Professional Documents

Culture Documents

DPFCleaning Work Sheet

Uploaded by

raul bringasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DPFCleaning Work Sheet

Uploaded by

raul bringasCopyright:

Available Formats

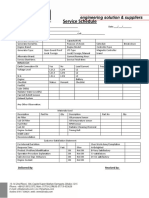

Diesel Particulate Filter (DPF) - Cleaning History Worksheet

www.fsxinc.com

Date: _________________________ Manufacturer/Distributor (Circle) Filter Dimensions

Filter Style: DPF Catalyst Caterpillar DCL International Mack OD _____ ID _____

Cleaire Detroit Diesel Isuzu PACCAR

Serial Number: _________________ Cummins ECS Johnson Matthey Volvo Overall Height __________

Ceramic Height__________

Part Number: __________________ Other: ____________________________________________

Mileage: _________________ Vehicle #: ___________________ Pin Gauging

Other Number: _________________

Depth of a totally clean cell

Engine: __________________ Model: _____________________ ______

Customer: _____________________ (Measure from Clean side)

Step 1 - Visual Inspection Refer to Filter Cleaning Reference Data Posters

Circle One Oil Soaked (circle): Yes No

Clean End Color (Circle): White, Cream,

Tan, Gray, Brown, Black, Other:_________ Chips, Gouges, Melting: Pass Fail

If Yes, then Red Tag.

Surface Cracks: Pass Fail

Dirty End Color (Circle): White, Cream, Loose Ceramic (Ceramic moves) : FSX does not recommend cleaning oil,

Tan, Gray, Brown, Black, Other:_________ Pass Fail

coolant, or fuel soaked DPF.

Pin Gauge clean side to check for melting and note Red Tag Continue Discoloration Ring: Yes or No (circle)

measurements (see grid at right)

TrapTester Airflow test ______________ w.g. Initial Black Hole Count (on clean side) (est.) (circle):

(Clean side down no gaskets) 0 5 15 10 20 50 100 100+ 1000+ Other:___________

Step 2 - Pneumatic Stage 1 Cleaning

2-minute Bypass Inspection; Important - Closely watch top surface of the DPF during first 2-minutes of air Location of

blast. Count defective cells allowing distinct spurts of ash or soot, and indicate number below.

target cells to test

Circle: 0 1 2 3 4 5 10 15 20 50 100 100+ 1000+

Red Tag: stop process if over 20 cells have heavy spurts of black, white, or gray particulate blow-

ing out the clean end of the DPF during the first two minutes. Pin Gauge Depth

(Measure available depth from dirty side of

Continue: if less than 20 defective cells (spurts) noted. filter – tap lightly if necessary)

Clean Dirty Side

Step 3 - After Pneumatic Cleaning Side After After

Position Step 1 Pneumatic Thermal

TrapBlaster Time (in minutes) (circle one): Pin Gauge dirty side for ash content and Step 2 Step 3

note measurement (see grid at right) Outer 1:00

15 20 25 30 Outer 2:00

Outer 3:00

40 50 60 Other:__________

Outer 4:00

TrapTester Airflow test ______________ w.g. (Clean side down no gaskets) Outer 5:00

Compare to FSX Baseline Chart Outer 6:00

Outer 7:00

Step 3 Status: Red Tag Green Tag-Process Complete Continue to Thermal Outer 8:00

Outer 9:00

Important: Before putting the filter in the Trap-

Step 4 - After Thermal Cleaning Blaster make sure core temp is at or below 125⁰F Outer 10:00

Outer 11:00

TrapBlaster Time (in minutes) (circle one): Outer 12:00

TrapBurner P1 (circle): Yes or No 15 20 25 30 40 50 60 Inner 1:30

Other:__________

Inner 3:00

TrapTester Airflow test ______________ w.g. Pin Gauge dirty side for ash content Inner 4:30

(Clean side down no gaskets) and note measurement (see grid at right) Inner 6:00

Compare to FSX Baseline Chart Inner 7:30

Final Step 4 status: Red Tag Green Tag Orange Tag Inner 9:00

Inner 10:30

Final comments: _________________________________

Inner 12:00

________________________________________________ Operator’s Initials:______________

________________________________________________ Center

Average

Copyright © 2012 FSX Inc. and FSX Equipment Inc. All rights reserved. No part of this material may be transmitted or reproduced in any form by any means without permission in writing from FSX Inc. and FSX Equipment Inc.

You might also like

- JH Step-1 & 2activitiesDocument34 pagesJH Step-1 & 2activitiesGREENEXE BUSINESS CONSULTANTNo ratings yet

- Defect TagDocument2 pagesDefect Tagazima amizaNo ratings yet

- Ge Healthcare PM Report: Lightspeed 5.XDocument1 pageGe Healthcare PM Report: Lightspeed 5.XGyannkNo ratings yet

- Automatic Transmission Diagnosis Information SheetDocument1 pageAutomatic Transmission Diagnosis Information SheetValentin IvanovNo ratings yet

- ATG Transmission WorksheetDocument1 pageATG Transmission WorksheetWeda OsbornNo ratings yet

- Site Assesment Pump ReportDocument1 pageSite Assesment Pump ReportThebe HanyaneNo ratings yet

- Driver Vehicle ChecklistDocument2 pagesDriver Vehicle Checklistmary517mary517No ratings yet

- Acm 2024 03 06 12 40Document4 pagesAcm 2024 03 06 12 40AtochkavNo ratings yet

- AS10169Document11 pagesAS10169JOECOOL67No ratings yet

- Fineco Vchecklist and Deployment FormDocument2 pagesFineco Vchecklist and Deployment FormAnonymous 5EPqIUNo ratings yet

- 05 Trip Sheet - IPM - QuartzDocument7 pages05 Trip Sheet - IPM - QuartzRebarNo ratings yet

- ATV UTV InspectionDocument4 pagesATV UTV InspectionGuillaume BolducNo ratings yet

- Weekly Vehicle Inspection: Driver Name: Vehicle No. PlateDocument4 pagesWeekly Vehicle Inspection: Driver Name: Vehicle No. PlateOP SECURITY SERVICES SDN BHDNo ratings yet

- A3 HardwareDocument49 pagesA3 HardwaresmrizalNo ratings yet

- In-Process Inspection Report For Infant Incubator PartsDocument4 pagesIn-Process Inspection Report For Infant Incubator PartsHilario AlinabonNo ratings yet

- Benedict Cuevas LHRDocument30 pagesBenedict Cuevas LHRann.manacioNo ratings yet

- AISC Paint Inspection LOG (Use This One)Document2 pagesAISC Paint Inspection LOG (Use This One)Richard100% (1)

- Measure LinerDocument1 pageMeasure LinerYustinus Nong MelkyNo ratings yet

- 88XX PRNTHDCKLSTDocument6 pages88XX PRNTHDCKLSTJared GeutherNo ratings yet

- Lean Six Sigma Green Belt Certification Course: Business Results For Projects Part - 1Document69 pagesLean Six Sigma Green Belt Certification Course: Business Results For Projects Part - 1Rajkumar VijNo ratings yet

- Service Schedule: Delivered By: Received byDocument1 pageService Schedule: Delivered By: Received bymd.monyrul islamNo ratings yet

- HC15 Manual PDFDocument24 pagesHC15 Manual PDFnstefosNo ratings yet

- Daily Mobile Equipments Inspection ChecklistDocument2 pagesDaily Mobile Equipments Inspection ChecklistibrahimNo ratings yet

- D - 16 Master - Pilot Exchange EditedDocument5 pagesD - 16 Master - Pilot Exchange EditedYamada NorringtonNo ratings yet

- Commissioning Report - FILTERDocument9 pagesCommissioning Report - FILTERGrace PentinioNo ratings yet

- Process Verification FormDocument1 pageProcess Verification Formdeva suryaNo ratings yet

- SD92 376Document4 pagesSD92 376tho huynhtanNo ratings yet

- Surface - Conditioning in MineSightDocument3 pagesSurface - Conditioning in MineSightTwo_TonguesNo ratings yet

- Exhibit 4.2 - UDR - Gas Scrubber SampleDocument2 pagesExhibit 4.2 - UDR - Gas Scrubber SampleErick SantosNo ratings yet

- Check List: Luggage CompartmentDocument2 pagesCheck List: Luggage CompartmentAngeli MalangNo ratings yet

- Global 8D Training Report Example: Created by Visteon Europe STA DepartmentDocument3 pagesGlobal 8D Training Report Example: Created by Visteon Europe STA DepartmentSudhaNo ratings yet

- Discussion Groups: Tutorial - Animating With Inventor StudioDocument3 pagesDiscussion Groups: Tutorial - Animating With Inventor Studiobhaskarghsh4No ratings yet

- Deskjet 9Xx Maintenance and TroubleshootingDocument8 pagesDeskjet 9Xx Maintenance and TroubleshootingLucas Suelen Isabela JoaquimNo ratings yet

- 70011Document51 pages70011donnieee77No ratings yet

- Toyota PickupDocument11 pagesToyota Pickupalexberhane3No ratings yet

- 12 Aftertreatment Diesel Oxidation Catalyst and Aftertreatment Diesel Particulate Filter Reuse GuidelinesDocument20 pages12 Aftertreatment Diesel Oxidation Catalyst and Aftertreatment Diesel Particulate Filter Reuse GuidelinesJohanny Barrera Hurtado100% (1)

- Pemaps FormDocument4 pagesPemaps FormDondon Jimenez100% (5)

- OFITE - Portable Roller OvenDocument1 pageOFITE - Portable Roller OvenLuisAlbertoVazquezNo ratings yet

- Checklist For Forklift InspectionDocument2 pagesChecklist For Forklift Inspectionlelu ojhaNo ratings yet

- Prequalification Form Contractor SpecificDocument8 pagesPrequalification Form Contractor Specificnameer khanNo ratings yet

- Subcontract Works (In Thousands of Pesos) Compan Y: Quantitative MethodsDocument3 pagesSubcontract Works (In Thousands of Pesos) Compan Y: Quantitative Methodsmohed ahmedNo ratings yet

- Jobsite Checklist: Pre-InstallationDocument5 pagesJobsite Checklist: Pre-InstallationClarensZedorfNo ratings yet

- Serdia Interface Upgradeformular enDocument2 pagesSerdia Interface Upgradeformular enikhtiyar aliNo ratings yet

- JE Custom Piston Order Form Update2Document1 pageJE Custom Piston Order Form Update2Arnold TurnipNo ratings yet

- Mold Design & Manufacturing Process (Catia)Document106 pagesMold Design & Manufacturing Process (Catia)Luan Venturoso100% (1)

- Vibratory Compactor Daily PMS Check ListDocument2 pagesVibratory Compactor Daily PMS Check ListGirlie Jade Ardiente JavierNo ratings yet

- LOSASDocument2 pagesLOSASIsabelNo ratings yet

- In-Process Inspection Report For Infant Incubator Parts9Document1 pageIn-Process Inspection Report For Infant Incubator Parts9Hilario AlinabonNo ratings yet

- Daily Maintenance Check SheetDocument5 pagesDaily Maintenance Check SheetPearlsgodNo ratings yet

- DOCUMMENT GUIDE FOR ATOLL SIMULATION by NyemeDocument10 pagesDOCUMMENT GUIDE FOR ATOLL SIMULATION by NyemeAlice FridayNo ratings yet

- Vehicle Details: Appraisal ReportDocument3 pagesVehicle Details: Appraisal ReportDragan CosicNo ratings yet

- Aftertreatment Diesel Particulate Filter SystemsDocument20 pagesAftertreatment Diesel Particulate Filter SystemsGerardo Diesel100% (3)

- 2-Cycle Failure Analysis ReportDocument2 pages2-Cycle Failure Analysis ReportTaller SurcoNo ratings yet

- DPR (5) - Barb (Titan) (Gargola)Document1 pageDPR (5) - Barb (Titan) (Gargola)Javier GarridoNo ratings yet

- DPR (10) - Rogue (Arcane Knight)Document12 pagesDPR (10) - Rogue (Arcane Knight)Javier GarridoNo ratings yet

- 07a Ptrschool WFT PTDocument61 pages07a Ptrschool WFT PTtriwicakNo ratings yet

- Diagnostic & Visual Inspection WorksheetDocument1 pageDiagnostic & Visual Inspection WorksheetKevin ValenzuelaNo ratings yet

- GRN Goods Received Note Adjusted JSDocument1 pageGRN Goods Received Note Adjusted JSIbrahim PatelNo ratings yet

- 1 B Air Compressor ChecklistDocument1 page1 B Air Compressor Checklistjohn rajNo ratings yet

- Solidworks 2018 Learn by Doing - Part 3: DimXpert and RenderingFrom EverandSolidworks 2018 Learn by Doing - Part 3: DimXpert and RenderingNo ratings yet

- Christensen CS3001Document2 pagesChristensen CS3001Julio Jesus Quijano VargasNo ratings yet

- RedMax Commercial Zero Turn Rider CZT 52 Owners Manual PDFDocument84 pagesRedMax Commercial Zero Turn Rider CZT 52 Owners Manual PDFJay WNo ratings yet

- The Tanker Chartering MarketDocument118 pagesThe Tanker Chartering MarketAlex Tanase100% (3)

- SUBARU Technical Reference Booklet: Basic Fuel Injection, Part 3Document134 pagesSUBARU Technical Reference Booklet: Basic Fuel Injection, Part 3Charlie Souza50% (2)

- DPVC 09 PetrobrasDocument47 pagesDPVC 09 PetrobrasClaudia MmsNo ratings yet

- 1.6 Fuel Cycle Coursera Calculations PresentationDocument37 pages1.6 Fuel Cycle Coursera Calculations Presentationalvares90No ratings yet

- Flexible-Fuel Vehicle - Wikipedia, The Free EncyclopediaDocument28 pagesFlexible-Fuel Vehicle - Wikipedia, The Free EncyclopediaShumway GordonNo ratings yet

- GlobalXPE Teco PDFDocument4 pagesGlobalXPE Teco PDFcelectricNo ratings yet

- Tpd2157en-04 (08-23)Document5 pagesTpd2157en-04 (08-23)ccssaa123No ratings yet

- Volvo-FH-Series Specifications UK PDFDocument18 pagesVolvo-FH-Series Specifications UK PDFmatab33No ratings yet

- Hydrochloric Acid and Miscelaneous Inorganic ChemicalsDocument4 pagesHydrochloric Acid and Miscelaneous Inorganic ChemicalsEbook DownloadNo ratings yet

- OECD IEA - Oil Information Donnees Sur Le Petrole. 2009Document723 pagesOECD IEA - Oil Information Donnees Sur Le Petrole. 2009Kader BakourNo ratings yet

- FB 209 GB pm615Document2 pagesFB 209 GB pm615muhammadnainNo ratings yet

- T4078 Techical Sheet and Manual CAT 320E LDocument36 pagesT4078 Techical Sheet and Manual CAT 320E Lricktmg100% (1)

- Hurto A PDVSA (3) : Sobreprecio de $18,2MM Rolls Royce Trent60Document101 pagesHurto A PDVSA (3) : Sobreprecio de $18,2MM Rolls Royce Trent60Tomás Lander0% (1)

- Fuel Injection & TurbochargingDocument4 pagesFuel Injection & Turbocharging6 avinashNo ratings yet

- The Science of Electric VehicleDocument5 pagesThe Science of Electric VehiclejsdhkadkjasNo ratings yet

- Isuzu Engine Service Manual Sumitomo PT 1Document168 pagesIsuzu Engine Service Manual Sumitomo PT 1Ronald100% (7)

- Trouble Shooting Charts PDFDocument7 pagesTrouble Shooting Charts PDFalekyaNo ratings yet

- Ge 7s04Document24 pagesGe 7s04nangkarak8201No ratings yet

- Dynamic Modeling, Design, and Simulation of A Combined PEM Fuel Cell and Ultracapacitor System For Stand-Alone Residential ApplicationsDocument9 pagesDynamic Modeling, Design, and Simulation of A Combined PEM Fuel Cell and Ultracapacitor System For Stand-Alone Residential ApplicationsCh RajaNo ratings yet

- The Jewish Revolutionary Spirit and Its Impact On World History - E. Michael JonesDocument46 pagesThe Jewish Revolutionary Spirit and Its Impact On World History - E. Michael JonesCristiano Ferrari67% (3)

- Axial Ae 1 Esc ManualDocument1 pageAxial Ae 1 Esc ManualEnache DanielNo ratings yet

- JGM767KNDocument6 pagesJGM767KNJosh FereiraNo ratings yet

- b2b Sales FINALDocument17 pagesb2b Sales FINALGourab RayNo ratings yet

- C 968 - 99 - Standard Test Methods For Analysis of Sintered Gadolinium Oxide-Uranium Dioxide PelletsDocument12 pagesC 968 - 99 - Standard Test Methods For Analysis of Sintered Gadolinium Oxide-Uranium Dioxide Pelletslywu2000No ratings yet

- 5.01 Biomass and Biofuels - IntroductionDocument9 pages5.01 Biomass and Biofuels - IntroductionRhita RayNo ratings yet

- General Information and Operating Instructions: GPU - 406 GPU - 409Document42 pagesGeneral Information and Operating Instructions: GPU - 406 GPU - 409William Jaldin CorralesNo ratings yet

- Jhon Sammuel - 110401044 - Tugas Motor BakarDocument5 pagesJhon Sammuel - 110401044 - Tugas Motor BakarAkhun NastiNo ratings yet

- 220cmr112 General O&M LNG Plan FacilitiesDocument12 pages220cmr112 General O&M LNG Plan Facilitieseka resmanaNo ratings yet