10% 13.82% 86.18% 1,037.70 103.77 34,260.44

12% 16.58% 83.42% 1,083.67 130.04 42,933.86

15% 20.73% 79.27% 1,152.62 172.89 57,082.32

Technical Pump Review Pages 5/5

Summary of Pumps Available Revision 00

Actual Pump Selected, at water rated

ZJQ1000-78-400

1.0 Main dredge pump specifications

Head Capacity Power Efficiency Speed Volt/Phase/Frequency

m cmh kW % rpm V/P/Hz

78.00 1,000.00 400.00 67 1,170.00 440/3P/60

2.0 Main dredge pump curve

Flow, cmh Head, m Efficiency Power, kW Theo. Power, kW

73 93.00 9.3% 191.70 198.93

275 90.00 31.3% 218.70 215.48

378 88.70 40.0% 229.50 228.41

519 87.00 48.7% 249.70 252.65

604 86.00 54.0% 251.10 262.12

714 85.00 60.0% 261.90 275.63

854 81.00 64.0% 297.00 294.53

976 79.00 66.3% 313.20 316.91

999 77.90 66.9% 317.60 316.99

1,055 75.80 66.7% 324.00 326.71

1,159 71.00 66.0% 342.90 339.75

1,244 68.00 64.7% 351.00 356.28

1,421 60.00 60.0% 369.90 387.22

1,458 53.50 54.0% 386.10 393.63

1,507 45.00 46.7% 391.50 395.71

100 80.0%

Head, m

90 Efficiency, % 70.0%

80

60.0%

70

50.0%

60

50 40.0%

40

30.0%

30

20.0%

20

10.0%

10

0 0.0%

500

400

300

200

100 Curve Power, kW

0

0 200 400 600 800 1000 1200 1400 1600

Technical Pump Review Pages 1/36

Tai'an ZJQ1000-78-400 Revision 00

3.0 Main dredge pump curve, slurry corrected flow 0.95

Flow, cmh Head, m Efficiency Power, kW Theo. Power, kW

69 83.93 9.3% 164.36 170.55

261 81.23 31.3% 187.51 184.74

359 80.05 40.0% 196.77 195.84

493 78.52 48.7% 214.09 216.62

574 77.62 54.0% 215.29 224.74

678 76.71 60.0% 224.55 236.32

811 73.10 64.0% 254.64 252.52

927 71.30 66.3% 268.53 271.71

949 70.30 66.9% 272.30 271.78

1,002 68.41 66.7% 277.79 280.11

1,101 64.08 66.0% 293.99 291.30

1,182 61.37 64.7% 300.94 305.47

1,350 54.15 60.0% 317.14 331.99

1,385 48.28 54.0% 331.03 337.49

1,432 40.61 46.7% 335.66 339.27

90 80.0%

Head, m

80 Efficiency, %

70.0%

70

60.0%

60

50.0%

50

40.0%

40

30.0%

30

20.0%

20

10 10.0%

0 0.0%

400

350

300

250

200

150

100 Curve Power, kW

50 Corrected Power, kW

0

0 200 400 600 800 1000 1200 1400 1600

Technical Pump Review Pages 2/36

Tai'an ZJQ1000-78-400 Revision 00

4.0 Pump curve modeling parameters for the backward-fitting process are as follows:

Water rated

a5 a4 a3 a2 a1 a0

Q-h -1.01E-13 3.73E-10 -5.09E-07 0.000299321362 -0.082162409600 97.782896002712

Q-n -7.27E-16 2.45E-12 -2.88E-09 0.000000809194 0.000990610091 0.019337324776

Q-p 3.17E-13 -1.30E-09 1.90E-06 -0.001168168266 0.396568345974 167.782441240840

Slurry corrected

a5 a4 a3 a2 a1 a0

Q-h -1.18E-13 4.13E-10 -5.36E-07 0.000299321362 -0.078054289120 88.249063642448

Q-n -9.39E-16 3.01E-12 -3.36E-09 0.000000896614 0.001042747465 0.019337324776

Q-p 3.51E-13 -1.37E-09 1.90E-06 -0.001109759853 0.357902932241 143.852470558865

5.0 The pump selections A to E should be adjusted according to the actual curve of the main dredge pump,

The following backward-fitting process was coded to MS Excel allows the initial conditions to be fitted

along the pump curve.

Backward fit calculate the

Check initial calculated

Start equivalent flow (qi) from

flow (q0) and head (h0)

initial head (h0)

Print curve flow (qi) and Yes Is q0

End head (h0)

= qi?

Recalculate head loss

calculation with new flow

equivalent (qi)

Print curve flow (qn) and

Store new head loss as

head (hi) Store qi = qn

new head (hn)

Yes Backward fit calculate the

Is qi =

new flow equivalent (qn)

qn?

from new head (hn)

Technical Pump Review Pages 3/36

Tai'an ZJQ1000-78-400 Revision 00

Pump Selection Calculations

Selection A

1.0 Initial Selection Parameter

Concentration by volume, % magnetite per sands 8% [-]

Concentration by volume, % solids per water 30% [-]

Magnetite density 5.200 T/m3

Marine sands density 1.800 T/m3

Seawater density 1.025 T/m3

Magne-sand density (comb) 2.072 T/m3

Raw feed density (comb) 1.339 T/m3

Initial feed gross, Q 1,000.00 cmh

Target concentrate grade, %Fe 63% [-]

Magnetic separation efficiency 90% [-]

Pumping efficiency 80% [-]

Mineral recovery rate 50% [-]

Operating hours per day 16.00 hours per day

Operating days per month 26.00 days per month

2.0 Head Calculation

Initial pipe size diameter selection 12.00 in

in SI (DN) 300.00 mm

Cross sectional area 0.0707 m2

Particle diameter, d50 1,250.00 µm

Vertical height:

from distribution header centerline to water line 15.00 m

from water line to seabed 70.00 m

from seabed to maximum minebed strata 30.00 m

Total depth from the header 115.00 m

With additional length (i.e. for sagging and others) 140.00 m

Total dynamic head for underwater slurry

1. Static head (above water line) 15.00 m

2. Static slurry head (differential balance column loss)

Static head (below water line) x (1 - SG fluid / SG mixture)

= 100 m x ( 1 - ( 1.025 / 1.3391 )) 23.46 m

3. Water friction loss (Darcy Formula)

= ( f x L ) x ( v^2 ) / ( 2 x g x d ) 7.95 m

Flow, cmh f, [-] Velocity, m/s Head loss, m

- - - -

500 0.02233 1.9649 2.05

1,000 0.02164 3.9298 7.95

1,250 0.02150 4.9122 12.34

1,400 0.02143 5.5017 15.43

4. Slurry friction loss 8.41 m

FL number for limit settling. See Figure 1. 1.42 [-]

Limiting velocity, vL. See Figure 1. 3.47 m/s

Technical Pump Review Pages 4/36

Tai'an ZJQ1000-78-400 Revision 00

Limiting flow, qL 0.25 m3/s

882.90 cmh

Percent difference of Q and qL using = 1 - (qL / Q) 11.71% [-]

Recommendation: Is percent change within 10-15%? Retain size.

Curve fit parameters for slurry resistance chart

Parameter Flow, cmh Velocity, m/s Head loss, m

0.7 x qL 618.03 2.4287 3.10

1.0 x qL 882.90 3.4696 6.22

1.3 x qL 1,147.77 4.5105 10.43

Parabolic parameter for slurry curve

Slurry friction loss curve

(h, k) 618.03 6.22 Water friction loss curve

18

(x, y) 1147.77 10.43

a 1.50E-05 16

14

Slurry friction loss curve - 8.41

12

x f(x) 1,000.00 8.41

100 10.24 10 1,000.00 -

300 7.74 8 1,000.00 8.41

500 6.43 6

800 6.72

4

1,000 8.41

1,200 11.30 2

1,400 15.38 0

0 200 400 600 800 1000 1200 1400 1600

Total dynamic head for underwater slurry

= 15 m + 23.46 m + 7.95 m + 8.41 m 54.82 m

3.0 Pipe size validation

Limit velocity,

FL [-] dia, mm Limit flow, qL, cmh Percent difference, % Size change requirement

vL, m/s

1.415 200.00 2.83 320.39 67.96% Increase pipe size.

1.415 250.00 3.17 559.71 44.03% Increase pipe size.

1.415 300.00 3.47 882.90 11.71% Retain size.

1.415 350.00 3.75 1298.02 -29.80% Reduce pipe size.

1.415 400.00 4.01 1812.42 -81.24% Reduce pipe size.

1.415 450.00 4.25 2432.99 -143.30% Reduce pipe size.

1.415 500.00 4.48 3166.17 -216.62% Reduce pipe size.

1.415 550.00 4.70 4018.06 -301.81% Reduce pipe size.

1.415 600.00 4.91 4994.45 -399.45% Reduce pipe size.

4.0 Power validation at various pipe diameter Head loss, m

700 Power, kW

mm head, m Power, kW Water head loss, m Slurry friction loss, m

200.00 116.44 608.38 600 64.89 13.10

250.00 71.34 372.71 500 20.40 12.48

300.00 54.82 286.39 7.95 8.41

400

350.00 53.55 279.81 3.59 11.50

400.00 51.42 268.65 300 1.81 11.15

450.00 50.29 262.72 200 0.99 10.84

500.00 49.61 259.18 0.58 10.57

100

550.00 49.15 256.79 0.36 10.34

600.00 48.77 254.81 - 0.23 10.08

200 250 300 350 400 450 500 550 600

Technical Pump Review Pages 5/36

Tai'an ZJQ1000-78-400 Revision 00

5.0 Pump Selection Result

Concentration by volume, % magnetite per sands 8% [-]

Concentration by volume, % solids per water 30% [-]

Head Ratio & Efficiency ratio 0.997749 [-]

Flowrate, rated at clean water 1,000.00 cmh

Minimum rated head, slurry 54.94 m

n, efficiency (minimum) 70% [-]

Rated power, kW 286.39 kW

Outlet size 300 mm

Technical Pump Review Pages 6/36

Tai'an ZJQ1000-78-400 Revision 00

Pump Selection Calculations

Selection B

1.0 Initial Selection Parameter

Concentration by volume, % magnetite per sands 10% [-]

Concentration by volume, % solids per water 30% [-]

Magnetite density 5.200 T/m3

Marine sands density 1.800 T/m3

Seawater density 1.025 T/m3

Magne-sand density (comb) 2.140 T/m3

Raw feed density (comb) 1.360 T/m3

Initial feed gross, Q 1,000.00 cmh

Target concentrate grade, %Fe 63% [-]

Magnetic separation efficiency 90% [-]

Pumping efficiency 80% [-]

Mineral recovery rate 50% [-]

Operating hours per day 16.00 hours per day

Operating days per month 26.00 days per month

2.0 Head Calculation

Initial pipe size diameter selection 12.00 in

in SI (DN) 300.00 mm

Cross sectional area 0.0707 m2

Particle diameter, d50 1,250.00 µm

Vertical height:

from distribution header centerline to water line 15.00 m

from water line to seabed 70.00 m

from seabed to maximum minebed strata 30.00 m

Total depth from the header 115.00 m

With additional length (i.e. for sagging and others) 140.00 m

Total dynamic head for underwater slurry

1. Static head (above water line) 15.00 m

2. Static slurry head (differential balance column loss)

Static head (below water line) x (1 - SG fluid / SG mixture)

= 100 m x ( 1 - ( 1.025 / 1.3595 )) 24.60 m

3. Water friction loss (Darcy Formula)

= ( f x L ) x ( v^2 ) / ( 2 x g x d ) 7.95 m

Flow, cmh f, [-] Velocity, m/s Head loss, m

- - - -

500 0.02233 1.9649 2.05

1,000 0.02164 3.9298 7.95

1,250 0.02150 4.9122 12.34

1,400 0.02143 5.5017 15.43

4. Slurry friction loss 8.58 m

FL number for limit settling. See Figure 1. 1.42 [-]

Limiting velocity, vL. See Figure 1. 3.58 m/s

Technical Pump Review Pages 7/36

Tai'an ZJQ1000-78-400 Revision 00

Limiting flow, qL 0.25 m3/s

911.12 cmh

Percent difference of Q and qL using = 1 - (qL / Q) 8.89% [-]

Recommendation: Is percent change within 10-15%? Reduce pipe size.

Curve fit parameters for slurry resistance chart

Parameter Flow, cmh Velocity, m/s Head loss, m

0.7 x qL 637.79 2.5063 3.29

1.0 x qL 911.12 3.5805 6.62

1.3 x qL 1,184.46 4.6546 11.09

Parabolic parameter for slurry curve

Slurry friction loss curve

(h, k) 637.79 6.62 Water friction loss curve

18

(x, y) 1184.46 11.09

a 1.50E-05 16

14

Slurry friction loss curve - 8.58

12

x f(x) 1,000.00 8.58

100 10.95 10 1,000.00 -

300 8.33 8 1,000.00 8.58

500 6.91 6

800 7.01

4

1,000 8.58

1,200 11.35 2

1,400 15.32 0

0 200 400 600 800 1000 1200 1400 1600

Total dynamic head for underwater slurry

= 15 m + 24.61 m + 7.95 m + 8.59 m 56.14 m

3.0 Pipe size validation

Limit velocity,

FL [-] dia, mm Limit flow, qL, cmh Percent difference, % Size change requirement

vL, m/s

1.415 200.00 2.92 330.63 66.94% Increase pipe size.

1.415 250.00 3.27 577.60 42.24% Increase pipe size.

1.415 300.00 3.58 911.12 8.89% Reduce pipe size.

1.415 350.00 3.87 1339.50 -33.95% Reduce pipe size.

1.415 400.00 4.13 1870.35 -87.04% Reduce pipe size.

1.415 450.00 4.39 2510.76 -151.08% Reduce pipe size.

1.415 500.00 4.62 3267.37 -226.74% Reduce pipe size.

1.415 550.00 4.85 4146.49 -314.65% Reduce pipe size.

1.415 600.00 5.06 5154.09 -415.41% Reduce pipe size.

4.0 Power validation at various pipe diameter Head loss, m

700 Power, kW

mm head, m Power, kW Water head loss, m Slurry friction loss, m

200.00 118.43 628.27 600 64.89 13.94

250.00 73.28 388.76 500 20.40 13.28

300.00 56.14 297.82 7.95 8.58

400

350.00 55.44 294.11 3.59 12.24

400.00 53.28 282.66 300 1.81 11.87

450.00 52.13 276.55 200 0.99 11.53

500.00 51.43 272.86 0.58 11.25

100

550.00 50.96 270.36 0.36 11.00

600.00 50.57 268.26 - 0.23 10.73

200 250 300 350 400 450 500 550 600

Technical Pump Review Pages 8/36

Tai'an ZJQ1000-78-400 Revision 00

5.0 Pump Selection Result

Concentration by volume, % magnetite per sands 10% [-]

Concentration by volume, % solids per water 30% [-]

Head Ratio & Efficiency ratio 0.997616 [-]

Flowrate, rated at clean water 1,000.00 cmh

Minimum rated head, slurry 56.27 m

n, efficiency (minimum) 70% [-]

Rated power, kW 297.82 kW

Outlet size 300 mm

Technical Pump Review Pages 9/36

Tai'an ZJQ1000-78-400 Revision 00

Pump Selection Calculations

Selection C

1.0 Initial Selection Parameter

Concentration by volume, % magnetite per sands 15% [-]

Concentration by volume, % solids per water 30% [-]

Magnetite density 5.200 T/m3

Marine sands density 1.800 T/m3

Seawater density 1.025 T/m3

Magne-sand density (comb) 2.310 T/m3

Raw feed density (comb) 1.411 T/m3

Initial feed gross, Q 1,000.00 cmh

Target concentrate grade, %Fe 63% [-]

Magnetic separation efficiency 90% [-]

Pumping efficiency 80% [-]

Mineral recovery rate 50% [-]

Operating hours per day 16.00 hours per day

Operating days per month 26.00 days per month

2.0 Head Calculation

Initial pipe size diameter selection 12.00 in

in SI (DN) 300.00 mm

Cross sectional area 0.0707 m2

Particle diameter, d50 1,250.00 µm

Vertical height:

from distribution header centerline to water line 15.00 m

from water line to seabed 70.00 m

from seabed to maximum minebed strata 30.00 m

Total depth from the header 115.00 m

With additional length (i.e. for sagging and others) 140.00 m

Total dynamic head for underwater slurry

1. Static head (above water line) 15.00 m

2. Static slurry head (differential balance column loss)

Static head (below water line) x (1 - SG fluid / SG mixture)

= 100 m x ( 1 - ( 1.025 / 1.4105 )) 27.33 m

3. Water friction loss (Darcy Formula)

= ( f x L ) x ( v^2 ) / ( 2 x g x d ) 7.95 m

Flow, cmh f, [-] Velocity, m/s Head loss, m

- - - -

500 0.02233 1.9649 2.05

1,000 0.02164 3.9298 7.95

1,250 0.02150 4.9122 12.34

1,400 0.02143 5.5017 15.43

4. Slurry friction loss 9.10 m

FL number for limit settling. See Figure 1. 1.42 [-]

Limiting velocity, vL. See Figure 1. 3.84 m/s

Technical Pump Review Pages 10/36

Tai'an ZJQ1000-78-400 Revision 00

Limiting flow, qL 0.27 m3/s

978.12 cmh

Percent difference of Q and qL using = 1 - (qL / Q) 2.19% [-]

Recommendation: Is percent change within 10-15%? Reduce pipe size.

Curve fit parameters for slurry resistance chart

Parameter Flow, cmh Velocity, m/s Head loss, m

0.7 x qL 684.68 2.6906 3.78

1.0 x qL 978.12 3.8438 7.61

1.3 x qL 1,271.55 4.9969 12.76

Parabolic parameter for slurry curve

Slurry friction loss curve

(h, k) 684.68 7.61 Water friction loss curve

18

18

(x, y) 1271.55 12.76

a 1.50E-05 16

16

14

14

Slurry friction loss curve - 9.10

12

12

x f(x) 1,000.00 9.10

100 12.72 10

10 1,000.00 -

300 9.82 88 1,000.00 9.10

500 8.12 66

800 7.81

44

1,000 9.10

1,200 11.58 22

1,400 15.26 -0

0 200 400 600 800 1000 1200 1400 1600

Total dynamic head for underwater slurry

= 15 m + 27.34 m + 7.95 m + 9.1 m 59.38 m

3.0 Pipe size validation

Limit velocity,

FL [-] dia, mm Limit flow, qL, cmh Percent difference, % Size change requirement

vL, m/s

1.415 200.00 3.14 354.95 64.51% Increase pipe size.

1.415 250.00 3.51 620.07 37.99% Increase pipe size.

1.415 300.00 3.84 978.12 2.19% Reduce pipe size.

1.415 350.00 4.15 1438.00 -43.80% Reduce pipe size.

1.415 400.00 4.44 2007.88 -100.79% Reduce pipe size.

1.415 450.00 4.71 2695.38 -169.54% Reduce pipe size.

1.415 500.00 4.96 3507.62 -250.76% Reduce pipe size.

1.415 550.00 5.20 4451.38 -345.14% Reduce pipe size.

1.415 600.00 5.44 5533.07 -453.31% Reduce pipe size.

4.0 Power validation at various pipe diameter Head loss, m

700 Power, kW

mm head, m Power, kW Water head loss, m Slurry friction loss, m

200.00 123.25 678.58 600 64.89 16.03

250.00 78.00 429.46 500 20.40 15.27

300.00 59.38 326.93 7.95 9.10

400

350.00 60.01 330.40 3.59 14.08

400.00 57.79 318.21 300 1.81 13.65

450.00 56.59 311.59 200 0.99 13.27

500.00 55.86 307.53 0.58 12.94

100

550.00 55.35 304.74 0.36 12.66

600.00 54.92 302.36 - 0.23 12.35

200 250 300 350 400 450 500 550 600

Technical Pump Review Pages 11/36

Tai'an ZJQ1000-78-400 Revision 00

5.0 Pump Selection Result

Concentration by volume, % magnetite per sands 15% [-]

Concentration by volume, % solids per water 30% [-]

Head Ratio & Efficiency ratio 0.997287 [-]

Flowrate, rated at clean water 1,000.00 cmh

Minimum rated head, slurry 59.54 m

n, efficiency (minimum) 70% [-]

Rated power, kW 326.93 kW

Outlet size 300 mm

Technical Pump Review Pages 12/36

Tai'an ZJQ1000-78-400 Revision 00

Pump Selection Calculations

Selection D

1.0 Initial Selection Parameter

Concentration by volume, % magnetite per sands 15% [-]

Concentration by volume, % solids per water 40% [-]

Magnetite density 5.200 T/m3

Marine sands density 1.800 T/m3

Seawater density 1.025 T/m3

Magne-sand density (comb) 2.310 T/m3

Raw feed density (comb) 1.539 T/m3

Initial feed gross, Q 1,000.00 cmh

Target concentrate grade, %Fe 63% [-]

Magnetic separation efficiency 90% [-]

Pumping efficiency 80% [-]

Mineral recovery rate 50% [-]

Operating hours per day 16.00 hours per day

Operating days per month 26.00 days per month

2.0 Head Calculation

Initial pipe size diameter selection 12.00 in

in SI (DN) 300.00 mm

Cross sectional area 0.0707 m2

Particle diameter, d50 1,250.00 µm

Vertical height:

from distribution header centerline to water line 15.00 m

from water line to seabed 70.00 m

from seabed to maximum minebed strata 30.00 m

Total depth from the header 115.00 m

With additional length (i.e. for sagging and others) 140.00 m

Total dynamic head for underwater slurry

1. Static head (above water line) 15.00 m

2. Static slurry head (differential balance column loss)

Static head (below water line) x (1 - SG fluid / SG mixture)

= 100 m x ( 1 - ( 1.025 / 1.539 )) 33.40 m

3. Water friction loss (Darcy Formula)

= ( f x L ) x ( v^2 ) / ( 2 x g x d ) 7.95 m

Flow, cmh f, [-] Velocity, m/s Head loss, m

- - - -

500 0.02233 1.9649 2.05

1,000 0.02164 3.9298 7.95

1,250 0.02150 4.9122 12.34

1,400 0.02143 5.5017 15.43

4. Slurry friction loss 9.10 m

FL number for limit settling. See Figure 1. 1.42 [-]

Limiting velocity, vL. See Figure 1. 3.84 m/s

Technical Pump Review Pages 13/36

Tai'an ZJQ1000-78-400 Revision 00

Limiting flow, qL 0.27 m3/s

978.12 cmh

Percent difference of Q and qL using = 1 - (qL / Q) 2.19% [-]

Recommendation: Is percent change within 10-15%? Reduce pipe size.

Curve fit parameters for slurry resistance chart

Parameter Flow, cmh Velocity, m/s Head loss, m

0.7 x qL 684.68 2.6906 3.78

1.0 x qL 978.12 3.8438 7.61

1.3 x qL 1,271.55 4.9969 12.76

Parabolic parameter for slurry curve

Slurry friction loss curve

(h, k) 684.68 7.61 Water friction loss curve

18

18

(x, y) 1271.55 12.76

a 1.50E-05 16

16

14

14

Slurry friction loss curve - 9.10

12

12

x f(x) 1,000.00 9.10

100 12.72 10

10 1,000.00 -

300 9.82 88 1,000.00 9.10

500 8.12 66

800 7.81

44

1,000 9.10

1,200 11.58 22

1,400 15.26 -0

0 200 400 600 800 1000 1200 1400 1600

Total dynamic head for underwater slurry

= 15 m + 33.4 m + 7.95 m + 9.1 m 65.45 m

3.0 Pipe size validation

Limit velocity,

FL [-] dia, mm Limit flow, qL, cmh Percent difference, % Size change requirement

vL, m/s

1.415 200.00 3.14 354.95 64.51% Increase pipe size.

1.415 250.00 3.51 620.07 37.99% Increase pipe size.

1.415 300.00 3.84 978.12 2.19% Reduce pipe size.

1.415 350.00 4.15 1438.00 -43.80% Reduce pipe size.

1.415 400.00 4.44 2007.88 -100.79% Reduce pipe size.

1.415 450.00 4.71 2695.38 -169.54% Reduce pipe size.

1.415 500.00 4.96 3507.62 -250.76% Reduce pipe size.

1.415 550.00 5.20 4451.38 -345.14% Reduce pipe size.

1.415 600.00 5.44 5533.07 -453.31% Reduce pipe size.

4.0 Power validation at various pipe diameter Head loss, m

700 Power, kW

mm head, m Power, kW Water head loss, m Slurry friction loss, m

200.00 129.31 777.27 600 64.89 16.02

250.00 84.07 505.35 500 20.40 15.27

300.00 65.45 393.40 7.95 9.10

400

350.00 66.08 397.19 3.59 14.08

400.00 63.86 383.88 300 1.81 13.65

450.00 62.66 376.66 200 0.99 13.27

500.00 61.92 372.23 0.58 12.94

100

550.00 61.42 369.17 0.36 12.66

600.00 60.98 366.58 - 0.23 12.35

200 250 300 350 400 450 500 550 600

Technical Pump Review Pages 14/36

Tai'an ZJQ1000-78-400 Revision 00

5.0 Pump Selection Result

Concentration by volume, % magnetite per sands 15% [-]

Concentration by volume, % solids per water 40% [-]

Head Ratio & Efficiency ratio 0.996684 [-]

Flowrate, rated at clean water 1,000.00 cmh

Minimum rated head, slurry 65.66 m

n, efficiency (minimum) 70% [-]

Rated power, kW 393.40 kW

Outlet size 300 mm

Technical Pump Review Pages 15/36

Tai'an ZJQ1000-78-400 Revision 00

Pump Selection Calculations

Selection E

1.0 Initial Selection Parameter

Concentration by volume, % magnetite per sands 20% [-]

Concentration by volume, % solids per water 40% [-]

Magnetite density 5.200 T/m3

Marine sands density 1.800 T/m3

Seawater density 1.025 T/m3

Magne-sand density (comb) 2.480 T/m3

Raw feed density (comb) 1.607 T/m3

Initial feed gross, Q 1,000.00 cmh

Target concentrate grade, %Fe 63% [-]

Magnetic separation efficiency 90% [-]

Pumping efficiency 80% [-]

Mineral recovery rate 50% [-]

Operating hours per day 16.00 hours per day

Operating days per month 26.00 days per month

2.0 Head Calculation

Initial pipe size diameter selection 12.00 in

in SI (DN) 300.00 mm

Cross sectional area 0.0707 m2

Particle diameter, d50 1,250.00 µm

Vertical height:

from distribution header centerline to water line 15.00 m

from water line to seabed 70.00 m

from seabed to maximum minebed strata 30.00 m

Total depth from the header 115.00 m

With additional length (i.e. for sagging and others) 140.00 m

Total dynamic head for underwater slurry

1. Static head (above water line) 15.00 m

2. Static slurry head (differential balance column loss)

Static head (below water line) x (1 - SG fluid / SG mixture)

= 100 m x ( 1 - ( 1.025 / 1.607 )) 36.22 m

3. Water friction loss (Darcy Formula)

= ( f x L ) x ( v^2 ) / ( 2 x g x d ) 7.95 m

Flow, cmh f, [-] Velocity, m/s Head loss, m

- - - -

500 0.02233 1.9649 2.05

1,000 0.02164 3.9298 7.95

1,250 0.02150 4.9122 12.34

1,400 0.02143 5.5017 15.43

4. Slurry friction loss 9.70 m

FL number for limit settling. See Figure 1. 1.42 [-]

Limiting velocity, vL. See Figure 1. 4.09 m/s

Technical Pump Review Pages 16/36

Tai'an ZJQ1000-78-400 Revision 00

Limiting flow, qL 0.29 m3/s

1,040.81 cmh

Percent difference of Q and qL using = 1 - (qL / Q) -4.08% [-]

Recommendation: Is percent change within 10-15%? Reduce pipe size.

Curve fit parameters for slurry resistance chart

Parameter Flow, cmh Velocity, m/s Head loss, m

0.7 x qL 728.57 2.8631 4.27

1.0 x qL 1,040.81 4.0901 8.60

1.3 x qL 1,353.05 5.3172 14.42

Parabolic parameter for slurry curve

Slurry friction loss curve

(h, k) 728.57 8.60 Water friction loss curve

18

18

(x, y) 1353.05 14.42

a 1.49E-05 16

16

14

14

Slurry friction loss curve - 9.70

12

12

x f(x) 1,000.00 9.70

100 14.50 10

10 1,000.00 -

300 11.34 88 1,000.00 9.70

500 9.38 66

800 8.68

44

1,000 9.70

1,200 11.92 22

1,400 15.33 -0

0 200 400 600 800 1000 1200 1400 1600

Total dynamic head for underwater slurry

= 15 m + 36.22 m + 7.95 m + 9.71 m 68.87 m

3.0 Pipe size validation

Limit velocity,

FL [-] dia, mm Limit flow, qL, cmh Percent difference, % Size change requirement

vL, m/s

1.415 200.00 3.34 377.70 62.23% Increase pipe size.

1.415 250.00 3.73 659.81 34.02% Increase pipe size.

1.415 300.00 4.09 1040.81 -4.08% Reduce pipe size.

1.415 350.00 4.42 1530.16 -53.02% Reduce pipe size.

1.415 400.00 4.72 2136.57 -113.66% Reduce pipe size.

1.415 450.00 5.01 2868.13 -186.81% Reduce pipe size.

1.415 500.00 5.28 3732.44 -273.24% Reduce pipe size.

1.415 550.00 5.54 4736.69 -373.67% Reduce pipe size.

1.415 600.00 5.78 5887.70 -488.77% Reduce pipe size.

4.0 Power validation at various pipe diameter Head loss, m

700 Power, kW

mm head, m Power, kW Water head loss, m Slurry friction loss, m

200.00 134.21 842.72 600 64.89 18.11

250.00 88.88 558.07 500 20.40 17.26

300.00 68.87 432.41 7.95 9.70

400

350.00 70.73 444.14 3.59 15.92

400.00 68.47 429.89 300 1.81 15.44

450.00 67.22 422.04 200 0.99 15.01

500.00 66.44 417.15 0.58 14.64

100

550.00 65.89 413.73 0.36 14.32

600.00 65.42 410.79 - 0.23 13.98

200 250 300 350 400 450 500 550 600

Technical Pump Review Pages 17/36

Tai'an ZJQ1000-78-400 Revision 00

5.0 Pump Selection Result

Concentration by volume, % magnetite per sands 20% [-]

Concentration by volume, % solids per water 40% [-]

Head Ratio & Efficiency ratio 0.996316 [-]

Flowrate, rated at clean water 1,000.00 cmh

Minimum rated head, slurry 69.12 m

n, efficiency (minimum) 70% [-]

Rated power, kW 432.41 kW

Outlet size 300 mm

Technical Pump Review Pages 18/36

Tai'an ZJQ1000-78-400 Revision 00

Adjusted Conditions Calculations 1358.66 0.00

Selection A

1.0 Initial Selection Parameter

Concentration by volume, % magnetite per sands 8% [-]

Concentration by volume, % solids per water 30% [-]

Magnetite density 5.200 T/m3

Marine sands density 1.800 T/m3

Seawater density 1.025 T/m3

Magne-sand density (comb) 2.072 T/m3

Raw feed density (comb) 1.339 T/m3

Initial feed gross, Q 1,358.66 cmh

Target concentrate grade, %Fe 63% [-]

Magnetic separation efficiency 90% [-]

Pumping efficiency 80% [-]

Mineral recovery rate 50% [-]

Operating hours per day 16.00 hours per day

Operating days per month 26.00 days per month

2.0 Head Calculation

Initial pipe size diameter selection 12.00 in

in SI (DN) 300.00 mm

Cross sectional area 0.0707 m2

Particle diameter, d50 1,250.00 µm

Vertical height:

from distribution header centerline to water line 15.00 m

from water line to seabed 45.00 m

from seabed to maximum minebed strata 20.00 m

Total depth from the header 80.00 m

With additional length (i.e. for sagging and others) 100.00 m

Total dynamic head for underwater slurry

1. Static head (above water line) 15.00 m

2. Static slurry head (differential balance column loss)

Static head (below water line) x (1 - SG fluid / SG mixture)

= 65 m x ( 1 - ( 1.025 / 1.3391 )) 15.25 m

3. Water friction loss (Darcy Formula)

= ( f x L ) x ( v^2 ) / ( 2 x g x d ) 10.39 m

Flow, cmh f, [-] Velocity, m/s Head loss, m

- - - -

679 0.02198 2.6696 2.66

1,359 0.02145 5.3392 10.39

1,698 0.02134 6.6740 16.15

1,902 0.02129 7.4749 20.21

4. Slurry friction loss 10.31 m

FL number for limit settling. See Figure 1. 1.42 [-]

Limiting velocity, vL. See Figure 1. 3.47 m/s

Technical Pump Review Pages 19/36

Tai'an ZJQ1000-78-400 Revision 00

Limiting flow, qL 0.25 m3/s

882.90 cmh

Percent difference of Q and qL using = 1 - (qL / Q) 35.02% [-]

Recommendation: Is percent change within 10-15%? Increase pipe size.

Curve fit parameters for slurry resistance chart

Parameter Flow, cmh Velocity, m/s Head loss, m

0.7 x qL 618.03 2.4287 2.21

1.0 x qL 882.90 3.4696 4.45

1.3 x qL 1,147.77 4.5105 7.45

Parabolic parameter for slurry curve

Slurry friction loss curve

(h, k) 618.03 4.45 Water friction loss curve

25

(x, y) 1147.77 7.45

a 1.07E-05

20

Slurry friction loss curve - 10.31

x f(x) 15 1,358.66 10.31

136 6.93 1,358.66 -

408 4.92 1,358.66 10.31

10

679 4.49

1,087 6.80

1,359 10.31 5

1,630 15.41

1,902 22.09 0

0 200 400 600 800 1000 1200 1400 1600 1800 2000

Total dynamic head for underwater slurry

= 15 m + 15.25 m + 10.39 m + 10.32 m 50.95 m

3.0 Pipe size validation

Limit velocity,

FL [-] dia, mm Limit flow, qL, cmh Percent difference, % Size change requirement

vL, m/s

1.415 200.00 2.83 320.39 76.42% Increase pipe size.

1.415 250.00 3.17 559.71 58.80% Increase pipe size.

1.415 300.00 3.47 882.90 35.02% Increase pipe size.

1.415 350.00 3.75 1298.02 4.46% Reduce pipe size.

1.415 400.00 4.01 1812.42 -33.40% Reduce pipe size.

1.415 450.00 4.25 2432.99 -79.07% Reduce pipe size.

1.415 500.00 4.48 3166.17 -133.04% Reduce pipe size.

1.415 550.00 4.70 4018.06 -195.74% Reduce pipe size.

1.415 600.00 4.91 4994.45 -267.60% Reduce pipe size.

4.0 Power validation at various pipe diameter Head loss, m

1,200 Power, kW

mm head, m Power, kW Water head loss, m Slurry friction loss, m

200.00 125.16 1097.19 1,000 85.56 9.36

250.00 66.06 579.08 26.90 8.92

800

300.00 51.04 447.45 10.48 10.31

350.00 43.20 378.73 600 4.74 8.22

400.00 40.60 355.91 2.39 7.96

400

450.00 39.30 344.47 1.31 7.74

500.00 38.56 338.04 200 0.77 7.55

550.00 38.10 334.01 0.47 7.38

600.00 37.75 330.95 - 0.30 7.20

200 250 300 350 400 450 500 550 600

Technical Pump Review Pages 20/36

Tai'an ZJQ1000-78-400 Revision 00

5.0 Backward-fitted results from actual pump curve conditions

Concentration by volume, % magnetite per sands 8% [-]

Concentration by volume, % solids per water 30% [-]

Head Ratio & Efficiency ratio 0.997749 [-]

Curve flow capacity, water rated 1,358.66 cmh

Curve head, m 50.95 m

Curve efficiency, % 56.68% [-]

Curve power, kW 322.76 kW

Corrected power, at slurry, kW 387.24 kW

Technical Pump Review Pages 21/36

Tai'an ZJQ1000-78-400 Revision 00

Adjusted Conditions Calculations 1351.48 (0.00)

Selection B

1.0 Initial Selection Parameter

Concentration by volume, % magnetite per sands 10% [-]

Concentration by volume, % solids per water 30% [-]

Magnetite density 5.200 T/m3

Marine sands density 1.800 T/m3

Seawater density 1.025 T/m3

Magne-sand density (comb) 2.140 T/m3

Raw feed density (comb) 1.360 T/m3

Initial feed gross, Q 1,351.48 cmh

Target concentrate grade, %Fe 63% [-]

Magnetic separation efficiency 90% [-]

Pumping efficiency 80% [-]

Mineral recovery rate 50% [-]

Operating hours per day 16.00 hours per day

Operating days per month 26.00 days per month

2.0 Head Calculation

Initial pipe size diameter selection 12.00 in

in SI (DN) 300.00 mm

Cross sectional area 0.0707 m2

Particle diameter, d50 1,250.00 µm

Vertical height:

from distribution header centerline to water line 15.00 m

from water line to seabed 45.00 m

from seabed to maximum minebed strata 20.00 m

Total depth from the header 80.00 m

With additional length (i.e. for sagging and others) 100.00 m

Total dynamic head for underwater slurry

1. Static head (above water line) 15.00 m

2. Static slurry head (differential balance column loss)

Static head (below water line) x (1 - SG fluid / SG mixture)

= 65 m x ( 1 - ( 1.025 / 1.3595 )) 15.99 m

3. Water friction loss (Darcy Formula)

= ( f x L ) x ( v^2 ) / ( 2 x g x d ) 10.39 m

Flow, cmh f, [-] Velocity, m/s Head loss, m

- - - -

679 0.02198 2.6696 2.66

1,359 0.02145 5.3392 10.39

1,698 0.02134 6.6740 16.15

1,902 0.02129 7.4749 20.21

4. Slurry friction loss 10.29 m

FL number for limit settling. See Figure 1. 1.42 [-]

Limiting velocity, vL. See Figure 1. 3.58 m/s

Technical Pump Review Pages 22/36

Tai'an ZJQ1000-78-400 Revision 00

Limiting flow, qL 0.25 m3/s

911.12 cmh

Percent difference of Q and qL using = 1 - (qL / Q) 32.58% [-]

Recommendation: Is percent change within 10-15%? Increase pipe size.

Curve fit parameters for slurry resistance chart

Parameter Flow, cmh Velocity, m/s Head loss, m

0.7 x qL 637.79 2.5063 2.35

1.0 x qL 911.12 3.5805 4.73

1.3 x qL 1,184.46 4.6546 7.92

Parabolic parameter for slurry curve

Slurry friction loss curve

(h, k) 637.79 4.73 Water friction loss curve

25

(x, y) 1184.46 7.92

a 1.07E-05

20

Slurry friction loss curve - 10.29

x f(x) 15 1,358.66 10.29

136 7.42 1,358.66 -

408 5.30 1,358.66 10.29

10

679 4.75

1,087 6.89

1,359 10.29 5

1,630 15.26

1,902 21.82 0

0 200 400 600 800 1000 1200 1400 1600 1800 2000

Total dynamic head for underwater slurry

= 15 m + 16 m + 10.39 m + 10.29 m 51.67 m

3.0 Pipe size validation

Limit velocity,

FL [-] dia, mm Limit flow, qL, cmh Percent difference, % Size change requirement

vL, m/s

1.415 200.00 2.92 330.63 75.54% Increase pipe size.

1.415 250.00 3.27 577.60 57.26% Increase pipe size.

1.415 300.00 3.58 911.12 32.58% Increase pipe size.

1.415 350.00 3.87 1339.50 0.89% Reduce pipe size.

1.415 400.00 4.13 1870.35 -38.39% Reduce pipe size.

1.415 450.00 4.39 2510.76 -85.78% Reduce pipe size.

1.415 500.00 4.62 3267.37 -141.76% Reduce pipe size.

1.415 550.00 4.85 4146.49 -206.81% Reduce pipe size.

1.415 600.00 5.06 5154.09 -281.37% Reduce pipe size.

4.0 Power validation at various pipe diameter Head loss, m

1,200 Power, kW

mm head, m Power, kW Water head loss, m Slurry friction loss, m

200.00 125.60 1098.97 1,000 84.66 9.95

250.00 67.09 587.01 26.61 9.49

800

300.00 51.54 450.95 10.37 10.18

350.00 44.43 388.71 600 4.69 8.74

400.00 41.83 366.01 2.36 8.48

400

450.00 40.53 354.57 1.30 8.24

500.00 39.79 348.10 200 0.76 8.04

550.00 39.32 344.01 0.47 7.86

600.00 38.96 340.88 - 0.30 7.67

200 250 300 350 400 450 500 550 600

Technical Pump Review Pages 23/36

Tai'an ZJQ1000-78-400 Revision 00

5.0 Backward-fitted results from actual pump curve conditions

Concentration by volume, % magnetite per sands 10% [-]

Concentration by volume, % solids per water 30% [-]

Head Ratio & Efficiency ratio 0.997749 [-]

Curve flow capacity, water rated 1,351.48 cmh

Curve head, m 51.67 m

Curve efficiency, % 57.35% [-]

Curve power, kW 321.67 kW

Corrected power, at slurry, kW 435.34 kW

Technical Pump Review Pages 24/36

Tai'an ZJQ1000-78-400 Revision 00

Adjusted Conditions Calculations 1338.85 (0.00)

Selection C

1.0 Initial Selection Parameter

Concentration by volume, % magnetite per sands 15% [-]

Concentration by volume, % solids per water 30% [-]

Magnetite density 5.200 T/m3

Marine sands density 1.800 T/m3

Seawater density 1.025 T/m3

Magne-sand density (comb) 2.310 T/m3

Raw feed density (comb) 1.411 T/m3

Initial feed gross, Q 1,338.85 cmh

Target concentrate grade, %Fe 63% [-]

Magnetic separation efficiency 90% [-]

Pumping efficiency 80% [-]

Mineral recovery rate 50% [-]

Operating hours per day 16.00 hours per day

Operating days per month 26.00 days per month

2.0 Head Calculation

Initial pipe size diameter selection 12.00 in

in SI (DN) 300.00 mm

Cross sectional area 0.0707 m2

Particle diameter, d50 1,250.00 µm

Vertical height:

from distribution header centerline to water line 15.00 m

from water line to seabed 45.00 m

from seabed to maximum minebed strata 20.00 m

Total depth from the header 80.00 m

With additional length (i.e. for sagging and others) 100.00 m

Total dynamic head for underwater slurry

1. Static head (above water line) 15.00 m

2. Static slurry head (differential balance column loss)

Static head (below water line) x (1 - SG fluid / SG mixture)

= 65 m x ( 1 - ( 1.025 / 1.4105 )) 17.76 m

3. Water friction loss (Darcy Formula)

= ( f x L ) x ( v^2 ) / ( 2 x g x d ) 10.09 m

Flow, cmh f, [-] Velocity, m/s Head loss, m

- - - -

669 0.02199 2.6307 2.59

1,339 0.02146 5.2613 10.09

1,674 0.02134 6.5767 15.68

1,874 0.02130 7.3659 19.63

4. Slurry friction loss 10.01 m

FL number for limit settling. See Figure 1. 1.42 [-]

Limiting velocity, vL. See Figure 1. 3.84 m/s

Technical Pump Review Pages 25/36

Tai'an ZJQ1000-78-400 Revision 00

Limiting flow, qL 0.27 m3/s

978.12 cmh

Percent difference of Q and qL using = 1 - (qL / Q) 26.94% [-]

Recommendation: Is percent change within 10-15%? Increase pipe size.

Curve fit parameters for slurry resistance chart

Parameter Flow, cmh Velocity, m/s Head loss, m

0.7 x qL 684.68 2.6906 2.70

1.0 x qL 978.12 3.8438 5.44

1.3 x qL 1,271.55 4.9969 9.11

Parabolic parameter for slurry curve

Slurry friction loss curve

(h, k) 684.68 5.44 Water friction loss curve

25

25

(x, y) 1271.55 9.11

a 1.07E-05

20

20

Slurry friction loss curve - 10.01

x f(x) 15

15 1,338.85 10.01

134 8.68 1,338.85 -

402 6.29 1,338.85 10.01

10

10

669 5.44

1,071 7.03

1,339 10.01 55

1,607 14.51

1,874 20.55 -0

0 200 400 600 800 1000 1200 1400 1600 1800 2000

Total dynamic head for underwater slurry

= 15 m + 17.77 m + 10.1 m + 10.01 m 52.86 m

3.0 Pipe size validation

Limit velocity,

FL [-] dia, mm Limit flow, qL, cmh Percent difference, % Size change requirement

vL, m/s

1.415 200.00 3.14 354.95 73.49% Increase pipe size.

1.415 250.00 3.51 620.07 53.69% Increase pipe size.

1.415 300.00 3.84 978.12 26.94% Increase pipe size.

1.415 350.00 4.15 1438.00 -7.41% Reduce pipe size.

1.415 400.00 4.44 2007.88 -49.97% Reduce pipe size.

1.415 450.00 4.71 2695.38 -101.32% Reduce pipe size.

1.415 500.00 4.96 3507.62 -161.99% Reduce pipe size.

1.415 550.00 5.20 4451.38 -232.48% Reduce pipe size.

1.415 600.00 5.44 5533.07 -313.27% Reduce pipe size.

4.0 Power validation at various pipe diameter Head loss, m

1,200 Power, kW

mm head, m Power, kW Water head loss, m Slurry friction loss, m

200.00 127.30 1123.69 1,000 83.08 11.45

250.00 69.79 616.08 26.12 10.91

800

300.00 52.95 467.41 10.18 10.01

350.00 47.43 418.66 600 4.60 10.06

400.00 44.84 395.79 2.32 9.75

400

450.00 43.51 384.12 1.27 9.48

500.00 42.75 377.42 200 0.74 9.25

550.00 42.27 373.10 0.46 9.04

600.00 41.89 369.74 - 0.30 8.82

200 250 300 350 400 450 500 550 600

Technical Pump Review Pages 26/36

Tai'an ZJQ1000-78-400 Revision 00

5.0 Backward-fitted results from actual pump curve conditions

Concentration by volume, % magnetite per sands 15% [-]

Concentration by volume, % solids per water 30% [-]

Head Ratio & Efficiency ratio 0.997287 [-]

Curve flow capacity, water rated 1,338.85 cmh

Curve head, m 52.86 m

Curve efficiency, % 58.45% [-]

Curve power, kW 319.82 kW

Corrected power, at slurry, kW 448.67 kW

Technical Pump Review Pages 27/36

Tai'an ZJQ1000-78-400 Revision 00

Adjusted Conditions Calculations 1303.53 0.00

Selection D

1.0 Initial Selection Parameter

Concentration by volume, % magnetite per sands 15% [-]

Concentration by volume, % solids per water 40% [-]

Magnetite density 5.200 T/m3

Marine sands density 1.800 T/m3

Seawater density 1.025 T/m3

Magne-sand density (comb) 2.310 T/m3

Raw feed density (comb) 1.539 T/m3

Initial feed gross, Q 1,303.53 cmh

Target concentrate grade, %Fe 63% [-]

Magnetic separation efficiency 90% [-]

Pumping efficiency 80% [-]

Mineral recovery rate 50% [-]

Operating hours per day 16.00 hours per day

Operating days per month 26.00 days per month

2.0 Head Calculation

Initial pipe size diameter selection 12.00 in

in SI (DN) 300.00 mm

Cross sectional area 0.0707 m2

Particle diameter, d50 1,250.00 µm

Vertical height:

from distribution header centerline to water line 15.00 m

from water line to seabed 45.00 m

from seabed to maximum minebed strata 20.00 m

Total depth from the header 80.00 m

With additional length (i.e. for sagging and others) 100.00 m

Total dynamic head for underwater slurry

1. Static head (above water line) 15.00 m

2. Static slurry head (differential balance column loss)

Static head (below water line) x (1 - SG fluid / SG mixture)

= 65 m x ( 1 - ( 1.025 / 1.539 )) 21.71 m

3. Water friction loss (Darcy Formula)

= ( f x L ) x ( v^2 ) / ( 2 x g x d ) 9.57 m

Flow, cmh f, [-] Velocity, m/s Head loss, m

- - - -

652 0.02202 2.5613 2.45

1,304 0.02147 5.1225 9.57

1,629 0.02136 6.4032 14.88

1,825 0.02131 7.1716 18.62

4. Slurry friction loss 9.53 m

FL number for limit settling. See Figure 1. 1.42 [-]

Limiting velocity, vL. See Figure 1. 3.84 m/s

Technical Pump Review Pages 28/36

Tai'an ZJQ1000-78-400 Revision 00

Limiting flow, qL 0.27 m3/s

978.12 cmh

Percent difference of Q and qL using = 1 - (qL / Q) 24.96% [-]

Recommendation: Is percent change within 10-15%? Increase pipe size.

Curve fit parameters for slurry resistance chart

Parameter Flow, cmh Velocity, m/s Head loss, m

0.7 x qL 684.68 2.6906 2.70

1.0 x qL 978.12 3.8438 5.44

1.3 x qL 1,271.55 4.9969 9.11

Parabolic parameter for slurry curve

Slurry friction loss curve

(h, k) 684.68 5.44 Water friction loss curve

25

25

(x, y) 1271.55 9.11

a 1.07E-05

20

20

Slurry friction loss curve - 9.53

x f(x) 15

15 1,303.53 9.53

130 8.72 1,303.53 -

391 6.36 1,303.53 9.53

10

10

652 5.45

1,043 6.81

1,304 9.53 55

1,564 13.70

1,825 19.32 -0

0 200 400 600 800 1000 1200 1400 1600 1800 2000

Total dynamic head for underwater slurry

= 15 m + 21.71 m + 9.58 m + 9.53 m 55.81 m

3.0 Pipe size validation

Limit velocity,

FL [-] dia, mm Limit flow, qL, cmh Percent difference, % Size change requirement

vL, m/s

1.415 200.00 3.14 354.95 72.77% Increase pipe size.

1.415 250.00 3.51 620.07 52.43% Increase pipe size.

1.415 300.00 3.84 978.12 24.96% Increase pipe size.

1.415 350.00 4.15 1438.00 -10.32% Reduce pipe size.

1.415 400.00 4.44 2007.88 -54.03% Reduce pipe size.

1.415 450.00 4.71 2695.38 -106.78% Reduce pipe size.

1.415 500.00 4.96 3507.62 -169.09% Reduce pipe size.

1.415 550.00 5.20 4451.38 -241.49% Reduce pipe size.

1.415 600.00 5.44 5533.07 -324.47% Reduce pipe size.

4.0 Power validation at various pipe diameter Head loss, m

1,200 Power, kW

mm head, m Power, kW Water head loss, m Slurry friction loss, m

200.00 126.91 1139.63 1,000 78.76 11.44

250.00 72.38 649.93 24.76 10.91

800

300.00 55.88 501.83 9.65 9.53

350.00 51.13 459.15 600 4.36 10.06

400.00 48.66 436.96 2.20 9.75

400

450.00 47.39 425.58 1.20 9.48

500.00 46.66 419.00 200 0.70 9.25

550.00 46.19 414.75 0.43 9.04

600.00 45.81 411.41 - 0.28 8.82

200 250 300 350 400 450 500 550 600

Technical Pump Review Pages 29/36

Tai'an ZJQ1000-78-400 Revision 00

5.0 Backward-fitted results from actual pump curve conditions

Concentration by volume, % magnetite per sands 15% [-]

Concentration by volume, % solids per water 40% [-]

Head Ratio & Efficiency ratio 0.996684 [-]

Curve flow capacity, water rated 1,303.53 cmh

Curve head, m 55.81 m

Curve efficiency, % 61.08% [-]

Curve power, kW 315.07 kW

Corrected power, at slurry, kW 481.69 kW

Technical Pump Review Pages 30/36

Tai'an ZJQ1000-78-400 Revision 00

Adjusted Conditions Calculations 1283.44 (0.00)

Selection E

1.0 Initial Selection Parameter

Concentration by volume, % magnetite per sands 20% [-]

Concentration by volume, % solids per water 40% [-]

Magnetite density 5.200 T/m3

Marine sands density 1.800 T/m3

Seawater density 1.025 T/m3

Magne-sand density (comb) 2.480 T/m3

Raw feed density (comb) 1.607 T/m3

Initial feed gross, Q 1,283.44 cmh

Target concentrate grade, %Fe 63% [-]

Magnetic separation efficiency 90% [-]

Pumping efficiency 80% [-]

Mineral recovery rate 50% [-]

Operating hours per day 16.00 hours per day

Operating days per month 26.00 days per month

2.0 Head Calculation

Initial pipe size diameter selection 12.00 in

in SI (DN) 300.00 mm

Cross sectional area 0.0707 m2

Particle diameter, d50 1,250.00 µm

Vertical height:

from distribution header centerline to water line 15.00 m

from water line to seabed 45.00 m

from seabed to maximum minebed strata 20.00 m

Total depth from the header 80.00 m

With additional length (i.e. for sagging and others) 100.00 m

Total dynamic head for underwater slurry

1. Static head (above water line) 15.00 m

2. Static slurry head (differential balance column loss)

Static head (below water line) x (1 - SG fluid / SG mixture)

= 65 m x ( 1 - ( 1.025 / 1.607 )) 23.54 m

3. Water friction loss (Darcy Formula)

= ( f x L ) x ( v^2 ) / ( 2 x g x d ) 9.28 m

Flow, cmh f, [-] Velocity, m/s Head loss, m

- - - -

642 0.02204 2.5218 2.38

1,283 0.02148 5.0436 9.28

1,604 0.02136 6.3045 14.43

1,797 0.02131 7.0610 18.05

4. Slurry friction loss 9.43 m

FL number for limit settling. See Figure 1. 1.42 [-]

Limiting velocity, vL. See Figure 1. 4.09 m/s

Technical Pump Review Pages 31/36

Tai'an ZJQ1000-78-400 Revision 00

Limiting flow, qL 0.29 m3/s

1,040.81 cmh

Percent difference of Q and qL using = 1 - (qL / Q) 18.90% [-]

Recommendation: Is percent change within 10-15%? Increase pipe size.

Curve fit parameters for slurry resistance chart

Parameter Flow, cmh Velocity, m/s Head loss, m

0.7 x qL 728.57 2.8631 3.05

1.0 x qL 1,040.81 4.0901 6.14

1.3 x qL 1,353.05 5.3172 10.30

Parabolic parameter for slurry curve

Slurry friction loss curve

(h, k) 728.57 6.14 Water friction loss curve

25

25

(x, y) 1353.05 10.30

a 1.07E-05

20

20

Slurry friction loss curve - 9.43

x f(x) 15

15 1,283.44 9.43

128 9.99 1,283.44 -

385 7.40 1,283.44 9.43

10

10

642 6.22

1,027 7.09

1,283 9.43 55

1,540 13.17

1,797 18.32 -0

0 200 400 600 800 1000 1200 1400 1600 1800 2000

Total dynamic head for underwater slurry

= 15 m + 23.55 m + 9.29 m + 9.43 m 57.25 m

3.0 Pipe size validation

Limit velocity,

FL [-] dia, mm Limit flow, qL, cmh Percent difference, % Size change requirement

vL, m/s

1.415 200.00 3.34 377.70 70.57% Increase pipe size.

1.415 250.00 3.73 659.81 48.59% Increase pipe size.

1.415 300.00 4.09 1040.81 18.90% Increase pipe size.

1.415 350.00 4.42 1530.16 -19.22% Reduce pipe size.

1.415 400.00 4.72 2136.57 -66.47% Reduce pipe size.

1.415 450.00 5.01 2868.13 -123.47% Reduce pipe size.

1.415 500.00 5.28 3732.44 -190.82% Reduce pipe size.

1.415 550.00 5.54 4736.69 -269.06% Reduce pipe size.

1.415 600.00 5.78 5887.70 -358.75% Reduce pipe size.

4.0 Power validation at various pipe diameter Head loss, m

1,200 Power, kW

mm head, m Power, kW Water head loss, m Slurry friction loss, m

200.00 127.82 1157.36 1,000 76.35 12.93

250.00 74.87 677.93 24.00 12.33

800

300.00 57.32 519.02 9.35 9.43

350.00 54.14 490.24 600 4.23 11.37

400.00 51.70 468.10 2.13 11.03

400

450.00 50.43 456.59 1.17 10.72

500.00 49.68 449.83 200 0.68 10.46

550.00 49.19 445.37 0.42 10.23

600.00 48.80 441.82 - 0.27 9.98

200 250 300 350 400 450 500 550 600

Technical Pump Review Pages 32/36

Tai'an ZJQ1000-78-400 Revision 00

5.0 Backward-fitted results from actual pump curve conditions

Concentration by volume, % magnetite per sands 20% [-]

Concentration by volume, % solids per water 40% [-]

Head Ratio & Efficiency ratio 0.996316 [-]

Curve flow capacity, water rated 1,283.44 cmh

Curve head, m 57.25 m

Curve efficiency, % 62.30% [-]

Curve power, kW 312.58 kW

Corrected power, at slurry, kW 498.63 kW

Technical Pump Review Pages 33/36

Tai'an ZJQ1000-78-400 Revision 00

Adjusted Conditions Calculations 991.09 27.36

Selection F (No Magnetite)

1.1 Initial Selection Parameter

Concentration by volume, % magnetite per sands 0% [-]

Concentration by volume, % solids per water 40% [-]

Magnetite density 5.200 T/m3

Marine sands density 1.800 T/m3

Seawater density 1.025 T/m3

Magne-sand density (comb) 1.800 T/m3

Raw feed density (comb) 1.335 T/m3

Initial feed gross, Q 991.09 cmh

Target concentrate grade, %Fe 63% [-]

Magnetic separation efficiency 90% [-]

Pumping efficiency 80% [-]

Mineral recovery rate 50% [-]

Operating hours per day 16.00 hours per day

Operating days per month 26.00 days per month

2.1 Head Calculation

Initial pipe size diameter selection 12.00 in

in SI (DN) 300.00 mm

Cross sectional area 0.0707 m2

Particle diameter, d50 1,250.00 µm

Vertical height:

from distribution header centerline to water line 15.00 m

from water line to seabed 45.00 m

from seabed to maximum minebed strata 20.00 m

Total depth from the header 80.00 m

With additional length (i.e. for sagging and others) 100.00 m

Total dynamic head for underwater slurry

1. Static head (above water line) 15.00 m

2. Static slurry head (differential balance column loss)

Static head (below water line) x (1 - SG fluid / SG mixture)

= 65 m x ( 1 - ( 1.025 / 1.335 )) 15.09 m

3. Water friction loss (Darcy Formula)

= ( f x L ) x ( v^2 ) / ( 2 x g x d ) 5.58 m

Flow, cmh f, [-] Velocity, m/s Head loss, m

- - - -

496 0.02234 1.9474 1.44

991 0.02165 3.8948 5.58

1,239 0.02150 4.8684 8.66

1,388 0.02144 5.4527 10.83

4. Slurry friction loss 5.57 m

FL number for limit settling. See Figure 1. 1.42 [-]

Limiting velocity, vL. See Figure 1. 2.99 m/s

Technical Pump Review Pages 34/36

Tai'an ZJQ1000-78-400 Revision 00

Limiting flow, qL 0.21 m3/s

759.61 cmh

Percent difference of Q and qL using = 1 - (qL / Q) 23.36% [-]

Recommendation: Is percent change within 10-15%? Increase pipe size.

Curve fit parameters for slurry resistance chart

Parameter Flow, cmh Velocity, m/s Head loss, m

0.7 x qL 531.73 2.0896 1.65

1.0 x qL 759.61 2.9851 3.31

1.3 x qL 987.49 3.8806 5.54

Parabolic parameter for slurry curve

Slurry friction loss curve

(h, k) 531.73 3.31 Water friction loss curve

25

25

(x, y) 987.49 5.54

a 1.07E-05

20

20

Slurry friction loss curve 1.00 5.57

x f(x) 15

15 991.09 5.57

99 5.32 991.09 -

297 3.90 991.09 5.57

10

10

496 3.32

793 4.04

991 5.57 55

1,189 7.95

1,388 11.17 -0

0 200 400 600 800 1000 1200 1400 1600 1800 2000

Total dynamic head for underwater slurry

= 15 m + 15.1 m + 5.58 m + 5.58 m 41.25 m

3.1 Pipe size validation

Limit velocity,

FL [-] dia, mm Limit flow, qL, cmh Percent difference, % Size change requirement

vL, m/s

1.415 200.00 2.44 275.65 72.19% Increase pipe size.

1.415 250.00 2.72 481.55 51.41% Increase pipe size.

1.415 300.00 2.99 759.61 23.36% Increase pipe size.

1.415 350.00 3.22 1116.75 -12.68% Reduce pipe size.

1.415 400.00 3.45 1559.33 -57.33% Reduce pipe size.

1.415 450.00 3.66 2093.24 -111.20% Reduce pipe size.

1.415 500.00 3.85 2724.03 -174.85% Reduce pipe size.

1.415 550.00 4.04 3456.96 -248.80% Reduce pipe size.

1.415 600.00 4.22 4297.00 -333.56% Reduce pipe size.

4.1 Power validation at various pipe diameter Head loss, m

1,200 Power, kW

mm head, m Power, kW Water head loss, m Slurry friction loss, m

200.00 82.58 447.27 1,000 45.53 6.96

250.00 51.04 276.43 14.31 6.63

800

300.00 41.25 223.40 5.58 5.57

350.00 38.72 209.74 600 2.52 6.11

400.00 37.28 201.94 1.27 5.92

400

450.00 36.54 197.92 0.70 5.75

500.00 36.11 195.58 200 0.41 5.61

550.00 35.83 194.06 0.25 5.48

600.00 35.60 192.82 - 0.16 5.35

200 250 300 350 400 450 500 550 600

Technical Pump Review Pages 35/36

Tai'an ZJQ1000-78-400 Revision 00

5.1 Backward-fitted results from actual pump curve conditions

Concentration by volume, % magnetite per sands 0% [-]

Concentration by volume, % solids per water 40% [-]

Head Ratio & Efficiency ratio 0.997854 [-]

Curve flow capacity, water rated 991.09 cmh

Curve head, m 68.61 m

Curve efficiency, % 66.71% [-]

Curve power, kW 277.85 kW

Corrected power, at slurry, kW 369.34 kW

Technical Pump Review Pages 36/36

Tai'an ZJQ1000-78-400 Revision 00

Confidential. Do not share without consent.

Actual Pump Selected, at water rated

Dragflow HY600HC

1.0 Main dredge pump specifications

Head Capacity Power Efficiency Speed Volt/Phase/Frequency

m cmh kW % rpm V/P/Hz

33.00 2,000.00 475.00 55 950.00

2.0 Main dredge pump curve

Flow, cmh Head, m Efficiency Power, kW Theo. Power, kW

500 49.00 22.0% 290.00 303.47

700 47.00 30.0% 308.00 298.84

1,000 44.00 38.0% 320.00 315.53

1,500 39.00 47.0% 345.00 339.18

2,000 33.00 55.0% 365.00 327.00

2,500 26.00 53.0% 370.00 334.20

2,800 22.00 45.0% 380.00 373.02

3,000 20.00 41.0% 385.00 398.78

3,500 18.00 39.0% 387.00 440.19

4,000 10.00 30.0% 380.00 363.33

4,500 4.00 28.0% 385.00 175.18

55 60.0%

Head, m

50 Efficiency, %

50.0%

45

40 40.0%

35

30.0%

30

25 20.0%

20

10.0%

15

10 0.0%

500

450

400

350

300

250

200

150

Curve Power, kW

100

50 Theoretical Power, kW

0

0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000

Technical Pump Review Pages 1/33

Dragflow HY600HC Revision 00

Confidential. Do not share without consent.

3.0 Main dredge pump curve, slurry corrected flow 0.95

Flow, cmh Head, m Efficiency Power, kW Theo. Power, kW

475 44.22 22.0% 248.64 260.18

665 42.42 30.0% 264.07 256.22

950 39.71 38.0% 274.36 270.52

1,425 35.20 47.0% 295.79 290.80

1,900 29.78 55.0% 312.94 280.36

2,375 23.47 53.0% 317.23 286.53

3,800 9.03 30.0% 325.80 311.51

4,275 3.61 28.0% 330.09 150.19

50 60.0%

Head, m

Efficiency, %

45

50.0%

40

40.0%

35

30 30.0%

25

20.0%

20

10.0%

15

10 0.0%

350

300

250

200

150

100

Curve Power, kW

50 Corrected Power, kW

0

0 500 1000 1500 2000 2500 3000 3500 4000 4500

Technical Pump Review Pages 2/33

Dragflow HY600HC Revision 00

Confidential. Do not share without consent.

4.0 Pump curve modeling parameters for the backward-fitting process are as follows:

Water rated

a5 a4 a3 a2 a1 a0

Q-h -1.36E-16 1.31E-12 -3.88E-09 0.000002825124 -0.008620822304 52.829632293919

Q-n -4.52E-18 6.16E-14 -2.85E-10 0.000000449339 0.000018220012 0.137997927448

Q-p 8.90E-16 -1.08E-11 4.86E-08 -0.000110928488 0.164633071273 230.580044067837

Slurry corrected

a5 a4 a3 a2 a1 a0

Q-h -2.89E-16 3.23E-12 -1.27E-08 0.000020773122 -0.023757380839 52.071658554867

Q-n 3.75E-18 -3.29E-14 1.07E-10 -0.000000272893 0.000593858472 -0.006520128956

Q-p -2.53E-16 3.48E-12 -1.51E-08 0.000013711292 0.054061106689 222.715898993015

5.0 The pump selections A to E should be adjusted according to the actual curve of the main dredge pump,

The following backward-fitting process was coded to MS Excel allows the initial conditions to be fitted

along the pump curve.

Backward fit calculate the

Check initial calculated

Start equivalent flow (qi) from

flow (q0) and head (h0)

initial head (h0)

Print curve flow (qi) and Yes Is q0

End head (h0)

= qi?

Recalculate head loss

calculation with new flow

equivalent (qi)

Print curve flow (qn) and

Store new head loss as

head (hi) Store qi = qn

new head (hn)

Yes Backward fit calculate the

Is qi =

new flow equivalent (qn)

qn?

from new head (hn)

Technical Pump Review Pages 3/33

Dragflow HY600HC Revision 00

Confidential. Do not share without consent.

Pump Selection Calculations

Selection A

1.0 Initial Selection Parameter

Concentration by volume, % magnetite per sands 8% [-]

Concentration by volume, % solids per water 30% [-]

Magnetite density 5.200 T/m3

Marine sands density 1.800 T/m3

Seawater density 1.025 T/m3

Magne-sand density (comb) 2.072 T/m3

Raw feed density (comb) 1.339 T/m3

Initial feed gross, Q 2,000.00 cmh

Target concentrate grade, %Fe 63% [-]

Magnetic separation efficiency 90% [-]

Pumping efficiency 80% [-]

Mineral recovery rate 50% [-]

Operating hours per day 16.00 hours per day

Operating days per month 26.00 days per month

2.0 Head Calculation

Initial pipe size diameter selection 20.00 in

in SI (DN) 500.00 mm

Cross sectional area 0.1963 m2

Particle diameter, d50 1,250.00 µm

Vertical height:

from distribution header centerline to water line 15.00 m

from water line to seabed 45.00 m

from seabed to maximum minebed strata 20.00 m

Total depth from the header 80.00 m

With additional length (i.e. for sagging and others) 100.00 m

Total dynamic head for underwater slurry

1. Static head (above water line) 15.00 m

2. Static slurry head (differential balance column loss)

Static head (below water line) x (1 - SG fluid / SG mixture)

= 65 m x ( 1 - ( 1.025 / 1.3391 )) 15.25 m

3. Water friction loss (Darcy Formula)

= ( f x L ) x ( v^2 ) / ( 2 x g x d ) 1.59 m

Flow, cmh f, [-] Velocity, m/s Head loss, m

- - - -

1,000 0.02033 1.4147 0.41

2,000 0.01953 2.8294 1.59

2,500 0.01935 3.5368 2.47

2,800 0.01928 3.9612 3.08

4. Slurry friction loss 3.96 m

FL number for limit settling. See Figure 1. 1.42 [-]

Limiting velocity, vL. See Figure 1. 4.48 m/s

Limiting flow, qL 0.88 m3/s

3,166.17 cmh

Percent difference of Q and qL using = 1 - (qL / Q) -58.31% [-]

Recommendation: Is percent change within 10-15%? Reduce pipe size.

Technical Pump Review Pages 4/33

Dragflow HYC600HC Revision 00

Confidential. Do not share without consent.

Curve fit parameters for slurry resistance chart

Parameter Flow, cmh Velocity, m/s Head loss, m

0.7 x qL 2,216.32 3.1355 1.95

1.0 x qL 3,166.17 4.4792 3.93

1.3 x qL 4,116.03 5.8230 6.59

Parabolic parameter for slurry curve

Slurry friction loss curve

(h, k) 2216.32 3.93 Water friction loss curve

8

(x, y) 4116.03 6.59

a 7.38E-07 7

6

Slurry friction loss curve - 3.96

x f(x) 5 2,000.00 3.96

200 6.93 4

2,000.00 -

600 5.86 2,000.00 3.96

1,000 5.02 3

1,600 4.21 2

2,000 3.96

1

2,400 3.95

2,800 4.18 0

0 500 1000 1500 2000 2500 3000

Total dynamic head for underwater slurry

= 15 m + 15.25 m + 1.6 m + 3.97 m 35.80 m

3.0 Pipe size validation

Limit velocity,

FL [-] dia, mm Limit flow, qL, cmh Percent difference, % Size change requirement

vL, m/s

1.415 200.00 2.83 320.39 83.98% Increase pipe size.

1.415 250.00 3.17 559.71 72.01% Increase pipe size.

1.415 300.00 3.47 882.90 55.85% Increase pipe size.

1.415 350.00 3.75 1298.02 35.10% Increase pipe size.

1.415 400.00 4.01 1812.42 9.38% Reduce pipe size.

1.415 450.00 4.25 2432.99 -21.65% Reduce pipe size.

1.415 500.00 4.48 3166.17 -58.31% Reduce pipe size.

1.415 550.00 4.70 4018.06 -100.90% Reduce pipe size.

1.415 600.00 4.91 4994.45 -149.72% Reduce pipe size.

4.0 Power validation at various pipe diameter Head loss, m

2,500 Power, kW

mm head, m Power, kW Water head loss, m Slurry friction loss, m

200.00 225.00 2351.11 2,000 185.40 9.36

250.00 97.44 1018.23 58.28 8.92

300.00 77.84 813.36 1,500 22.71 24.88

350.00 48.73 509.23 10.27 8.22

400.00 43.39 453.38 1,000 5.18 7.96

450.00 40.82 426.57 2.84 7.74

500.00 39.46 412.29 500 1.66 7.55

550.00 38.65 403.90 1.02 7.38

600.00 38.11 398.20 - 0.66 7.20

200 250 300 350 400 450 500 550 600

5.0 Pump Selection Result

Concentration by volume, % magnetite per sands 8% [-]

Concentration by volume, % solids per water 30% [-]

Head Ratio & Efficiency ratio 0.997749 [-]

Flowrate, rated at clean water 2,000.00 cmh

Minimum rated head, slurry 35.88 m

n, efficiency (minimum) 70% [-]

Rated power, kW 374.11 kW

Outlet size 500 mm

Technical Pump Review Pages 5/33

Dragflow HYC600HC Revision 00

Confidential. Do not share without consent.

Pump Selection Calculations

Selection B

1.0 Initial Selection Parameter

Concentration by volume, % magnetite per sands 10% [-]

Concentration by volume, % solids per water 30% [-]

Magnetite density 5.200 T/m3

Marine sands density 1.800 T/m3

Seawater density 1.025 T/m3

Magne-sand density (comb) 2.140 T/m3

Raw feed density (comb) 1.360 T/m3

Initial feed gross, Q 2,000.00 cmh

Target concentrate grade, %Fe 63% [-]

Magnetic separation efficiency 90% [-]

Pumping efficiency 80% [-]

Mineral recovery rate 50% [-]

Operating hours per day 16.00 hours per day

Operating days per month 26.00 days per month

2.0 Head Calculation

Initial pipe size diameter selection 20.00 in

in SI (DN) 500.00 mm

Cross sectional area 0.1963 m2

Particle diameter, d50 1,250.00 µm

Vertical height:

from distribution header centerline to water line 15.00 m

from water line to seabed 45.00 m

from seabed to maximum minebed strata 20.00 m

Total depth from the header 80.00 m

With additional length (i.e. for sagging and others) 100.00 m

Total dynamic head for underwater slurry

1. Static head (above water line) 15.00 m

2. Static slurry head (differential balance column loss)

Static head (below water line) x (1 - SG fluid / SG mixture)

= 65 m x ( 1 - ( 1.025 / 1.3595 )) 15.99 m

3. Water friction loss (Darcy Formula)

= ( f x L ) x ( v^2 ) / ( 2 x g x d ) 1.59 m

Flow, cmh f, [-] Velocity, m/s Head loss, m

- - - -

1,000 0.02033 1.4147 0.41

2,000 0.01953 2.8294 1.59

2,500 0.01935 3.5368 2.47

2,800 0.01928 3.9612 3.08

4. Slurry friction loss 4.24 m

FL number for limit settling. See Figure 1. 1.42 [-]

Limiting velocity, vL. See Figure 1. 4.62 m/s

Limiting flow, qL 0.91 m3/s

3,267.37 cmh

Percent difference of Q and qL using = 1 - (qL / Q) -63.37% [-]

Recommendation: Is percent change within 10-15%? Reduce pipe size.

Technical Pump Review Pages 6/33

Dragflow HYC600HC Revision 00

Confidential. Do not share without consent.

Curve fit parameters for slurry resistance chart

Parameter Flow, cmh Velocity, m/s Head loss, m

0.7 x qL 2,287.16 3.2357 2.07

1.0 x qL 3,267.37 4.6224 4.18

1.3 x qL 4,247.59 6.0091 7.01

Parabolic parameter for slurry curve

Slurry friction loss curve

(h, k) 2287.16 4.18 Water friction loss curve

8

(x, y) 4247.59 7.01

a 7.38E-07 7

6

Slurry friction loss curve - 4.24

x f(x) 5 2,000.00 4.24

200 7.39 4

2,000.00 -

600 6.28 2,000.00 4.24

1,000 5.40 3

1,600 4.53 2

2,000 4.24

1

2,400 4.19

2,800 4.37 0

0 500 1000 1500 2000 2500 3000

Total dynamic head for underwater slurry

= 15 m + 16 m + 1.6 m + 4.24 m 36.83 m

3.0 Pipe size validation

Limit velocity,

FL [-] dia, mm Limit flow, qL, cmh Percent difference, % Size change requirement

vL, m/s

1.415 200.00 2.92 330.63 83.47% Increase pipe size.

1.415 250.00 3.27 577.60 71.12% Increase pipe size.

1.415 300.00 3.58 911.12 54.44% Increase pipe size.

1.415 350.00 3.87 1339.50 33.02% Increase pipe size.

1.415 400.00 4.13 1870.35 6.48% Reduce pipe size.

1.415 450.00 4.39 2510.76 -25.54% Reduce pipe size.

1.415 500.00 4.62 3267.37 -63.37% Reduce pipe size.

1.415 550.00 4.85 4146.49 -107.32% Reduce pipe size.

1.415 600.00 5.06 5154.09 -157.70% Reduce pipe size.

4.0 Power validation at various pipe diameter Head loss, m

3,000 Power, kW

mm head, m Power, kW Water head loss, m Slurry friction loss, m