Professional Documents

Culture Documents

Course Outline - 1191774296maintenance Engineering and Management

Course Outline - 1191774296maintenance Engineering and Management

Uploaded by

goitom0 ratings0% found this document useful (0 votes)

5 views2 pagesOriginal Title

course outline_1191774296Maintenance Engineering and Management (1)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views2 pagesCourse Outline - 1191774296maintenance Engineering and Management

Course Outline - 1191774296maintenance Engineering and Management

Uploaded by

goitomCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

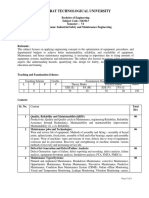

Wollo University

kombolcha institute of technology

Department of Industrial Engineering

Course Number: IEng 3150 Credit Hours: 3

Course Title: Maintenance Engineering and Contact Hours: 2 Lecture hrs and 3 tur.

Management hrs

rd

Target group : 3 year industrial

engineering

Course Objective

The course is intended to enable the student to:

Understand theoretical and practical aspects of maintenance practice in industrial

setup;

Understand basics of damages of typical components of machinery and thereby

help the student realize the state of damage of machinery;

Realize the use of the concepts of reliability, maintainability and availability in

maintenance technology which are helpful in the prediction of plant performance;

Understand the organization of a maintenance department, maintenance planning

and decision-making processes;

Develop practical skill by providing some practical work of maintenance;

Course Description

Damages and their causes; Damages of typical machine components; Determination of

the state of damage of equipment; Elements of maintenance technology; Maintenance

Planning and Organization; Reliability, Maintainability and Availability; Spares

Provisioning; Networking; Reconditioning Processes.

Course Outline:-

1. Introduction

1.1 Definition of Maintenance

1.2 Objectives of Maintenance

1.3 Types of Maintenance

2. Fundamental Theories of Damages

2.1 Fundamental Theories of Damages

2.2 Typical Damages of Machine Parts

2.3 Determination of the State of Damage /Failure

3. Elements of Maintenance Technology

3.1 Accessibility

3.2 Simplification

3.3 Standardization and Interchange ability

3.4 Modularization

3.5 Identification and Labelling.....

4. Decision Making

4.1 Economic Issues

4.2 Legal Issues

4.3 Maintenance Service Contracts (MSCs

4.4 Information flows for MSC decision making

5. Basic Probability Concepts and Reliability, Maintainability, and Availability

5.1 Rules for combining probabilities

5.2 Probability Distribution Function

5.3 Reliability, Maintainability, and Availability

6. Maintenance Planning and Organization of Maintenance Planning

6.1 Plant subdivision according to responsibility

7. Spares Provisioning

8. Network Analysis for Planning and Control of Maintenance Work

9. Reconditioning Processes

Pre-requisites: Plant Design

Co-requisites:

Textbook:

Teaching Material on “Maintenance of Machinery” prepared by Dr. AlemBazezew

References:

1. Gertsbakh, I.B., Stastistical Reliability Theory, Marcel Dekker, Inc., 1989.

2. Gopalakkrishinan, P., Banerji, A.K., Maintenance and Spare Parts Management,

Prentice Hall of India Private Limited, New Delhi - 110001, 2002.

3. Halpern, S., The Assurance Sciences, an Introduction to Quality Control and

Reliability, Prentice-Hall Inc., Englewood Cliffs, NJ, 1978.

4. Kececioglu, Dimitri, Maintainability, Availability, and Operational Readiness,

Vol. I, Prentice - Hall PJR, Upper Saddle River, NJ, 1995.

5. Kelly, A., Harris, M.J., Management of Industrial Maintenance, Butterworths &

C. (Publishers) Ltd., London, 1978.

6. Moubray, John, Reliability - Centered Maintenance, 2nd ed., Industrial Press Inc.,

NY, 1997.

7. Neale, M. J., The Tribology Handbook, 2nd ed., Butterworths - Heinmann

Publishing Ltd., 1995.

8. Smith, Charles O., Introduction to Reliability in Design, McGraw - Hill Inc.,

1976.

Method of Delivery:

Lectures supported by tutorials

Group project work

Individual assignment

Practical project work

Evaluation:

Individual Assignment: 10 %

Mid-semester Exam: 20 %

Group Practical Project: 30%

Final Examination: 40 %

Attendance Requirement:

Minimum of 75% attendance during lecture hours

100% attendance during practical work sessions, except for some unprecedented

mishaps

Presence during industrial visit session/sessions

Semester Hours:

48 lecture hours plus 48 tutor hours, a total of 96 hours

You might also like

- Junior Mechanic EngineDocument246 pagesJunior Mechanic EngineraghananduNo ratings yet

- KP AKBansal Eng AIFAS PDFDocument65 pagesKP AKBansal Eng AIFAS PDFRakesh Singh100% (1)

- Total Productive Maintenance: The Evolution in Maintenance and EfficiencyDocument7 pagesTotal Productive Maintenance: The Evolution in Maintenance and Efficiencylaukik_rautNo ratings yet

- Maintenance 1Document40 pagesMaintenance 1Muhammad BilalNo ratings yet

- Tes Potensi Akademik Bid. BAHASA INGGRIS PDFDocument98 pagesTes Potensi Akademik Bid. BAHASA INGGRIS PDFYuniarso Adi Nugroho100% (1)

- Anindita Ghosh - Claiming The City - Protest, Crime, and Scandals in Colonial Calcutta, C. 1860-1920 (2016, Oxford University Press)Document297 pagesAnindita Ghosh - Claiming The City - Protest, Crime, and Scandals in Colonial Calcutta, C. 1860-1920 (2016, Oxford University Press)Amitrajit BasuNo ratings yet

- 402050A - Quality & Reliability Engg-sYLLABUSDocument2 pages402050A - Quality & Reliability Engg-sYLLABUSashish RautNo ratings yet

- Maintenance EngineeringDocument67 pagesMaintenance EngineeringV.Muthu KumarNo ratings yet

- Machine Fault Signature AnalysisDocument10 pagesMachine Fault Signature AnalysisKotha MahipalNo ratings yet

- Management Science Decision Making Through Systems ThinkingDocument3 pagesManagement Science Decision Making Through Systems ThinkingSiimplisius Ryski-tigaNo ratings yet

- Extending Equipment’s Life Cycle – The Next Challenge for Maintenance: 1, #12From EverandExtending Equipment’s Life Cycle – The Next Challenge for Maintenance: 1, #12No ratings yet

- Face Prep For 2023 Batch Students Registered List - Jain UniversityDocument10 pagesFace Prep For 2023 Batch Students Registered List - Jain Universitydalavai srikanthNo ratings yet

- Zero Breakdown Maintenance Training Course: Email: WebsiteDocument4 pagesZero Breakdown Maintenance Training Course: Email: WebsiteSalim82 LKNo ratings yet

- Productivity and Reliability-Based Maintenance Management, Second EditionFrom EverandProductivity and Reliability-Based Maintenance Management, Second EditionNo ratings yet

- Workshop Organization and ManagementDocument4 pagesWorkshop Organization and Managementjohn nderitu67% (3)

- Industrial Management Course OutlineDocument2 pagesIndustrial Management Course OutlineQurat Ul Ain NaqviNo ratings yet

- Course Outline M EDocument3 pagesCourse Outline M EBahredin AbdellaNo ratings yet

- MANF 5317 Maintenance of Machinery Lecture NotesDocument76 pagesMANF 5317 Maintenance of Machinery Lecture Notesrobel metikuNo ratings yet

- MimDocument8 pagesMimBiniam Nega100% (2)

- Importance and Objectives of Maintenance Types of Maintenance, Maintenance Systems Planned and Unplanned MaintenanceDocument17 pagesImportance and Objectives of Maintenance Types of Maintenance, Maintenance Systems Planned and Unplanned MaintenanceDeblina ChakrabortyNo ratings yet

- Course Outlines For Different SubjectsDocument7 pagesCourse Outlines For Different SubjectsjosephNo ratings yet

- ANDT - Student Panel MaintainenceDocument5 pagesANDT - Student Panel MaintainenceSAATVIK JAINNo ratings yet

- MEE 506 Work Plan For StudentsDocument3 pagesMEE 506 Work Plan For StudentsAkunwa GideonNo ratings yet

- Me 542 Maintenance PlanningDocument2 pagesMe 542 Maintenance PlanningMohammed GamalNo ratings yet

- Course DetailsDocument2 pagesCourse DetailsAkash RajanNo ratings yet

- Maintenance Engineering (ME6012)Document68 pagesMaintenance Engineering (ME6012)ElementifyItNo ratings yet

- Plant Maintenance and Safety EngineeringDocument3 pagesPlant Maintenance and Safety EngineeringBhushan Shankar KambleNo ratings yet

- Plant Utilities and Maintenance CPB 20004 Prolog. Karte 00: Mohd Syazwan B Mohd GhazaliDocument10 pagesPlant Utilities and Maintenance CPB 20004 Prolog. Karte 00: Mohd Syazwan B Mohd GhazaliAdam BukhariNo ratings yet

- Automobile Maintenance Management and TechniquesDocument2 pagesAutomobile Maintenance Management and TechniquesGODNo ratings yet

- Maintenance Management - Course Outline (4) (AutoRecovered)Document3 pagesMaintenance Management - Course Outline (4) (AutoRecovered)Raju SainiNo ratings yet

- Sylb Ise Ise 510 Duffuaa 202Document3 pagesSylb Ise Ise 510 Duffuaa 202Noman Ullah ChoudharyNo ratings yet

- Reliability Eng Syllabus PE-4211 Armaments Sept 27Document7 pagesReliability Eng Syllabus PE-4211 Armaments Sept 27Charlton S.InaoNo ratings yet

- SL. NO. NO. Topics Syllabus Unit - I Principles and Practices of Maintenance PlanningDocument214 pagesSL. NO. NO. Topics Syllabus Unit - I Principles and Practices of Maintenance PlanningMuthamizhan TamilNo ratings yet

- Project SynopsisDocument5 pagesProject SynopsisAnkit MishraNo ratings yet

- Maintenance Engineering: Ms Sadiya MushtaqDocument21 pagesMaintenance Engineering: Ms Sadiya MushtaqMuhammad KamranNo ratings yet

- Course Outline MFG IIDocument2 pagesCourse Outline MFG IIAbrham ChanieNo ratings yet

- Plant Maintenance and Safety Course Code: 3341906Document8 pagesPlant Maintenance and Safety Course Code: 3341906Dhaval UpadhyayNo ratings yet

- 1.what Is A FailureDocument26 pages1.what Is A FailureReginaldy FalNo ratings yet

- Maintence and Safety PDFDocument97 pagesMaintence and Safety PDFariNo ratings yet

- MPE 411-Course Content.Document2 pagesMPE 411-Course Content.kandeabigaelNo ratings yet

- Wachemo University College of Engineering and Technology School: Electrical and Mechanical Engineering Department of Mechanical EngineeringDocument2 pagesWachemo University College of Engineering and Technology School: Electrical and Mechanical Engineering Department of Mechanical EngineeringYonael MezmureNo ratings yet

- ME1012 Maintenance Engineering Study MaterialsDocument37 pagesME1012 Maintenance Engineering Study Materialssathurvedha50% (2)

- A Generic ConceptualDocument13 pagesA Generic Conceptualziyad alturkiNo ratings yet

- ResumeDocument5 pagesResumeVaibhav Vithoba NaikNo ratings yet

- Gujarat Technological University: Page 1 of 3Document3 pagesGujarat Technological University: Page 1 of 3starboyNo ratings yet

- Budomo, RenanteDDocument65 pagesBudomo, RenanteDRenante Dela Cruz BudomoNo ratings yet

- Maintenance Engineering (Che-405) : DR Sikander Rafiq Assoc. ProfessorDocument37 pagesMaintenance Engineering (Che-405) : DR Sikander Rafiq Assoc. ProfessorHajra AamirNo ratings yet

- Seit Engineering Obe Syllabus Km40103Document4 pagesSeit Engineering Obe Syllabus Km40103Daniel LynchNo ratings yet

- ME SyllabusDocument2 pagesME SyllabusarsharmNo ratings yet

- Maintenance Management CoolDocument56 pagesMaintenance Management CoolEmmanuel KutaniNo ratings yet

- CH 01, Introduction To MaintenanceDocument50 pagesCH 01, Introduction To MaintenanceSurafel AlemuNo ratings yet

- EngineeringDocument187 pagesEngineeringMuhammad SaleemNo ratings yet

- Basic Maintenance Practices Program - RevisedDocument11 pagesBasic Maintenance Practices Program - RevisedMathias NsimbeNo ratings yet

- CH 01 IntrouctionDocument49 pagesCH 01 Introuctionlayike alemayehuNo ratings yet

- 2023306172-Preview File - Maintenance Fitter - Mechanical FGDocument30 pages2023306172-Preview File - Maintenance Fitter - Mechanical FGGhodke ParmeshwarNo ratings yet

- Fce 2521 TerotechnologyDocument1 pageFce 2521 TerotechnologyCharles OndiekiNo ratings yet

- Become What You Want To Be: Unit GuideDocument6 pagesBecome What You Want To Be: Unit GuideMq SharozNo ratings yet

- Course OutlineDocument3 pagesCourse OutlineIgombe IsaacNo ratings yet

- Syllabus DFM 2014Document29 pagesSyllabus DFM 2014sudheer920% (1)

- Design of Machine Element OutlineDocument2 pagesDesign of Machine Element OutlineWolelaw FikaduNo ratings yet

- PM Report 1Document77 pagesPM Report 1Kurt Ross RicamaraNo ratings yet

- IJETR031103Document6 pagesIJETR031103erpublicationNo ratings yet

- RTPMDocument2 pagesRTPMG. RajeshNo ratings yet

- 7 - Mansor Et AlDocument10 pages7 - Mansor Et Algroovercm15No ratings yet

- Franz Wagner & Sohn GMBH: U-Tube Manometer D 116 FDocument1 pageFranz Wagner & Sohn GMBH: U-Tube Manometer D 116 Fdickliu dickliuNo ratings yet

- Peac Usjr 2cidamDocument2 pagesPeac Usjr 2cidamJhay-r Bayotlang IINo ratings yet

- Mindray Resona I9 Brochure Rev B - CR46819Document4 pagesMindray Resona I9 Brochure Rev B - CR46819Walid MohamedNo ratings yet

- Dapus 3Document3 pagesDapus 3marsya yollandaNo ratings yet

- Part 1. Pictures: Questions 1 To 3Document4 pagesPart 1. Pictures: Questions 1 To 3Adinda AisNo ratings yet

- ABB SUE 3000 Product DescriptionDocument24 pagesABB SUE 3000 Product DescriptionDustin VazquezNo ratings yet

- Science Investigatory Project 4Document10 pagesScience Investigatory Project 4SuperNo ratings yet

- Extramural Projects GuidelinesDocument25 pagesExtramural Projects GuidelinesJobin Tom Mandapam100% (1)

- Boiling ReportDocument5 pagesBoiling ReportVAIBHAV MISHRANo ratings yet

- REVISED RUBRICS ASSESSMENT TOOLS OF THE PLAN English 11 ADocument1 pageREVISED RUBRICS ASSESSMENT TOOLS OF THE PLAN English 11 AHenry Kahal Orio Jr.No ratings yet

- Minimum Number of Heat Exchanger 2019Document37 pagesMinimum Number of Heat Exchanger 2019Arina HazirahNo ratings yet

- Machine Learning: Dr. Muhammad AsadullahDocument69 pagesMachine Learning: Dr. Muhammad AsadullahSyed Kamran Ahmad1No ratings yet

- OOP ProgramsDocument19 pagesOOP ProgramsRohan patilNo ratings yet

- Hakuform 30-15 Schmierfett: Safety Data SheetDocument6 pagesHakuform 30-15 Schmierfett: Safety Data SheetLuis AyalaNo ratings yet

- 7 Advanced Pandas Tricks For Data ScienceDocument11 pages7 Advanced Pandas Tricks For Data ScienceTeto ScheduleNo ratings yet

- Pulmonary ReportDocument2 pagesPulmonary ReportJo peggNo ratings yet

- Crystals: Ffraction Data and Density Functional TheoryDocument9 pagesCrystals: Ffraction Data and Density Functional TheoryDea Amelia SaputriNo ratings yet

- Bangalore JustDial & OthersDocument56 pagesBangalore JustDial & OthersAbhishek SinghNo ratings yet

- Climate Change in Cities Due To Global Warming andDocument6 pagesClimate Change in Cities Due To Global Warming andGourab MondalNo ratings yet

- Nav 3 Activity#4Document2 pagesNav 3 Activity#4CLIJOHN PABLO FORDNo ratings yet

- Wireless and Mobile Communications: Abhijit Bhowmick Sense VIT, Vellore, TN, IndiaDocument28 pagesWireless and Mobile Communications: Abhijit Bhowmick Sense VIT, Vellore, TN, IndiaAANCHALNo ratings yet

- Storytelling Score SheetDocument2 pagesStorytelling Score SheetZykehNo ratings yet

- సచివాలయంలో ఆధార్ సేవలుDocument4 pagesసచివాలయంలో ఆధార్ సేవలుVamsiNo ratings yet

- Diagnostic OperationDocument11 pagesDiagnostic OperationDaniel Rhasty-ghee AhmanorNo ratings yet

- ContinueDocument2 pagesContinueHarshit DubeyNo ratings yet