Professional Documents

Culture Documents

Sahkundiyar 29121389 MidExam

Uploaded by

sahkunOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sahkundiyar 29121389 MidExam

Uploaded by

sahkunCopyright:

Available Formats

Developing New Product Gasoil Low Sulphur 50 ppm

SAHKUNDIYAR

29121389

SCHOOL OF BUSINESS AND MANAGEMENT

INSTITUT TEKNOLOGI BANDUNG

TAHUN 2022

SCHOOL OF BUSINESS AND MANAGEMENT 2022 1

SCHOOL OF BUSINESS AND MANAGEMENT 2022 2

1. Introductrion

1.1. Introduction

A. Pertamina Dumai Refinery is one of the Facilities owned by Pertamina/PT. KPI which

located in Dumai, Riau.

Picture 1. Pertamina Refinery

This refinery processing crude oil from Rokan Block (Minas, Duri) also Banyu Urip

from Cepu. The product of Pertamina Dumai Refinery consist of LPG, Gasoline series

(Pertalite, Pertamax), Gasoil 2500 ppm, Gasoil 300 ppm, and Green Coke.

Picture 2. Configuration Pertamina Dumai Refinery

SCHOOL OF BUSINESS AND MANAGEMENT 2022 3

B. Owing to Paris Agreement and commitment all country to reduce GHG emission and

contribute decarbonization activities, one of the challenges for fuel producer is

providing cleaner fuel (lower sulphur content), Currently the gasoil product of

Pertamina has specification around 300 ppm wt, this number is still not meet EURO

IV spec which is maximum sulphur content 50 ppm.

1.2. Problem Statement

Pertamina Dumai Refinery is challenged to produce new product gasoil 50 ppm (EURO

IV comply), it is big challenge since previously no experience yet but from the design

stream of Dumai Refinery it is possible for producing gasoil 50 ppm from Hydrocracker.

Further analysis and evaluation need to be conducted to ensure the method of production

and facility needed.

2. Methodology

2.1. Literature Review

A process is a sequence of steps that transforms a set of inputs into a set of outputs. Most

people are familiar with the idea of physical processes, such as those used to bake a cake

or to assemble an automobile. A product development process is the sequence of steps or

activities that an enterprise employs to conceive, design, and commercialize a product.

Many of these steps and activities are intellectual and organizational rather than physical.

Some organizations define and follow a precise and detailed development process, while

others may not even be able to describe their process. Furthermore, every organization

employs a process at least slightly different from that of every other organization. In fact,

the same enterprise may follow different processes for each of several different types of

development projects

The generic product development process consists of six phases, as illustrated in Exhibit

2-2. The process begins with a planning phase, which is the link to advanced research and

technology development activities. The output of the planning phase is the project’s

mission statement, which is the input required to begin the concept development phase

and which serves as a guide to the development team. The conclusion of the product

development process is the product launch, at which time the product becomes available

for purchase in the marketplace

One way to think about the development process is as the initial creation of a wide set of

alternative product concepts and then the subsequent narrowing of alternatives and

increasing specification of the product until the product can be reliably and repeatably

produced by the production system. Note that most of the phases of development are

defined in terms of the state of the product, although the production process and marketing

plans, among other tangible outputs, are also evolving as development progresses. Another

way to think about the development process is as an information-processing system. The

process begins with inputs such as the corporate objectives, strategic opportunities,

available technologies, product platforms, and production systems. Various activities

process the development information, formulating specifications, concepts, and design

details. The process concludes when all the information required to support production

and sales has been created and communicated. A third way to think about the development

process is as a risk management system. In the early phases of product development,

SCHOOL OF BUSINESS AND MANAGEMENT 2022 4

various risks are identified and prioritized. As the process progresses, risks are reduced as

the key uncertainties are eliminated and the functions of the product are validated. When

the process is completed, the team should have substantial confidence that the product will

work correctly and be well received by the market. Exhibit 2-2 also identifies the key

activities and responsibilities of the different functions of the organization during each

development phase. Because of their continuous involvement in the process, we choose to

articulate the roles of marketing, design, and manufacturing. Representatives from other

functions, such as research, finance, project management, field service, and sales, also

play key roles at particular points in the process. The six phases of the generic

development process are:

a. Planning: The planning activity is often referred to as “phase zero” because it precedes

the project approval and launch of the actual product development process. This phase

begins with opportunity identification guided by corporate strategy and includes

assessment of technology developments and market objectives. The output of the

planning phase is the project mission statement, which specifies the target market for

the product, business goals, key assumptions, and constraints

b. Concept development: In the concept development phase, the needs of the target

market are identified, alternative product concepts are generated and evaluated, and

one or more concepts are selected for further development and testing. A concept is a

description of the form, function, and features of a product and is usually accompanied

by a set of specifications, an analysis of competitive products, and an economic

justification of the project

c. System-level design: The system-level design phase includes the definition of the

product architecture, decomposition of the product into subsystems and components,

preliminary design of key components, and allocation of detail design responsibility

to both internal and external resources. Initial plans for the production system and final

assembly are usually defined during this phase as well. The output of this phase usually

includes a geometric layout of the product, a functional specification of each of the

product’s subsystems, and a preliminary process flow diagram for the final assembly

process

d. Detail design: The detail design phase includes the complete specification of the

geometry, materials, and tolerances of all of the unique parts in the product and the

identification of all of the standard parts to be purchased from suppliers. A process

plan is established and tooling is designed for each part to be fabricated within the

production system. The output of this phase is the control documentation for the

product—the drawings or computer files describing the geometry of each part and its

production tooling, the specifications of the purchased parts, and the process plans for

the fabrication and assembly of the product

e. Testing and refinement: The testing and refinement phase involves the construction

and evaluation of multiple preproduction versions of the product. Early (alpha)

prototypes are usually built with production-intent parts—parts with the same

geometry and material properties as intended for the production version of the product

but not necessarily fabricated with the actual processes to be used in production

f. Production ramp-up: In the production ramp-up phase, the product is made using the

intended production system. The purpose of the ramp-up is to train the workforce and

to work out any remaining problems in the production processes. Products produced

during production ramp-up are sometimes supplied to preferred customers and are

carefully evaluated to identify any remaining flaws

SCHOOL OF BUSINESS AND MANAGEMENT 2022 5

2.2. Methodology

The methodology applied for developing new product gasoil 50 ppm can be described as

follow:

3. Analysis

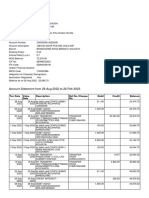

3.1. Analyze the Data

From the lab analysis data, it is known that there is possibility Pertamina Dumai able to

produce Gasoil 50 ppm from Hydocracker. The stream of each Plant in Pertamina Dumai

as follow:

Table.1 Product Stream of Gasoline component in Pertamina Dumai

From above data, it can be seen that Gasoil 50 ppm can be produced from Plant

Hydrocracker which is the suplhur <10 ppm. The challenge is we don’t have any

method/procedure how to develop new product yet.

Tabel 2.Complete specification of Gasoil 50 ppm

SCHOOL OF BUSINESS AND MANAGEMENT 2022 6

4. Result and Conclusion

4.1. Result and Explanation

Regarding the product development and design, it is challenging to produce new product

Gasoil 50 ppm, since this slate of product was never produced before, several activities

which can done as follow:

a. Planning

In the planning step, the main activities are identified what is the current situation of

stream quality data, then prepare the action item need to be taken. From the analysis

data it is known that gasoil 50 ppm could be produced from Hydrocracker Plant, but

this early data should be followed up by evaluation, modification further.

In the end of Planning phase decided several target as follow:

- Project mission: to develop and launch new product gasoil 50 ppm

- Specific target market: high technology/end cars which need better fuel quality,

everyone who prioritize high quality fuel for their cars,

- Business goal: to produce and sell gasoil 50 ppm since the price is higher than

- Initial plan how to realize commercial production of the new product

b. Concept development

In the concept development, we need to develop some detail of the fundamental of

new product development as follow:

- Target Market: high technology/end cars which need better fuel quality, everyone

who prioritize high quality fuel for their cars,

- New Product concept creation: consist of several activities such are data gathering,

analysis and evaluation stream product to meet gasoil 50 ppm spec, review the

production facilities (line and storage tank, lifting)

- The economic impact of this new development product is quite interesting as

follow:

Table 3. Financial Impact Estimate

SCHOOL OF BUSINESS AND MANAGEMENT 2022 7

c. System Level Design

To produce gasoil 50 ppm the scheme that can implemented as follow

- Stream Kerosene and gasoil from HCU will be blend in line/sequently into

dedicated storage tank, after the production finished then the product will be

analyzed as gasoil 50 ppm.

- The on-spec gasoil 50 ppm will be lifting to the vessel

Picture 3. Scheme for producing new product gasoil 50 ppm

- Refer evaluation and lab analysis, the blending composition for producing gasoil

50 ppm will be 85% Kerosene HCU and 15% Solar HCU with final quality as

follow (on spec):

Tabel 3. Lab Analysis for blending composition

SCHOOL OF BUSINESS AND MANAGEMENT 2022 8

d. Testing and refinement

After conducting lab scale test, then it is needed to verify actual Plant for producing

Gasoil 50 ppm

Table 4. Item checking list for producing new gasoil 50 ppm

After checking all option for producing Gasoil 50 ppm, also ensure facilities needed it

is concluded that Pertamina Dumai is able to produce Gasoil 50 ppm

e. Production ramp-up

Before production ramp up, it is needed to develop system and procedure for ensuring

that the production process from step production planning, execution, analysis, and

sales/lifting.

- Establisht work procedure which covering method for producing gasoil 50 ppm

- Establish management of change related facilities (line and storage tank, etc) in

order ensuring that production activity of gasolil 50 ppm will meet the quality

aspect and safe

- Execute production new gasoil 50 ppm with previous blending composition and

utilize the facilities that has been prepared

- Lifting/sale the on spec gasoil 50 ppm to the customer

4.2. Conclusion

Pertamina Dumai refinery has hig possibility to produce new product gasoil 50 ppm since

there is Plant Hydrocracker which can produce low sulphur product. The main challenging

that there were no method and no further evaluation conducted to produced new product.

By conduncting several activities product and design development (planning, concept

development, system level design, detail design, testing and production ramp up) then new

product gasoil 50 ppm can be produced.

SCHOOL OF BUSINESS AND MANAGEMENT 2022 9

Reference:

- Ulrich, Eppinger. Product Design and Development

- SBM ITB. (2022). Process Design and Analysis. Bandung: SBM ITB.

- SBM ITB. (2022). Project Management. Bandung: SBM ITB

SCHOOL OF BUSINESS AND MANAGEMENT 2022 10

Exhibit

List of Figure:

Figure 1. Pertamina Refinery

Figure 2. Configuration Pertamina Dumai Refinery

Figure 3. Scheme for producing new product gasoil 50 ppm

List of Table:

Table 1. Product Stream of Gasoline component in Pertamina Dumai

Table 2. Complete specification of Gasoil 50 ppm

Table 3. Financial Impact Estimate

Table 4. Item checking list for producing new gasoil 50 ppm

SCHOOL OF BUSINESS AND MANAGEMENT 2022 11

You might also like

- Develop Compact Dishwasher DoorDocument44 pagesDevelop Compact Dishwasher DoorSaikiran KandunuriNo ratings yet

- 15me835 PLCM Module 3Document24 pages15me835 PLCM Module 3prashanth prabhuNo ratings yet

- Chemical Process Design & EconomicsDocument46 pagesChemical Process Design & Economicskatamani temple100% (2)

- Operations and Supply Chain Management Week 3Document6 pagesOperations and Supply Chain Management Week 3Rhyn RutherfordNo ratings yet

- New Product Development WikipediaDocument9 pagesNew Product Development WikipediaBreylin CastilloNo ratings yet

- New Product Development - WikipediaDocument52 pagesNew Product Development - Wikipediaatreyee dalal chowdhuryNo ratings yet

- PPC - Unit 2 - Part 2Document10 pagesPPC - Unit 2 - Part 2virk42000No ratings yet

- Ingeniero de ProductoDocument27 pagesIngeniero de ProductoJuan Diego Arroyave SernaNo ratings yet

- New Product DevelopmentDocument9 pagesNew Product Developmenthmltdt9221No ratings yet

- Development Process and OrganizationDocument30 pagesDevelopment Process and OrganizationHapsoro Agung JatmikoNo ratings yet

- Process Management Engineering Design Ideation Design ManufacturingDocument5 pagesProcess Management Engineering Design Ideation Design ManufacturingPraWin KharateNo ratings yet

- Chapter 3 Design of Products & ServicesDocument15 pagesChapter 3 Design of Products & ServicesAbdullah Bin SerajNo ratings yet

- Solutions Manual: Software Quality AssuranceDocument122 pagesSolutions Manual: Software Quality AssuranceSanapala Amit100% (1)

- New Product Processes: Lecture By: Dr. Y.S. Cheah Sunway University Business School Sunway UniversityDocument38 pagesNew Product Processes: Lecture By: Dr. Y.S. Cheah Sunway University Business School Sunway UniversitypeachNo ratings yet

- Operations ManagementDocument6 pagesOperations ManagementAjit DasNo ratings yet

- Topic 7 Design For Quality Product and Product Excellence StudentsDocument7 pagesTopic 7 Design For Quality Product and Product Excellence StudentsMonica Pablo SabadoNo ratings yet

- 3P Lean Production Preparation PDFDocument12 pages3P Lean Production Preparation PDFshan4600100% (2)

- Chapter No Chapter Name 1 2 Company Profile 3 An Over View of Company Department 4 Production ProcessDocument28 pagesChapter No Chapter Name 1 2 Company Profile 3 An Over View of Company Department 4 Production ProcessNithin Raj AnchanNo ratings yet

- ApuntesDocument9 pagesApuntesap9515No ratings yet

- Operations and Supply Chain Management 15th EditionDocument18 pagesOperations and Supply Chain Management 15th EditionKimNo ratings yet

- Product DevtDocument26 pagesProduct DevtRalph Gene Trabasas FloraNo ratings yet

- Process Design Analysis BreakdownDocument2 pagesProcess Design Analysis Breakdownanushka goelNo ratings yet

- AcknowledgementDocument51 pagesAcknowledgementmonirba48No ratings yet

- ASSIGNMENT 1 Oct 2022 - OPM545 - FinalDocument7 pagesASSIGNMENT 1 Oct 2022 - OPM545 - FinalMuhammad Syafiq AbdullahNo ratings yet

- Various Stages in New Product DevelopmentDocument16 pagesVarious Stages in New Product DevelopmentSadanand GundareNo ratings yet

- ASSIGNMENTDocument8 pagesASSIGNMENTwkbg5pw8mkNo ratings yet

- Innovation Management How Ensure Business Competitiveness SustainabilityDocument25 pagesInnovation Management How Ensure Business Competitiveness SustainabilityRached LazregNo ratings yet

- General Overall Design ConsiderationsDocument4 pagesGeneral Overall Design ConsiderationsJuan Manuel Chavarria SoteloNo ratings yet

- An Overview of Chemical Process Design EngineeringDocument8 pagesAn Overview of Chemical Process Design EngineeringAzri RazakNo ratings yet

- The Product Manager and The ProductDocument24 pagesThe Product Manager and The ProductRohitkumariluNo ratings yet

- SDLC Process Model & Spiral Model OverviewDocument4 pagesSDLC Process Model & Spiral Model OverviewParvathi GoudNo ratings yet

- Pensonic Blender DFMA (Group 1)Document51 pagesPensonic Blender DFMA (Group 1)Shf Kamaludin100% (3)

- Process structure overviewDocument2 pagesProcess structure overviewnavi vermaNo ratings yet

- Process Selection, Design and Analysis Chapter SummaryDocument8 pagesProcess Selection, Design and Analysis Chapter SummaryBless YacatNo ratings yet

- Redesigning A Product Strategy For Alignment To ManagementDocument9 pagesRedesigning A Product Strategy For Alignment To ManagementLuis BarretoNo ratings yet

- Engineering Department ProcedureDocument29 pagesEngineering Department ProcedureOmar Ahmed Elkhalil100% (1)

- Product & Project Life Cycle MGMTDocument23 pagesProduct & Project Life Cycle MGMTsjindal02No ratings yet

- ProdMan Unit 3Document5 pagesProdMan Unit 3Jenalyn floresNo ratings yet

- Tugas Supply Chain ManagementDocument11 pagesTugas Supply Chain ManagementRobert ParkNo ratings yet

- A Quality Software Process For Rapid Application DevelopmentDocument17 pagesA Quality Software Process For Rapid Application DevelopmentTøn Hømmë Dė CønfïancėNo ratings yet

- Quality Improvement Methodologies For Continuous Improvement of Production Processes and Product Quality and Their EvolutionDocument6 pagesQuality Improvement Methodologies For Continuous Improvement of Production Processes and Product Quality and Their EvolutionMike CardenasNo ratings yet

- R&D ManagementDocument35 pagesR&D ManagementUsha Vaidehi100% (1)

- Generic Product Development ProcessDocument3 pagesGeneric Product Development Processhannah_clarice0% (1)

- Chapter 3 OM EditedDocument19 pagesChapter 3 OM EditedSeid KassawNo ratings yet

- Stage Gate Management GuideDocument36 pagesStage Gate Management GuideJesus vazquezNo ratings yet

- Chapter 2 The New Products ProcessDocument7 pagesChapter 2 The New Products ProcessmanoNo ratings yet

- Manufacturing Management: What is Manufacturing TechnologyDocument30 pagesManufacturing Management: What is Manufacturing TechnologyAbbyramy DanabalaNo ratings yet

- Implementing Odoo MethodologyDocument13 pagesImplementing Odoo MethodologyBuscad0r100% (5)

- Iptc 22107 MsDocument16 pagesIptc 22107 MsSuryadi YadiNo ratings yet

- CHAPTER 1.3 Prod PLanning SystemDocument5 pagesCHAPTER 1.3 Prod PLanning SystemSyrill CayetanoNo ratings yet

- Product design process and AMF organizational caseDocument50 pagesProduct design process and AMF organizational caseRakesh UpadhyayNo ratings yet

- NPD Procedure PDFDocument5 pagesNPD Procedure PDFRohit AttriNo ratings yet

- Product Development Process OverviewDocument42 pagesProduct Development Process OverviewFurkan GünayNo ratings yet

- Final Exam PDFDocument11 pagesFinal Exam PDFwaqasNo ratings yet

- m2MATERILA AMIEDocument4 pagesm2MATERILA AMIEHemantkumar TungNo ratings yet

- C. Productivity Production ConceptDocument7 pagesC. Productivity Production ConceptPradyuman VermaNo ratings yet

- Wa0000.Document13 pagesWa0000.Divya DhandeNo ratings yet

- Optimize Project Management Software DevelopmentDocument67 pagesOptimize Project Management Software DevelopmentSaumya SwapnesawrNo ratings yet

- DISC Advance Interpretation TechniqueDocument12 pagesDISC Advance Interpretation TechniquesahkunNo ratings yet

- ABC Analysis Guide for Inventory ManagementDocument123 pagesABC Analysis Guide for Inventory ManagementManish SinghNo ratings yet

- MCD Mandiri Process Engineering 9 Sep 2020Document6 pagesMCD Mandiri Process Engineering 9 Sep 2020sahkunNo ratings yet

- 7 13 PDFDocument7 pages7 13 PDFsahkunNo ratings yet

- Pengambangan Biorefefinery Pertamina PDFDocument12 pagesPengambangan Biorefefinery Pertamina PDFsahkunNo ratings yet

- Kronologis Start Up HCU-211 Tahun 2018 PDFDocument7 pagesKronologis Start Up HCU-211 Tahun 2018 PDFsahkunNo ratings yet

- Kronologis Start Up HCU-211 Tahun 2018 PDFDocument7 pagesKronologis Start Up HCU-211 Tahun 2018 PDFsahkunNo ratings yet

- 7 13Document7 pages7 13sahkunNo ratings yet

- Circular Guidelines and Schedule of Design Engineering Module ForDocument3 pagesCircular Guidelines and Schedule of Design Engineering Module ForAnmol KingNo ratings yet

- ISO CERTIFIED COMPANYDocument8 pagesISO CERTIFIED COMPANYGaurav RaghuvanshiNo ratings yet

- Industrial Disputes ResolutionDocument9 pagesIndustrial Disputes ResolutionNitinNo ratings yet

- Donatus Pharmacy: Personnel Scheduling With Employee PreferencesDocument11 pagesDonatus Pharmacy: Personnel Scheduling With Employee PreferencesHridaya RamanarayananNo ratings yet

- BuxlyDocument13 pagesBuxlyAimen KhatanaNo ratings yet

- Martin Pring On Market Momentum - IndicadoresDocument357 pagesMartin Pring On Market Momentum - IndicadoresÉdipo Henrique83% (6)

- Sample Copy - Mphasis &finsource PDFDocument2 pagesSample Copy - Mphasis &finsource PDFSameer ShaikhNo ratings yet

- Service Design Package ContentsDocument10 pagesService Design Package ContentsAlberto AlvaradoNo ratings yet

- Draft Law Making Process in IndiaDocument28 pagesDraft Law Making Process in IndiaMeraNo ratings yet

- Vacation Planning and Tour ManagementDocument114 pagesVacation Planning and Tour ManagementDhawal RajNo ratings yet

- Consumer and Firm Behavior: The Work-Leisure Decision and Profit MaximizationDocument22 pagesConsumer and Firm Behavior: The Work-Leisure Decision and Profit MaximizationRachit BhagatNo ratings yet

- Curriculum VitaeDocument2 pagesCurriculum Vitaeapi-628389548No ratings yet

- 5 Key Financial Ratios and How To Use ThemDocument10 pages5 Key Financial Ratios and How To Use ThemdiahNo ratings yet

- Selling Groceries Through The Cloud in A Tier II City in IndiaDocument12 pagesSelling Groceries Through The Cloud in A Tier II City in IndiaFathima HeeraNo ratings yet

- Substantive Procedures: 1) Trade RecievablesDocument3 pagesSubstantive Procedures: 1) Trade RecievablesMeghaNo ratings yet

- Group 9 Eabdm s13Document3 pagesGroup 9 Eabdm s13DIOUF SHAJAHAN K TNo ratings yet

- UBO - Lecture 03 - Mechanistic and Organic Forms of Organisational StructureDocument24 pagesUBO - Lecture 03 - Mechanistic and Organic Forms of Organisational StructureSerena AboNo ratings yet

- Doles Vs AngelesDocument2 pagesDoles Vs Angelesfermo ii ramosNo ratings yet

- EContent 1 2023 06 24 10 20 29 QTDM Studymaterialfeb23pdf 2023 03 15 11 44 02Document23 pagesEContent 1 2023 06 24 10 20 29 QTDM Studymaterialfeb23pdf 2023 03 15 11 44 02Tom CruiseNo ratings yet

- Bank StatementDocument5 pagesBank StatementSANJIB GHOSHNo ratings yet

- Annual Income Statement Report Name: Laporan Laba Rugi / Nama / Ery Abd Nasir PelupessyDocument2 pagesAnnual Income Statement Report Name: Laporan Laba Rugi / Nama / Ery Abd Nasir PelupessyErry Abdul Nasir PelupessyNo ratings yet

- Girish KSDocument3 pagesGirish KSSudha PrintersNo ratings yet

- Just Dial Limited Letter of OfferDocument68 pagesJust Dial Limited Letter of Offervarun_bhuNo ratings yet

- Food Truck Financial Model Excel Template v1.8Document77 pagesFood Truck Financial Model Excel Template v1.8hanswuytsNo ratings yet

- Claim Form GMCDocument7 pagesClaim Form GMCBhaskar RawatNo ratings yet

- 22-Civis Mathimata Scholis Ope 1Document5 pages22-Civis Mathimata Scholis Ope 1MargaritaNo ratings yet

- Complaint (Final)Document31 pagesComplaint (Final)Kirk Yngwie EnriquezNo ratings yet

- Basics of Business Mathematics in 40 CharactersDocument17 pagesBasics of Business Mathematics in 40 CharactersAbhishek JainNo ratings yet

- Quality Function Deployment in House-Building MarketDocument10 pagesQuality Function Deployment in House-Building MarketMarvi HarsiNo ratings yet

- Engineering Economics Questions Problem SolvingDocument4 pagesEngineering Economics Questions Problem SolvingLouie Jay LayderosNo ratings yet