Professional Documents

Culture Documents

BGCC 23+362 Dynamic Test Report

BGCC 23+362 Dynamic Test Report

Uploaded by

RAJKUMAR CHATTERJEE. (RAJA.)0 ratings0% found this document useful (0 votes)

8 views15 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views15 pagesBGCC 23+362 Dynamic Test Report

BGCC 23+362 Dynamic Test Report

Uploaded by

RAJKUMAR CHATTERJEE. (RAJA.)Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 15

Hitya% Nitya Laboratories

TEST REPORT OF DYNAMIC

PILE LOAD TEST

Name of Project

4 Laning of Jind —Gohana (Pkg: 1) Section from Km.00.000 to Km.40+601 (Project Length

Kim, 40,601) of NH-352a in State of Haryana under Bharatmala Pariyojna under NH (0) to be

Implemented on Hybrid Annuity Model (Ham)

Client

National Highway Authority of In

Independent Engineer

Casta Engineers Private Limited in J.V. With Sowil Limited

Concessionaire

Gohana Sonipat Highway Pvt.Ltd.

Contractor

Brij Gopal Construction Company Pvt. Ltd.

Casting Date

11/02/2023

Testing Date

14/ 03/ 2023

Location of Pile

CH-23-362, (Al) Pile No.03 (LHS)

Report No.:

NL/BLB/2303 1502

Prepared By

Nitya’

Werk for Quality

NITYA LABORATORIES

Address: Plot No.118, Church Road, Behind Kausik Vatika, Bhagat Singh Colony, Ballabgarh,

Faridabad, Delhi NCR, India

Tel.: +91-129-2241021

Mobile No.: +91-981 1062878

E-Mail ID: info@nityalab.com, labsnitya@gmail.com

Website: www.nityalab.com

Laboratories I Faridabad (Haryana) I Jammu J&K)*} Ma age (Karnataka) 1

Hitya® Nitya Laboratories

ok foray

INDEX

Introduction ..

we

Pile Details

z

1

2

3 Test Equipmen

4 PDA Field Testing and Results...

5

6

7

CAPWAP Analysis...

Results...

na

Conclusion ..

Annexure-A...

Annexure-B

Photograph

Nitya’. Nitya Laboratories

1. Introduetion

Mis. Brij Gopal Construction Company had entrusted the work of High-Strain Dynamic

‘Testing of R.C. bored piles installed at Project “Four Lanning of Jind - Gohana Section of

NH-352A.

The aim of testing was to evaluate pile static capacity and measure settlement under applied

load. This report presents the results of dynamic pile testing and analysis using the Pile

Driving Analyzer and CAPWAP Program, The test was conducted in accordance with ASTM

4945-00 on 14/03/2023.

2. Pile Details

Pile No. AI(LHS) |

_ Pile no-03,

Pile length below sensor, m 30.2

Pile length below Cut-off Level, m 30.0

Pile Diameter, mm 1200

Conerete Grade M35

Hammer Weight, Ton 4.5408

Cateulation as

per approved

os Methodology

Required Hammer Weight 42MT.

1.5% of

Design Load

Drop Height, m Lo.

Design Load, Ton 280.0

Safe Load, Ton 420.0

1stime

_ Design Load

Soil data ‘As Geological

Data

Hitya%s Nitya Laboratories

3. Test Equipment

A Pile Driving Analyzer™ and its associated pile top force and velocity transducers were used

to conduct the dynamic pile test.

‘Two strain transducers and two accelerometers were attached to the pile head. They were mounted

‘on opposite sides of the pile to cancel bending effects during each strike of the hammer. The

signals of strain and acceleration were conditioned and processed by PDA.

‘The PDA is a micro-processor-based signal conditioner and digital computer. Signals of pile

top force and velocity were measured and analyzed during each strike of the pile driving

hammer and stored in the Analyzer. The pile top force and velocity —time curves were

displayed on laptop computer screen. Real time analogue

mnals of the pile top force and

velocity were also recorded using the PDA and later stored in the field computer unit.

The PDA onsite uses a program based on closed form Case-Goble solutions to compute static

is subsequently checked with the

computer program CAPWAP to confirm the static pile capacity obtained on site.

pile capacity from the pile top force and velocity data. Thi

4. PDA Field Testing

Dynamic testing on the pile was conducted by striking the pile with hammer for several blows

during the restriking process. During testing of the pile, complete dynamic measurements were

obtained for each hammer blow delivered to the pile.

‘The PDA measures the total (static plus dynamic) resistance acting on the pile. The portion of total

tes

ance that is computed as static resistance by the analyzer is determined by the soil damping

factor Je set into the analyzer. A more accurate independent measure of the applicable

soil-damping factor was determined using a CAPWAP analysis.

The values measured by the PDA on field are obtained assuming that the Pile is uniform

throughout its length. Also, the soil parameters like quake and damping should be assumed

during the field test. Hence the CAPWAP is mandatory for all bored piles to estimate realis

soil parameters as well as pile profile. On field, PDA measures the field capacity while

CAPWAP refines the field the field results and hence field capacities measured using PDA

may not match with the CAPWAP analysis.

Hitya%s Nitya Laboratories

et or culty

‘The BETA value (Integrity Factor) indicates the pile impedance and is derived from the CAPWAP

analysis. The PDA is basically used to compute capacity and the BETA factor. Particularly for

bored piles may never be 100% due to inherentof installation. A BETA factor less than 60%

indicates a shaft with poor integrity.Such shaft may require remedial action in the form of

reduced loads, redesi

ingthe cap or installation of additional pile as recommended by the

design engineer.

[ Integrity (BETA Factor) | Comment —

100% OK

80% - 99% Minor Defect

60% = 80% ‘Some Defect

I <60% Major Defect

‘The PDA field capacity is estimated by either RMX or RSU for an assumed Je value and

‘on the assumption of uniform cross ~ section of the pile. RMX is the maximum Case —

Goble Resistance (Maximum Capacity) for the assume Je value (Case Damping) at the project

site. The RMX capacity generally holds good when the pile shows a reasonable movement

under the load. The RSU capacity is applicable when there is very high skin friction and in

most cases the pile movement is normal. Hence a more real

estimate of the pile

capacity is obtained from the CAPWAP analysis conducted on one typical blow at the end of

testing program,

5. CAPWAP Analysis

A selected PDA field recording of forces and velocity data for a blow delivered tothe piles

was further analyzed using the CAPWAP (Case Pile Wave Analysis Program) computer software.

‘The analysis involved applying the measured pile top velocity time record to the top of a lumped-

mass and spring wave equation model of the pile.

‘The program computes the pile top force-time record and this is then compared to the actual

measured force- time record. The pile and soil resistance model are then adjusted in an

iterative procedure until good match is obtained between measured and computed forces.

The pile and soil models can then be used to determine the estimated static load- settlement curve.

‘The CAPWAP capacities are ultimate values. They must be reduced by means of an appropriate

factor of safety to yield a design or workingload. The results of CAPWAP analysis for a typical

blow is briefly summarized in Annexure-A.

Hlitya®s Nitya Laboratories

ik foray

6. Results

‘The CAPWAP analysis results showed that pile had achieved of First Drop 1.0 Load achieved

489 tons at the time of testing. The capacity is applicable at the time of testing and further soil

strength changes with time had to be considered.

The CAPWAP results showed that the maximum compressive stress experiencedby the pile at the

hammer impact was about 4.5 N/mm?. This stress is within allowable i

was observed to be OK.

its. The

From CAPWAP analysis, the pile top load vs. settlement curve is obtained by simulating stati

load test. The pile top settlement at 555 Tons (equivalent test load for static test) is estimated to be

around 3 mm. Please refer to st

jc analysis in Annexure A.

7. Conclusion

1. The CAPWAP analysis results for Pile showed that it had achieved an activated capacity

of 555.0 Tons at the time of testing which is more thanthe required Test Load of

420.0 Tons.

2. The stresses in the pile were within the acceptable limits during any stage of testing.

3. The pi

integrity was observed OK.

4, This report has been prepared as per guidelines given in ASTM D4945. No other warranty,

expressed or implied, is made. ‘The findings provided in this report are based on the result

of the i

ividual pile tested andinformation made available to us.

Note:

1. The Results given in this report are based on the test conducted at site asper relevant

Code. T

representative of Customer / Owner / Contractor during the site work.

report only represents for Site / Test Location, which indicated, to us by

2. The report shall not reproduce or cannot be produced for any court of law without written

approval of the laboratory.

Witya® Nitya Laboratories

ok for ualty

Annexure-A.

Client + National Highway Authority of India (Ministry of Road Transport & Highway)

Independent Engineer: Casta Engineers Private Limited in J.V. With Sowil Limited

Contractor + Brij Gopal Construction Company.

Location + Ch.23+362 AI Pile no.03 LHS

Testing Date + 14-03-2023

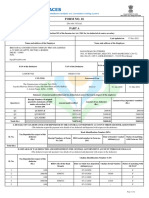

SUMMARY OF CAPWAP ANALYSIS RESULTS

Pile No. Pile-03 | Required /PermissibleLimits

‘Activated pile eapacity in Ton 355.0 1.5 x Design Load

‘Skin Friction in Ton 246.5 =

End Bearing in Ton 2126 ei

Factor of Safety 13 AS Per IS -2911 (IV)

Sale Pile Capacity in Ton 420.0

Total Displacement 3.0

‘Compressive Stress in Nimm* 40 ‘Max 0.85fek

“Tensile Stress in Nima? 103 ‘Max 0.12Fek

(80% - 99% Classified as

Pile Integrity (Below Sensor Level) oK minor defect)

Hitya%s Nitya Laboratories

io ruaiyy

Date of testing: - 14/03/2023

CAPHAP SUMMARY RESULTS

‘Total CAPWAP Capacity: 4590.2; along Shaft 2486.2; at Toe 2104.0 lat

Soil Dist. Depth Ra Force Sun (Unit = Unit «Quake

‘Sgmt ‘Below Below in Pile of Resist. Resist.

Wo. Gages Grade Ru (Depth) (Area)

= = vat vat sat a/m kea =

2

fee ata) ata ara) ee ara) 20.56 1.0

gee tale re) as0'o a sors) 36.81 1.0

300 7a 70 167.5 8 669.4 18.68 1.0

495 84 220.2 7 889.5 24.55 1.0

S19 11.7 180.0 .7 1069.5, 20.08 1.0

(ee ala cle reno) fe 32a14 18.06 0.9

few isle 1 uists) vass'e 0 1465.2 26.08 0.8

e@ 19.0 018.9 a 7 1546.5 9.07 0.9

9 24 2.2 186.8 9 1733.3, 20.84 0.9

wo 23.8 23.6 399.0 9 2132.3 44.50 0.9

ee rr 0 2486.2 39.47 0.9

avg. shatt 226.0 95.62 25.36 0.9

08 2104.0 1260.35 1.0

Soil Mode Paraneters/Extensions Shaft

‘smith Damping Factor 1.78

case Damping Factor 0.43,

Damping Type Viscous

Unloading Quake (% of Loading quake) 30

Reloading Level (8 of Ba) 100

Unloading Level (8 of Ra) 20

CAPWAP match quality = (Wave Up Match) ; RSA = 0

Observed: Final set = 1.0mm; Blow Count. = =~ 1000 b/m

Computed: Final set = 0.2mm; Blow Count = = 9999 b/m

PS (0176) CAL: 248.57 RF: 2-00) FO (49D) CAL: 169.8) RE:W1.00

[AG (E5790) CAL: 360; RF: 1.00; AT (RSBIO) CAL: 367; RF: 1.00,

max. Top Comp. Stress = 4.7 MPa (T= 24.1 me, max= 1.008 x Top)

max. Comp. Stress = 47 we ae 2m, Te 24.1 ms)

max. Tens. Stress 02 MPa (= 0.3 m, T= 37.0 ms)

max. Energy (E100) = 4.6 m3; max, Measured Top Displ. (OMK)= 1.5 mm

Witya%s Nitya Laboratories

ok for ua

Pile Dist. max ins ma eres

Sgant Below Force = Feree © Comp. Tons. ‘Trnst.

No. Gages Stress Stress Energy

= Yat at wpa Mea i

1 0.3 5287.1 -1188.7 7-12.02 as

2 0.7 5290.3. -1158.2 7 1.02 46

‘ 2.0 5302.9 ~1155.5 7 1.02 as

10 3.4 5081.2 1091.4 as -0.97 a3

14 4.8 5107.5 1097.0 as -0.97 43

18 6.1 4701.6 -980.8 42 -0.87 3.8

22 758 4532.4 -927.2 40 0.82 3.6

26 8.8 4583.0 -936.5 a1 0.83 3.6

2010.2 4337.8 -365.8 3.8 -0.77 34

3411.6 4385.0 -875.6 3.90.77 34

3812.9 4190.6 -819.2 37 0.72 3.1

3 aas2a 019.7 3.7 0.72 3a

46 15.6 4054.6 760.5 3.6 0.67 29

5017.0 3772.5 -670.3, 3.3 -0.59 26

54 18.3. 3794.2 -659.9 34-058 26

se 19.7 3705.3 ~619.4 3.3 -0.55 25

62 1 3720.1 608.3 33 70.84 2.5

66 4 2 528.4 32 0.47 23

0 3505.8 -517.1 a2 0.46 23

™ 3007.1 -366.3 2.7 0.32 18

n 3026.0 ~363.9 27 0.32 1s

Absolute ar

-1.02

case MerHoD

= aE aE aE LE LL aL

RP 36513261 2911-2540 «2170-1800 14291089 see 318

x 4252 3052 «3452-3051 2651. ««2251«1900 «159713261055,

RU 2977 -2539«-2102,-«1664 «1226 «788381 ° ° °

Ray = 0 (an; RAZ = 3937 Om

Current CAPWAP Ru = 4590 (KM) ; Corresponding J(RP)= 0.00; J(FX) = 0.00

woe VP so VTez FT]. MSDN SET = EUS, KE,

w/e ome Rm mm mK

0.35 22.64 3629 «3716 «5572-15 «1.01.0 4.7 34S 204

PILE PROFILE AND PILE MODEL

Depth Tee Eodaius Spec. Weight Porin,

= 2 Mea am =

0.0 1.33 4473.8 23.563 3.77

26.2 2.33 3473.8 23.563 a7

‘Toe Area 1.33 =

ilitya%s Nitya Laboratories

Date of testing: - 14/03/2023

Segant Dist. Impedance Imped. Tension Perin, Wave

mumber 8.6. change Slack EE. Speed

min/s 8mm a ows

2 0.3.—«-2616.5 -74.6 0.00 0.000 -0.00 0.000 3.77 3787.8

2 0.7 10293.3 0.0 0.000.000 -0.00 9,000 3.77 3787.8

77 26.2 10283.3 0.0 0.000.000 0.00 0.000 3.77 3787.8,

Wave Speed: Pile Top 3787.8, Elastic 3787.8, Overall 3787.8 m/s

Pile Damping 2.00 8

otal volune: 29.300 a’: Volume ratio considering added impedance: 0.990

Time (ms) 0.0

Tine Incr 0.005

STATIC AUALYSTS

Step Ho. Top Load ‘top Disp oe Disp.

a Ss mm

° 0.0 0.0

82 nea 0.0

166 232.1 00

246 348.2 0.0

328 460.2 on

20 580.3 on

492 696.4 oa

574 e124 on

656 928.5 on

28 1046.5 on

220 aaso.6 02

302 3276.7 02

988 3392.7 02

1066 1508.6 02

ane 1623.6 0.2

3232 73914 02

ai 3055.2 03

1406 1970.4 0.3

as? 2085.5 03

1582 2200.8 0.3

682 2316.7 03

1797 2431.9 0:3

1308 2547.2 oa

2028 2662.3 0

ase 2071.7 oa

2201 2092.9 oa

2434 3008.4 os

3123.8 0.5

za 3238.6 os

2905 3353.4 0.6

3077 3460.4 0.6

3257 3563.4 0.6

10

Nitya’. Nitya Laboratories

Date of testing: - 03/03/2023

STATIC ANALYSIS

Monotonie D-Toe, E-P R-Toe

Step Wo. Top Lead ‘top Diep. ‘toe toad toe Diep.

tt = es ==

3446 25 1393.0 0.7

3645 26 2473.5 07

3ese 27 1556.6 0.7

4086 2 1639.0 oe

4331 29 3720.1 oe

4596 3.0 2799.1 0.9

4985 32 1674.9 0.9

5205 33 1946.2 1.0

5566 34 2010.7 aa

5980 35 2063.8 aa

634s 36 2092.3 12

este 26 2100.7 13

6656 37 2103.0 13

nz 37 2103.6 a3

e740 3.7 2103.8 13

6754 3.7 2103.8 13

76 3.7 2103.8 13

6765 a7 2103.8 13

e167 27 2104.0 13

an 3 2104.0 aa

7987 39 2104.0 as

9597 ao 2io4.o aa

9207 az 2104.0 ae

9817 a3 1s

0427 a4 2.0

31037 as 22

a1s0s a6 22

aa7a9 a6 23

21056 an 23

nsie ar 23

31943 ar 23

asse an 23

11965 ar 23

11969 a7 23

asm an 23

32055 a6 23

32137 as 23

229 as 23

32301, aa 22

32383 a4 22

azees a3 22

a2se7 42 22

2629 42 22

ana an 2a

32793 ao 23

12875 a0 2a

Wityas Nitya Laboratories

ik for uly

Date of testing: - 03/03/2023

STATIC ANALYSIS

Monotonic D-Toe, E-P R-Toe

Step Wo. ‘Top Load, ‘op Disp, Toe Load ‘Toe Disp.

at =m a .

12987 3197.5 3.9 2 22

13038 3081.6 3.9 ia 2a

asiza 2966.6 38 9 2a

asi91 2869.9 3.7 6 2a

13226 2822.2 3.7 5 2a

asa 2797.9 3.7 2 22

33253 2785.8 37 6 2a

13257 2780.4 37 9 2a

13259 27.7 37 a 2a

13260 2716.4 37 7 2a

13261 2775.0 37 3 2a

13348 2660.0 3.6 2 2.0

13438 2544.7 3.5 2.0

13832 2428.9 35 2.0

13620 2313.4 24 2.0

13733 ziga.1 3.3 20

382 2083.3 3.2 18

13959 1967.7 322 Le

14084 1952.2 3a 1

342n7 1736.7 3.0 19

14357 1621.5 29 1

14504 1506.4 2 Le

14659 3391.3 27 2

aasaa 1276.0 26 1

1491 1160.6 25 7

15168 1045.8 24 17

15354 930.7 23 1.7

15549 815.7 22 Le

15756 700.7 2.0 Le

15979 588.0 19 1s

ae21e 479.9 18 1s

16475 377.7 17 at

16755 282.5 16 14

1317063 195.6 1s 13

37409 119.7 1.3 1.3

37802 57.6 12 12

18263 14.8 La aa

Hitya%s Nitya Laboratories

ke fru

Annexure-B

Upward travelling wave signal matching of Routine Pile

13

Nitya’ Nitya Laboratories

ik for ay

tm

Saas ured Free, velocity imp Upm: Wave a evel 0.000

Force x Velocity Impedance Graph of Routine Pile

(cross section {m2}

Depth tm)

Cross Section Area of Pile showing No defect in the Pile throughout the length

4

Nitya Laboratories

hitya’s

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Wire BasketDocument1 pageWire BasketRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- DFS %Document4 pagesDFS %RAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- BGCC PKG-2 265Document1 pageBGCC PKG-2 265RAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- GI SIEVE 31.5aDocument1 pageGI SIEVE 31.5aRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Casagrande ApparatusDocument1 pageCasagrande ApparatusRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Beaker 500 MLDocument1 pageBeaker 500 MLRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Fine Value AppaturausDocument1 pageFine Value AppaturausRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- LateralDocument2 pagesLateralRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Nitya Lab Profile 05.5Document34 pagesNitya Lab Profile 05.5RAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Sehedule GDocument1 pageSehedule GRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Silt ContentDocument2 pagesSilt ContentRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- 3BGCC Jind12092022Document1 page3BGCC Jind12092022RAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- 1BGCC Jind12092022Document1 page1BGCC Jind12092022RAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Methodology of Dynamic PileDocument10 pagesMethodology of Dynamic PileRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Find The Quantity of Cement For 1 m3 of Concrete 6220a0fb68fa98206b0879b2Document2 pagesFind The Quantity of Cement For 1 m3 of Concrete 6220a0fb68fa98206b0879b2RAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- DPR NewDocument166 pagesDPR NewRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Cube Strength & Cylinder StrengthDocument5 pagesCube Strength & Cylinder StrengthRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Report Emulsion SS-1Document1 pageReport Emulsion SS-1RAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Pankaj DocumentDocument11 pagesPankaj DocumentRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Settlement Analysis For Shallow Foundations Elastic Settlement Computed From Theory of ElasticityDocument7 pagesSettlement Analysis For Shallow Foundations Elastic Settlement Computed From Theory of ElasticityRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- PDF - SolverDocument7 pagesPDF - SolverRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- 20MM - 63.150 TonDocument1 page20MM - 63.150 TonRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Report GSBDocument1 pageReport GSBRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- LQM - Ec': A. L/4aterial Source No: Sample Rnforrrration BDocument2 pagesLQM - Ec': A. L/4aterial Source No: Sample Rnforrrration BRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- BGCC M01495Document2 pagesBGCC M01495RAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Reports SoilDocument3 pagesReports SoilRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet