Professional Documents

Culture Documents

BestPractices 16

BestPractices 16

Uploaded by

PabloOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BestPractices 16

BestPractices 16

Uploaded by

PabloCopyright:

Available Formats

BEST PRACTICE NO.

16

KNOWING THE COST OF STEAM

1. COST OF STEAM • Boiler efficiency: A higher boiler efficiency will provide

Knowing the correct cost of steam is very important for a lower steam cost. Boiler efficiency will vary depending

many reasons, and all of them have to do with improving on the boiler operation firing rate or load demand.

the company’s bottom line: Lower firing rates or steam load demand will have lower

boiler efficiency. Understanding and documenting the

1. To properly evaluate the economics of proposed fuel-air ratio is extremely important. Boiler efficiency is

steam system efficiency improvement projects. If the calculated by using PTC 4.1.

calculated steam cost is not accurate, many feasible

energy projects may be missed or rejected, while 1.2. Unloaded Steam Cost vs. Loaded Steam Cost

infeasible projects may be approved for implementation There are two methods to calculate steam cost (unloaded

2. To serve as a basis for optimizing the steam or loaded). The simplest method to determine the cost

generation system and minimizing costs of steam is to calculate the unloaded steam cost, which

3. To provide a true cost for the production areas for only requires reviewing the boiler operation (steam Btu,

accountability in energy consumption feedwater Btu, boiler efficiency, and fuel cost). The loaded

Steam cost is the first benchmark of any steam steam cost takes into account all aspects and costs of

system management program. Unfortunately, a high producing steam, which provides a more accurate steam

percentage of industrial plants have not benchmarked cost.

the cost of steam. A loaded steam cost is the

most important steam cost for any steam system 1.2.1. Unloaded Steam Cost

management program. The unloaded cost is a basic comparison between

the amount of steam produced and the cost of the fuel

1.1. What Affects the Cost of Steam? required to produce it. The basic equation for calculating

the unloaded steam cost includes the cost of the fuel,

Many factors in the steam system affect the cost of steam. operating steam pressure, feedwater Btu, and the boiler

A large percentage of the varying factors can be changed efficiency.

or improved based on a proactive steam management

program. Examples of a few of the factors that can affect Here is the equation to calculate an unloaded steam

steam cost include the following: cost:

• Fuel cost: Lower cost fuels will provide a lower steam

cost.

• Operating steam pressure: Is not a major factor and

must be reviewed carefully for each boiler before = Steam cost, unloaded

implementing. = Fuel cost in $/MMBtu

• Percentage of make-up water or percentage of = Enthalpy of steam, in Btu/lb.

condensate return: Normal condensate return will = Enthalpy of boiler feedwater in Btu/lb.

have a higher Btu content than make-up water. Today’s = True boiler efficiency (ASME PTC 4.1)

industrial benchmark for condensate return is 90%, if the o Percentage

plant is not injecting steam for the process. = Steam cost is measured in 1,000 lbs. per hour

Inveno Engineering Inc. | www.invenoinc.com | kelly.paffel@invenoinc.com

True boiler efficiency (ηB) takes into consideration all

aspects that influence boiler efficiency, including the

following:

• Moisture content in the fuel

• Combustion air temperature

• Radiation losses

• Flue gas losses

• Blowdown losses

• Etc.

(Refer to ASME PTC 4.1 for additional calculation details.)

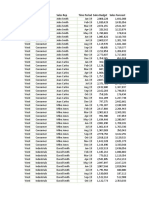

Figure 1: Steam Cost Print

Example I

The outlined steam cost example uses one steam generator (boiler), a single fuel, and one steam pressure.

The example of unloaded steam cost calculation uses the deaerator feedwater Btu content, which does

not take into consideration make-up water or condensate return. Also, the calculation uses only one boiler

efficiency.

Steam is being generated @ 100 psig and is being returned to a deaerator tank operating @ 10 psig. Fuel

cost is $9.50/MMBtu ($/GJ), and boiler efficiency is 80%.

Inveno Engineering Inc. | www.invenoinc.com | kelly.paffel@invenoinc.com

2. IMPROVING THE CALCULATION OF THE The condensate return systems are

UNLOADED COST OF STEAM classified as follows:

2.1. Condensate Return to the Boiler Operation 1. Gravity or atmospheric (GR): Condensate

return pressure maintained at or close to 0 psig

The amount of condensate being returned has a significant 2. Low pressure (LP): Condensate being returned

effect on the cost of steam and should be considered when between 1 and 15 psig

calculating the unloaded steam cost. The limitation to the 3. Medium pressure (MP): Condensate being

unloaded steam cost calculation is the fact the calculation returned between 16 and 99 psig

has the deaerator feedwater Btu content as the Btu input 4. High pressure (HP): Condensate being returned at

parameter for the calculation. The deaerator uses steam 100 psig or higher

from the boiler operation to heat the feedwater to an 5. Make-up water (MW): Water added to the steam

operational pressure/temperature. Therefore, the deaerator system to offset any condensate lost in the system

prevents an understanding of the benefits of condensate not being returned to the boiler operation

return at various pressures versus using make-up water.

Using the equation below will provide the plant a better

Condensate being returned to the deaerator tank can be understanding of the value of condensate recovery in

from several different return systems, and a percentage of the plant operation. A “modified” enthalpy of the boiler

condensate flow must be used based on a measurement or feedwater can be calculated as follows:

an estimated amount. hf = % (GR) + %(LP) + %(MP) + %(HP) + %(MW)

Figure 2: Steam System Layout

Inveno Engineering Inc. | www.invenoinc.com | kelly.paffel@invenoinc.com

Example II

Steam is being generated @ 100 psig, and 60% of the condensate is being returned through an

atmospheric return system, 20% is being returned through a 10 psig return system, and the remaining

20% is using make-up water @ 60°F. Fuel cost is $9.50/MMBtu, and boiler efficiency is 80%.

hf = %(GR) + %(LP) + %(MP) + %(HP) + %(MW)

hf = 0.60(180) + 0.20(208) + 0.0(MP) + 0.0(HP) + 0.20(28)

hf = 155.2 Btu/lb.

2.2. Loaded Cost of Steam

The loaded steam cost is the preferred method for plant The true cost of steam can easily be 2 to 3 times the value

accountability with today’s high energy costs. Load Coast of the unloaded steam cost. This will make a dramatic

takes into account many different factors related to steam difference in evaluating the different energy, efficiency, and

generation. Therefore, the loaded cost of steam provides a emission projects.

much more accurate cost for steam production. This value

will also provide more clarity when evaluating production Road Map

costs, utility billing issues, as well as energy efficiency

projects. Below are some of the factors that need to be 1. Determine the unloaded cost of steam.

included in the calculation of a loaded steam cost: 2. Determine the unloaded cost of steam using the

calculations for the condensate return systems.

• Electrical power 3. Determine the loaded cost of steam.

• Chemical cost

• Water and sewer

• Emissions payments

• Labor cost

o Management

o Operations

o Maintenance

• Waste disposal

• Maintenance cost

• New projects

• Etc.

Inveno Engineering Inc. | www.invenoinc.com | kelly.paffel@invenoinc.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Gator Olympic Swim CampDocument1 pageGator Olympic Swim CampPabloNo ratings yet

- 2020 Gator Swim Camp Brochure v1Document5 pages2020 Gator Swim Camp Brochure v1PabloNo ratings yet

- 2008 RFPDocumentsDocument139 pages2008 RFPDocumentsPabloNo ratings yet

- SB LunchRoomFacilitiesDocument2 pagesSB LunchRoomFacilitiesPabloNo ratings yet

- Metal Accounting and ReconciliationDocument1 pageMetal Accounting and ReconciliationPabloNo ratings yet

- Gold Outlook 2023Document10 pagesGold Outlook 2023PabloNo ratings yet

- ENR06272022 TopPSF CompressedDocument6 pagesENR06272022 TopPSF CompressedPabloNo ratings yet

- Maximizing Success in Integrated Delivery Workshop Forms v1.0Document22 pagesMaximizing Success in Integrated Delivery Workshop Forms v1.0PabloNo ratings yet

- Keyplan 600 Miami WorldcenterDocument1 pageKeyplan 600 Miami WorldcenterPabloNo ratings yet

- BulkdensitDocument1 pageBulkdensitPabloNo ratings yet

- PIF Annual Report 2021Document50 pagesPIF Annual Report 2021Pablo100% (1)

- FEL Stage GatedProcess Online 2023Document2 pagesFEL Stage GatedProcess Online 2023PabloNo ratings yet

- C304-99 AbiertoDocument107 pagesC304-99 AbiertoPabloNo ratings yet

- As Built Critical PathsDocument5 pagesAs Built Critical PathsPablo100% (1)

- Blockchain EssentialsDocument2 pagesBlockchain EssentialsPabloNo ratings yet

- Forbes CompensationDocument1 pageForbes CompensationPabloNo ratings yet

- Statistical PERT Normal Edition Quick Start Guide For Version 5.0Document21 pagesStatistical PERT Normal Edition Quick Start Guide For Version 5.0PabloNo ratings yet

- Revisiting Project Performance Final Report - 1Document23 pagesRevisiting Project Performance Final Report - 1PabloNo ratings yet

- Proceso de Reclutamiento ComunidadesDocument1 pageProceso de Reclutamiento ComunidadesPabloNo ratings yet

- Why Capital Project Systems Succeed or Fail Independent Project Analysis - CapDocument8 pagesWhy Capital Project Systems Succeed or Fail Independent Project Analysis - CapPabloNo ratings yet

- The Construction Productivity Imperative - McKinsey & CompanyDocument13 pagesThe Construction Productivity Imperative - McKinsey & CompanyPabloNo ratings yet

- Bias Busters Pruning Projects ProactivelyDocument3 pagesBias Busters Pruning Projects ProactivelyPabloNo ratings yet

- ValQ Tutorial For Beginners Sales Performance DataDocument7 pagesValQ Tutorial For Beginners Sales Performance DataPabloNo ratings yet

- C200-97 AbiertoDocument32 pagesC200-97 AbiertoPabloNo ratings yet

- Freestanding Single Point Anchor SystemDocument2 pagesFreestanding Single Point Anchor SystemPabloNo ratings yet

- Queue & Hang Balance FactorDocument10 pagesQueue & Hang Balance FactorPabloNo ratings yet