Professional Documents

Culture Documents

Poly (Ethylene-Co-Acrylic Acid) : Parameter Unit Value References

Uploaded by

Matt HillocksOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Poly (Ethylene-Co-Acrylic Acid) : Parameter Unit Value References

Uploaded by

Matt HillocksCopyright:

Available Formats

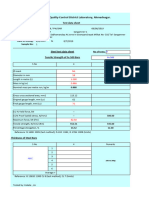

EAA poly(ethylene-co-acrylic acid)

PARAMETER UNIT VALUE REFERENCES

GENERAL

Common name - poly(ethylene-co-acrylic acid)

ACS name - 2-propenoic acid, polymer with ethene

Acronym - EAA

CAS number - 9010-77-9

SYNTHESIS

Monomer(s) structure - O

H2C CH2 H2C CHCOH

Monomer(s) CAS number(s) - 74-85-1; 79-10-7

Monomer(s) molecular weight(s) dalton, g/ 28.05; 72.06

mol, amu

Acrylic acid content % 5-38

Aromacity % 0-10 of aromatic protons

Temperature of polymerization o

C 240-300

Pressure of polymerization MPa 200-300

Number average molecular dalton, g/ 280-160,000 Wiggins, K M; Bielawski, C W,

weight, Mn mol, amu Polym. Chem., 4, 2239-45, 2013.

Mass average molecular weight, dalton, g/ 450-86,000

Mw mol, amu

Polydispersity, Mw/Mn - 1.1-3.97 McAlduff, M; Reven, L, Macromol-

ecules, 38, 3745-53, 2005.

STRUCTURE -

Crystallinity % 8-37 Zhang, J; Chen, S; Su, J; Shi, X;

Jin, J; Wang, X; Xu, Z, J. Therm.

Anal. Calorim., 97, 959-67, 2009.

Peak crystallization temperature o

C 85-90

Avrami constants, k/n - -/3-4 Zhang, J; Chen, S; Su, J; Shi, X;

Jin, J; Wang, X; Xu, Z, J. Therm.

Anal. Calorim., 97, 959-67, 2009.

COMMERCIAL POLYMERS

Some manufacturers - Dow; DuPont

Trade names - Primacor; Nucrel

PHYSICAL PROPERTIES

Density at 20oC g cm-3 0.92-0.96

o

Bulk density at 20 C g cm -3 0.5-0.6

Color - clear to white to off-white to yellow

Haze % 3.7-4

o

Gloss, 60 , Gardner (ASTM D523) % 74-76

Odor - acidic

Melting temperature, DSC o

C 75-112

Softening point o

C 92-140

Thermal degradation o

C 325

Glass transition temperature o

C -28 to 86

Vicat temperature VST/A/50 o

C 40-90

HANDBOOK OF POLYMERS / Copyrights 2016; ChemTec Publishing 93

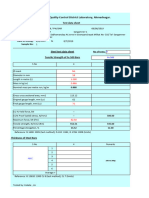

EAA poly(ethylene-co-acrylic acid)

PARAMETER UNIT VALUE REFERENCES

pKa 4.25 Laney, K A, Elastic Modulus of

Poly(ethylene-co-acrylic acid)

Copolymers and Ionomers, Diss.,

Princeton, May 2010.

Coefficient of friction - 0.3; 0.15-0.18 (with slip) Luo, N; Janorkar, A V; Hirt, D E;

Husson, S M; Schwark, D W, J.

Appl. Polym. Sci., 97, 2242-48,

2005.

Permeability to oxygen, 25oC cm3 mm 180-550

m-2 day-1

atm-1

Permeability to water vapor, 25oC g mm 0.0.37-0.44

m-2 atm-1

24 h-1

MECHANICAL & RHEOLOGICAL PROPERTIES

Tensile strength MPa 5.8-24 Li, D; Sur, G S, J. Ind. Eng. Chem.,

20, 3122-7, 2014.

Tensile modulus MPa 22-130

Tensile stress at yield MPa 7.2-10

Elongation % 390-640

Flexural modulus MPa 110

Young’s modulus MPa 65-115 Valenza, A; Visco, A M; Acierno, D,

Polym. Test., 21, 101-9, 2002.

Dart drop impact g 410

Elmendorf tear strength g 270-730

Shore D hardness - 50-51

Melt viscosity, shear rate=1000 Pa s 0.93-7

s-1

Melt index, 190oC/2.16 kg g/10 min 1.5-1300

CHEMICAL RESISTANCE

Alkalis - good

Aliphatic hydrocarbons - poor

Aromatic hydrocarbons - poor

FLAMMABILITY

Ignition temperature o

C >250 to 340

WEATHER STABILITY

Stabilizers - silica coated ZnO particles shield polymer for UV radiation Ramasamy, M; Kim, Y J; Gao, H;

Yi, D K; An, J H, Mater. Res. Bull.,

51, 85-91, 2014.

BIODEGRADATION

Stabilizers - benzoyl chloride Matche, R S; Kulkarni, G; Raj B, J.

Appl. Polym. Sci., 100, 3063-68,

2006.

TOXICITY

NFPA: Health, Flammability, - 1/1/0; 1/0/0 (HMIS)

Reactivity rating

94 HANDBOOK OF POLYMERS / Copyrights 2016; ChemTec Publishing

EAA poly(ethylene-co-acrylic acid)

PARAMETER UNIT VALUE REFERENCES

Carcinogenic effect - not listed by ACGIH, NIOSH, NTP

TLV, ACGIH ppm 2 (acrylic acid)

OSHA ppm 10 (acrylic acid)

Oral rat, LD50 mg kg -1 >2,350; >5,000

Skin rabbit, LD50 mg kg -1 >2,000

PROCESSING

Typical processing methods - cast film, extrusion blown film, extrusion coating, lamination

Processing temperature o

C 193-288 (extrusion); 305-325 (blown film)

Additives used in final products - Slip: erucamide, grafted 12-aminododecamide Luo, N; Janorkar, A V; Hirt, D E;

Husson, S M; Schwark, D W, J.

Appl. Polym. Sci., 97, 2242-48,

2005.

Applications - packaging multilayer films, resins for hot-melt adhesives,

resins for pressure-sensitive adhesives; products: hot-melt

packaging, curtain coating, bookbinding, glue stick, masking

tapes, carpet tape, mounting tape, paper, strapping tapes,

thermoplastic road marking

Outstanding properties - adhesion, environmental stress cracking resistance, optical

properties, strength

BLENDS

Suitable polymers - cellulose, PA6, PE, PP, starch

ANALYSIS

FTIR (wavenumber-assignment) cm-1/- OH 3500; C-H 2925, 2850, 1450, 1465, 1375; C=O Valenza, A; Visco, A M; Acierno, D,

1710, 1230-1320; C-C 940 Polym. Test., 21, 101-9, 2002.

HANDBOOK OF POLYMERS / Copyrights 2016; ChemTec Publishing 95

You might also like

- Cellulose Acetate Butyrate: Parameter Unit Value ReferencesDocument4 pagesCellulose Acetate Butyrate: Parameter Unit Value ReferencesMatt HillocksNo ratings yet

- Uorinated Ethylene-Propylene Copolymer: Parameter Unit Value ReferencesDocument4 pagesUorinated Ethylene-Propylene Copolymer: Parameter Unit Value ReferencesdiǝgOz F.No ratings yet

- Per Uoroalkoxy Resin: Parameter Unit Value ReferencesDocument3 pagesPer Uoroalkoxy Resin: Parameter Unit Value ReferencesdiǝgOz F.No ratings yet

- CelluloseDocument5 pagesCelluloseMatt HillocksNo ratings yet

- Poly (Alpha Methylstyrene)Document1 pagePoly (Alpha Methylstyrene)Hải quan TPHCMNo ratings yet

- UltrasonS6010 IsoDocument2 pagesUltrasonS6010 IsoKablayialijanNo ratings yet

- Characterization and Indentificatio of Plastic PDFDocument24 pagesCharacterization and Indentificatio of Plastic PDFWatthana KlairutsameeNo ratings yet

- Ficha Tecnica PoliamidaDocument6 pagesFicha Tecnica PoliamidaJ Alex ParraNo ratings yet

- Studies On The Effect of Ageing On A Range of UK Polymer Bonded ExplosivesDocument27 pagesStudies On The Effect of Ageing On A Range of UK Polymer Bonded ExplosivesKis KhisbiahNo ratings yet

- PDF Kulor Balls2015 PDFDocument156 pagesPDF Kulor Balls2015 PDFJasonNo ratings yet

- Ultrason E 3010: Polyethersulfone (PESU)Document2 pagesUltrason E 3010: Polyethersulfone (PESU)AmirNo ratings yet

- General Information: ABS (Extrusion)Document4 pagesGeneral Information: ABS (Extrusion)Cristian Alexander Daza TorresNo ratings yet

- CP75BK01 DatasheetDocument2 pagesCP75BK01 DatasheetKal Al-SaleemNo ratings yet

- Rigid PVCDocument1 pageRigid PVCRND KencanaNo ratings yet

- Propriedades Das Matrizes PolimericasDocument7 pagesPropriedades Das Matrizes PolimericasllepsterlNo ratings yet

- F F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Document4 pagesF F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Karishma Prabhu100% (1)

- Cellulose Acetate ButyrateDocument2 pagesCellulose Acetate Butyratenagbocca100% (1)

- Specifications Asfalto 50-80-2023Document1 pageSpecifications Asfalto 50-80-2023H JNo ratings yet

- Cu-Pr (Copper-Praseodymium) : H. OkamotoDocument1 pageCu-Pr (Copper-Praseodymium) : H. OkamotoCarlos LlaequeNo ratings yet

- Epofine 740 - Finehard 5200Document4 pagesEpofine 740 - Finehard 5200Karishma PrabhuNo ratings yet

- Test Certificate: Dayang Fastener Manufacturing Co.,LtdDocument1 pageTest Certificate: Dayang Fastener Manufacturing Co.,LtdjohnnyNo ratings yet

- 929 - PD, CBR, LL&PL JamkDocument84 pages929 - PD, CBR, LL&PL Jamkrahul pardeshiNo ratings yet

- Rpo SpecificationDocument2 pagesRpo SpecificationMayuresh Sudhir MokalNo ratings yet

- 920 - Sand, Cr. Metal (Sie - Flaki) KarDocument93 pages920 - Sand, Cr. Metal (Sie - Flaki) Karrahul pardeshiNo ratings yet

- AWC800 - Red Super Polymer (95A)Document1 pageAWC800 - Red Super Polymer (95A)Jas SumNo ratings yet

- (AdvanSix) (TDS) Aegis H135ZPDocument3 pages(AdvanSix) (TDS) Aegis H135ZPMarcos KodairaNo ratings yet

- Iso Dis 23936-2appendix+a08Document33 pagesIso Dis 23936-2appendix+a08Abel Lopez JoachinNo ratings yet

- PORON 4790-92-25041 P Extra SoftSlow ReboundSupportedDocument2 pagesPORON 4790-92-25041 P Extra SoftSlow ReboundSupportedkarpagsNo ratings yet

- SH8900-H (White) EngDocument4 pagesSH8900-H (White) EngKollinNo ratings yet

- An Evaluationofthe Short Rodtechniqueto Measurethe Fracture Toughnessof PolymersDocument11 pagesAn Evaluationofthe Short Rodtechniqueto Measurethe Fracture Toughnessof PolymersNameira WulanNo ratings yet

- Vehring AAPS 2006 Particle Design Via Spray DryingDocument27 pagesVehring AAPS 2006 Particle Design Via Spray Dryingfatemeh afariNo ratings yet

- General Purpose Polystyrene, GPPS, LabDocument1 pageGeneral Purpose Polystyrene, GPPS, LabEslam A. FahmyNo ratings yet

- Martins RubberDocument18 pagesMartins RubbermaNo ratings yet

- Properties of Common Optical Polymers: F D C DDocument1 pageProperties of Common Optical Polymers: F D C DHugo MakNo ratings yet

- Ficha Tecnica Perno M12Document1 pageFicha Tecnica Perno M12CARLOS RODRIGO ROJO ROJONo ratings yet

- O Ring Data SheetDocument3 pagesO Ring Data Sheetandri putrantoNo ratings yet

- RC Base Oil Sn150Document2 pagesRC Base Oil Sn150Royal Global Energy RGENo ratings yet

- Makrolon RW6267 X ISO enDocument3 pagesMakrolon RW6267 X ISO envahdatvahedyNo ratings yet

- Styrolution TDS400900481370Document3 pagesStyrolution TDS400900481370joshNo ratings yet

- Correlación para Obtener La Presión Mínima de MiscibilidadDocument14 pagesCorrelación para Obtener La Presión Mínima de MiscibilidadXimena M. CastellanosNo ratings yet

- Chapter 8 - Polymer Glossary and IndexDocument11 pagesChapter 8 - Polymer Glossary and IndexGarry TaylorNo ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- 03 Aminian InfuseDocument21 pages03 Aminian InfuseHat CopterNo ratings yet

- EVA Test PropeetiesDocument37 pagesEVA Test Propeetiessimon sembiringNo ratings yet

- M-106 Material PropertiesDocument1 pageM-106 Material Propertiesshabianreyhandisya2017.tmNo ratings yet

- ULTRADUR B4300G6 (03p023)Document3 pagesULTRADUR B4300G6 (03p023)ayala castroNo ratings yet

- NP 140Document5 pagesNP 140Nicole YangNo ratings yet

- Tat e Van Gerpen (2003)Document4 pagesTat e Van Gerpen (2003)Laís C. PoletoNo ratings yet

- MSS PJ PJMaterialsDataSheetDocument2 pagesMSS PJ PJMaterialsDataSheetAndreNo ratings yet

- 10.1515 Secm.2002.10.1.35Document10 pages10.1515 Secm.2002.10.1.35MARIA FERNANDA BETANCOURT SOTONo ratings yet

- Total Azolla ZSDocument1 pageTotal Azolla ZSVelibor KaranovicNo ratings yet

- Plastic Deformation in Tensile Testing: Renewable Energy Equipment DesignDocument17 pagesPlastic Deformation in Tensile Testing: Renewable Energy Equipment DesignNoman AhmedNo ratings yet

- Dyes and PigmentsDocument8 pagesDyes and PigmentsBehramand KhanNo ratings yet

- Product Technical Data Sheet: Unit Value MethodDocument2 pagesProduct Technical Data Sheet: Unit Value Methodhamza OUADINo ratings yet

- Normas para Pruebas en Mantenimiento de Equipos de SubestacionesDocument4 pagesNormas para Pruebas en Mantenimiento de Equipos de SubestacionesCarlos A. Chalco DelgadoNo ratings yet

- Oil Stability A DSC Alternative For The Active Oxygen MethodDocument2 pagesOil Stability A DSC Alternative For The Active Oxygen MethodTaty mignon princeNo ratings yet

- TDS SW 901 3Document5 pagesTDS SW 901 3Frans Hendra WinartaNo ratings yet

- How To Choose Permanent Magnet Materials: 5. Grade and Magnetic PropertiesDocument11 pagesHow To Choose Permanent Magnet Materials: 5. Grade and Magnetic PropertiesdNo ratings yet

- Poly AcrylonitrileDocument16 pagesPoly AcrylonitrileParul Kumar SharmaNo ratings yet

- CAPhDocument2 pagesCAPhMatt HillocksNo ratings yet

- The Dynamic Viscosity of Polypropylene MeltDocument10 pagesThe Dynamic Viscosity of Polypropylene MeltMatt HillocksNo ratings yet

- Int J Applied Ceramic Tech - 2022 - Dong - Additive Manufacturing of Silicon Nitride Ceramics A Review of Advances andDocument21 pagesInt J Applied Ceramic Tech - 2022 - Dong - Additive Manufacturing of Silicon Nitride Ceramics A Review of Advances andMatt HillocksNo ratings yet

- Polymer-Polymer Interfacial Slip in Multilayered FilmsDocument24 pagesPolymer-Polymer Interfacial Slip in Multilayered FilmsMatt HillocksNo ratings yet

- Imeko TC10 2016 052Document6 pagesImeko TC10 2016 052Matt HillocksNo ratings yet

- Characterization of Ultrafine Particles and VOCs EDocument15 pagesCharacterization of Ultrafine Particles and VOCs EMatt HillocksNo ratings yet

- J4Ds Welcome Handout TSH MARCH 2023Document12 pagesJ4Ds Welcome Handout TSH MARCH 2023Matt HillocksNo ratings yet

- Prepare Foundation Flyer V5Document2 pagesPrepare Foundation Flyer V5Matt HillocksNo ratings yet

- PI EGGER Edging ABS enDocument6 pagesPI EGGER Edging ABS enArki ValaNo ratings yet

- PIDIGI 2022 Per Web OkDocument68 pagesPIDIGI 2022 Per Web OkPiquattro dooNo ratings yet

- Design World - Fastener Engineering Handbook 2022Document76 pagesDesign World - Fastener Engineering Handbook 2022William CamposNo ratings yet

- Cavi FlexDocument11 pagesCavi FlexCandace BlackburnNo ratings yet

- Jaourtak 1030: Technical Data SheetDocument1 pageJaourtak 1030: Technical Data SheetTruong Anh TuanNo ratings yet

- How To Construct and Operate A Bottle RocketDocument13 pagesHow To Construct and Operate A Bottle RocketKyle MasonNo ratings yet

- Googlepreview PDFDocument244 pagesGooglepreview PDFFREDY CORREANo ratings yet

- Adhesive FormulationDocument5 pagesAdhesive Formulationjraman2475% (4)

- Kleiberit 761.8Document12 pagesKleiberit 761.8Muhammad AhsanNo ratings yet

- Euromelt 362Document1 pageEuromelt 362charbelNo ratings yet

- VersaDrum Bulk Melters With Gear PumpDocument2 pagesVersaDrum Bulk Melters With Gear PumpNordson Adhesive Dispensing SystemsNo ratings yet

- Synthesia CatalogDocument5 pagesSynthesia CatalogCarlotta C.100% (1)

- Brochure Orevac-T Avril-2012Document6 pagesBrochure Orevac-T Avril-2012Le MinhNo ratings yet

- Foam Core Construction: Tools Tips and TricksDocument12 pagesFoam Core Construction: Tools Tips and TricksRohan KulkarniNo ratings yet

- The Complete Guide To Polyurethane PUR Hot Melt AdhesivesDocument3 pagesThe Complete Guide To Polyurethane PUR Hot Melt AdhesivesCarlotaNo ratings yet

- Processing Hot-Melt Pressure-Sensitive AdhesiveDocument12 pagesProcessing Hot-Melt Pressure-Sensitive AdhesiveCaio OliveiraNo ratings yet

- 000 281e 2.0Document7 pages000 281e 2.0EstebanRiveraNo ratings yet

- Pastillation BERNDORF GDocument10 pagesPastillation BERNDORF Garie_almachiNo ratings yet

- Adhesive BondingDocument26 pagesAdhesive BondingmaniNo ratings yet

- Prodas 905-tdsDocument2 pagesProdas 905-tdsMatias MarambioNo ratings yet

- AcResin - The Acrylic HotmeltDocument12 pagesAcResin - The Acrylic HotmeltRajNo ratings yet

- 2016-17 Catalogue in ExcelDocument588 pages2016-17 Catalogue in ExcelIliyanPetrovNo ratings yet

- 03 - 120803 Hot Melt Extrusion With BASF Pharma PolymersDocument201 pages03 - 120803 Hot Melt Extrusion With BASF Pharma PolymersMoeen Khan Risaldar100% (1)

- Vinnapas Solid Resins Brochure 2016 - 7409 - ENDocument24 pagesVinnapas Solid Resins Brochure 2016 - 7409 - ENJohnNo ratings yet

- MUS0330202ECENGDocument87 pagesMUS0330202ECENGGermán Cahuasquí VelasquezNo ratings yet

- MK - Adhesive Used in - Corugate IndustryDocument2 pagesMK - Adhesive Used in - Corugate Industryamila209No ratings yet

- EZ Flow II - Prod - Mark - SHT - AFP 1 392Document2 pagesEZ Flow II - Prod - Mark - SHT - AFP 1 392Darwin Gabriel Ponce BravoNo ratings yet

- TDS-HM Millon MF 3s 0.35mm, Nasa-T 0.20mm-20200116Document2 pagesTDS-HM Millon MF 3s 0.35mm, Nasa-T 0.20mm-20200116tranngocthuonghoaiNo ratings yet

- PAL 03 3011 Mini Squirt ApplicatorDocument2 pagesPAL 03 3011 Mini Squirt ApplicatorJOSEANTONIO2001No ratings yet