Professional Documents

Culture Documents

Warehouse 21

Warehouse 21

Uploaded by

Abdul Rahim0 ratings0% found this document useful (0 votes)

7 views5 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views5 pagesWarehouse 21

Warehouse 21

Uploaded by

Abdul RahimCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 5

Besom

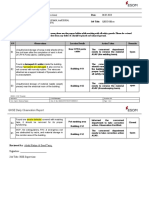

Warehouse Safety Inspection Checklist

Projec E1f0020 NEO? atic Bs oie IS 0-23

| Locatio LvAresoose F019 TENTSIORE | Denatment waresiecdse

CA A NA

No, | General Area Inspection

Are aisles clear and open for material transfers? No product shall be stored in aisles where it

blocks equipment maneuvering. Lea}

Are floor and rack storage limits properly posted? One sign near the entrance of the warehouse Trener

should indicate the floor rating. All racks should be labeled with load ratings. a

n? Bent racks and beams must be repaired or Bot

\

Are rack uprights and beams in good condit

replaced. All racks should be bolted to the floor. ae

Are designated open areas clear of blockage? Such areas include 18 inch perimeters along

interior walls as well as electrical panels and eye wash units. eal

Are fire extinguishers up to date for inspections, in good condition, where they belong and

unobstructed? atl

Overhead fire sprinklers up to date for inspections, in good condition, where they belong and

unobstructed? onl”

Are all emergency exits clear of blockage and are the exit signs in good condition? Inspect both

inside and outside for blockage of the exits. All exit signs should be lit & all emergency lights =F

tested.

Pallets must be in good condition. Empties must be stored properly. No broken or protruding ra

wood or nails. No pallets on edge. Avoid ‘storing empty pallets in quantities or densities in excess

of overhead fire sprinkler combustible load ratings.

Are overhead lighting, skylights and roofs in good condition? Check for leaks, broken panels /

ight bulbs and missing bulb shields.

©EI Seif 2019 jh repre.

Uncontrolled when printed P Rite

ESOM-OSH Templato is

[Asprovet GQHSE Manager [ Revision: 02

Finn Auman ALIGE Nanarimant | fan M+ E@ARA MeL Ad ARANA >E nea

Warehouse Safety Inspection Checklist

Loose/unboxed materials which might fall from a stack are properly stored by blocking,

interlocking or limiting the height of the pile to prevent falling hazards. Insure product stack

heights are enforced to prevent container crushing and falling materials.

Bags, containers, bundles, etc. are stored in tiers that are stacked, blocked, interlocked and

imited in height so that they are stable and secure to prevent sliding or collapse.

Derail and/or bumper blocks are provided on spur railroad tracks where a rolling car could

contact other cars being worked on or roll out into entrances to buildings, work or traffic areas.

All hazardous materials' containers are properly labeled, indicating the chemical's identity, the

manufacturer’s name and address, and appropriate hazard warnings.

There is a system in place and periodically evaluated to insure each new chemical procured or

received is checked to insure it is accompanied by a MSDS.

ventory of chemicals), accessible, and well organized.

MSDS book is up to date (annua

Employees use proper personal protective equipment when handling chemicals.

All chemicals are stored according to the manufacturer's recommendations and local or national

fire codes. (i.e. flammable cabinets, cans, etc.)

Employees use proper lifting technique for the materials being handled.

ie

Products and containers that are most frequently moved by hand are stored at rack heights that 4]

minimize bending / stooping or excess reach to pick up or place?

Are visitors and drivers remaining in designated safe areas and walkways?

Is there sufficient room to maneuver materials? Dock area floors should be olean and free of

trash, debris, or stored items that block the safe Passage of loaded equipment

©EI Seif 2019

Uncontrolled when printed

ESOM-OSH Template

[ Approved: [ HSE Manager Revision: 02

Wa

rehouse Safety Inspection Checklist

ESOM

Are there sufficient waste cans for the area and are those cans properly labeled and emptied on

a regular basis? In general are floors, ceilings, and exhaust fans clean and free of cobwebs and

dust buildup?

's there adequate natural or mechanical ventilation to control any potential atmospheric hazards?

Where propane powered equipment is in use the ventilation must be tested to rule out excess

carbon dioxide/monoxide.

General Inspection for Equipment

NA

Inspect all ladders and hand tools and indicate here that they are in good condition or in need of

any repair.

NOTE: remove any unsafe equipment from service while awaiting repair.

Inspect all ladders and hand tools and indicate here that they are

in good condition or in need of any repair.

NOTE: remove any unsafe equipment from service while awaiting repair.

x

Are forklifts being operated safely and inspected at the start of every shift? Observe powered

industrial truck operations and review training certifications to confirm operators have been

adequately trained and evaluated.

Do forklifis have functioning warning devices such as back-up alarms, strobes, or horns? Test

equipment as needed, report repairs, and tag out equipment that repairs are

made.

Are battery charging/changing areas designated for that purpose and contain appropriate

emergency flushing facilities (i.e. eyewash and shower)?

Are guards in place for any hazard points on moving equipment such as bell guards on

compressors or conveyors? Inspect all powered work tools as well (i.e. cords, insulation,

shrouds, casing, guards, etc.).

SE

f

©El Seif 2019

Uncontrolled when printed

ESOM-OSH Template

Approved: QHSE Manager Revision: 02

Doc. Qwnar: OHSE Denartmant | Nac In: FROM.NSH.nd.annna.ak ‘dae

Warehouse Safety Inspection Checklist ESOM

Are propane tanks stored correctly and are the tank exchange and/or tank

intained? Appropriate signs are in place and area is free of trash

Are all fire sprinkler control valves in their open position? Do a visual check to insure the valves

are fully open.

Forklifts that are used in hazardous locations (i.e. around flammable materials) are properly

marked / labeled / tagged for the specific hazardous location.

General Safety and Training cA NA

Are all employees properly trained and is training and certification up to date? Inspect records to

verify training is documented and up to date

Are emergency evacuation routes and guidelines posted?

Are the appropriate OSHA and Employee Rights posters posted in a conspicuous place?

Are your employees actively and meaningfully involved in workplace safety programs? (Le.

participate in accident investigations, etc.)

Are accidents, near misses and injuries being investigated and are unsafe con

corrected, reported/documented in a timely manner?

Ate MSDS available to employees and are they up to date and complete? We

Employees are properly trained and outfitted for weather / temperature extremes. (ie. heat eH

|__| stress, cold weather, etc.)

VAL AN

©EI Seif 2019

Uncontrolled when printed

ESOM-OSH Template :

Approve ] QHSE Manager Revision: 02

Rar Owner OSE Nanartmant | Rae IN- FSOMASHLAZAnnNAAR Sis wae

Warehouse Safety Inspection Checklist ESOM

Newly-hired employees receive documented general material handling and task specific

ergonomics training. Verify through observations that employees practice safe lifting techniques al

on the job.

All employees are trained in the requirements of the hazard communication standard. Including a

review of each MSDS and the specifics of existing and potential hazards of chemicals in the work a

place, precautions and safe work practices.

All employee training is documented Wa

- 05°93

NA = Not Applicable: The item cited does not applicable in particular operation

A= Acceptable: The conditions within your area(s) comply with the safety standard requirements.

CA= Corrective Action: The significant hazards were found to be unacceptable but corrective action was taken during the

inspection, :

: : wsed dn tikeTs

; Petes) VO EO ar

/ absve rredoved oh % aufnent -

w Al’ the Cian Gk a sore olesed Te Gucemd

@E 2019

Ur trolled whi

ESOM-OSH Template eae rae

Approved: QHSE Manager Revision: 02

Dae Owner QOHSF Nenartmant | Rar In: FSAM.ASi-N4nnnna2R Dana Re

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Petrol Week 12dsdDocument6 pagesPetrol Week 12dsdAbdul RahimNo ratings yet

- LPG LastdsdDocument7 pagesLPG LastdsdAbdul RahimNo ratings yet

- LPG 57 04Document1 pageLPG 57 04Abdul RahimNo ratings yet

- B29week 12DASDocument6 pagesB29week 12DASAbdul RahimNo ratings yet

- Week 11 LPG 56Document8 pagesWeek 11 LPG 56Abdul RahimNo ratings yet

- LPweek 12Document2 pagesLPweek 12Abdul RahimNo ratings yet

- 02-03-2023 LPG 57Document1 page02-03-2023 LPG 57Abdul RahimNo ratings yet

- 002 James 002Document1 page002 James 002Abdul RahimNo ratings yet

- 001 James 001Document7 pages001 James 001Abdul RahimNo ratings yet

- LPG Near KitcDocument1 pageLPG Near KitcAbdul RahimNo ratings yet

- 003 James 003Document1 page003 James 003Abdul RahimNo ratings yet

- Petrol ChecklistDocument7 pagesPetrol ChecklistAbdul RahimNo ratings yet

- Kitchen 18Document2 pagesKitchen 18Abdul RahimNo ratings yet

- B.75,75 LaundryDocument3 pagesB.75,75 LaundryAbdul RahimNo ratings yet

- 06.05.2023, Daily Observation Report - Service ZoneDocument2 pages06.05.2023, Daily Observation Report - Service ZoneAbdul RahimNo ratings yet

- 08.05.2023, Daily Observation Report - Service ZoneDocument2 pages08.05.2023, Daily Observation Report - Service ZoneAbdul RahimNo ratings yet

- 04.05.2023, Daily Observation Report - Service ZoneDocument2 pages04.05.2023, Daily Observation Report - Service ZoneAbdul RahimNo ratings yet

- 03.05.2023, Daily Observation Report - Service ZoneDocument2 pages03.05.2023, Daily Observation Report - Service ZoneAbdul RahimNo ratings yet