Professional Documents

Culture Documents

ES9-98 - Rev AG Diesel Spec

Uploaded by

Md AfzanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ES9-98 - Rev AG Diesel Spec

Uploaded by

Md AfzanCopyright:

Available Formats

Specification No.

ES 9-98AG

Table 7. Distillate Fuels - Physical and Chemical Requirements (see Note 2)

Physical and Chemical ES9-98 Limits Test Methods

Descriptions

Sulfur See Table 1 D2622, D4294, D5453 or

D7220.

Aromatics 35% by volume maximum. ASTM D1319 and D6591

(see Note 1)

Carbon residue on 10% < 0.35%. ASTM D524

distillation residue

Cloud point At least 10oF (6oC) below expected minimum ASTM D2500

ambient temperature.

Copper strip corrosion No 3 (3hr at 122oF (50oC)). ASTM D130

Distillation 90% distillation temperature from 540F (282oC) ASTM D86

to 640oF (338oC).

End point at 690oF (366oC) maximum.

Flash point > 100 oF (38oC) or > legal limit. ASTM D93

Fuel Bound Nitrogen Measurement required for liquid emissions ASTM D4629 or D5762

guarantees

LHV >18,000 Btu/lb, >41838 kJ/kg. ASTM D240

Lubricity, HFRR @ 60oC 520 micron maximum. ASTM D6079

Olefins and Diolefins 5% by volume maximum. ASTM D1319

Pour point At least 10oF (6oC) below cloud point. ASTM D97

Reid vapor pressure < 3 psia, < 20.6 kPa ASTM D323

Specific Gravity 0.775 - 0.875 ASTM D1298

Viscosity, Kinematic 1 - 12 centistokes at 100oF (38oC) ASTM D445

Notes:

1) Use ASTM D5186 for fuels having final boiling points over 600F.

2) These fuel properties are established at the refinery. If the project fuel exceeds these limits, it

will not be treatable through centrifuge or filtration at site. If any property deviates from these

limits, approval from Solar is required.

Caterpillar: Confidential Green 14

Specification No. ES 9-98AG

Table 8. Distillate Fuels - Contaminant Limits (see Notes 1 & 2)

Description of Contaminants ES9-98 Limits Test Methods

Ash (see Note 2) < 0.01 % maximum. ASTM D482

Liquid, Water < 0.25 cc free water per liter at an ambient ASTM D6304

temp of 80oF (27oC)

Sodium & Potassium See Table 1. ASTM D3605 or

D7111

Solids <2.6 mg/liter of sediment, solid or hard ASTM D6217

contaminants, 90% of the 2.6 mg shall be less

than 5 micron in size. Max allowable size < 10

micron

Calcium & Magnesium See Table 1. D3605, D511 or

D7111

Chlorine See Table 1. ASTM D512

Fluorine See Table 1. ASTM D1179

Lead See Table 1. ASTM D3605,

D3559 or D7111

Vanadium (see Note 2) See Table 1. ASTM D3605,

D3373 or D7111

Others – Aluminum + Silicon, Antimony, See Table 1. ASTM D7111

Arsenic, Bismuth, Boron, Cadmium, Gallium,

Indium, Mercury and Phosphorous

Notes:

1) If the project fuel exceeds these contaminant limits, fuel must be treated to achieve full contaminant

quality compliance.

2) Non-compliant fuel-bound organometallic contaminants are not treatable by centrifuge

a. Multiple Fuel Sources - If more than one fuel source is available, individual fuel

analyses of all fuel sources must be submitted to review to ensure proper fuel

handling.

8.2.1 BIODIESEL - Biodiesel is a fuel that is typically made from various sources including

vegetable oils, animal fat and used cooking oils. The oils or animal fats are chemically processed to

form a fatty acid methyl ester (FAME). Raw oils from vegetables, animal fats and/or waste cooking

oils are not considered to be a biodiesel fuel. The biodiesel is typically blended with the diesel fuel

and the fuel blend should not exceed 20 percent (%) by volume and this is referred as B20 biodiesel

fuel. Any biodiesel blend above B20 must be reviewed by Solar. The fuel quality must meet the

requirements listed in Table 7, 8 and 9.

Table 9. Biodiesel Fuels - Physical and Chemical Requirements

Biodiesel (B20) Properties Test Method Limits

Biodiesel/Fatty Acid methyl Ester ASTM D7371 20% by volume maximum

(FAME)

Methanol EN 14110 0.05% wt maximum

Oxidation Stability EN 14112 6 hours minimum

Acid Number ASTM D664 0.3 KOH/g maximum

Monoglyceride ASTM D6584 0.1% wt maximum

Diglyceride ASTM D6584 0.05% wt maximum

Triglyceride ASTM D6584 0.05% wt maximum

Free Glycerin ASTM D6584 0.005 % wt maximum

Total Glycerin ASTM D6584 0.05% wt maximum

Caterpillar: Confidential Green 15

Specification No. ES 9-98AG

Table 1. Maximum Allowable Contaminant Concentrations

Limit(Note 1) in Fuel Equivalent

Contaminant Test Method

Concentrations

10,000 ppmw FEC (See note 5A, 5B,

Sulfur (see Notes 2, 3, & 5C & 6). ASTM D1072, D1266, D2622,

4) Additional restrictions apply for D4294, D5453 or D7220.

SoLoNOx liquid operation (See note 6)

Sodium + Potassium 0.5 ppmw FEC ASTM D3605 or D7111

Vanadium 0.5 ppmw FEC ASTM D3605, D3373 or D7111

Lead 1 ppmw FEC ASTM D3605, D3559 or D7111

Calcium + Magnesium 2 ppmw FEC ASTM D3605, D511 or D7111

Fluorine 1 ppmw FEC ASTM D1179, D3868

Chlorine 0.15 weight percent or 1,500 ppmw FEC ASTM D512, D808, D1253,

Others (See Notes 7 & 8) 0.5 ppmw FEC

Notes:

(1) The limits given are FUEL EQUIVALENT CONCENTRATIONS (FEC), i.e., the maximum allowable

concentration of each contaminant as if each contaminant is found solely in a fuel with LHV - 18,380

Btu/lb. (such as diesel #2). Instructions for performing calculations are provided in Appendix A, Form

3091, Total Site Contamination Worksheet.

(2) For installations with exhaust heat recovery equipment, it is important to maintain sulfur levels at below

the SO3 dew point. Because conversion from SO 2, to SO3 in the combustor is a function of several

factors that are not readily definable, it is recommended that fuel sulfur is limited to less than 0.5%

weight FEC. This value is based on 60:1 air-to-fuel ratio at up to 17% conversion for an acid dew point

of 240F.

(3) If sulfur is present in the form of hydrogen sulfide, appropriate precautions must be taken to detect

leaks because of the highly toxic nature of this gas even in trace quantities. High sulfur fuels

(exceeding limits) may be used with special provisions; however, such fuels must be reviewed and

approved in writing by Engineering prior to use.

(4) U.S. Federal and local Air Pollution control districts may require lower limits for sulfur.

(5A) Harsh environment protection hardware and ancillary equipment is required for gas fuel with H 2S

concentration greater than 3000 ppmw FEC or liquid fuel with sulfur concentration more than 2000

ppmw FEC.

(5B) Sites with alkali-laden air (Marine, salt beds, salt mines), poor ambient air quality or proximity to sulfur

sources require harsh environment protection hardware regardless of sulfur levels.

(5C) Higher sulfur levels (> 10,000 ppmw FEC) can be considered for a specific application and must be

approved in writing by engineering.

(6) Liquid fuel sulfur content limits and specific fuel handling and storage requirements are required for

SoLoNOx liquid fuel operation. Low emissions on diesel fuel require lower sulfur limits. Restrictions

do not apply to kerosene or jet fuel A. See section 10.1.

(7) The following contaminants are unlikely to be present except in unusual or accidental contamination

of air, fuel or water supplies. However, if detected at levels greater than 0.5 ppmw FEC fuel

equivalent, special treatment and precautions are required.

Mercury – Cadmium – Bismuth – Arsenic – Indium – Antimony – Phosphorous – Boron -

Gallium –Aluminum + Silicon.

(8) Any other trace element with concentrations over 0.5 ppmw FEC fuel equivalent should be discussed with,

and reviewed, by Engineering.

Caterpillar: Confidential Green 4

You might also like

- Gas Sweetening and Processing Field ManualFrom EverandGas Sweetening and Processing Field ManualRating: 4 out of 5 stars4/5 (7)

- Cummins G12 Diesel Fuel Oil Use in Aggreko EnginesDocument2 pagesCummins G12 Diesel Fuel Oil Use in Aggreko EnginesAhmed AbdullahNo ratings yet

- Corrosion and Materials Selection: A Guide for the Chemical and Petroleum IndustriesFrom EverandCorrosion and Materials Selection: A Guide for the Chemical and Petroleum IndustriesNo ratings yet

- Shellsol D 60 TDSDocument7 pagesShellsol D 60 TDSMichael SimoniNo ratings yet

- Test Specifications For Biodiesel FuelDocument6 pagesTest Specifications For Biodiesel FuelYariela CedeñoNo ratings yet

- Acetone SHELL SPEC 2010 PDFDocument3 pagesAcetone SHELL SPEC 2010 PDFLuka BraciNo ratings yet

- Jordan Petroleum Refinery Co. Ltd. Diesel Specification QS-PL 112 Laboratories & Quality Control DepartmentDocument2 pagesJordan Petroleum Refinery Co. Ltd. Diesel Specification QS-PL 112 Laboratories & Quality Control DepartmentMohammed Nuseir100% (1)

- 17 - Dcn8015enDocument4 pages17 - Dcn8015enJustice MachiwanaNo ratings yet

- Polar Premiuim Long Life Pro TDS EngDocument4 pagesPolar Premiuim Long Life Pro TDS EngwesmaNo ratings yet

- Eswp 111 Testing Fuel For Generators Drilldown of Nfpa 110 and Astm d975Document4 pagesEswp 111 Testing Fuel For Generators Drilldown of Nfpa 110 and Astm d975MOHAMED BOUDENNo ratings yet

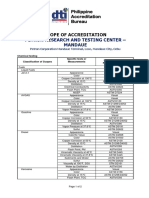

- Scope of Accreditation PRTC MandaueDocument2 pagesScope of Accreditation PRTC MandaueKent DoyuhimNo ratings yet

- TDS - Shellsol GP1 Ex Shell - 06 March 2012Document2 pagesTDS - Shellsol GP1 Ex Shell - 06 March 2012Fadhli KusumaNo ratings yet

- S-Oil+hydro+fluid TDS PDFDocument1 pageS-Oil+hydro+fluid TDS PDFphucdc095041No ratings yet

- Premium Gasoline 91 RONDocument1 pagePremium Gasoline 91 RONbohdanturgenevNo ratings yet

- Scope of Accreditation ITS GUAM CHEM IADocument3 pagesScope of Accreditation ITS GUAM CHEM IAJaz DeNo ratings yet

- Jordan Petroleum Refinery Co. Ltd. L. P.G Specification QS-PL 101 Laboratories & Quality Control DepartmentDocument1 pageJordan Petroleum Refinery Co. Ltd. L. P.G Specification QS-PL 101 Laboratories & Quality Control DepartmentMohammed NuseirNo ratings yet

- API Engine Oil Classifications Infineum 2017Document12 pagesAPI Engine Oil Classifications Infineum 2017iosalcido100% (1)

- 4376 Industrial Gear Oil CLP 320Document1 page4376 Industrial Gear Oil CLP 320ralish12No ratings yet

- Standard Specification of Russian Export Blend Crude Oil REBCODocument1 pageStandard Specification of Russian Export Blend Crude Oil REBCOВиктор Владимирович100% (1)

- Pmma-Lg Pmma Ih 830a (Natural)Document1 pagePmma-Lg Pmma Ih 830a (Natural)AVLight AutomotivesNo ratings yet

- Datasheet KetonesmibkasiapacificDocument3 pagesDatasheet Ketonesmibkasiapacificnitin birajdarNo ratings yet

- Shellsol A150 ND q7497 Eu 18042016Document3 pagesShellsol A150 ND q7497 Eu 18042016sizmaruNo ratings yet

- Xylene T1404 TDS - 10-3-2016Document2 pagesXylene T1404 TDS - 10-3-2016Faez Ahammad MazumderNo ratings yet

- Shellsol T q7412 AmDocument3 pagesShellsol T q7412 AmRagavendra Prabu GovindarajuNo ratings yet

- 450F HsdviDocument2 pages450F HsdviJoJo kNo ratings yet

- Central West SpecificationsDocument67 pagesCentral West Specificationseko handoyoNo ratings yet

- Spesifikasi B35Document1 pageSpesifikasi B35Jofanny Ferdian RahmansyahNo ratings yet

- Jordan Petroleum Refinery Co. Ltd. Kerosene Specification QS-PL 111 Laboratories & Quality Control DepartmentDocument1 pageJordan Petroleum Refinery Co. Ltd. Kerosene Specification QS-PL 111 Laboratories & Quality Control DepartmentMohammed NuseirNo ratings yet

- Quality Control of Products in Petroleum RefiningDocument29 pagesQuality Control of Products in Petroleum RefiningAdrian RodriguezNo ratings yet

- Shellsol T q7412 PDFDocument3 pagesShellsol T q7412 PDFmeNo ratings yet

- Aeroshell Calibrating Fluid 2Document2 pagesAeroshell Calibrating Fluid 2Ricardo LacskoNo ratings yet

- D 117 - 10 PDFDocument16 pagesD 117 - 10 PDFali basimNo ratings yet

- Shellsol A150 q7493 Eu 18042016Document3 pagesShellsol A150 q7493 Eu 18042016Henry FloresNo ratings yet

- Sasol Sales - Spec - 8Document1 pageSasol Sales - Spec - 8Shailesh JainNo ratings yet

- Shellsol 2046 Ar: Technical DatasheetDocument3 pagesShellsol 2046 Ar: Technical DatasheetJavier Godoy MirandaNo ratings yet

- TDS Luban HDPE Blow-DMDA 6200Document2 pagesTDS Luban HDPE Blow-DMDA 6200Nazmul - Polymet SANo ratings yet

- ASTM D 130-10 - Corrosiveness To Copper From Petroleum Products by Copper Strip TestDocument9 pagesASTM D 130-10 - Corrosiveness To Copper From Petroleum Products by Copper Strip TestAnak Ayam100% (1)

- Din/ Iso Astm RangeDocument2 pagesDin/ Iso Astm RangeSumitBhaumikNo ratings yet

- Implementasi B35 Rev01Document21 pagesImplementasi B35 Rev01ppd brcgNo ratings yet

- Ceypetco SpecificationDocument1 pageCeypetco Specificationbasharat121No ratings yet

- Shell Saraline 185V TDSDocument3 pagesShell Saraline 185V TDSYanu Ismadi100% (2)

- PDS Aramco PP CP390N Rev 20180116Document1 pagePDS Aramco PP CP390N Rev 20180116Bogdan ShevchenkoNo ratings yet

- Certificate of Analysis: Requirements Results TestDocument1 pageCertificate of Analysis: Requirements Results TestJJoseNo ratings yet

- Zerex G05 Antifreeze Coolant ValvolineDocument3 pagesZerex G05 Antifreeze Coolant ValvolineFloyd PriceNo ratings yet

- Astm D130 PDFDocument10 pagesAstm D130 PDFPedro Alua100% (2)

- Aramco PP CP390NA: PolypropyleneDocument1 pageAramco PP CP390NA: PolypropylenesubakialamNo ratings yet

- Gasoil Specification SPC 2016Document1 pageGasoil Specification SPC 2016Mohamed GasimNo ratings yet

- Primax 97 (Euro 2m Ron97 Gasoline)Document1 pagePrimax 97 (Euro 2m Ron97 Gasoline)batugiokNo ratings yet

- QP Report of JetDocument3 pagesQP Report of Jetbj100% (1)

- Esterex™ TM111: Synthetic FluidDocument2 pagesEsterex™ TM111: Synthetic FluidDinesh babuNo ratings yet

- Super Gasoline 95 RONDocument1 pageSuper Gasoline 95 RONxtrooz abiNo ratings yet

- 009 Polyester Ortho SP 5119 Am Tds Amr Egypt Pa. No 4Document1 page009 Polyester Ortho SP 5119 Am Tds Amr Egypt Pa. No 4Yousef LotfyNo ratings yet

- Synesstic12 TDSDocument2 pagesSynesstic12 TDScotteNo ratings yet

- Shell Turbo Oil J 32Document2 pagesShell Turbo Oil J 32Agus F RahmanNo ratings yet

- Lexan™ 8010 Uncoated Polished Film DatasheetDocument3 pagesLexan™ 8010 Uncoated Polished Film DatasheetTeng Yan ChanNo ratings yet

- Mobil Diesel Oil B20 Marketing SpecDocument3 pagesMobil Diesel Oil B20 Marketing SpecsatriasinagaNo ratings yet

- TDS DNDC 7152 AstmDocument2 pagesTDS DNDC 7152 AstmOsamah JoubsenNo ratings yet

- SQ1 Mogas95Document1 pageSQ1 Mogas95Basant Kumar SaxenaNo ratings yet

- Comparison Oil TestDocument2 pagesComparison Oil Testdede azandriNo ratings yet

- NETZSCH Dispersionizer Omega ENDocument8 pagesNETZSCH Dispersionizer Omega ENMd AfzanNo ratings yet

- Instruction Manual For CFD Energy TransportDocument17 pagesInstruction Manual For CFD Energy TransportMd AfzanNo ratings yet

- Etiqa Family Takaful - Panel Hospitals - FY2022Document3 pagesEtiqa Family Takaful - Panel Hospitals - FY2022Md AfzanNo ratings yet

- MLP GlobalGraduateTalentProgramme2021Document1 pageMLP GlobalGraduateTalentProgramme2021Md AfzanNo ratings yet

- List of Companies Vacancies DetailsDocument6 pagesList of Companies Vacancies DetailsMd AfzanNo ratings yet

- BAYAN MDR - Updated 15 June 2021Document1 pageBAYAN MDR - Updated 15 June 2021Md AfzanNo ratings yet

- Industy Code of Practice For Safe Working in A Confined Space 2010Document80 pagesIndusty Code of Practice For Safe Working in A Confined Space 2010Abd Rahim100% (2)

- Hope You Enjoyed Your Ride!: JustgrabDocument1 pageHope You Enjoyed Your Ride!: JustgrabMd AfzanNo ratings yet

- Distillation ColumnsDocument6 pagesDistillation ColumnsSK ChuaNo ratings yet

- Prelim FindingsDocument17 pagesPrelim FindingsMd AfzanNo ratings yet

- Experienced - Resourceful - Timeliness: Hysys Ansys Pipenet Pipesim Flarenet OlgaDocument1 pageExperienced - Resourceful - Timeliness: Hysys Ansys Pipenet Pipesim Flarenet OlgaMd AfzanNo ratings yet

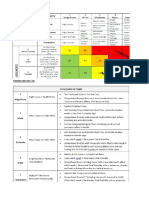

- HAZID TemplateDocument38 pagesHAZID TemplateMd AfzanNo ratings yet

- Request For Confirmation Complete - Graduation Letter v2Document1 pageRequest For Confirmation Complete - Graduation Letter v2Md AfzanNo ratings yet

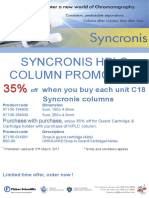

- HPLC Column Promo Flyer-Page2 - Oct 2016Document1 pageHPLC Column Promo Flyer-Page2 - Oct 2016Md AfzanNo ratings yet

- Terms and Conditions (Final) - FGFDocument3 pagesTerms and Conditions (Final) - FGFMd AfzanNo ratings yet

- Innovate PromoDocument15 pagesInnovate PromoMd AfzanNo ratings yet

- ASTM D 882-02 - Thin-Plastic-Sheeting PDFDocument10 pagesASTM D 882-02 - Thin-Plastic-Sheeting PDFzeqs9No ratings yet

- Normal Abnormal Operation PDFDocument21 pagesNormal Abnormal Operation PDFMd AfzanNo ratings yet

- Qatari AirwayDocument4 pagesQatari AirwayReband AzadNo ratings yet

- Requirement OutlineDocument2 pagesRequirement OutlineMd AfzanNo ratings yet

- Internship at DeleumDocument1 pageInternship at DeleumAiman SyazwanNo ratings yet

- Section A: HKCEE Paper I Running Answer Text 2000 ChemistryDocument11 pagesSection A: HKCEE Paper I Running Answer Text 2000 ChemistryKathy WongNo ratings yet

- Chem 2 Lab 6Document10 pagesChem 2 Lab 6Misael BarradasNo ratings yet

- Reactive Intermediates: Advanced Organic ChemistryDocument58 pagesReactive Intermediates: Advanced Organic ChemistryVaisaakh ElanthoorNo ratings yet

- HSC Chemistry II Board Paper 2013Document2 pagesHSC Chemistry II Board Paper 2013Vaibhav GaikwadNo ratings yet

- Nfpa 497 2012Document1 pageNfpa 497 2012Kaka Baba100% (1)

- Recent Advances in Liquid Organic Hydrogen Carriers: An Alcohol-Based Hydrogen EconomyDocument15 pagesRecent Advances in Liquid Organic Hydrogen Carriers: An Alcohol-Based Hydrogen EconomySajid Mohy Ul Din100% (1)

- Pratice QuestionsDocument7 pagesPratice QuestionsAlabuzhev VladNo ratings yet

- IB Acids and BasesDocument45 pagesIB Acids and BasesAhmad Hajj AliNo ratings yet

- CSEC Chemistry January 2011 P2Document18 pagesCSEC Chemistry January 2011 P2AshleyNo ratings yet

- Reactions of Aliphatic Alcohols and PhenolDocument9 pagesReactions of Aliphatic Alcohols and Phenolmoon star angelNo ratings yet

- Ammonium CarbamateDocument2 pagesAmmonium CarbamateMichely CarvalhoNo ratings yet

- Chrmistry - STD 10 - Hydrogen ChlorideDocument14 pagesChrmistry - STD 10 - Hydrogen ChlorideMohit NaiduNo ratings yet

- Carbonic Hydronium Conc - PDFDocument2 pagesCarbonic Hydronium Conc - PDFbencleeseNo ratings yet

- PracticeTests Answers All Chem360Document109 pagesPracticeTests Answers All Chem360EthanNo ratings yet

- Two-Phase Total Synthesis of Taxanes: Tactics and StrategiesDocument28 pagesTwo-Phase Total Synthesis of Taxanes: Tactics and StrategiesTạ Đình TrungNo ratings yet

- Documents - Tips Solubility of Calcium Soaps of Gum Rosin Rosin Acids and Fatty AcidsDocument2 pagesDocuments - Tips Solubility of Calcium Soaps of Gum Rosin Rosin Acids and Fatty AcidsSaad AhmedNo ratings yet

- Sea Salt Body Scrub Formula: Ingredient Trade Name/Vendor %Document2 pagesSea Salt Body Scrub Formula: Ingredient Trade Name/Vendor %AyoeYoeRamndaniNo ratings yet

- Jiping Liu - Nitrate Esters Chemistry and Technology-Springer (2019) PDFDocument694 pagesJiping Liu - Nitrate Esters Chemistry and Technology-Springer (2019) PDFClaudia Patricia Tapia RiveraNo ratings yet

- F321 Module 1 Practice 3Document7 pagesF321 Module 1 Practice 311pearcerNo ratings yet

- Benzene 2Document9 pagesBenzene 2claimstudent3515No ratings yet

- Daftar Obat-Formularium 2020Document3 pagesDaftar Obat-Formularium 2020Rio HerisonNo ratings yet

- In Vitro Evaluation of Antioxidant Potential of Artocarpus Chama BuchDocument6 pagesIn Vitro Evaluation of Antioxidant Potential of Artocarpus Chama Buchliska ramdanawatiNo ratings yet

- Avra Price List 2019-20Document117 pagesAvra Price List 2019-20nandigama chakradharNo ratings yet

- CN 15 en 05Document19 pagesCN 15 en 05Toni D.No ratings yet

- Dwnload Full Organic Chemistry 9th Edition Ebook PDFDocument51 pagesDwnload Full Organic Chemistry 9th Edition Ebook PDFadolfo.milliken178100% (29)

- Chem2ob3 Final Exam 2013Document22 pagesChem2ob3 Final Exam 2013HadNo ratings yet

- International Abbreviations For Polymers and Polymer ProcessingDocument226 pagesInternational Abbreviations For Polymers and Polymer ProcessingTrevor J. HutleyNo ratings yet

- Lipid PDFDocument5 pagesLipid PDFKhổng Tiến ĐạtNo ratings yet

- PREPARATION OF POTASSIUM ALUMINUM SULFATE, KAl (SO4) 2 - 12H2O (Alum)Document5 pagesPREPARATION OF POTASSIUM ALUMINUM SULFATE, KAl (SO4) 2 - 12H2O (Alum)vinsmoke1No ratings yet

- BS en Iso 6326-3-1998Document14 pagesBS en Iso 6326-3-1998Rasool Fakhraei100% (1)